Waterborne glass nano-paint containing composite metal nanometer nuclear particles and preparation

A composite metal and nano-core technology, applied in the field of coatings, can solve the problems of single function, complex preparation process and insufficient performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

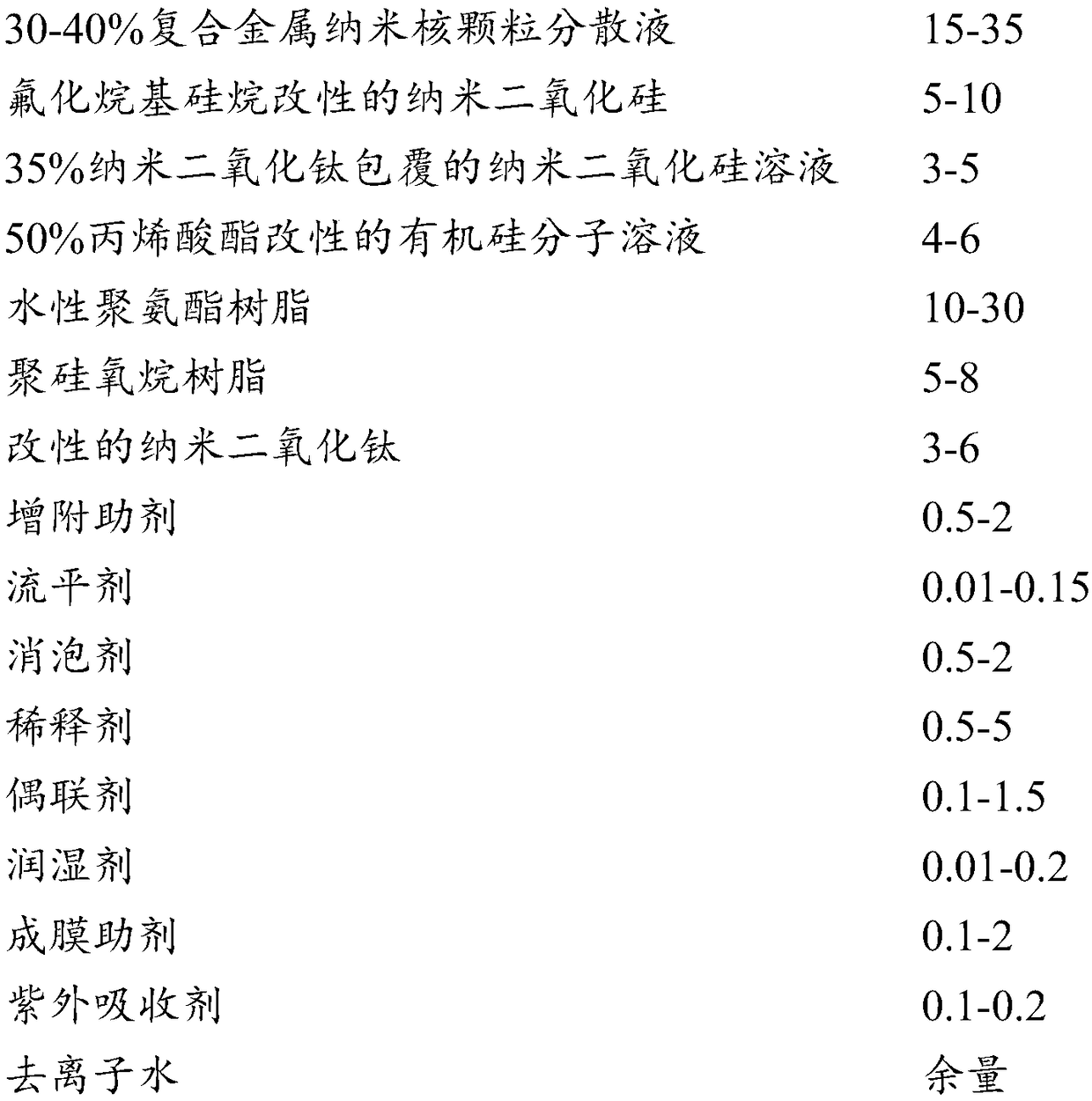

Method used

Image

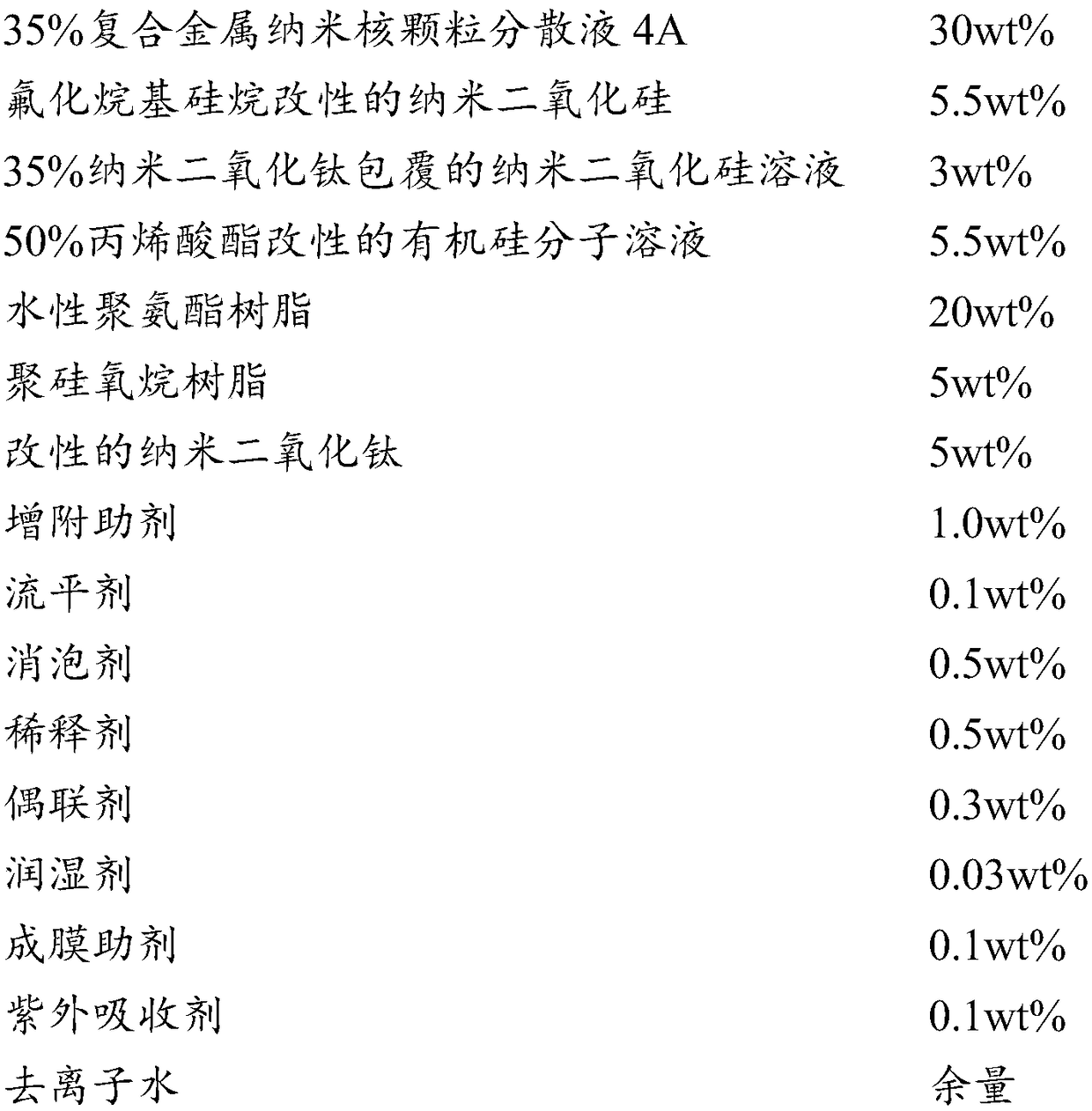

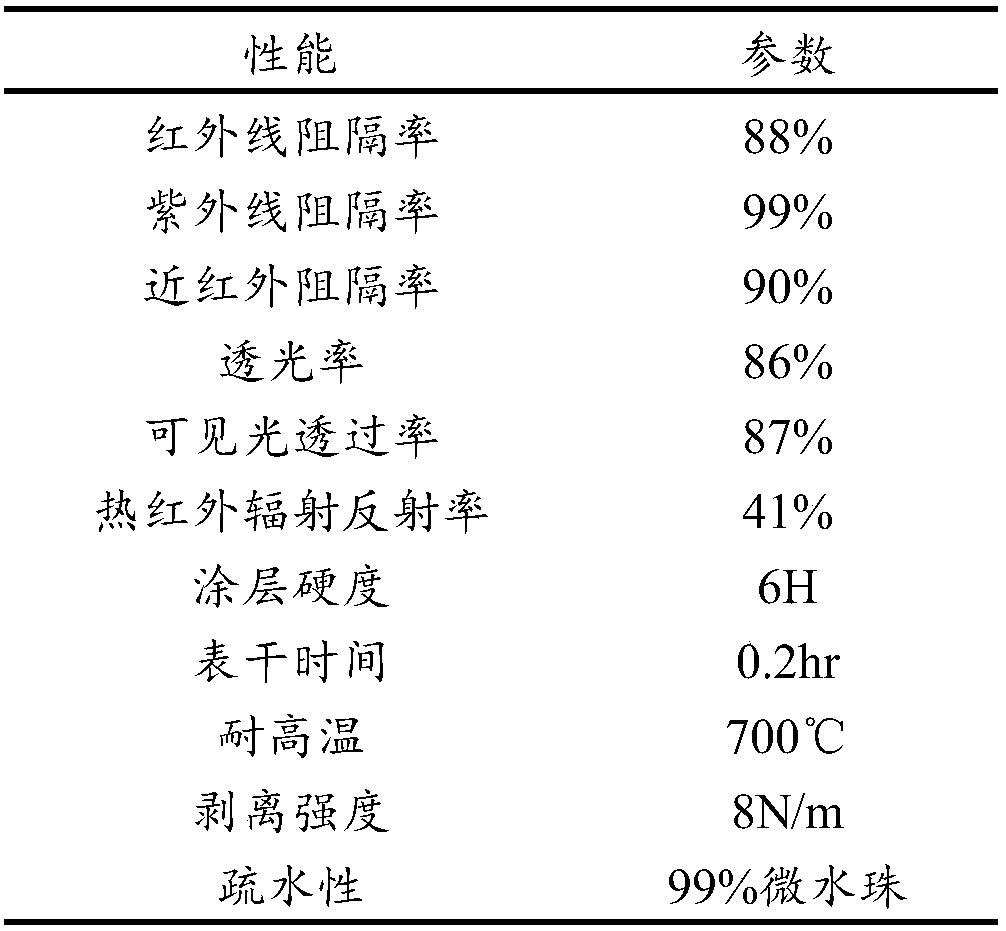

Examples

preparation example 1A

[0082] Preparation Example 1A: Preparation of molybdenum-doped vanadium dioxide nanopowder material coated with nano-titanium dioxide in component A-nano-titanium dioxide

[0083] (1) Step 1, prepare modified nano vanadium dioxide particles doped with molybdenum:

[0084] Add KH560, vanadium dioxide particles and molybdenum particles to propanol solvent, wherein the amount of vanadium dioxide particles added is 150g / L, the amount of molybdenum particles added is 30g / L, and the mass fraction of coupling agent KH560 is 2% After mixing evenly, use the high-energy ball mill ball mill with a ball-to-material ratio of 30:1, set the ball mill speed at 800 rpm for 8 hours, filter and separate, wash, and dry to obtain molybdenum-doped modified nanometer powder with a uniform particle size. Vanadium oxide particles with a median particle size of 60nm;

[0085] (2) Step 2, nano-titanium dioxide coating:

[0086]The above-mentioned modified vanadium dioxide nanoparticles doped with moly...

preparation example 1B

[0087] Preparation Example 1B: Preparation of Component A-nano-titanium dioxide-coated tungsten-doped vanadium dioxide nanopowder material in composite metal nano-core particles

[0088] (1) Step 1, prepare modified nano vanadium dioxide particles doped with tungsten:

[0089] Add KH560, vanadium dioxide particles and tungsten particles to butanol solvent, wherein the amount of vanadium dioxide particles added is 160g / L, the amount of tungsten particles added is 40g / L, and the mass fraction of coupling agent KH560 is 1.5% After mixing evenly, use a high-energy ball mill with a ball-to-material ratio of 30:1 for ball milling, set the ball milling speed at 800 rpm for 8 hours, filter and separate, wash, and dry to obtain the modified nanometer powder doped with tungsten with uniform particle size. Vanadium oxide particles with a median particle size of 55nm;

[0090] (2) Step 2, nano-titanium dioxide coating:

[0091] The above-mentioned modified vanadium dioxide nanoparticles...

preparation example 2

[0092] Preparation example 2: Preparation of component B-tungsten / fluorine co-doped vanadium dioxide nanopowder in composite metal nano-core particles

[0093] Take 1.0 moles of vanadium pentoxide V 2 o 5 As the raw material, oxalic acid is used as the reducing agent, sodium tungstate dihydrate is selected as the tungsten dopant, ammonium fluoride is selected as the fluorine dopant (the molar amounts of tungsten and fluorine elements are 0.1 moles respectively), and urea with a concentration of 1.5M As a precipitating agent, add 1200ml of distilled water and react for 72 hours in a 190-degree hydrothermal reactor to obtain blue-black silk powder precipitation. After washing, nano-grinding, and drying, calcinate in a tubular resistance furnace at 800°C under the protection of a nitrogen atmosphere. Annealed for 5 hours to obtain a tungsten / fluorine co-doped vanadium dioxide powder, wherein the tungsten / fluorine is 5% of the molar weight of the vanadium dioxide. The average pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com