Waste tire cleaning system

A waste tire and cleaning system technology, applied in the directions of cleaning methods and utensils, cleaning methods using tools, recycling technology, etc., can solve the problems of inconvenient cleaning of waste tires, etc., to extend the cleaning time, strengthen the limit effect, and strengthen the cleaning. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

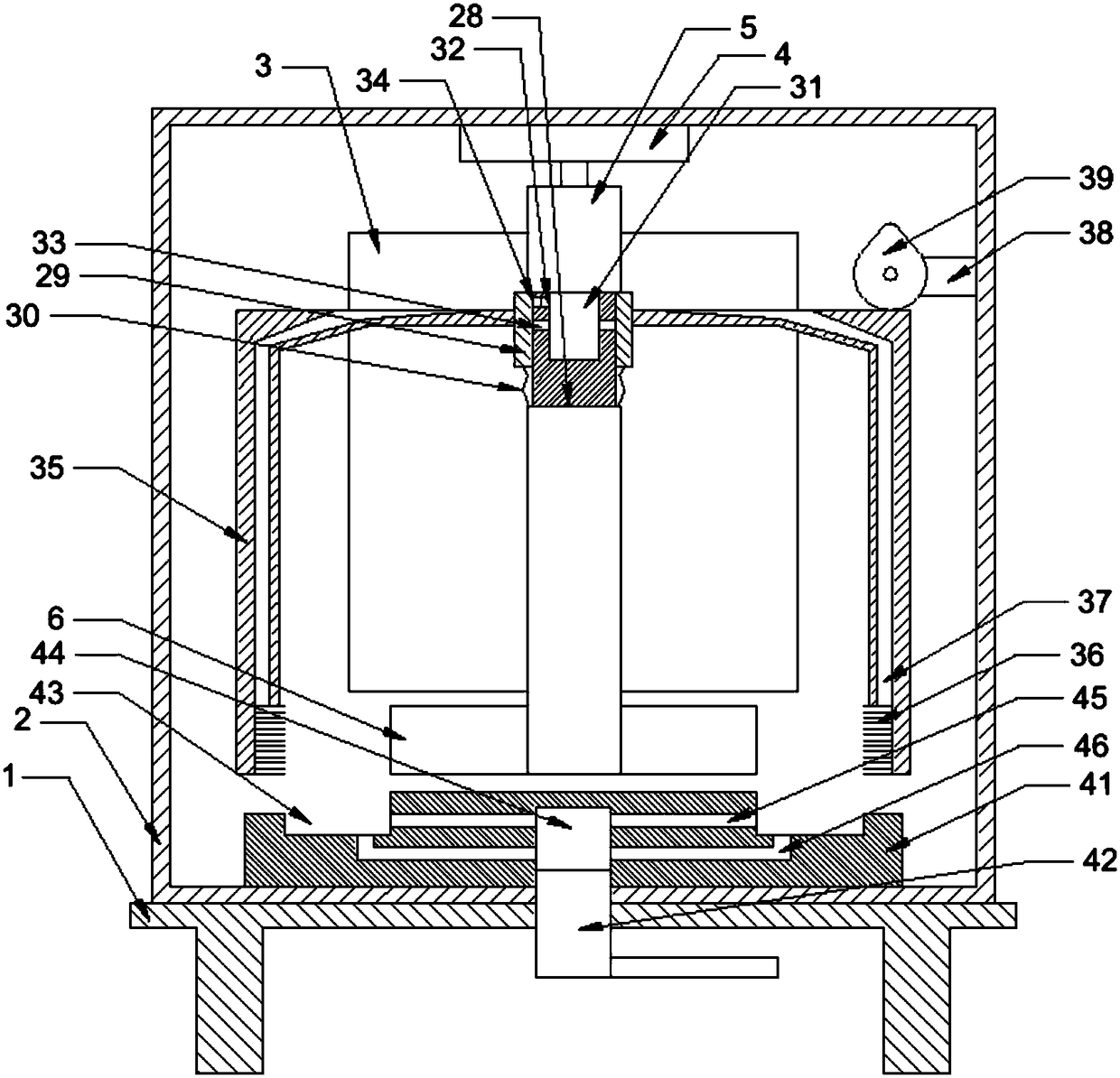

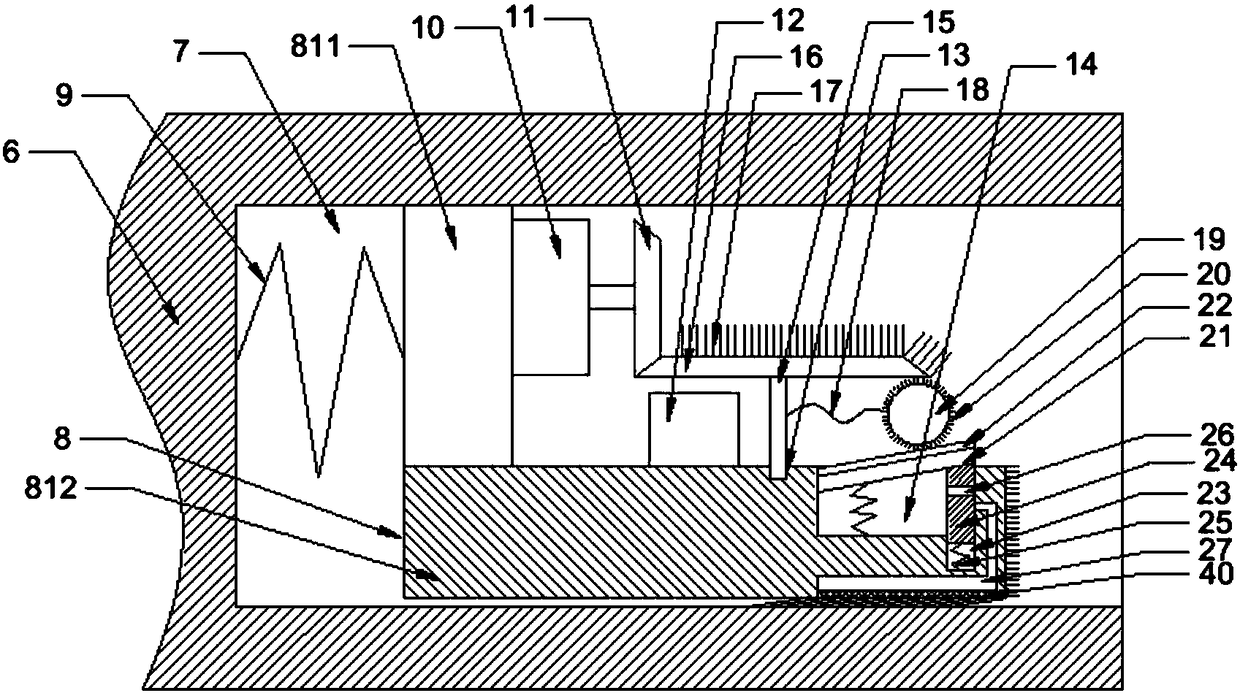

[0019] Further detailed explanation through specific implementation mode below:

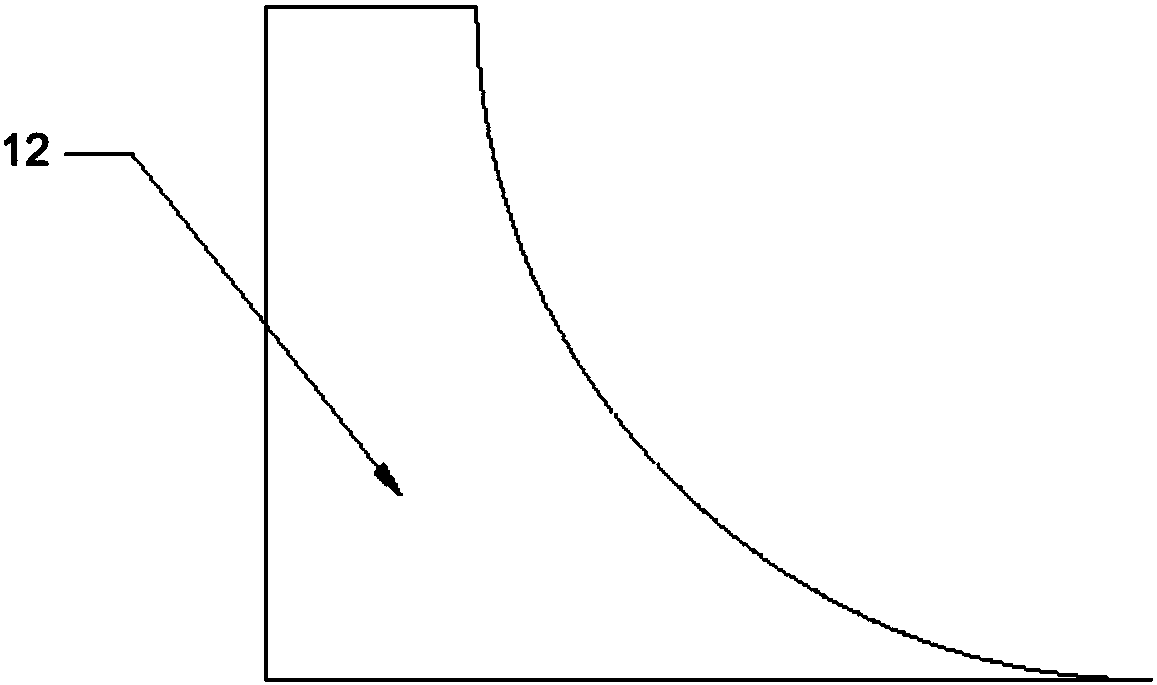

[0020] The reference signs in the drawings of the description include: bracket 1, box body 2, opening 3, first motor 4, auxiliary shaft 5, side bar 6, transverse groove 7, L-shaped block 8, vertical section 811, and transverse section 812 , first spring 9, second motor 10, driving bevel gear 11, guide block 12, auxiliary tank 13, water storage tank 14, circular shaft 15, driven bevel gear 16, upper cleaning bristle 17, steel wire 18, spheroid 19, inner Cleaning bristle 20, inclined plate 21, sponge layer 22, vertical groove 23, slide block 24, the 3rd spring 25, transverse hole 26, water channel 27, ring groove 28, ring block 29, the 4th spring 30, water tank 31, enter Water hole 32, water outlet hole 33, seal cover 34, support bar 35, outer cleaning bristle 36, channel 37, the 3rd motor 38, cam 39, filter screen 40, holding object platform 41, threaded rod 42, groove 43, negative Pressure hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com