Patents

Literature

30results about How to "Good surface roughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

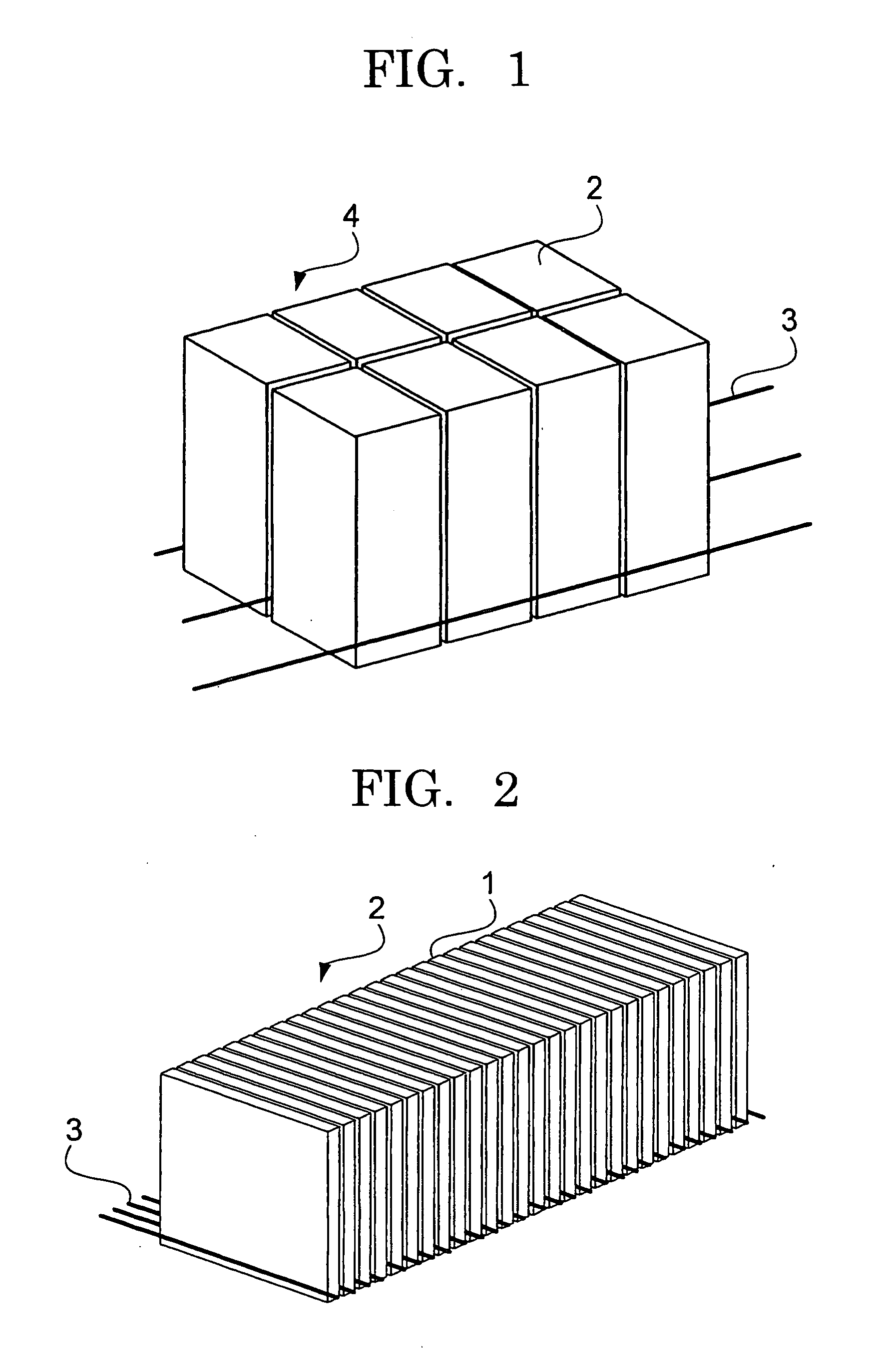

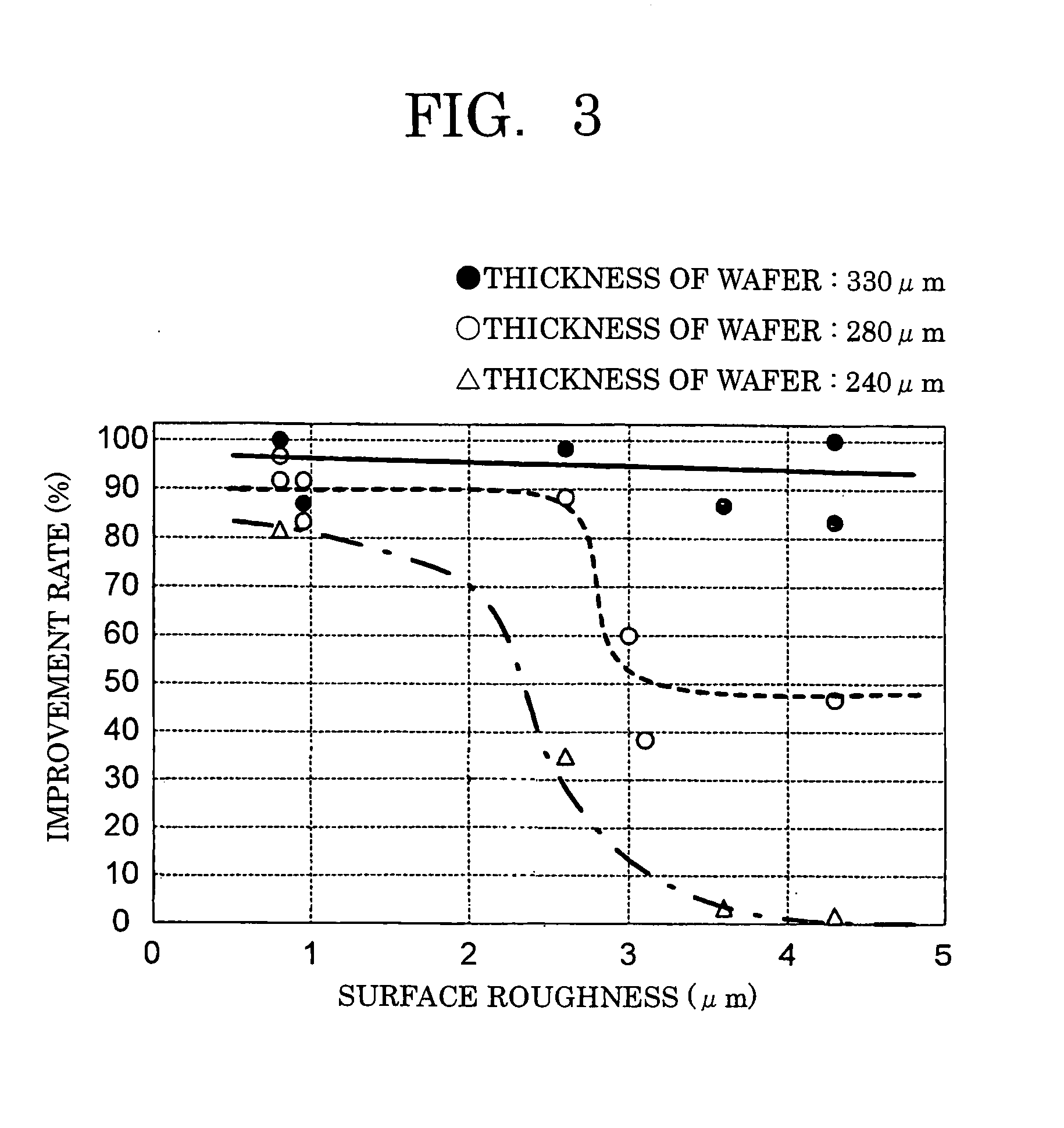

Method of Producing Silicon Blocks and Silicon Wafers

InactiveUS20080223351A1Good surface roughnessLittle damageOther chemical processesFine working devicesAmount of substanceMass ratio

In a method of producing silicon blocks by cutting a silicon ingot by the use of a silicon ingot cutting slurry containing abrasive grains and an alkaline substance so as to provide the silicon blocks that can be produced into silicon wafers each having a thin thickness with reduced substrate damage at the time of producing a solar battery, the content of said alkaline substance is at least 3.5 mass % with respect to the mass of the entire liquid components of said slurry, and said slurry contains an organic amine of from 0.5 to 5.0 by a mass ratio with respect to water in the liquid components of said slurry. Said slurry is used at a pH of 12 or more and at a temperature of from 65 to 95 degrees C.

Owner:MITSUBISHI ELECTRIC CORP

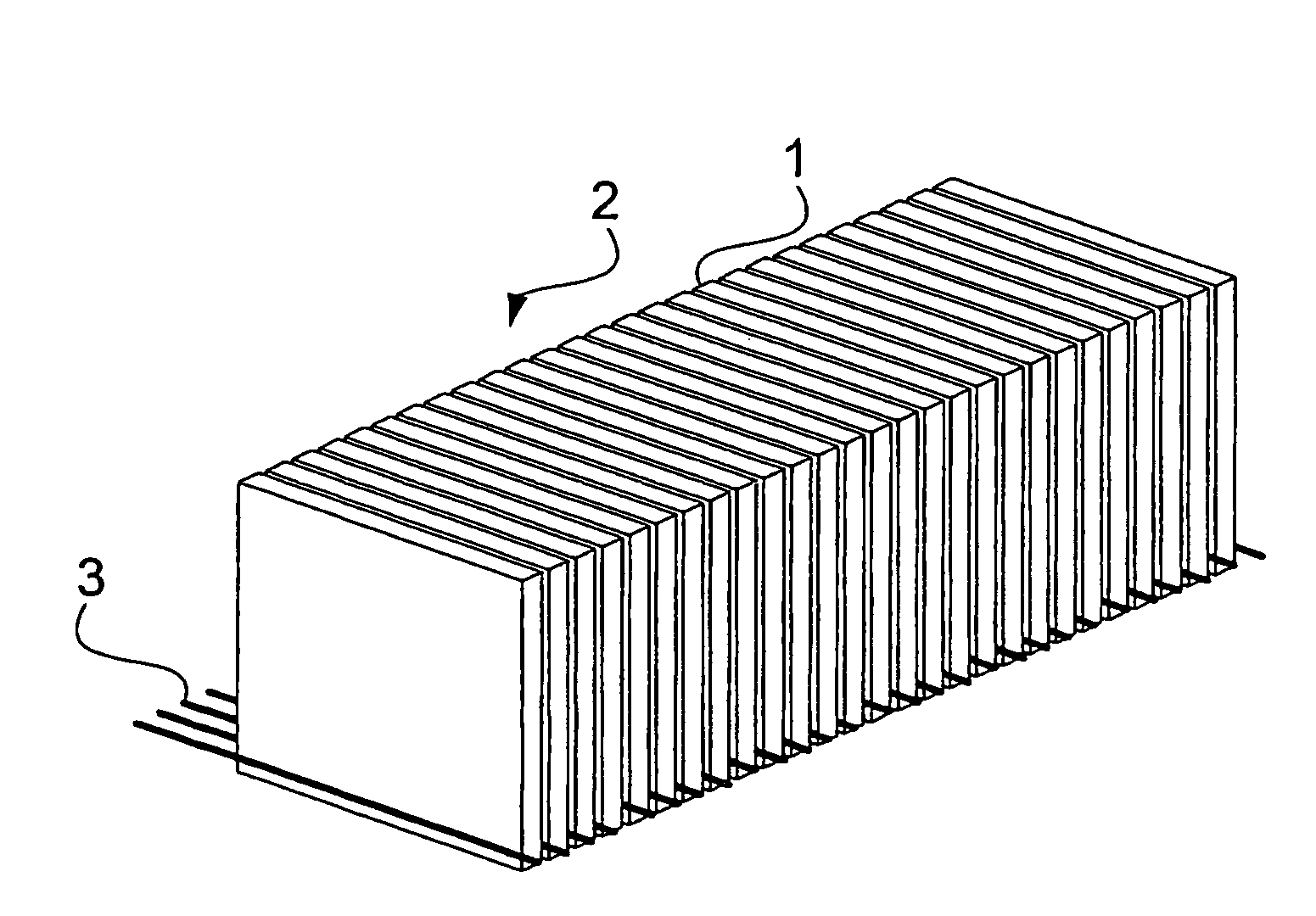

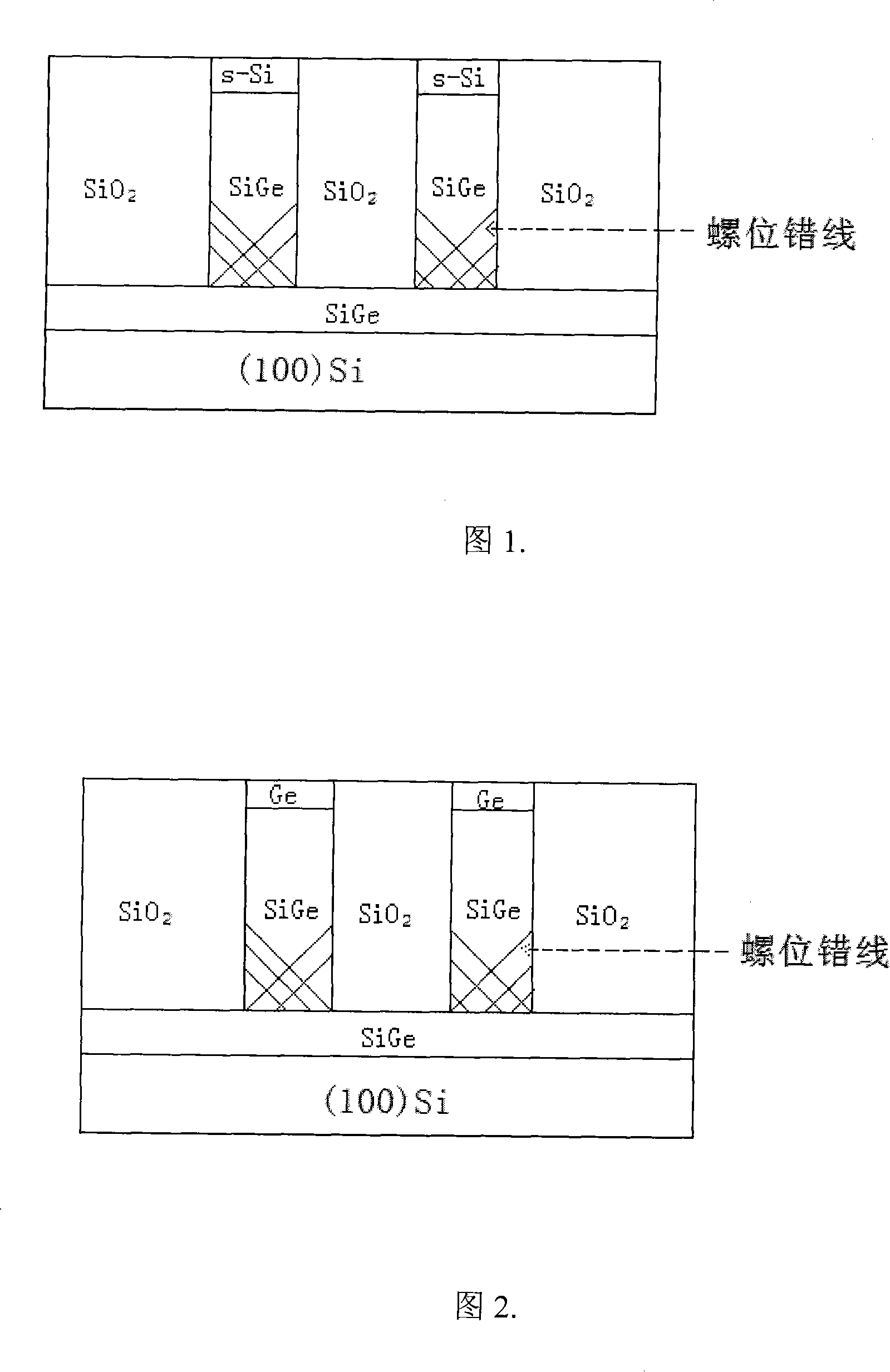

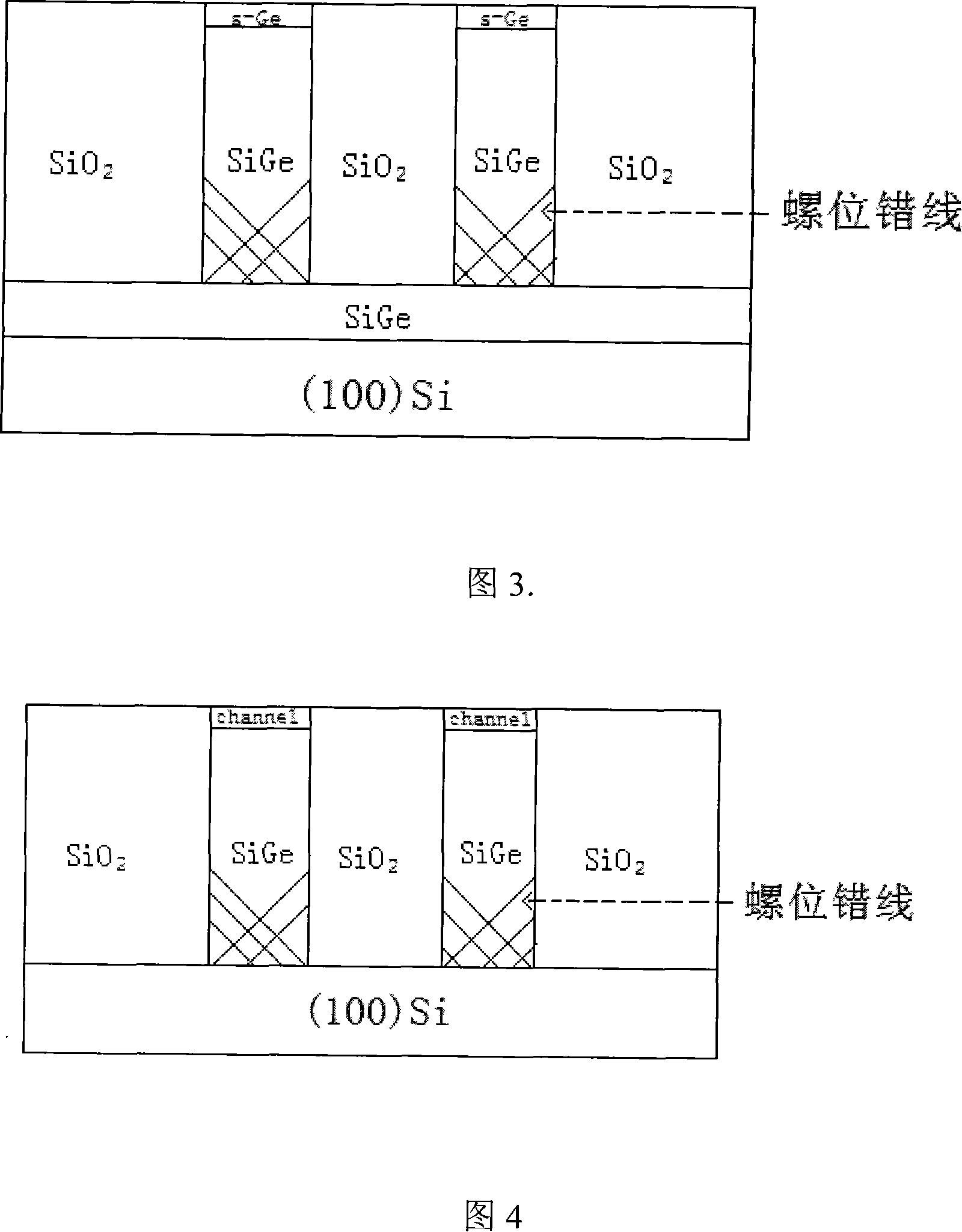

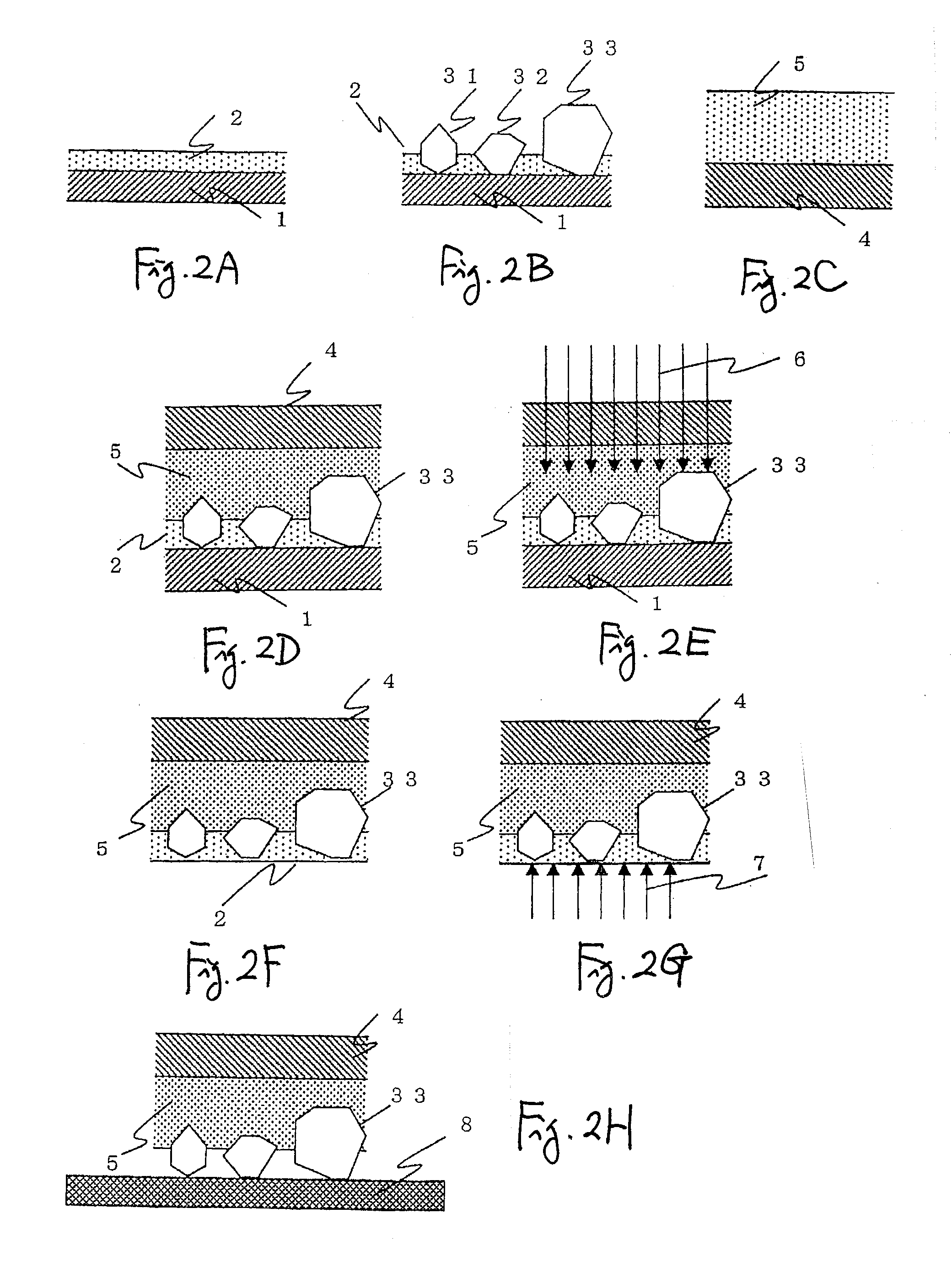

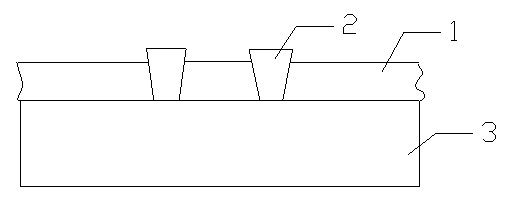

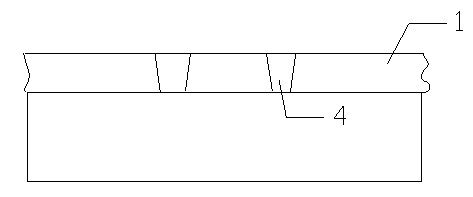

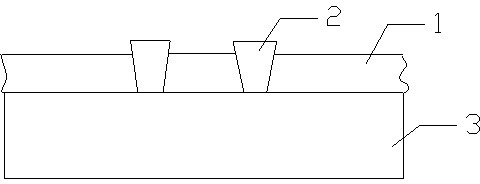

A method for obtaining low bit discrepancy density extension thin film via using neck down extension

InactiveCN101150054AGood surface roughnessIncrease concentrationSemiconductor/solid-state device manufacturingDislocationOptoelectronics

This invention discloses a method for using necking extension to get extension films of low dislocation density, which utilizes deposition, selective extension and thermal oxidation to prepare GeSi substrates of low dislocation density and channels of high migration rate and gets films of exremely low dislocation density on a silicon wafer meeting the requirement of MOS devices or luminescent devices.

Owner:JIANGXI SORNID HI TECH

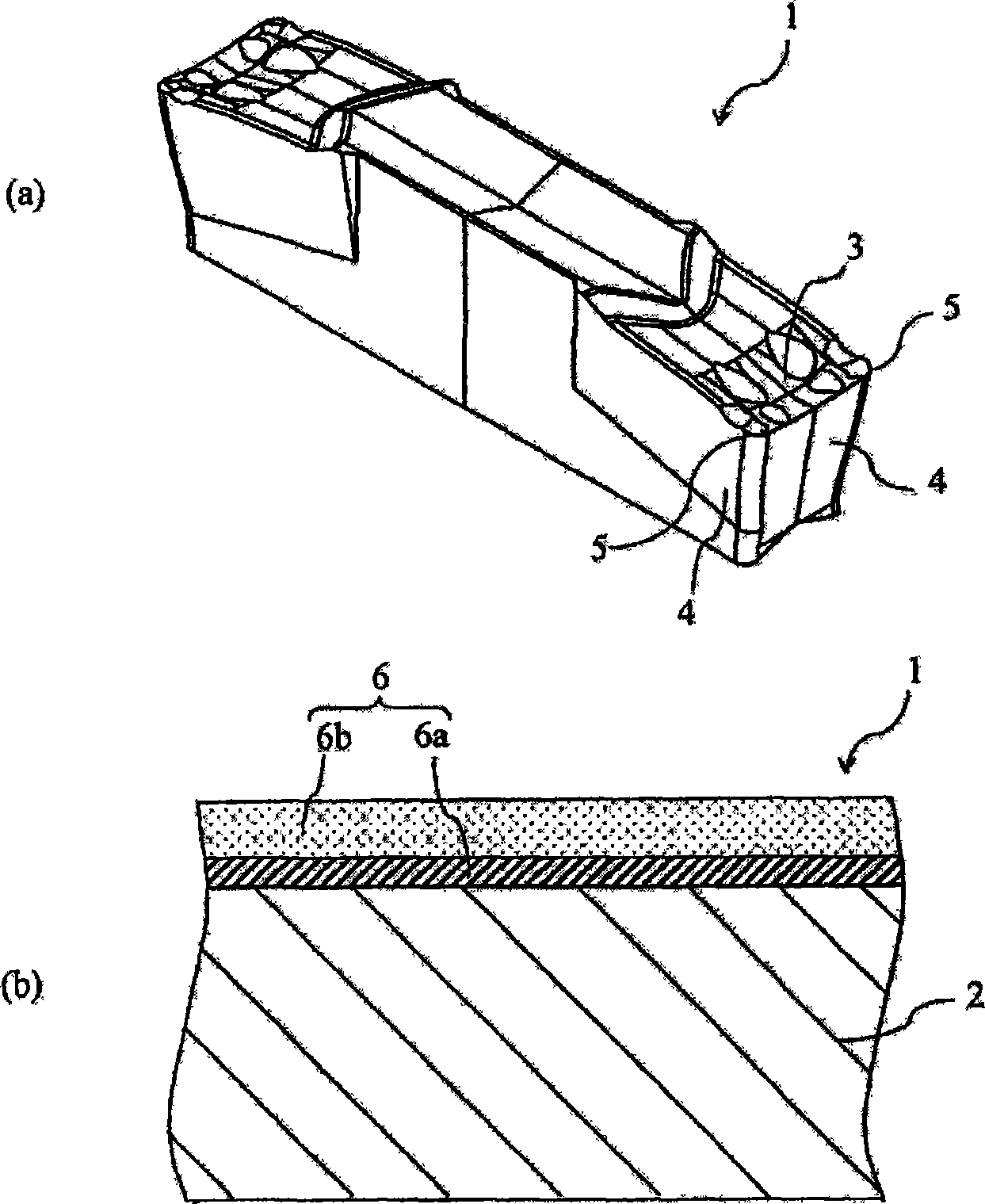

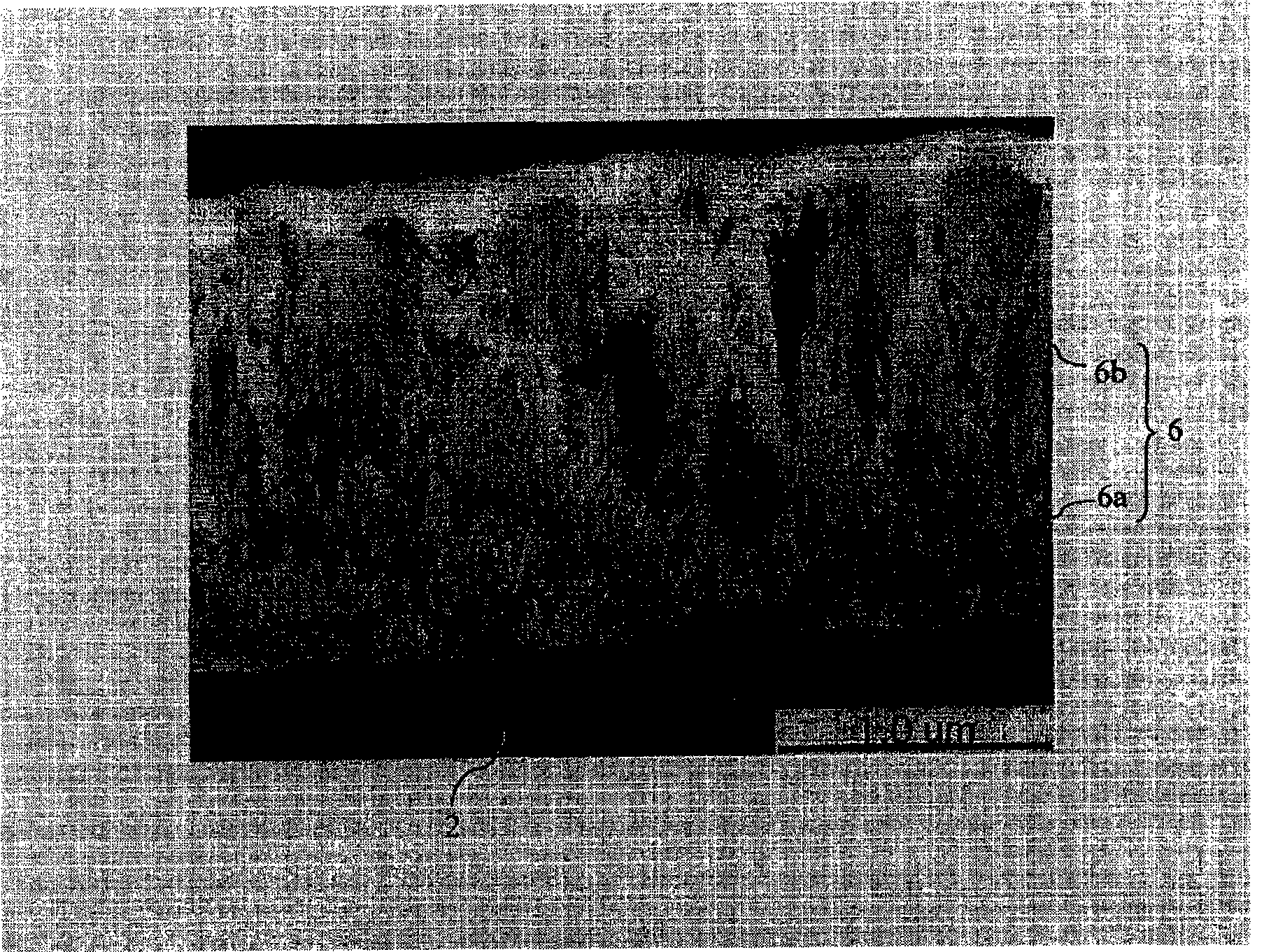

Surface-coated tool

InactiveCN101400465AImprove wear resistanceImprove chip resistanceVacuum evaporation coatingSputtering coatingRare-earth elementCrystallization

A surface coated tool including a substrate, and stacked layers composed of two coating layers represented by the following general formula (1) on the substrate is provided. A first coating layer to be coated on the surface of the substrate, which has a thickness of 0.1 to 1 [mu]m, is composed of a granular crystal having a mean crystal diameter of 0.01 to 0.1[mu]m. A second coating layer to be coated on the surface of the first coating layer, which has a thickness of 0.5 to 5 [mu]m, is composed of columnar crystal grown in a direction perpendicular to the substrate, and the columnar crystal has a mean crystal width of 0.05 to 0.3[mu]m in a direction parallel to the substrate while a mean crystal width thereof is larger than the mean crystal diameter of the first coating layer. [Formula 3] M 1 - a Al a (C b N 1-b ) (1) wherein, M represents at least one metal element selected from the group consisting of the elements of Groups 4, 5 and 6 of the periodic table, Si and rare earth elements, ''a'' satisfies the relation of 0.25 a 0.75, and ''b'' satisfies the relation of 0 b 1.

Owner:KYOCERA CORP

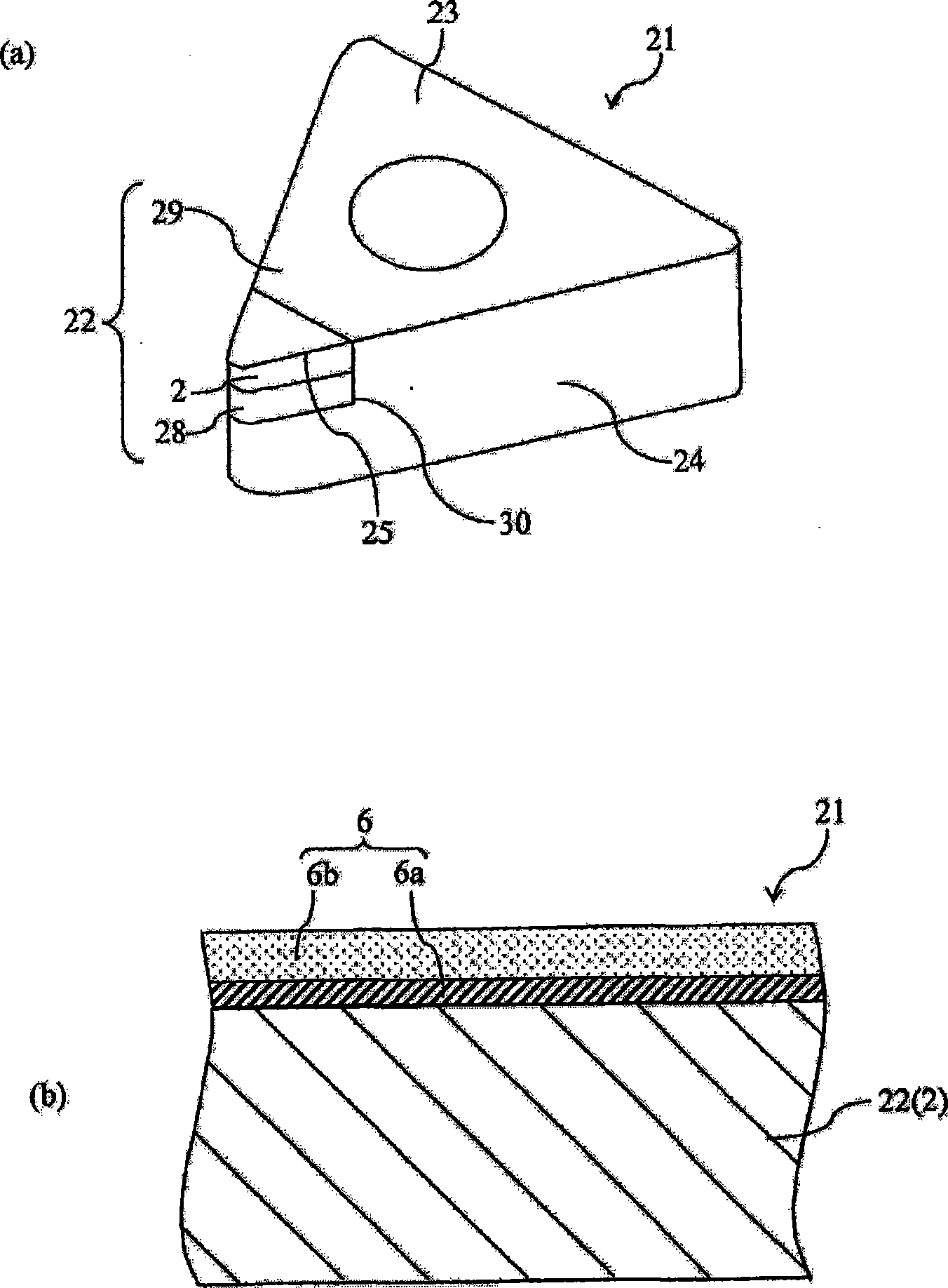

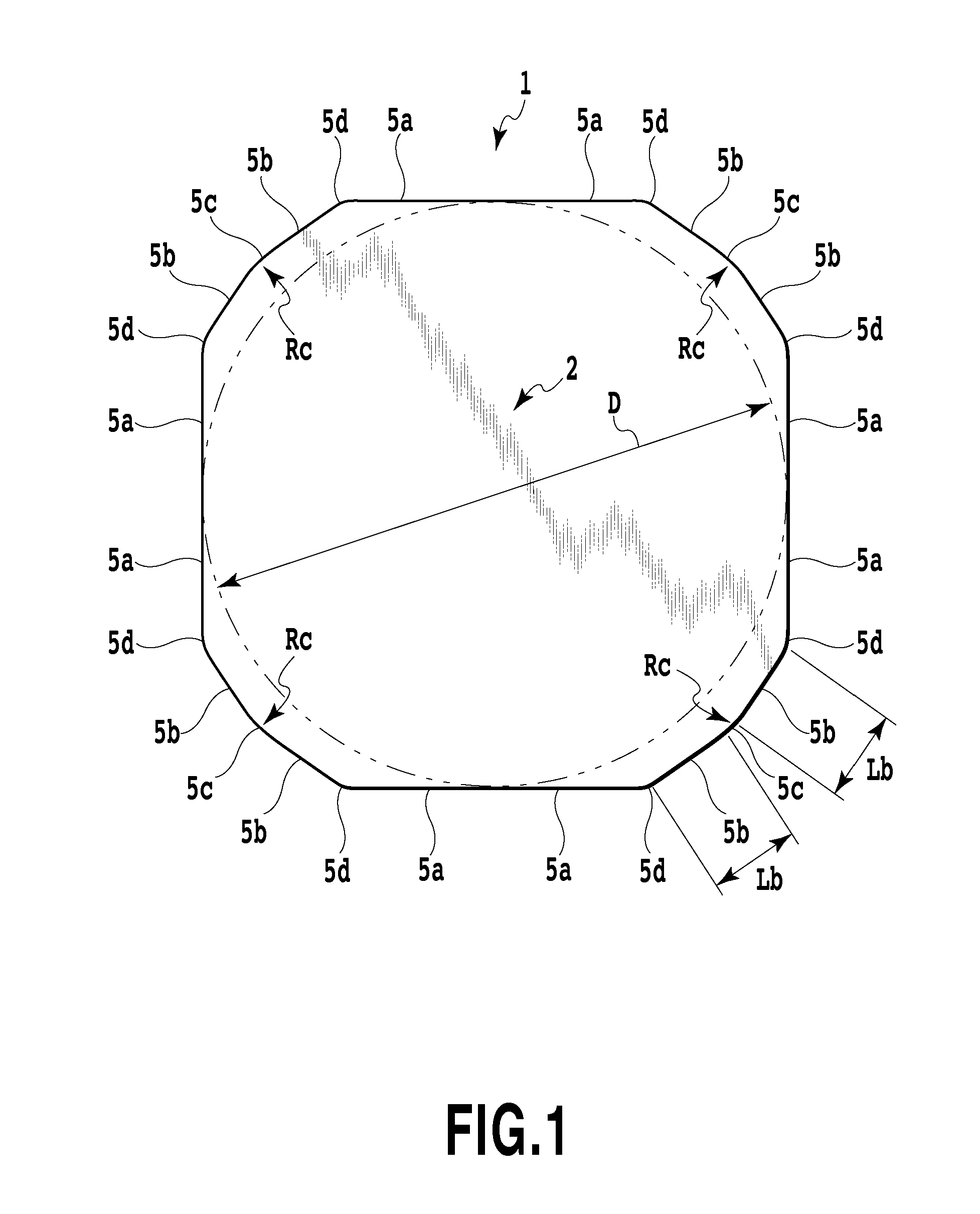

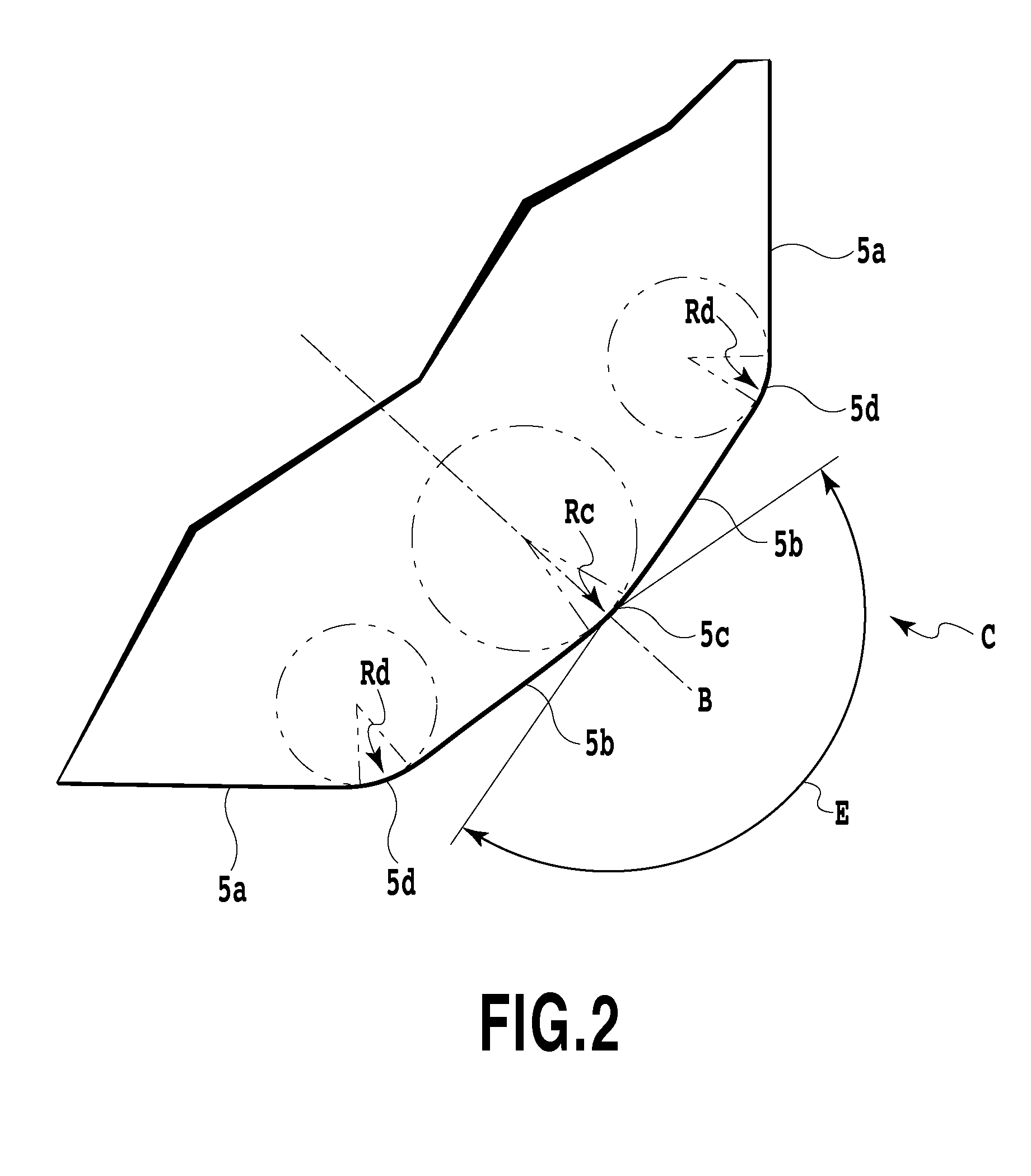

Cutting Insert and Indexable Face Mill

ActiveUS20120087748A1Good surface roughnessIncrease resistanceMilling cuttersTurning toolsEngineeringVertical angle

A pair of sub-flank surfaces is formed at a vertex angle portion of an insert body having a substantially polygonal, plate-like shape, and between the sub flank surfaces, a vertex flank surface at a vertical angle portion is formed substantially in a protrusive, curved shape, and is smoothly connected to the sub-flank surfaces in a tangential direction. The vertex flank surface at the vertex angle portion is extended across the entire thickness of the insert body, and boundary lines, between the vertex flank surface at the vertex angle portion and a pair of minor cutting edges, are parallel to each other. A second curved ridge line, which is formed between (i) the flank surface and (ii) the rake surface, and a first curved ridge line, which is formed between (i) the flank surface and (ii) the seat surface, have approximately same shape.

Owner:TUNGALOY CORP

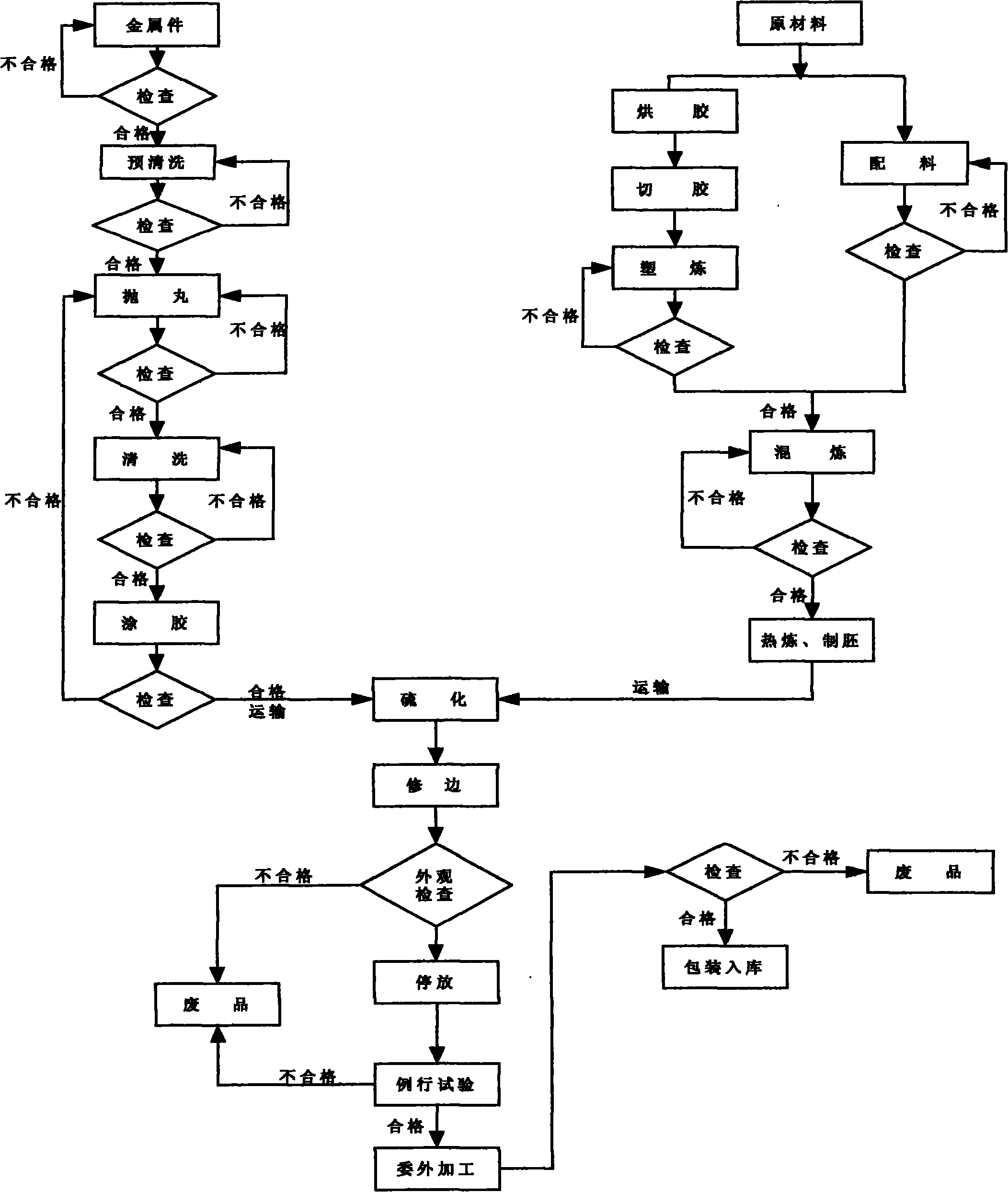

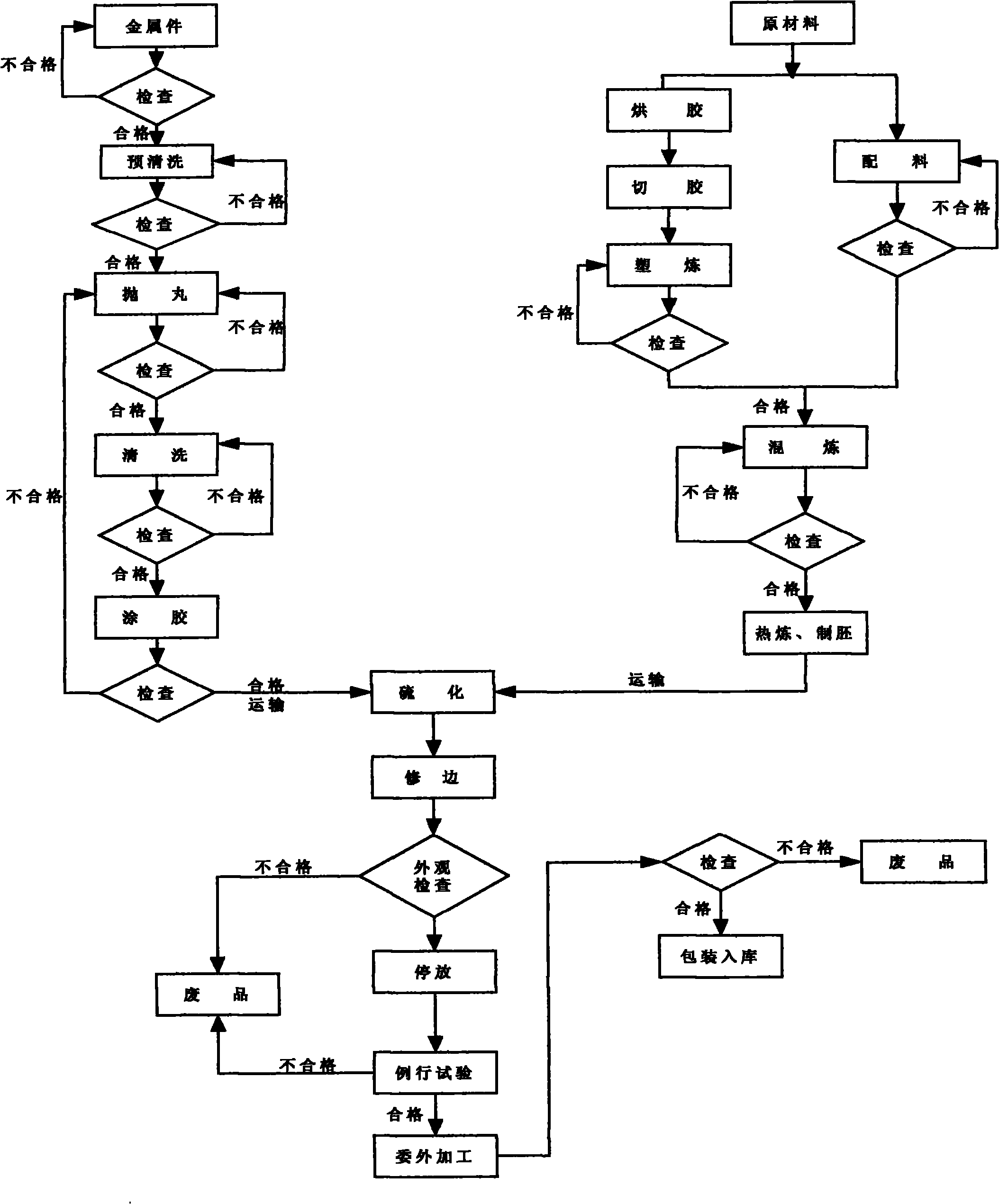

Manufacturing technology of air spring rubber stack

ActiveCN102022469AGood surface roughnessImprove adhesionSpringsGas based dampersAir suspensionMegasonic cleaning

The invention relates to a manufacturing technology of an air spring rubber stack, which comprises the pretreatment technology of a metal piece, the preparation technology of rubber material and the vulcanization technology. In the pretreatment technology of the metal piece, the pre-cleaning process step is added, so that grease on the surface of the metal piece can be removed better; the shot blasting process step can ensure better surface roughness of the metal piece, and can simultaneously improve the bonding force between an adhesive and a framework and the strength of a metal framework; the ultrasonic washing can further remove the grease on the surface of the metal framework and dust taken in during the shot blasting process, raise the temperature of ultrasonic washing liquor and prolong cleaning time appropriately, and further reach the better cleaning effect. The selection of parameters of the vulcanization technology can directly affect the matching between the adhesive and the rubber reaction speed and the formation of a cross bond between rubber and the adhesive, and products with good adhesive bonding effect can be obtained through the parameters selected by the invention.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

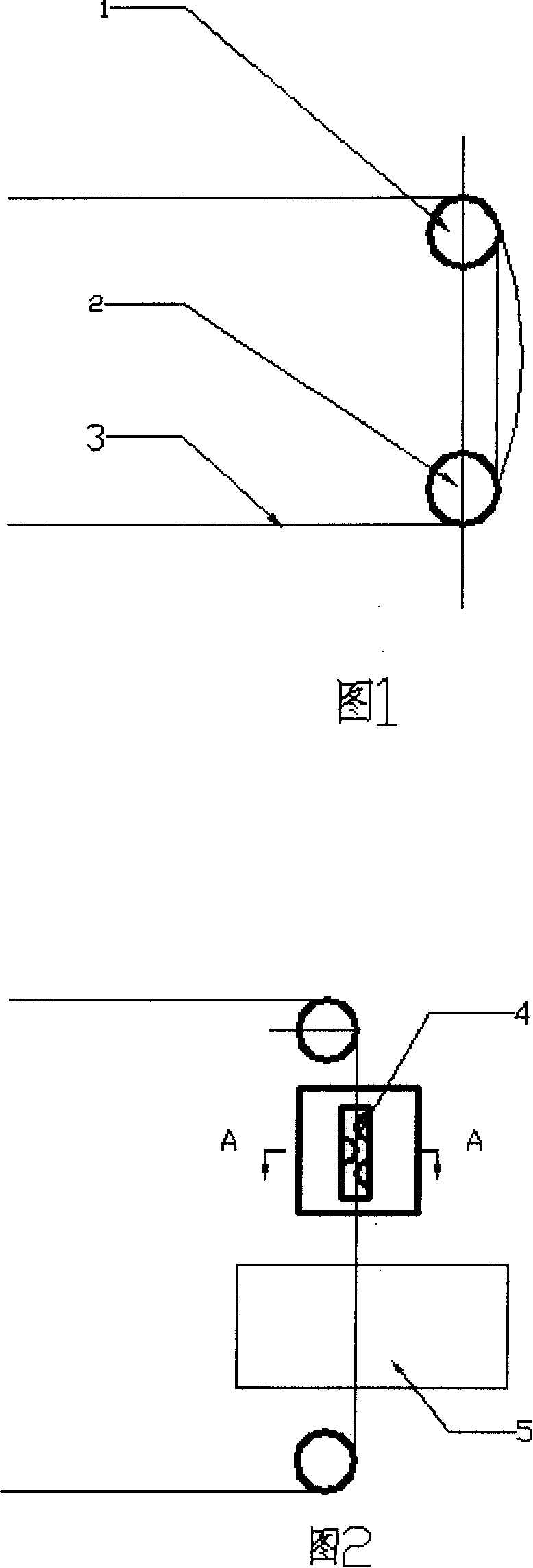

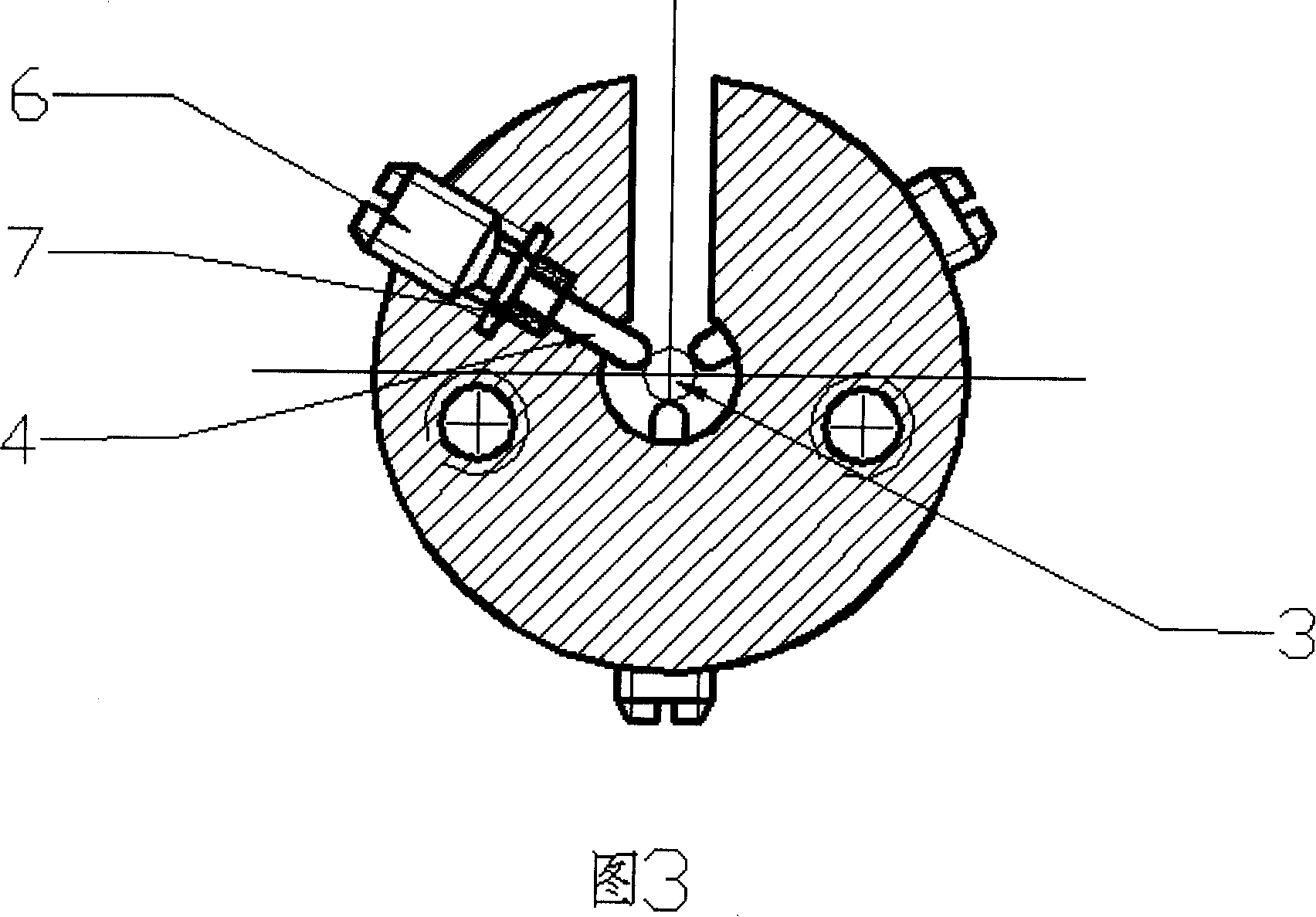

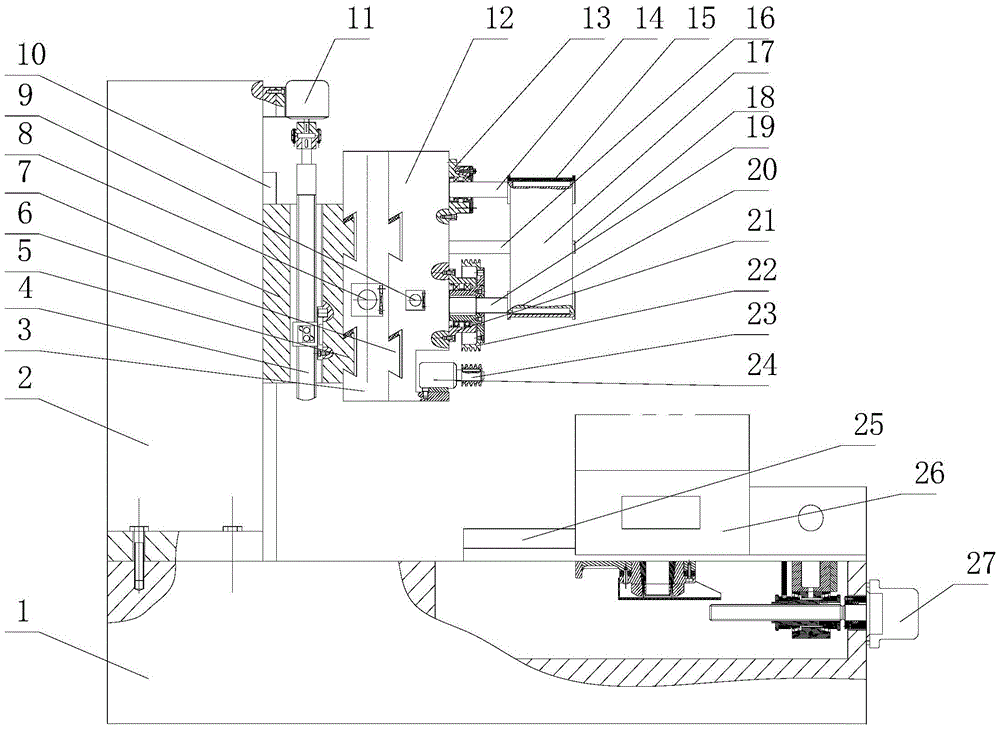

Molybdenum wire guide for electric spark wire cutting machine

InactiveCN101085484AEliminate jitterEliminate vibrationElectrical-based machining electrodesChinese charactersWire cutting

The invention relates to the guider regulating the movement track of the molybdenum wire. It is a electrical spark wire cutting machine's guider. It features in the hollow cylindrical support base with notch at one side, surrounded by a limit structure with the shape like the Chinese character 'pin' connected by diamond, spring and micro tune bolt sequentially. It can increase the surface machining gross degree from 3.2 mu m to 2.5 mu m.

Owner:泰安緁孚制衣有限责任公司

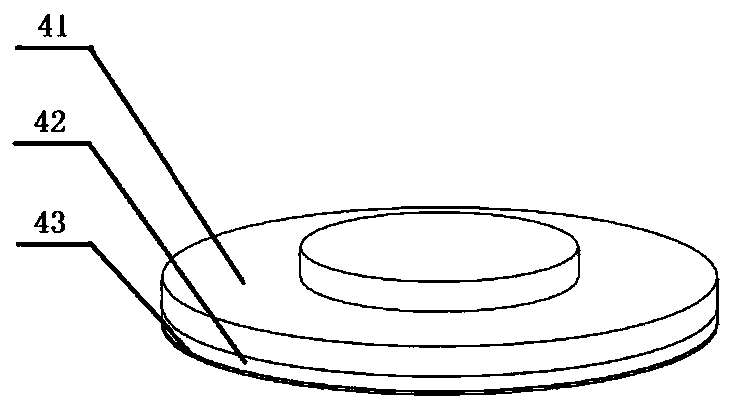

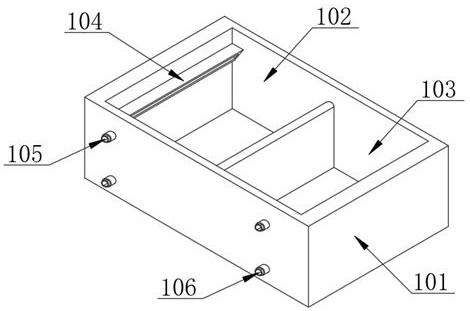

High-frequency micro-amplitude vibration device applied to ultra-fast polishing of large-caliber complex curved surface

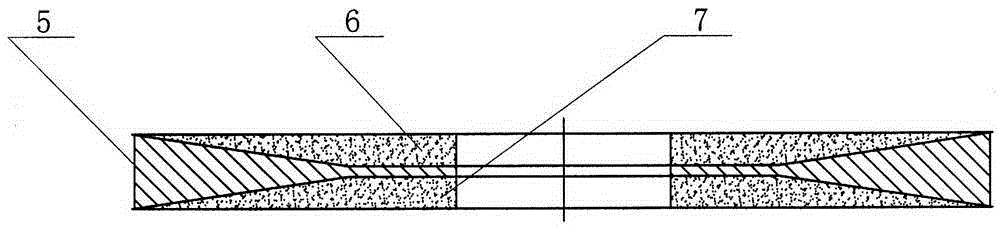

ActiveCN110450014AGood surface roughnessGood medium and high frequency surface shape error distributionOptical surface grinding machinesMillisecondMotor vibration

The invention discloses a high-frequency micro-amplitude vibration device applied to ultra-fast polishing of a large-caliber complex curved surface. The high-frequency micro-amplitude vibration devicecomprises a voice coil motor vibration platform capable of moving in two-dimensional direction and a flexible multi-layer polishing disc arranged on the voice coil motor vibration platform, wherein the flexible multi-layer polishing disc is composed of a rigid polishing bottom plate, a flexible polishing layer and a polishing section which are sequentially connected, and the flexible polishing layer adopts an elastic material with a deformation response time of tens of milliseconds to hundreds of milliseconds. By controlling the amplitude and the phase of a voice coil motor of each dimension,the movement of the specified amplitude and the designated direction of the polishing disc can be realized. According to the high-frequency micro-amplitude vibration device, and the surface roughnesscan be quickly improved under the premise of maintaining the surface shape error.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Method of producing polishing sheet

InactiveUS20100293865A1Good surface roughnessSuperior polishing capabilityAbrasion apparatusGrinding devicesAverage diameterEngineering

Owner:NIHON MICRO COATING

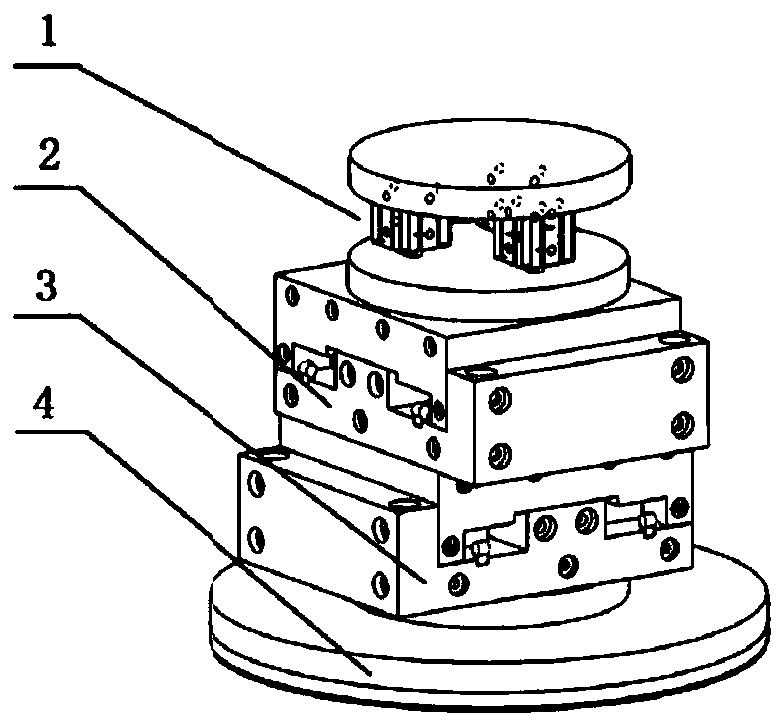

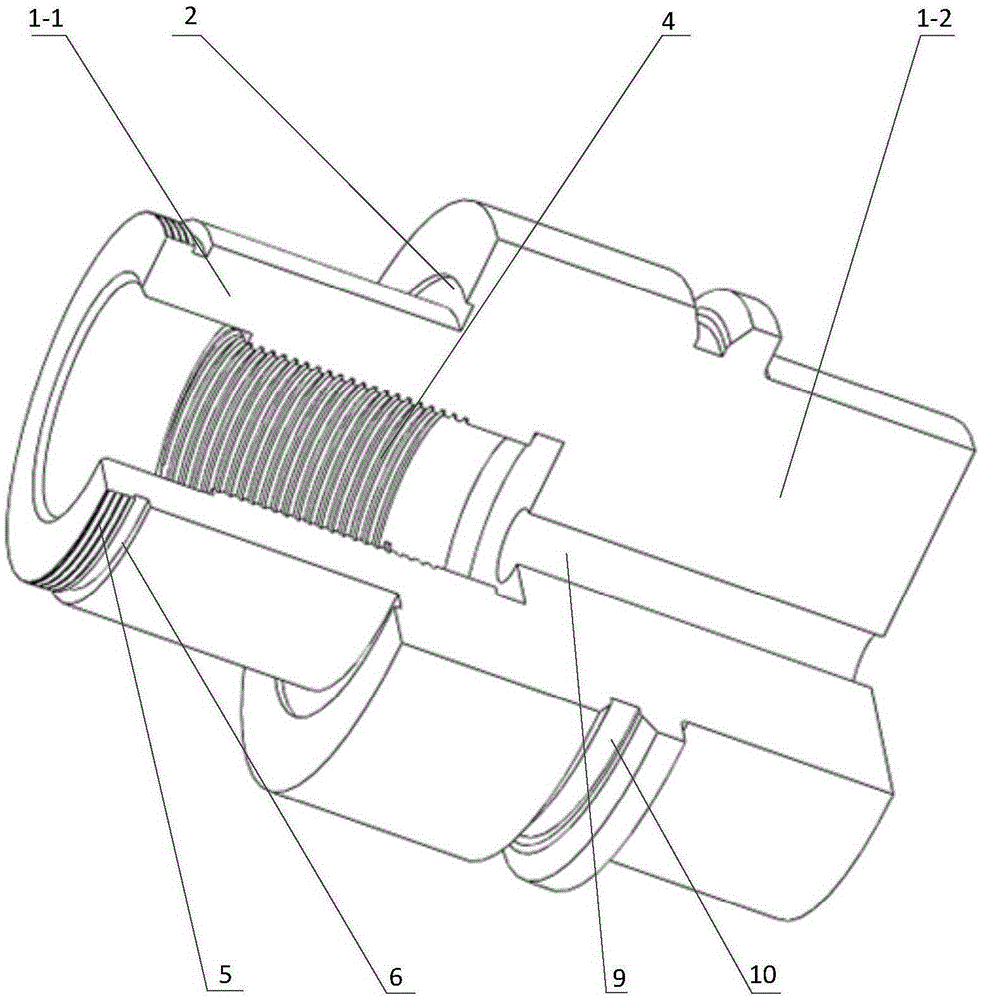

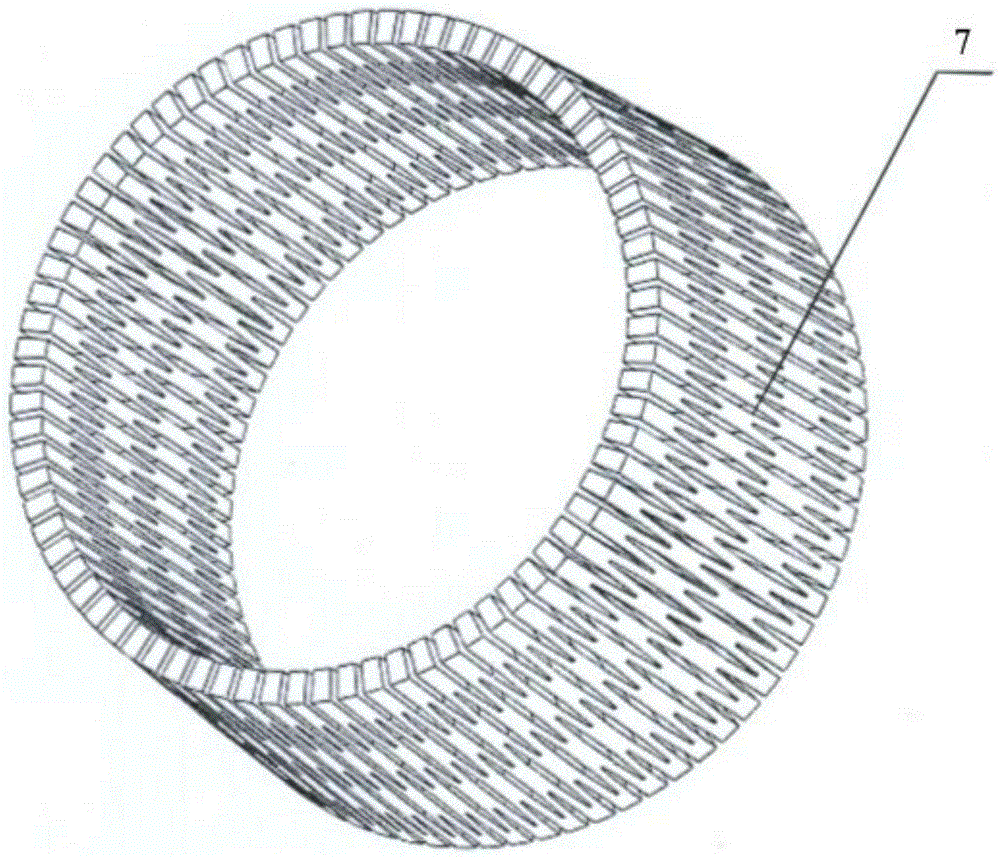

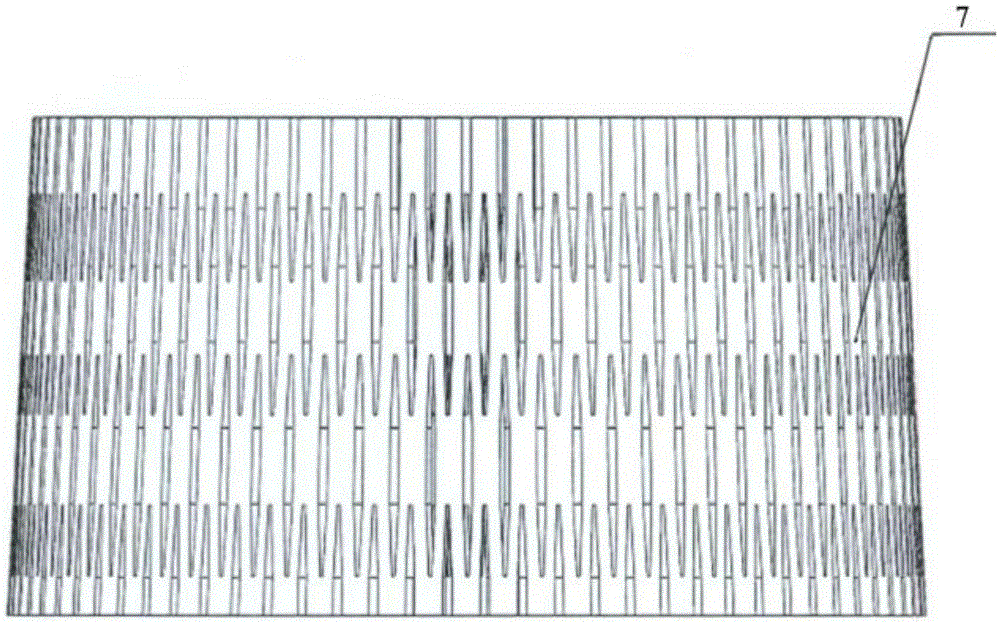

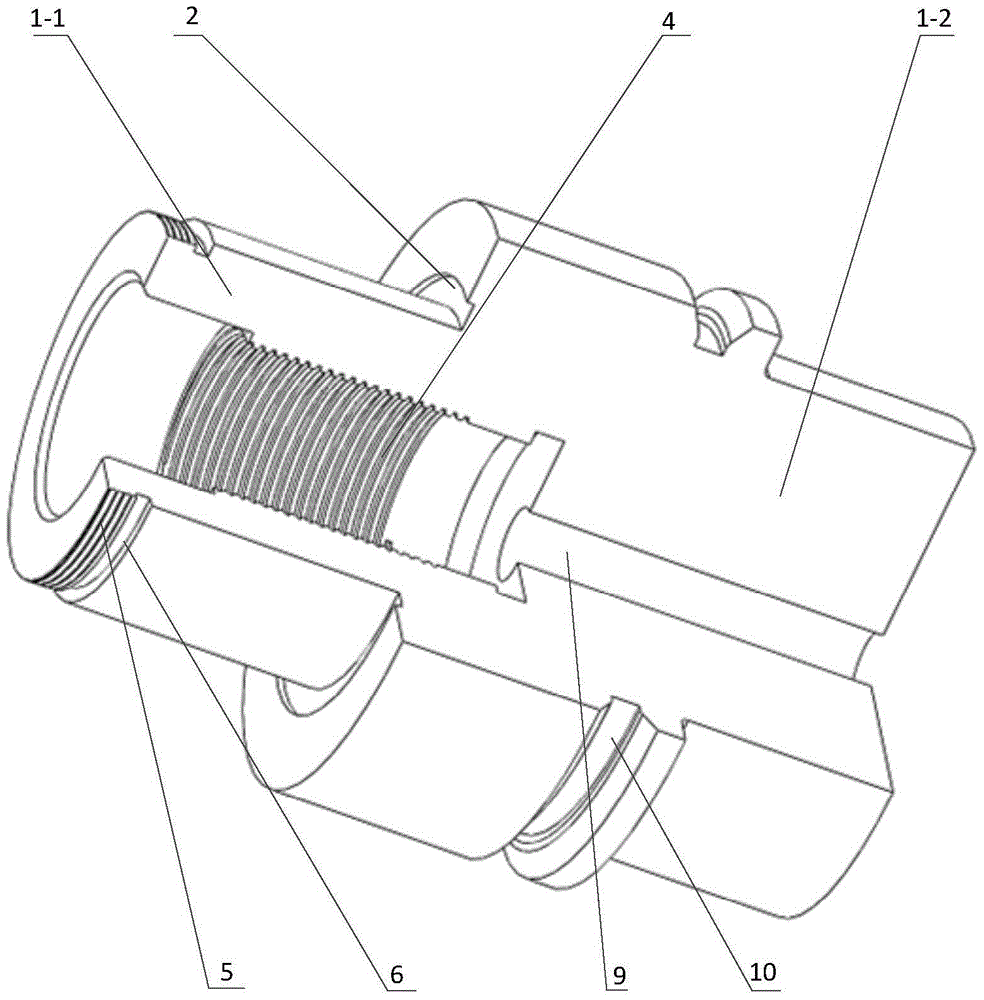

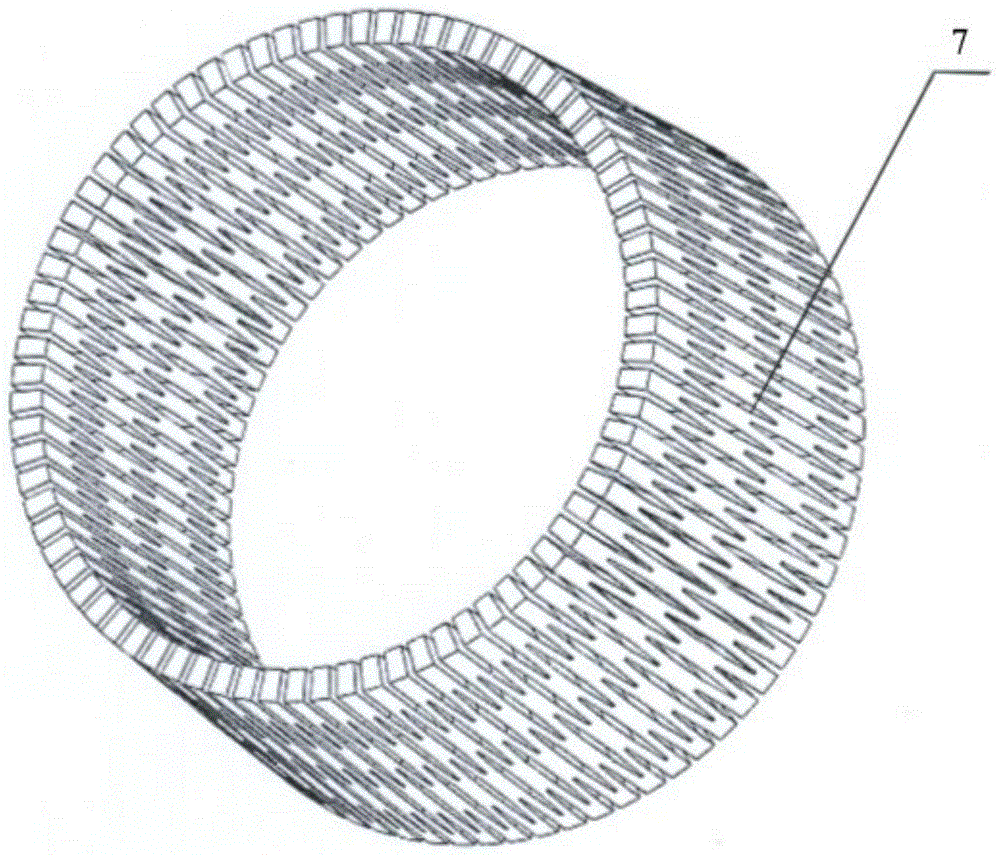

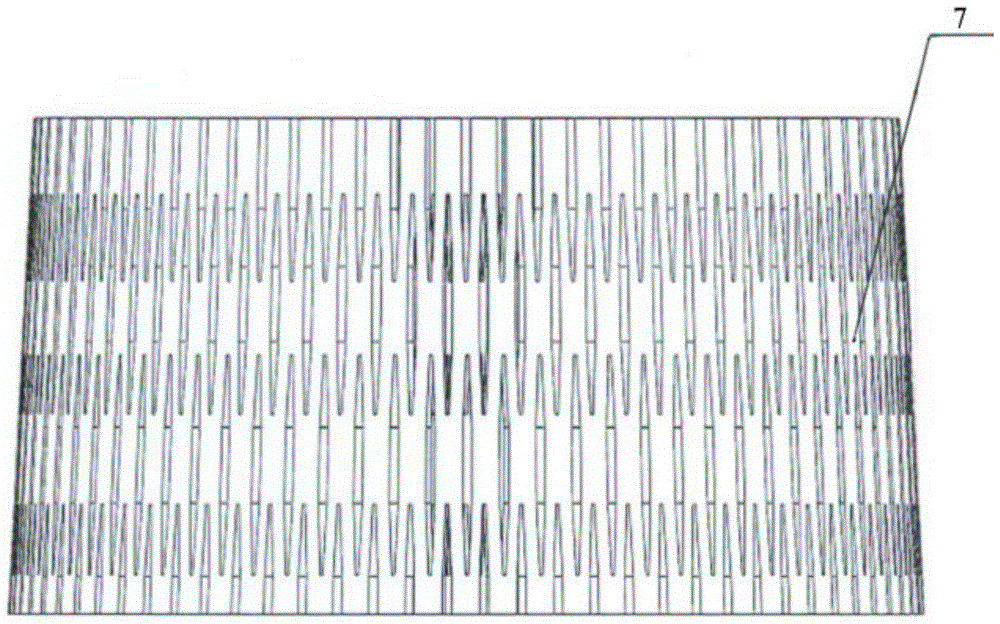

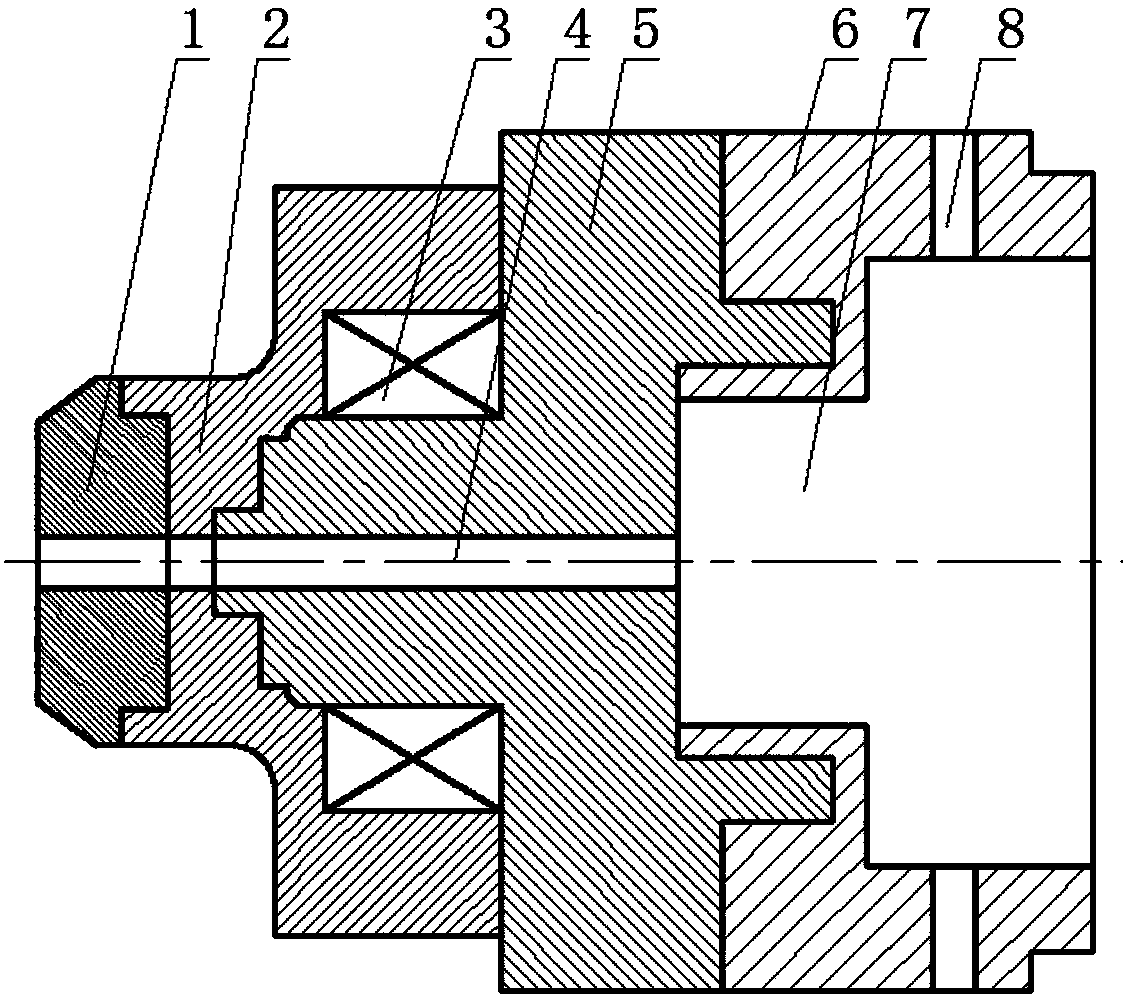

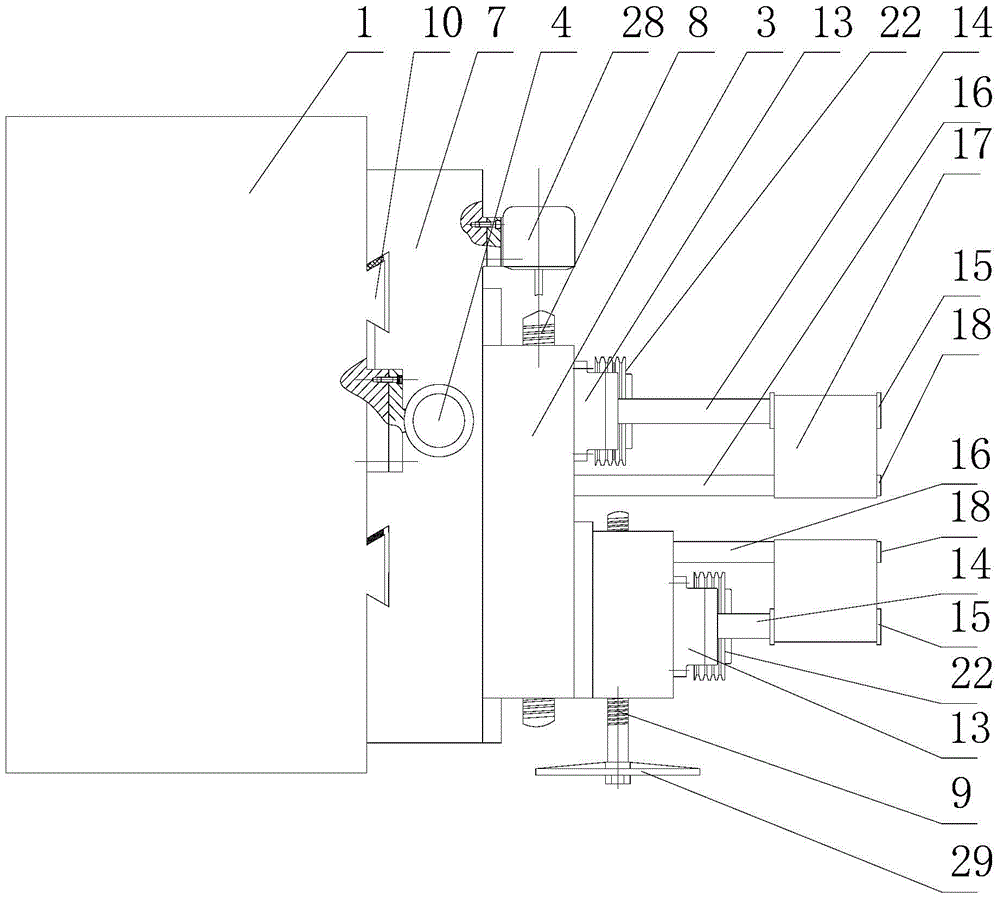

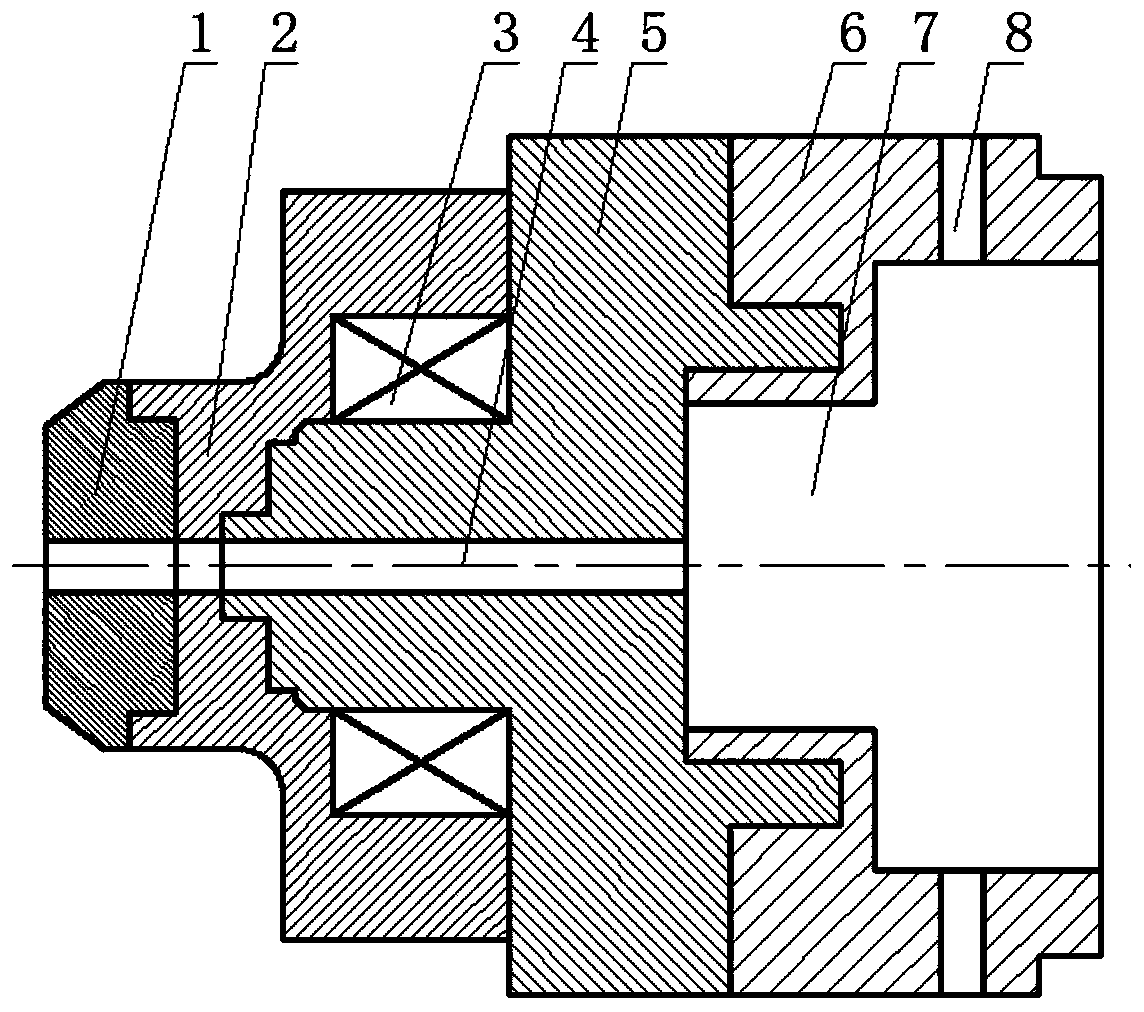

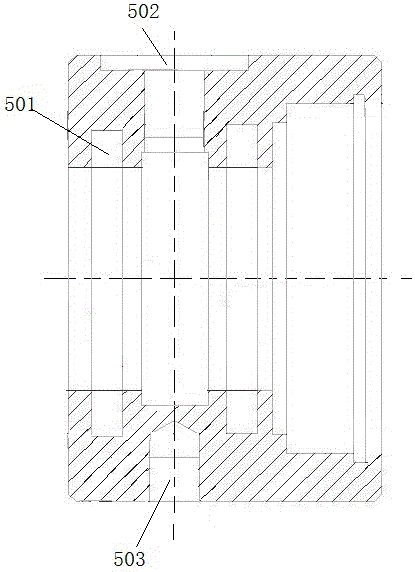

Net-shaped taper sleeve self-compensating centrifugal expansion high-speed cutter handle

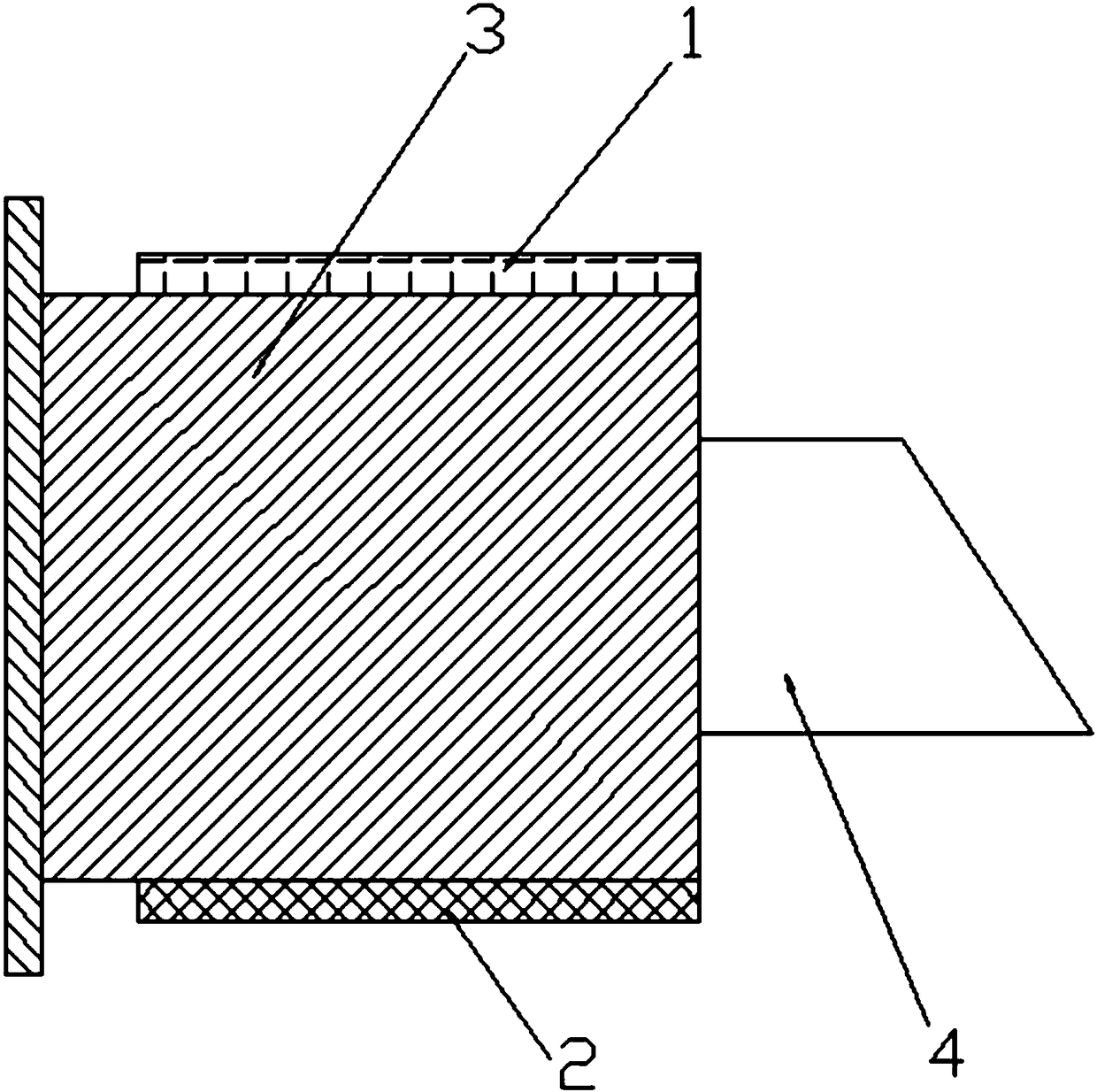

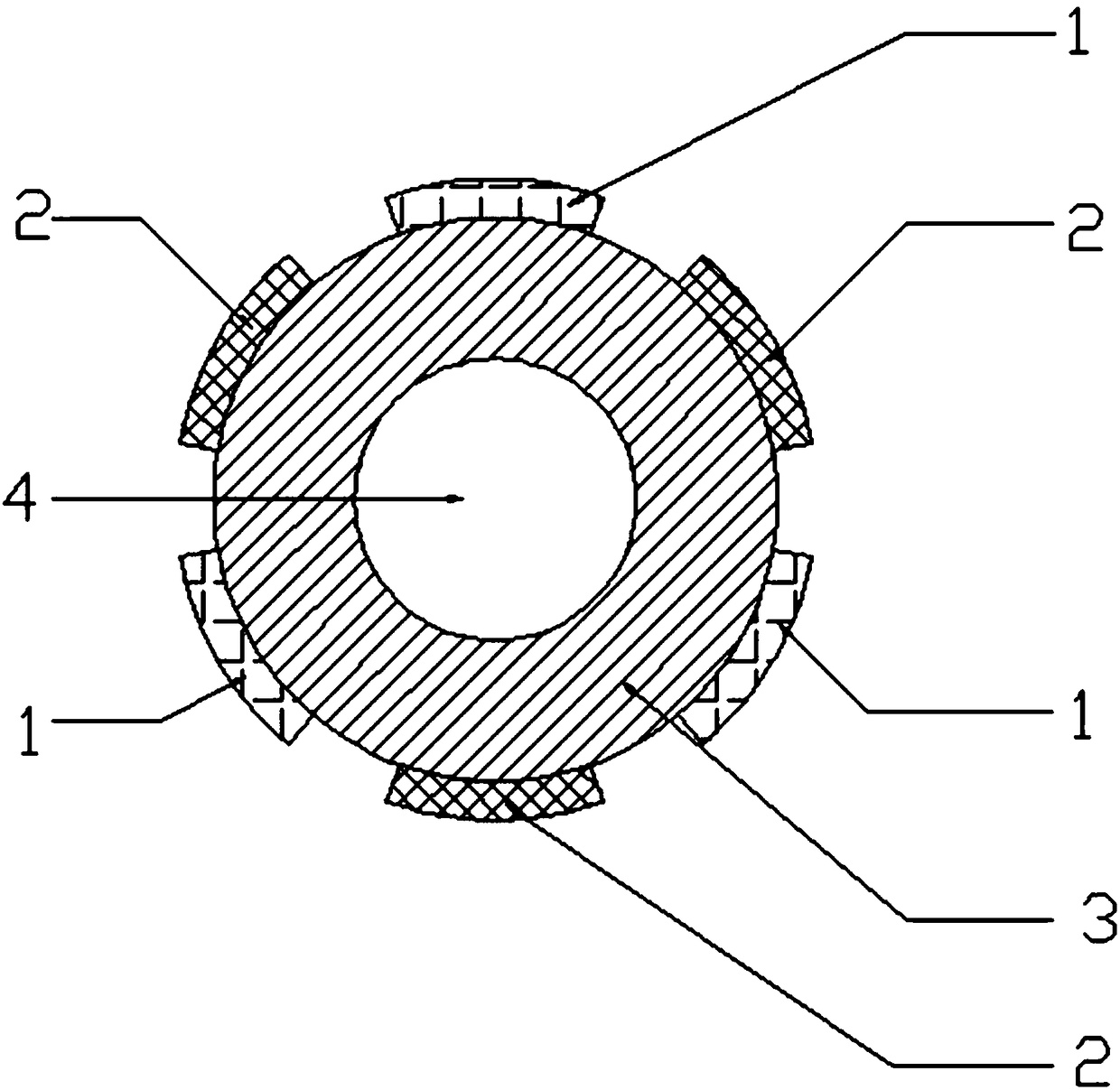

ActiveCN105312943AEnhanced ability to resist high-frequency flutterIncrease limit speedPositioning apparatusMetal-working holdersDynamic balanceSolid structure

The invention discloses a net-shaped taper sleeve self-compensating centrifugal expansion high-speed cutter handle. The handle body of the cutter handle is of an integral solid structure consisting of a front end handle body and a rear end handle body; the front end handle body and the rear end handle body are coaxial cylinders; the diameter of the front end handle body is smaller than that of the rear end handle body; a circle of groove is formed in the end surface of the rear end handle body around the connection part of the front end handle body, and a disc spring is arranged in the groove; a threaded groove is formed from the end surface of the front end handle body toward the rear handle handle body along the axis; a shaft shoulder is machined on the front end of the front end handle body and a fine pitch thread and a threaded tool withdrawal groove are formed in the front end handle body; a net-shaped taper sleeve sleeves the outer wall of the front end handle body; a fine pitch lock nut is arranged on the fine pitch thread of the front end handle body in front of the net-shaped taper sleeve; the front end and the rear end of the net-shaped taper sleeve are in contact with the fine pitch thread and the disc spring; a cylindrical clamping groove is formed in the end surface of the rear end handle body along the axis toward the inside; and a V-shaped tool changing groove is formed in the outer wall of the rear end handle body. The net-shaped taper sleeve self-compensating centrifugal expansion high-speed cutter handle has the advantages that the limiting speed is high; the dynamic balance performance is good; the rigid and the position precision are high; the strength is high; and the like.

Owner:YANSHAN UNIV

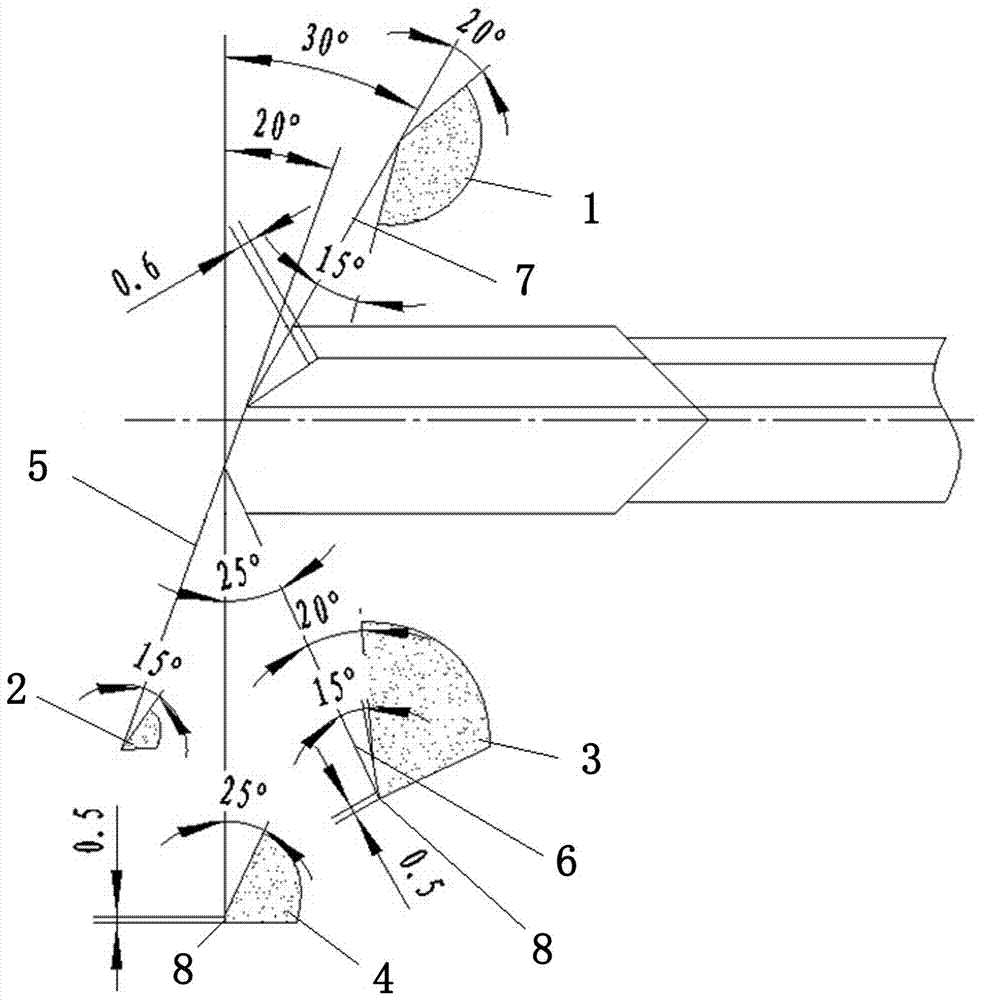

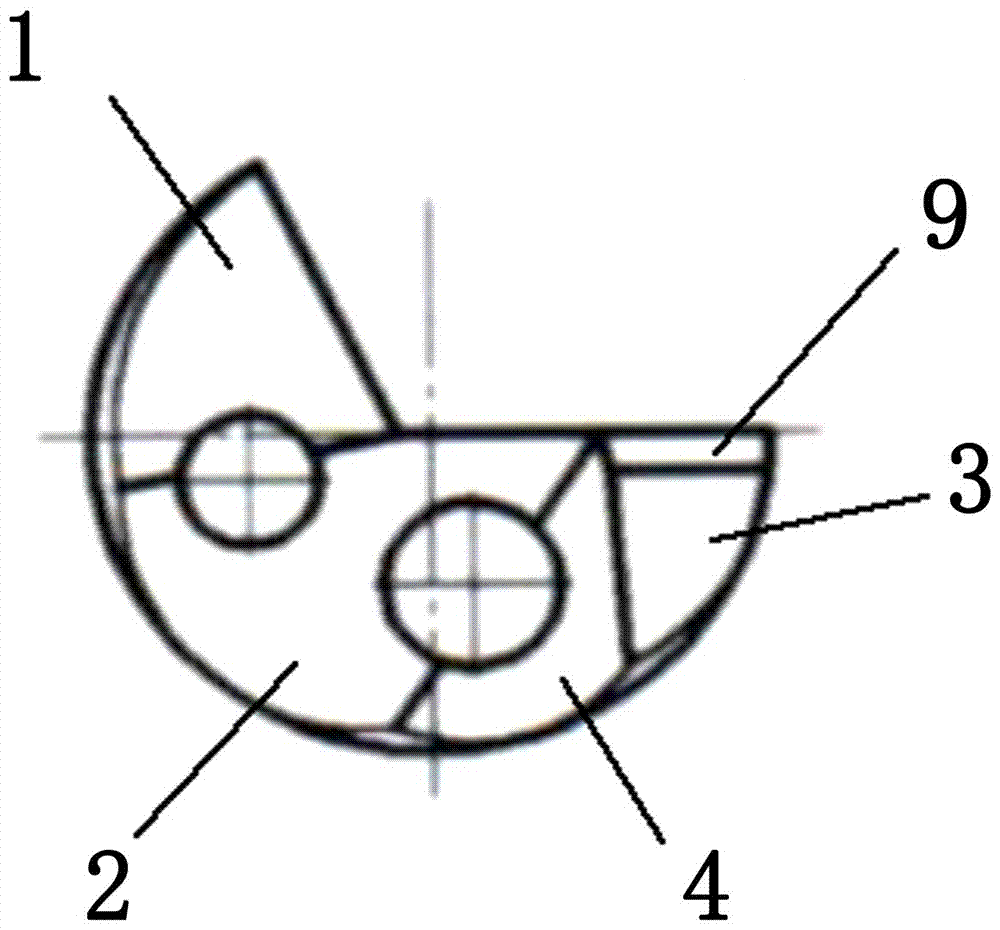

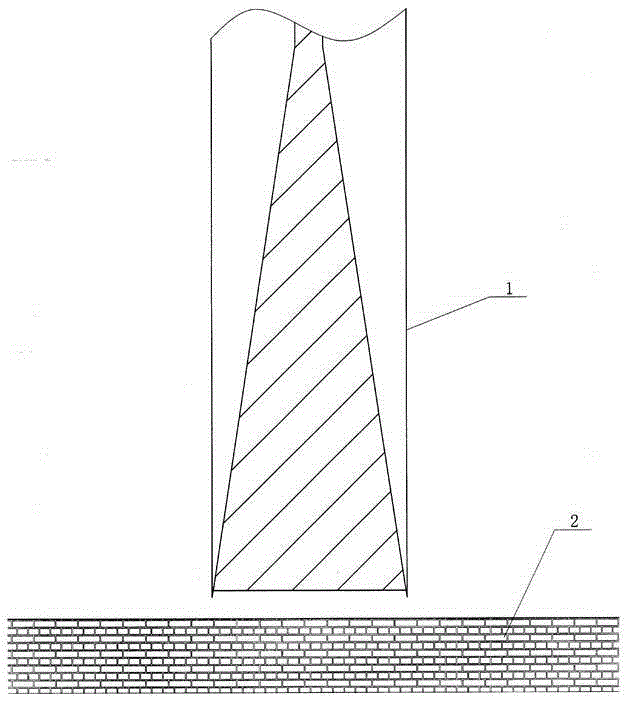

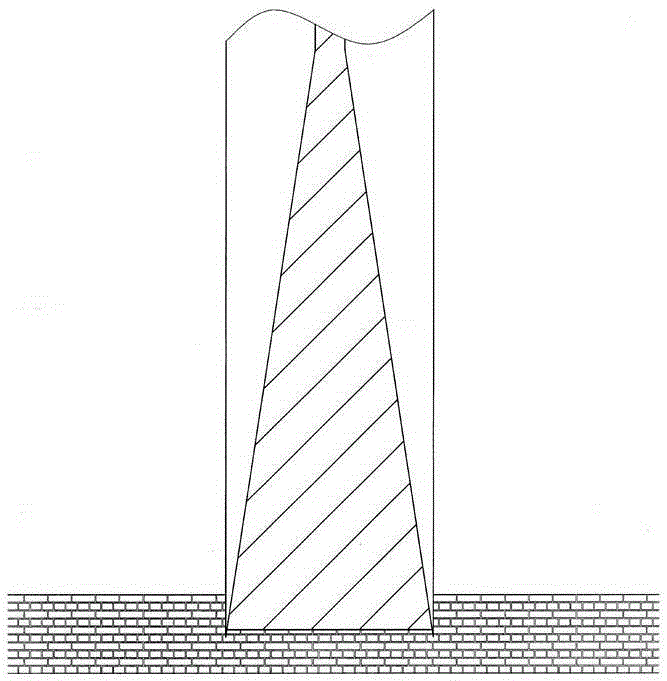

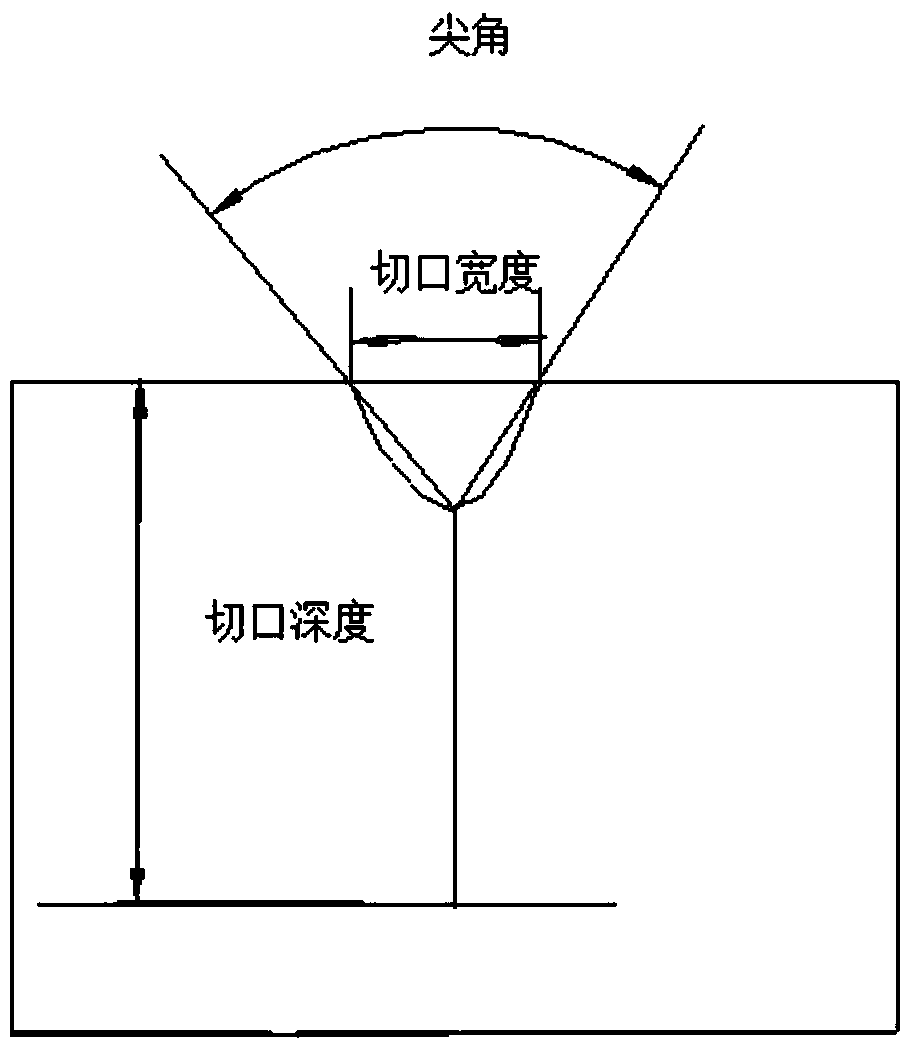

Reaming method and tool thereof for small-diameter deep holes

InactiveCN106964802AImprove straightnessGood surface roughnessTransportation and packagingMaintainance and safety accessoriesGun drillEngineering

The invention particularly relates to a reaming method and a tool thereof for small-diameter deep holes. The reaming method and the tool thereof for the small-diameter deep holes can solve the problem that the surface roughness and the straightness are difficult to guarantee when an existing gun-drill is used for reaming machining of the small-diameter deep holes. According to the reaming method for the small-diameter deep holes, the machining tool feeding technology specifically comprises the steps that a drill bit moves forwards by 0.08mm, then quickly withdraws by 3 mm, then quickly moves forwards by 2.99mm and then is fed by 0.08 mm, and the steps are circularly fed to the end of machining. According to the tool for the small-diameter deep holes, specifically, a tool bit of a gun-drill is sharpened at a certain angle, the included angles of an oil passing surface 1 and an oil passing inclined surface 7 is 20 degrees and 15 degrees respectively, the included angle between an inner tool edge clearance angle surface 2 and a main inclined surface 5 is 15 degrees, the included angle between a tool nose clearance angle surface 4 and a vertical surface is 25 degrees, and the included angle between a clearance angle surface 3 and an auxiliary inclined surface 6 is 20 degrees. The reaming method and the tool thereof for the small-diameter deep holes have the advantages that the deep holes with the high straightness and the good surface roughness can be machined, the efficiency is high, the cost is low, and the application range is wide.

Owner:SHANXI PINGYANG IND MACHINERY

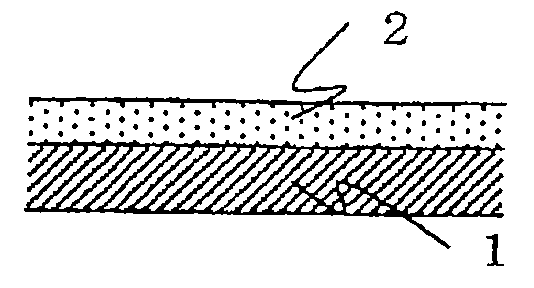

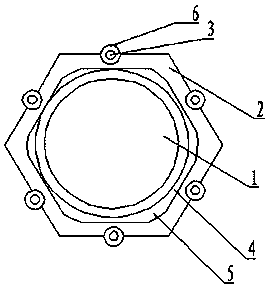

Cold-drawn precision steel pipe

InactiveCN104358944AHigh dimensional accuracyGood surface roughnessRigid pipesPlastic materialsSurface roughness

The invention discloses a cold-drawn precision steel pipe which comprises three layers of structures, wherein an outer supporting pipe is arranged on the outermost layer, a hexagonal steel pipe, and used for supporting the whole cold-drawn precision steel pipe, and has a safety protection effect; a conveying pipeline is arranged on the innermost layer, and an inner wall alloy pipe and comprises alloy steel pipes; a filling layer is arranged between the outer pipe and the inner pipe and comprises dense plastic materials, and an arc-shaped groove is formed in the filling layer; foam shock absorption rings are arranged at the two end parts of the cold-drawn precision steel pipe, so that two steel pipes can be conveniently connected. The cold-drawn precision steel pipe has the benefits that the cold-drawn precision steel pipe is high in size precision, good in inner and outer surface roughness, high-pressure-resistant, leak-proof, high in precision, good in smoothness and free of cold-bending deformation at a joint.

Owner:ZHANGJIAGANG RENHE HIGH PRECISION TUBE

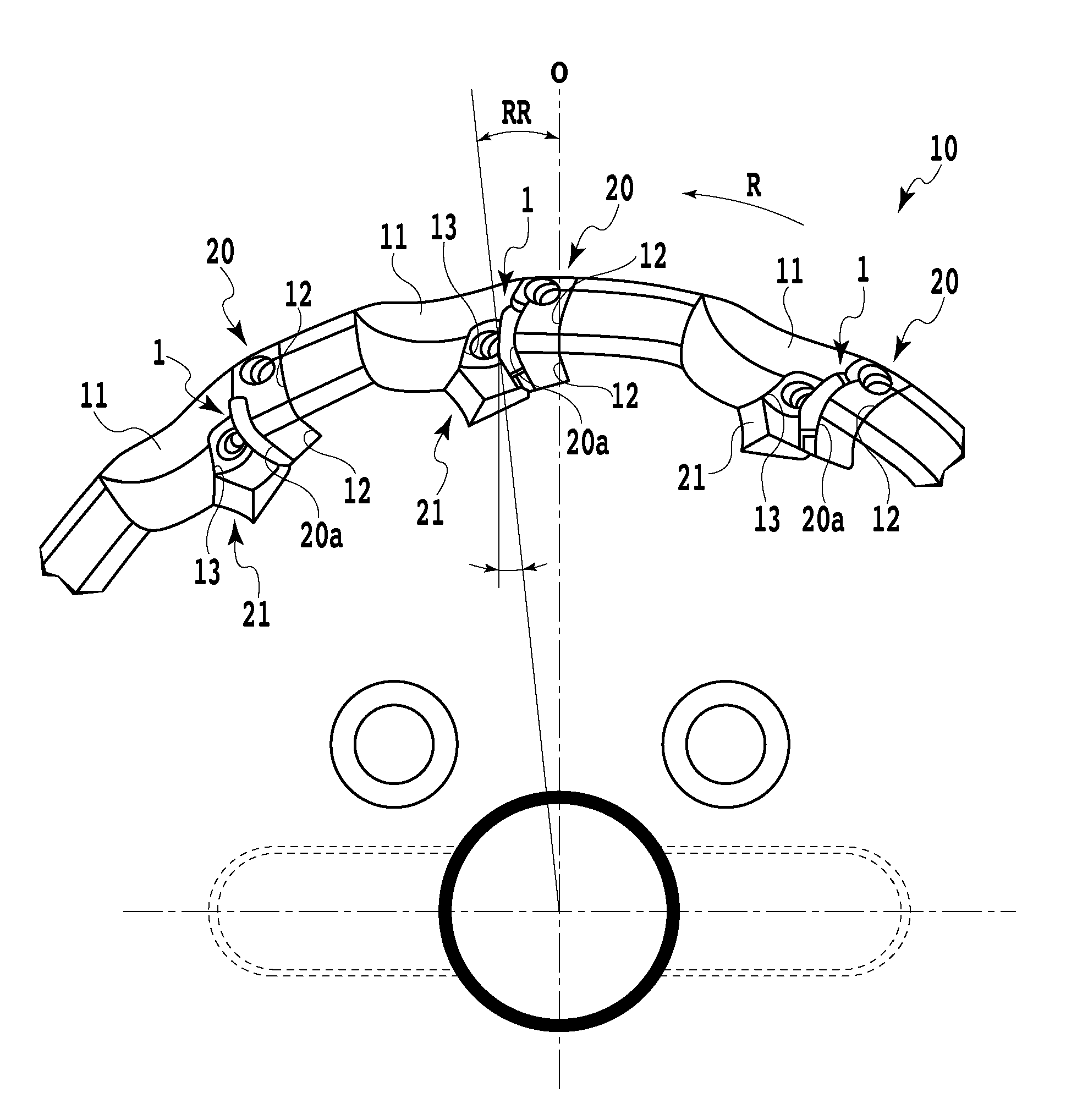

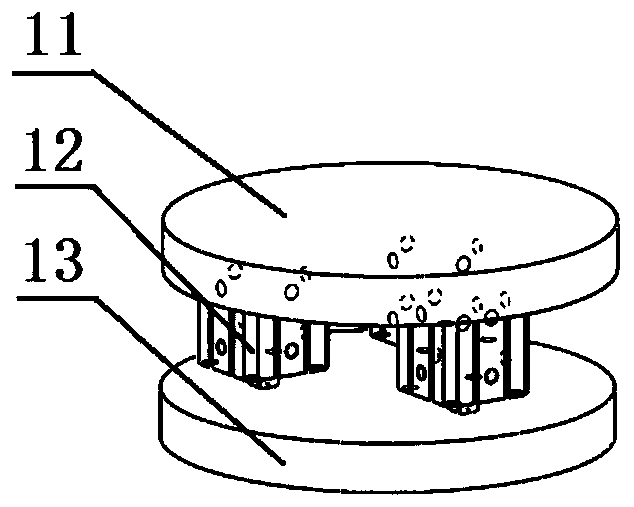

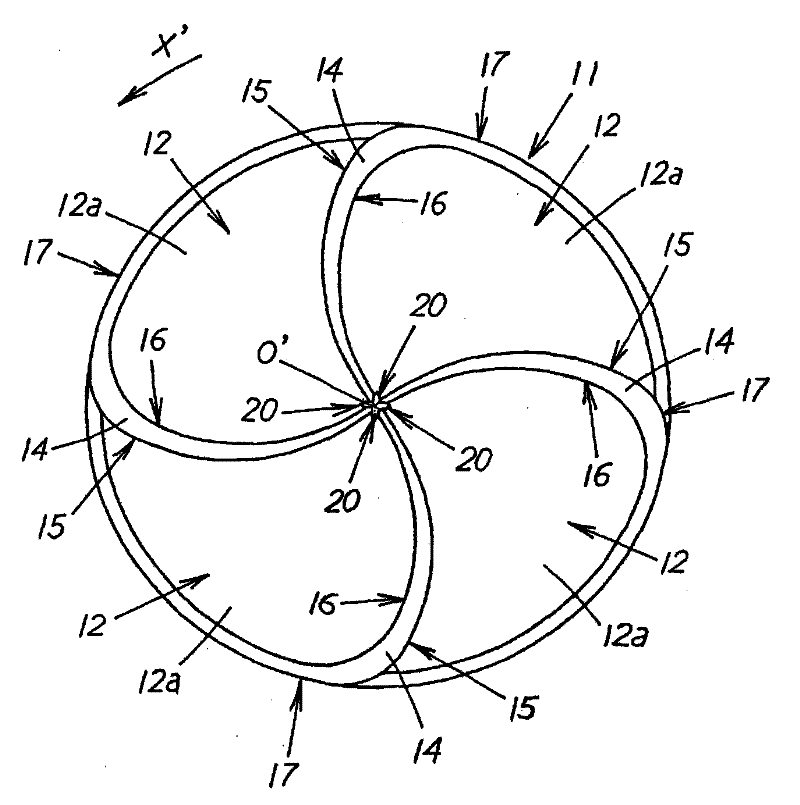

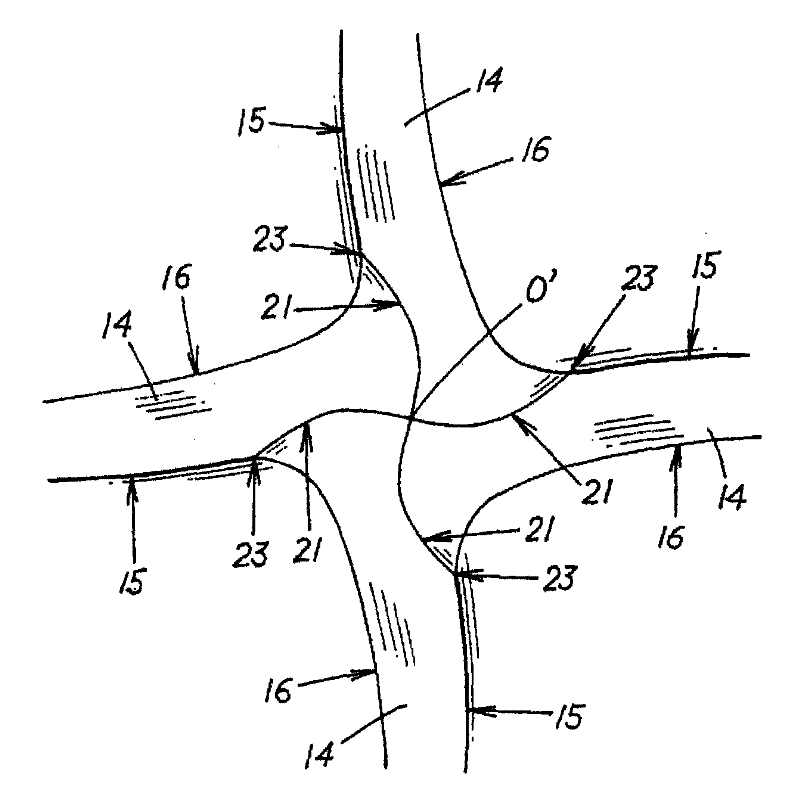

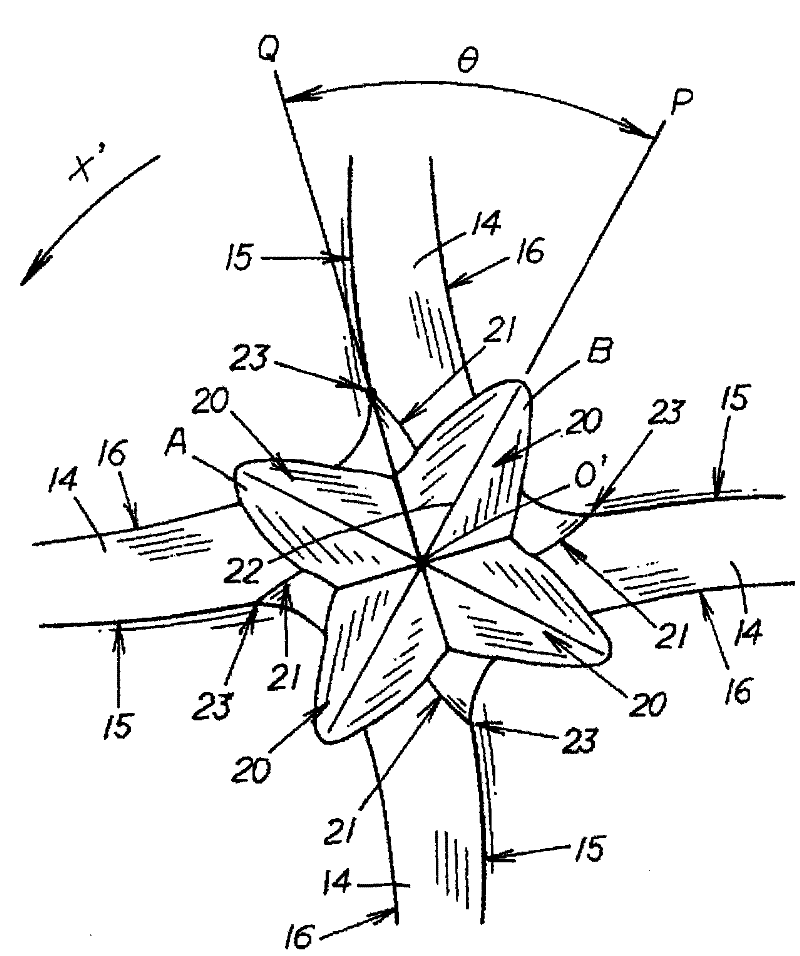

Ball end mill

ActiveCN101790432BEfficient dischargeIncrease feed rateMilling cuttersMilling cutterSurface roughness

A ball end mill exhibiting extremely excellent practicality in which machining surface roughness can be improved while prolonging the lifetime. On the outer circumference of a tool body (11), a plurality of spiral chip discharge grooves (12) are formed from the distal end toward the proximal end of the tool, and a ball blade (15) is provided at the intersection ridge line of the face of the chip discharge groove (12) and the flank (14) at the distal end of the tool body (11). In such a ball end mill, two or more ball blades (15) are provided at the tip of the ball end mill, and one groove (20) having a substantially V-shaped or U-shaped cross-section and extending outward from the center (O') of rotation of the tool is provided between respective ball blades (15) at the distal end of the tool.

Owner:UNION TOOL

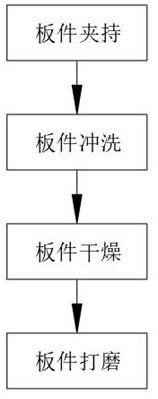

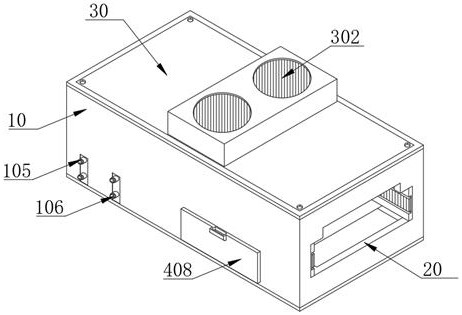

Surface treatment process of HDI plate based on chemical nickel-gold plating coating

ActiveCN114599156AGood surface roughnessHigh speedPrinted circuit liquid treatmentInsulating layers/substrates workingChemical platingPrinted circuit board

The invention relates to the technical field of surface treatment, in particular to a surface treatment process of an HDI plate based on a chemical nickel-gold plating coating, and the surface treatment process comprises the steps of clamping, washing, drying and polishing a plate, a washing tank is arranged in a treatment box, and the surface of the HDI plate is washed by using a pickling solution, so that the surface of the HDI plate is subjected to micro-etching; the method comprises the following steps: removing rust scale, an oxidation film and other rust on the metal surface of a pre-plated printed circuit board, activating the metal surface of an HDI plate, adding chemical plating accelerators with different functions into a pickling solution, sufficiently adsorbing the accelerators on the inner walls of blind holes and through holes of the HDI plate before chemical plating, feeding the HDI plate into a chemical plating tank, and carrying out chemical plating on the inner walls of the blind holes and the through holes of the HDI plate after the HDI plate is fed into the chemical plating tank. As the concentration of the accelerator adsorbed in the blind hole is higher than that of the accelerator adsorbed on the plate surface, the growth speed of the chemical plating layer is obviously higher than that of the plate surface, so that a good metal plating layer is obtained, and the generation efficiency of the surface coating of the HDI plate can be effectively improved.

Owner:CHANGZHOU AOHONG ELECTRONICS

A self-compensating centrifugal expansion high-speed tool holder with mesh tapered sleeve

ActiveCN105312943BEnhanced ability to resist high-frequency flutterIncrease limit speedPositioning apparatusMetal-working holdersSolid structureDynamic balance

The invention discloses a net-shaped taper sleeve self-compensating centrifugal expansion high-speed cutter handle. The handle body of the cutter handle is of an integral solid structure consisting of a front end handle body and a rear end handle body; the front end handle body and the rear end handle body are coaxial cylinders; the diameter of the front end handle body is smaller than that of the rear end handle body; a circle of groove is formed in the end surface of the rear end handle body around the connection part of the front end handle body, and a disc spring is arranged in the groove; a threaded groove is formed from the end surface of the front end handle body toward the rear handle handle body along the axis; a shaft shoulder is machined on the front end of the front end handle body and a fine pitch thread and a threaded tool withdrawal groove are formed in the front end handle body; a net-shaped taper sleeve sleeves the outer wall of the front end handle body; a fine pitch lock nut is arranged on the fine pitch thread of the front end handle body in front of the net-shaped taper sleeve; the front end and the rear end of the net-shaped taper sleeve are in contact with the fine pitch thread and the disc spring; a cylindrical clamping groove is formed in the end surface of the rear end handle body along the axis toward the inside; and a V-shaped tool changing groove is formed in the outer wall of the rear end handle body. The net-shaped taper sleeve self-compensating centrifugal expansion high-speed cutter handle has the advantages that the limiting speed is high; the dynamic balance performance is good; the rigid and the position precision are high; the strength is high; and the like.

Owner:YANSHAN UNIV

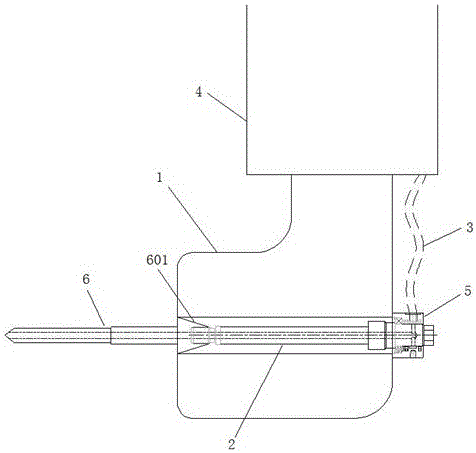

CNC Machine Tool and Its Omnidirectional Intelligent Vibration Reduction Tool

ActiveCN106077726BHigh strengthHigh precisionTurning toolsMetal working apparatusNumerical controlTool bit

The invention discloses an omni-directional intelligent vibration damping cutting tool of a numerically-controlled machine tool. The omni-directional intelligent vibration damping cutting tool comprises a tool shank and a tool bit. One end of the tool shank is used for being connected with a tool rest. The other need of the tool shank is used for being connected with the tool bit. The side face of the tool shank is provided with piezoelectric film sensors used for detecting vibration and deformation of the tool shank. The side face of the tool shank is also provided with piezoelectric film drivers used for driving the tool shank to conduct reverse vibration and deformation according to detection signals of the piezoelectric film sensors. The piezoelectric film sensors and the piezoelectric film drivers are arranged oppositely. The omni-directional intelligent vibration damping cutting tool also comprises a controller which is in communication connection with the piezoelectric film sensors and the piezoelectric film drivers. Generated noise is low. The structure of the omni-directional intelligent vibration damping cutting tool cannot be damaged. The strength of the omni-directional intelligent vibration damping cutting tool is guaranteed. The machining precision, the machined surface roughness and the adaptability are improved, and the response frequency bandwidth and the reaction speed of vibration control are increased. The invention further discloses the numerically-controlled machine tool comprising the omni-directional intelligent vibration damping cutting tool.

Owner:GUANGDONG UNIV OF TECH

Cutting method of aramid fiber composite material

ActiveCN104015211BExcellent machinabilityExtended service lifeMetal working apparatusMilling cutterCemented carbide

The invention provides a cutting processing method of an aramid fiber composite material, which firstly cuts the aramid fiber by using a cutter, and then cuts off the aramid fiber composite material to be removed. Said tool consists of two identical round solid carbide cutting blades and a high-speed steel disc milling cutter, alternatively, said tool comprises a blade, a shank and an attachment hole for attachment to a tool holder, The blade is in the shape of a strip in the feeding direction of the tool, and several cutting units are arranged in two rows along a straight line on the blade. Adopting the present invention, its cutting quality and cutting efficiency are obviously superior to the existing cutting processing method of aramid fiber composite material, the cutting processing efficiency is at least 2 times higher than the original one, and the processing quality is at least 1 grade higher than the original one.

Owner:吉林航空维修有限责任公司

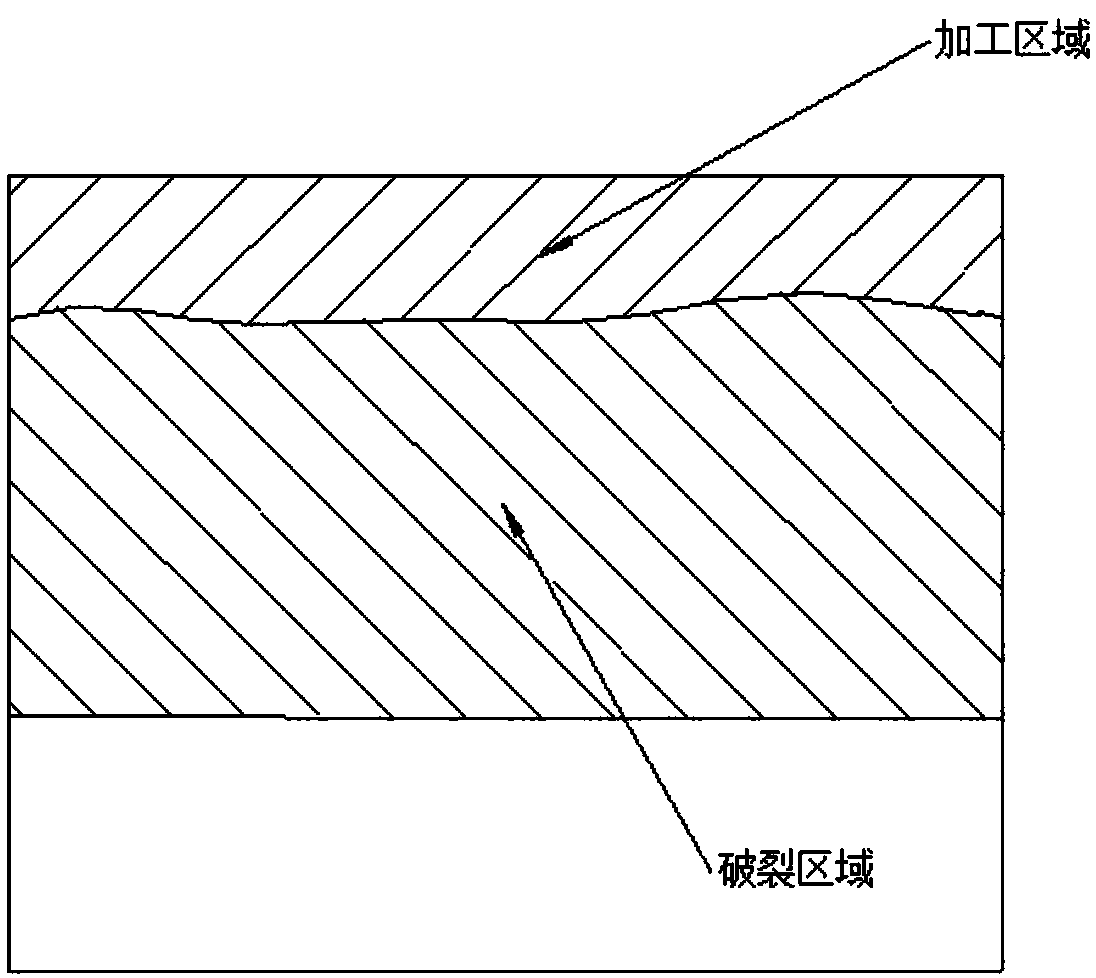

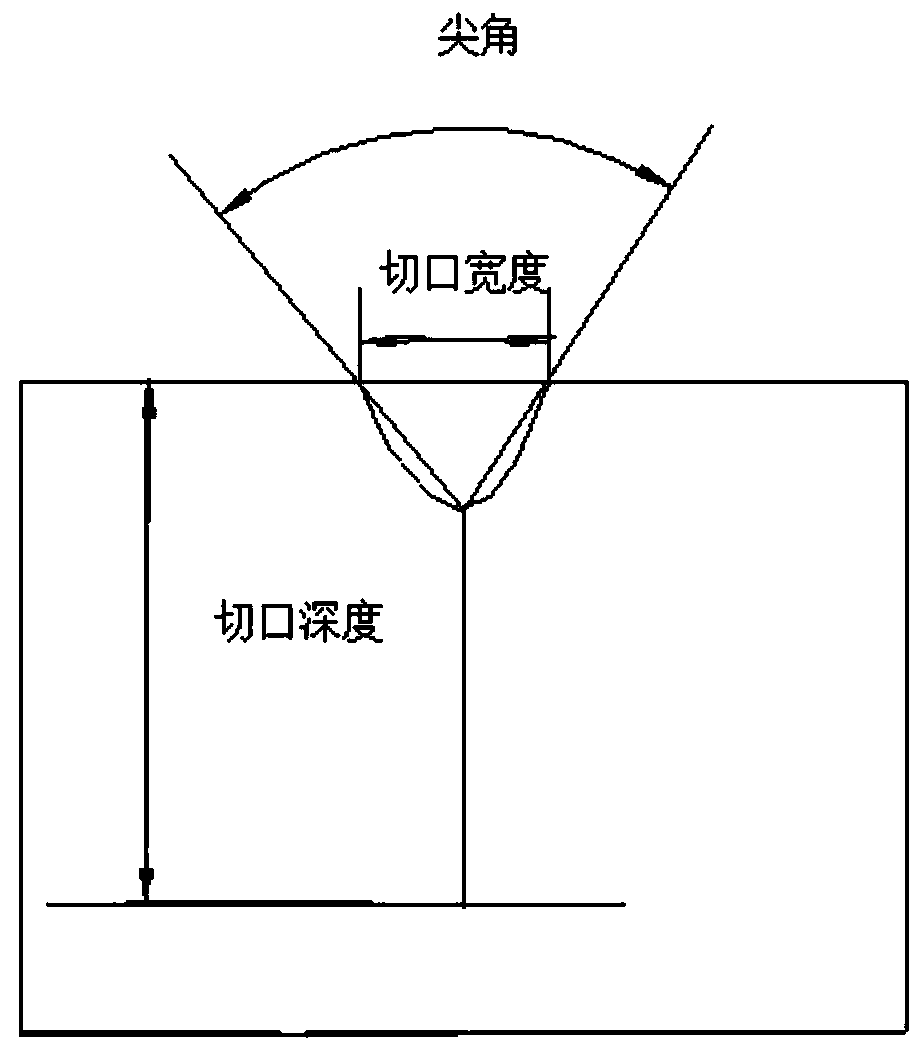

Carbon dioxide laser machining method of PCBN and carbon dioxide laser machining device of PCBN

ActiveCN108311795AImprove the efficiency of cutting PCBNReduce formationOther manufacturing equipments/toolsLaser beam welding apparatusHeat-affected zoneHexagonal boron nitride

The invention relates to a carbon dioxide laser machining method of PCBN. The surface of a material is cut by utilizing laser, and the generated temperature gradient in the cutting process results inphase change of cubic boron nitride to hexagonal boron nitride, so that great thermal stress and internal stress are caused, and the material produces cracks and propagating cracks in the kerf direction. The machining method is totally different from the traditional laser machining principle; the PCBN laser cutting efficiency is improved effectively; and the forming areas of a heat-affected zone and a recasting layer of the material are reduced, and the roughness of the machined surface is improved.

Owner:TIANJIN UNIV OF SCI & TECH

Nickel alloy light guide plate cavity

InactiveCN102566253AGood surface roughnessShort production cycleOriginals for photomechanical treatmentOptical light guidesOptoelectronicsLight guide

Owner:昆山美微电子科技有限公司

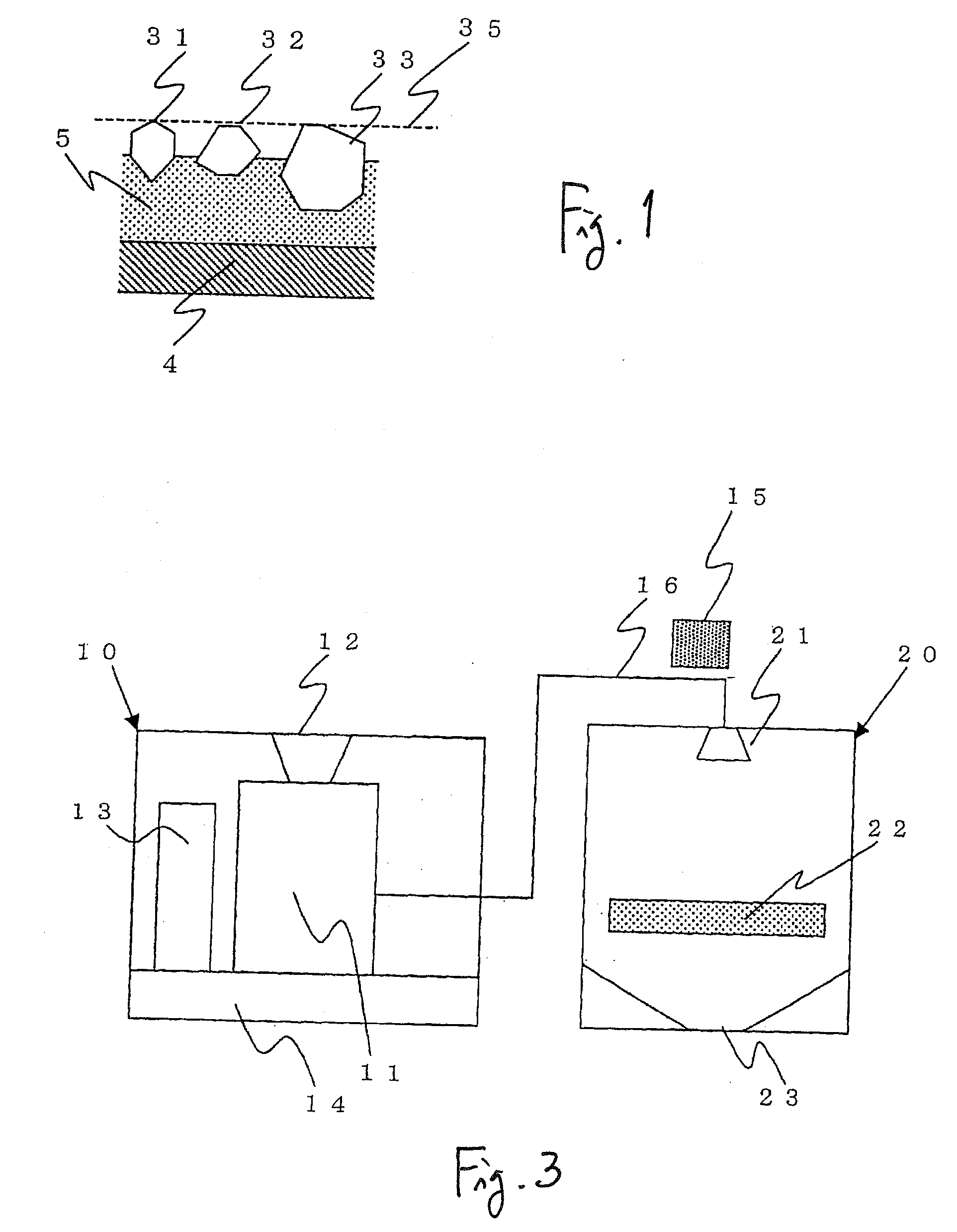

Large gear abrasive belt grinding machine

The invention provides a large gear adhesive belt tooth grinding machine, and relates to a large gear machining device. The large gear adhesive belt tooth grinding machine comprises a machine base, a stand column, a rotating working table, a servo motor, a ball screw I and a power head, and is characterized in that the rotating working table is assembled at one end of the upper portion of the machine base, the stand column is assembled at the other end of the upper portion of the machine base, the power head is assembled on the stand column through a swallow-tail-shaped guide rail I, the servo motor is assembled on the stand column and connected with the ball screw I on the power head so as to drive the power head to move up and down along the swallow-tail-shaped guide rail I, and the rotating working table is assembled on the machine base through the guide rail, connected with a rapid oil cylinder on the machine base and driven by the rapid oil cylinder to move leftward and rightward along the guide rail. The large gear adhesive belt tooth grinding machine has the advantages of being novel in structure, easy and convenient to machine, convenient to use, high in grinding efficiency, high in adaptability, high in machined product quality, short in auxiliary time and the like, and therefore the large gear adhesive belt tooth grinding machine is a novel large gear adhesive belt tooth grinding machine which integrates economical efficiency and practicability.

Owner:DALIAN JIAOTONG UNIVERSITY

Carbon dioxide laser processing method and processing device for pcbn

ActiveCN108311795BImprove the efficiency of cutting PCBNReduce formationOther manufacturing equipments/toolsLaser beam welding apparatusCarbon dioxide laser lightHeat-affected zone

The invention relates to a carbon dioxide laser machining method of PCBN. The surface of a material is cut by utilizing laser, and the generated temperature gradient in the cutting process results inphase change of cubic boron nitride to hexagonal boron nitride, so that great thermal stress and internal stress are caused, and the material produces cracks and propagating cracks in the kerf direction. The machining method is totally different from the traditional laser machining principle; the PCBN laser cutting efficiency is improved effectively; and the forming areas of a heat-affected zone and a recasting layer of the material are reduced, and the roughness of the machined surface is improved.

Owner:TIANJIN UNIV OF SCI & TECH

Head replaceable cutting tool, cutting head, and tool body

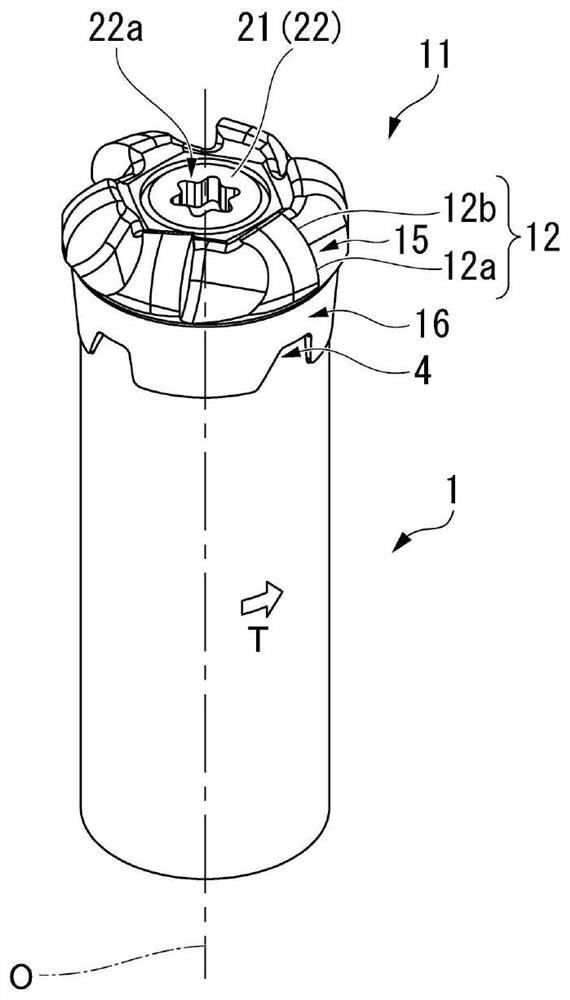

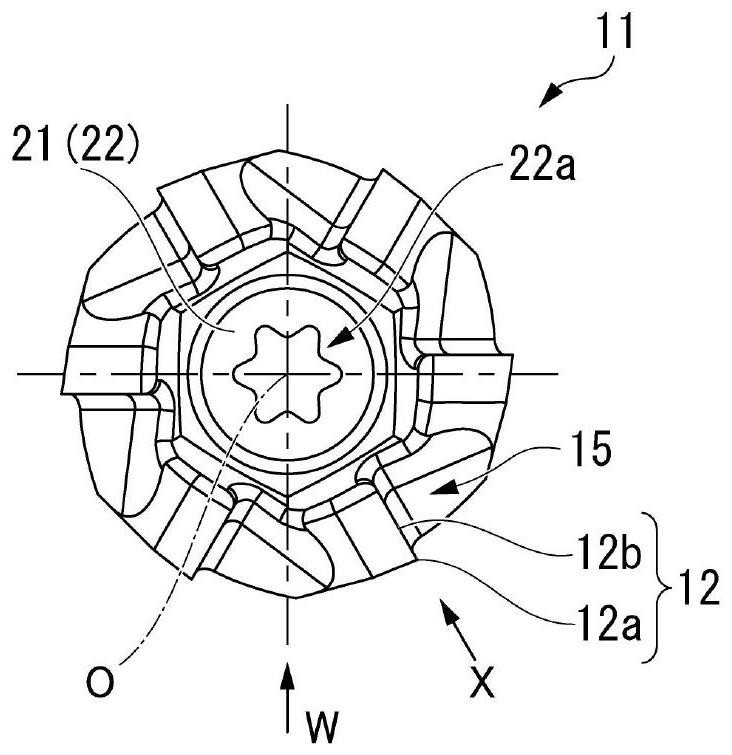

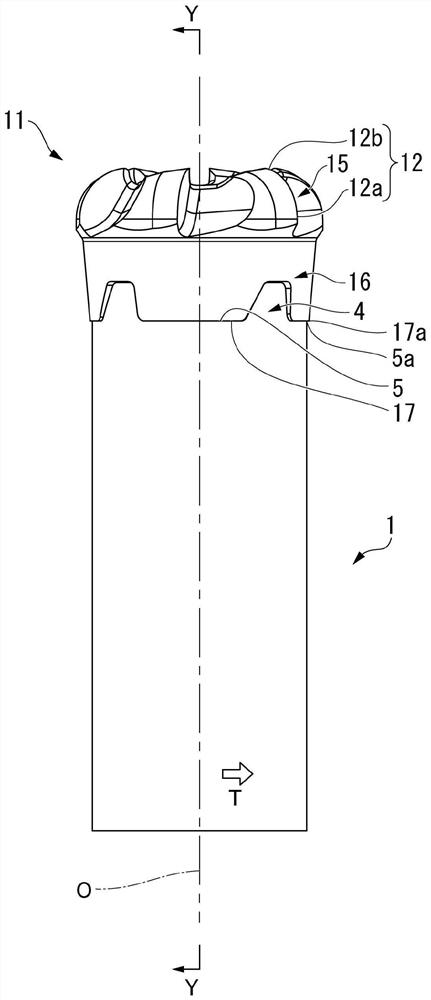

PendingCN114080288AImprove installation strengthImprove rigidityTool workpiece connectionTransportation and packagingEngineeringGeneral surgery

This head replaceable cutting tool comprises: a shaft-like tool body (1) which is rotated around an axis line (O) in a tool rotation direction (T); and a cutting head (11) provided with a cutting edge (12) and detachably attached to a front end of the tool body (1). The tool body (1) and the cutting head (11) are attached to each other with a body-side abutting surface (5) on a front end surface of the tool body (1) abutting against and closely attached to a head-side abutting surface (17) on a rear end surface of the cutting head (11). A recess (16) and a protrusion (4) insertable into the recess (16) are formed on the rear end surface of the cutting head (11) and the front end surface of the tool body (1), respectively. The recess (16) and the protrusion (4) are formed to become wider in a circumferential direction toward a radially outer peripheral side with respect to the axis line (O).

Owner:MOLDINO TOOL ENG LTD

Inner-cooling component for machine tool accessory

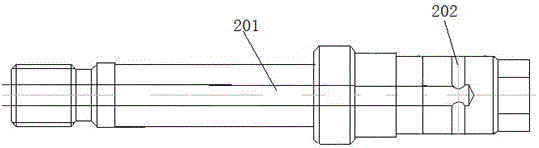

PendingCN107433491AImprove processing efficiencyImprove processing qualityMaintainance and safety accessoriesRotational axisEngineering

The invention provides an inner-cooling component for a machine tool accessory. The inner-cooling component for the machine tool accessory comprises the machine tool accessory, an inner-cooling connecting hose, a cylinder and an inner-cooling tool. The machine tool accessory comprises a rotation shaft. The rotation shaft is installed in the machine tool accessory along the horizontal direction, and the tail end of the rotation shaft is extended to the exterior of the machine tool accessory and is connected with the cylinder. The middle part of the rotation shaft is provided with a through hole along the axial direction. The tail end of the rotation shaft is radially provided with two water injection holes communicated with the through hole. One end of the inner-cooling connecting hose is connected with a water discharging hole of a machine tool spindle, and the other end is communicated with the cylinder, so cutting fluid discharged from the water discharging hole of the machine tool spindle is fed into the water injection holes. The inner-cooling component is capable of providing the inner-cooling function for the machine tool accessory, the accessory machining can be realized by many high-performance tools and high-rotation-speed cutting tools, and the machining efficiency and machining quality of the accessory are improved.

Owner:NINGXIA KOCEL MOLD

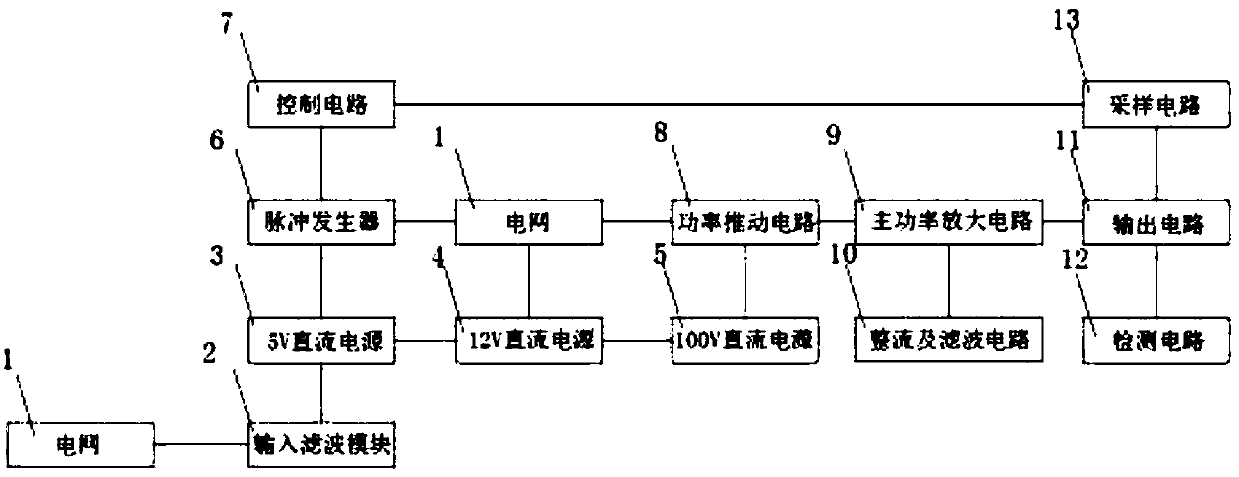

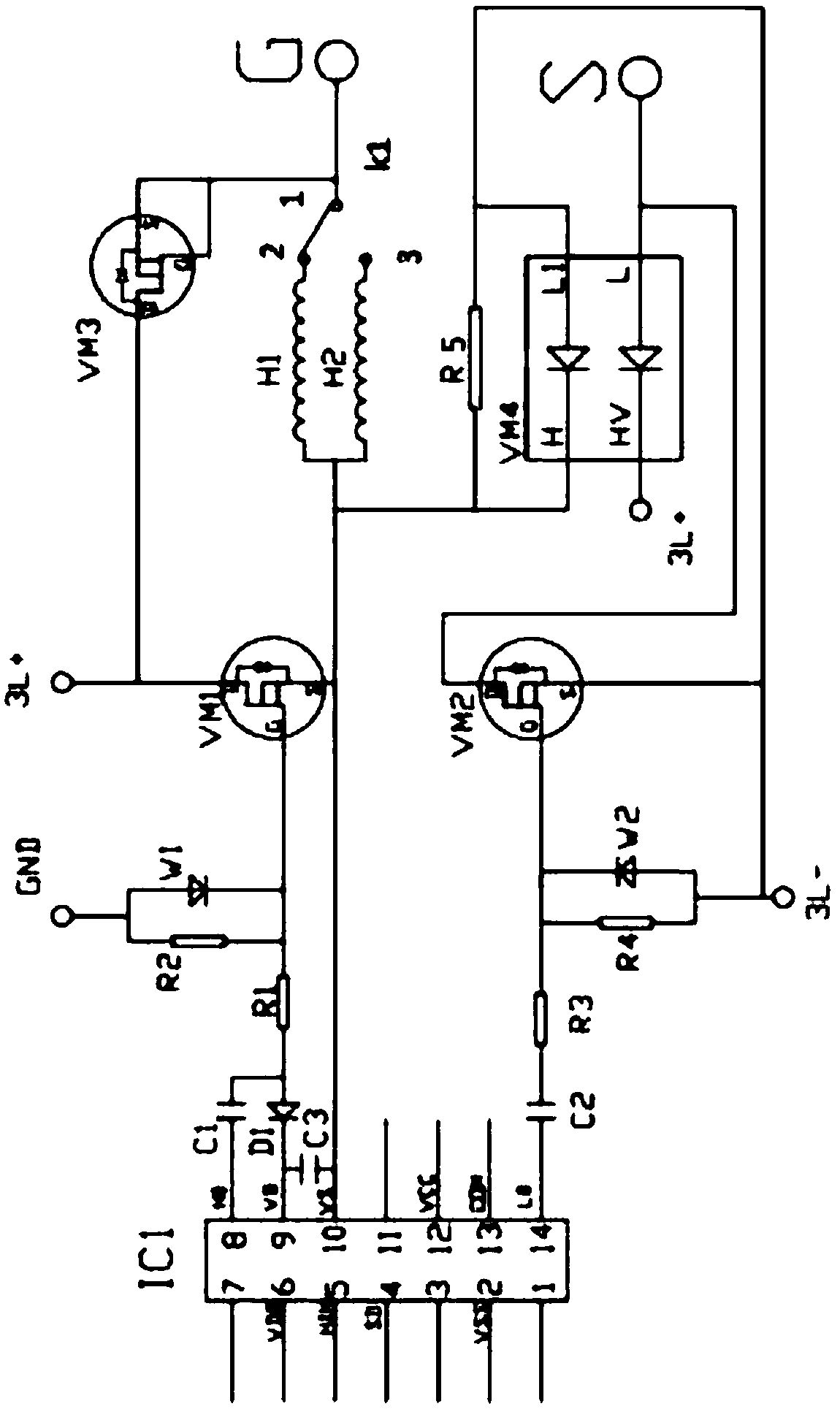

Intelligent high-speed energy-saving linear cutting high-frequency pulse power supply

PendingCN107695470AImprove stabilityGood surface roughnessElectric circuitsPower conversion systemsNumerical controlMachined surface

The invention discloses an intelligent high-speed energy-saving linear cutting high-frequency pulse power supply. The intelligent high-speed energy-saving linear cutting high-frequency pulse power supply comprises a pulse generator, the control end of the pulse generator is electrically connected with a control circuit, the output end of the pulse generator is electrically connected with a power grid, and the power grid is electrically connected with a 12V direct current power supply. The 12V direct current power supply is electrically connected with a 5V direct current power supply and a 100Vdirect current power supply, the 5V direct current power supply is electrically connected with the input end of the pulse generator, the input end of the pulse generator is electrically connected with an input filter circuit through the 5V direct current power supply, and the input filter circuit is electrically connected with the power grid. The intelligent high-speed energy-saving linear cutting high-frequency pulse power supply is economical and practical, an output circuit of the intelligent high-speed energy-saving linear cutting high-frequency pulse power supply can output impulse waveforms with different effects, and a numerical control spark cutting machine tool is made to be low in loss, high in energy and high in working speed; and the pulse waveforms output by the output circuit are stable, so that the roughness of machined surfaces is greatly improved.

Owner:肇庆市高讯数控设备有限公司

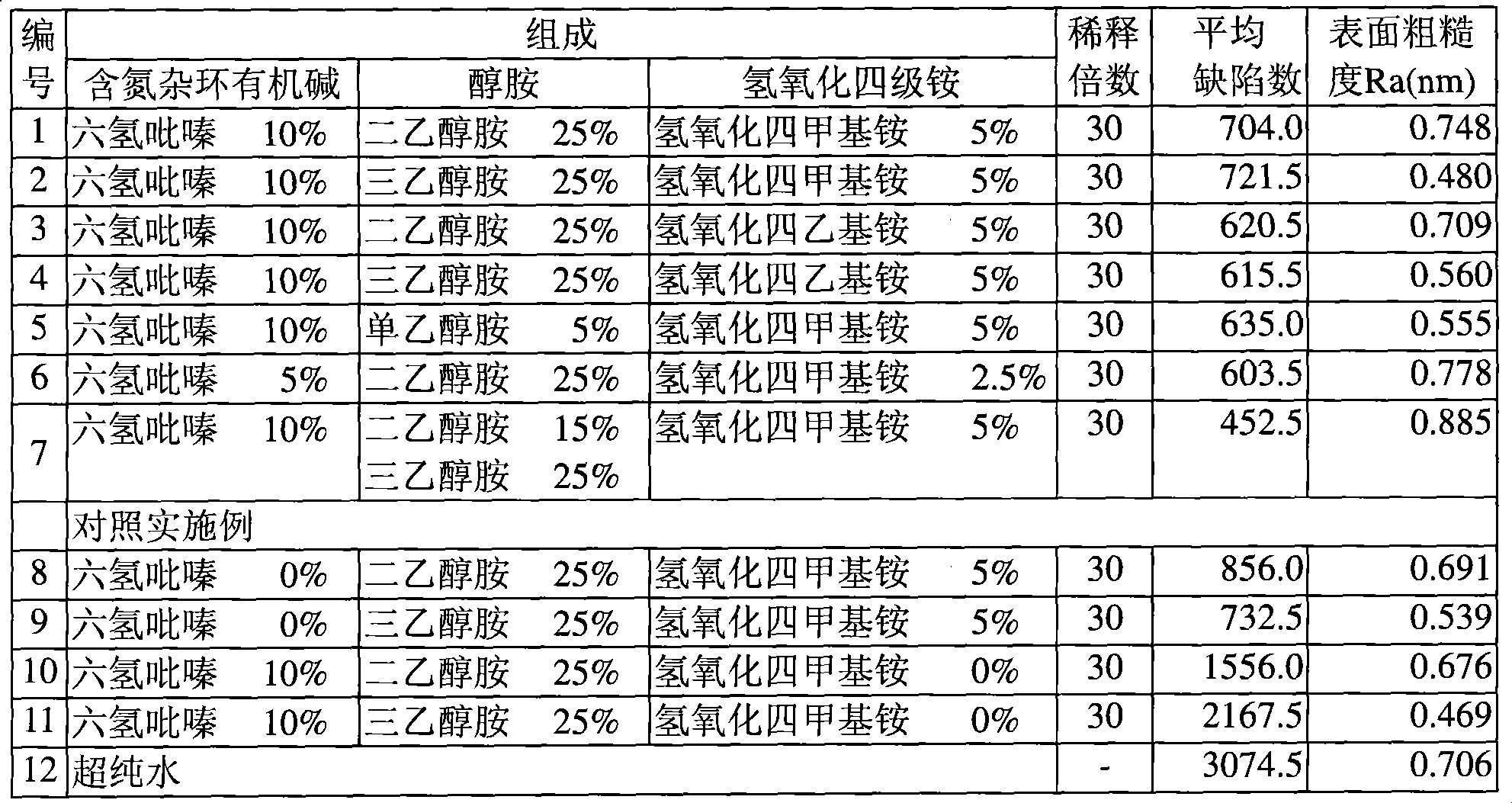

Aqueous cleaning compositions for semi-conductor copper processing

ActiveCN101362986AReduce the number of defectsGood surface roughnessNon-surface-active detergent compositionsSemiconductor/solid-state device manufacturingPollutantChemical-mechanical planarization

The invention relates to a water phase cleaning composition which is used in or after the chemical mechanical planarization during the copper processing of an integrated circuit, and the water phase cleaning composition comprises 0.05 to 20 percent by weight of nitrogen-containing heterocyclic organic base, 0.05 to 50 percent by weight of alkylol amine, 0.01 to 10 percent by weight of quaternary ammonium hydroxide and water. When the water phase cleaning composition is used in or after the planarization process of a semiconductor, the cleaning composition can effectively remove residual pollutants from the surface of a chip and simultaneously give the better surface roughness to the surface of the chip.

Owner:EPOCH MATERIAL CO LTD

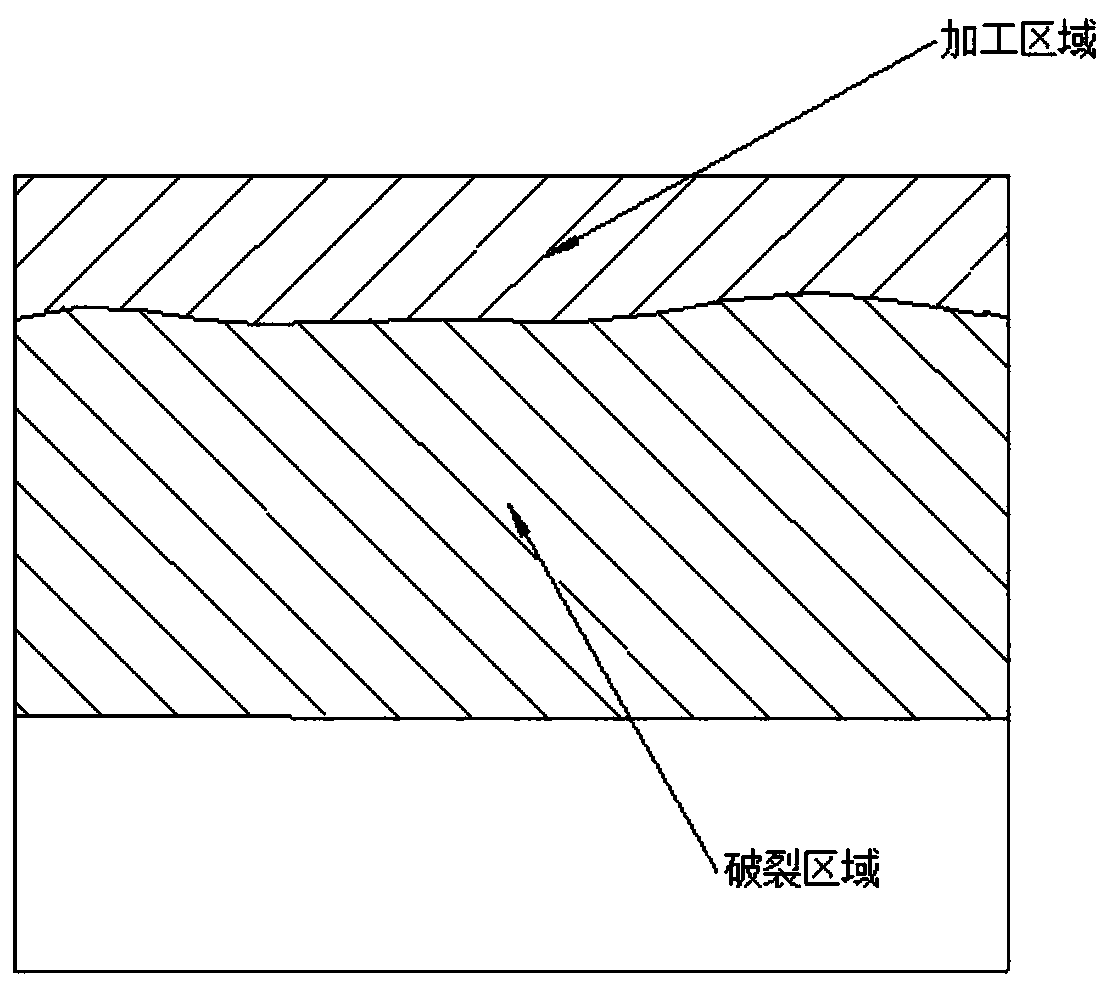

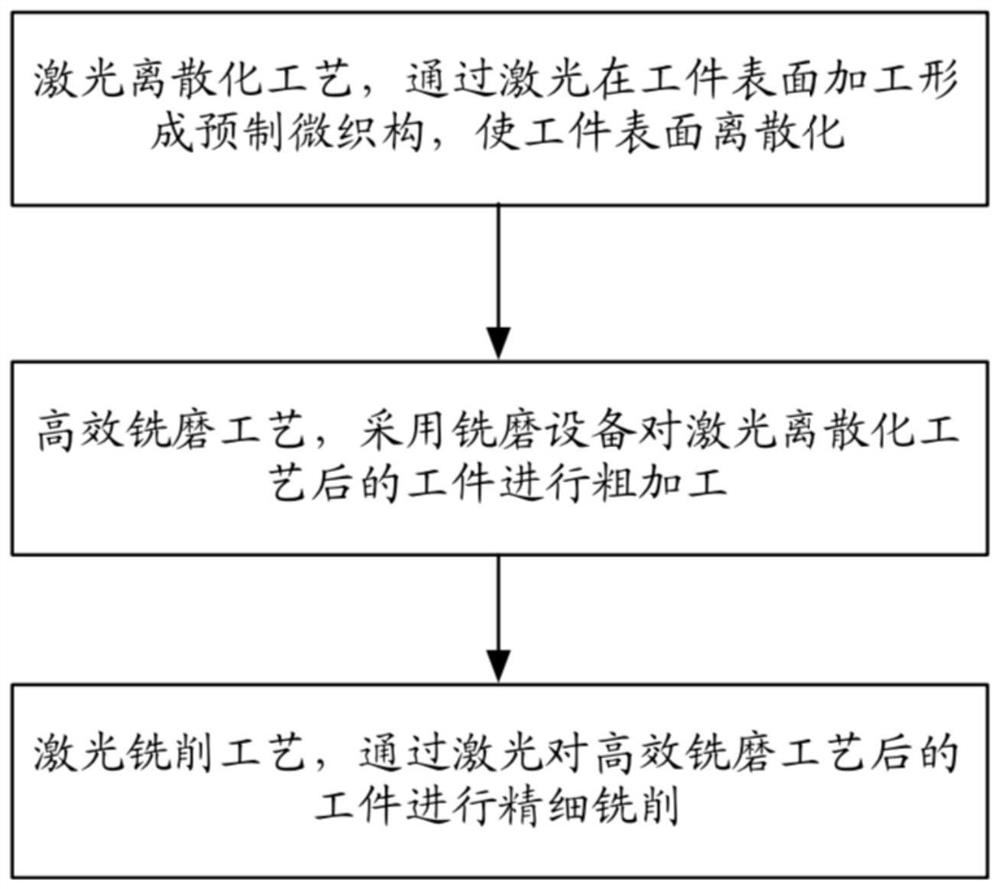

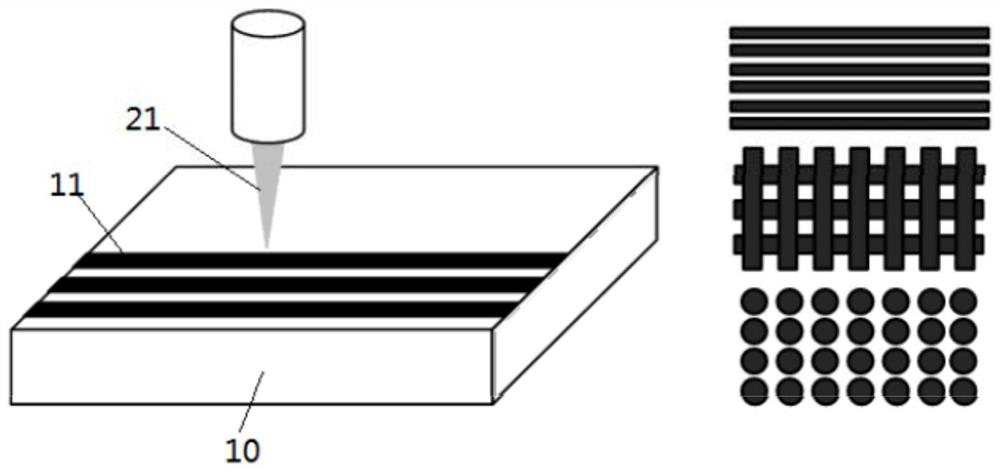

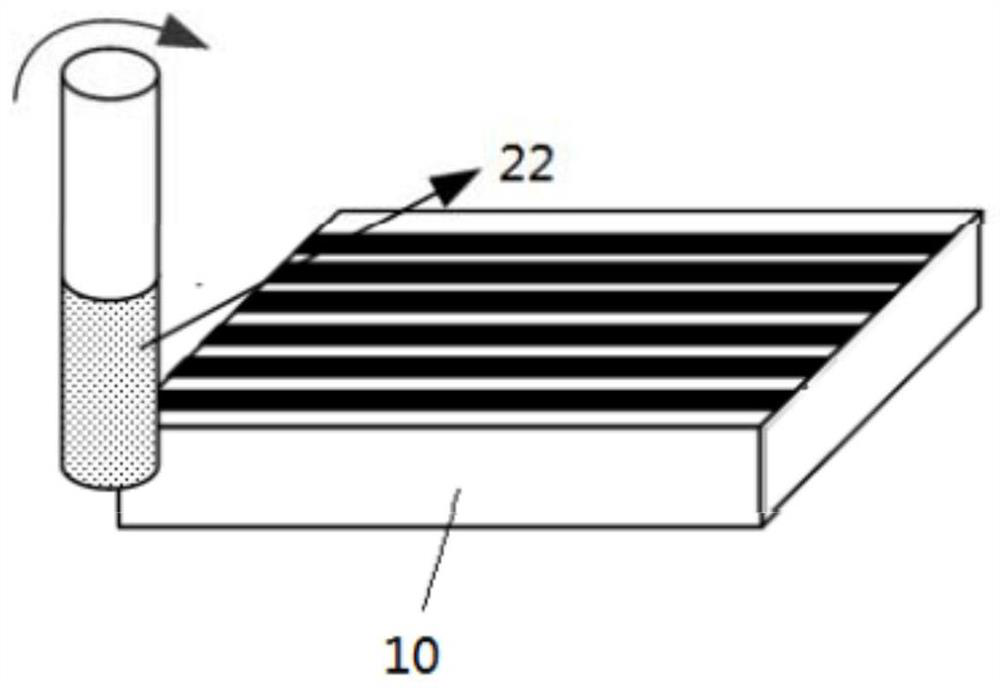

Composite processing method based on laser discretization, high-efficiency milling and laser milling

ActiveCN110091054BImprove machinabilityGood surface roughnessLaser beam welding apparatusLaser processingMachined surface

The invention discloses a compound processing method based on laser discretization, high-efficiency milling and laser milling. The method includes: a laser discretization process, forming a prefabricated micro-texture on the surface of a workpiece by laser processing, so as to discretize the surface of the workpiece; The high-efficiency milling and grinding process uses milling equipment to rough-machine the workpiece after the laser discretization process; the laser milling process uses laser to perform fine milling on the workpiece after the high-efficiency milling and grinding process. The invention combines laser discretization, high-efficiency milling and laser milling technology, can improve the machinability of difficult-to-machine materials, realize high-efficiency and high-removal rate processing, improve the surface roughness of processing, and can process in different regions according to the characteristics of the workpiece; through multiple The combined process of technology greatly improves the processing efficiency, processing accuracy and processing quality.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

A kind of low-carbon selenium-containing free-cutting steel for instruments and meters and its manufacturing method

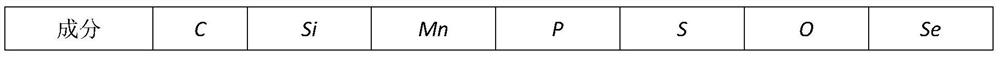

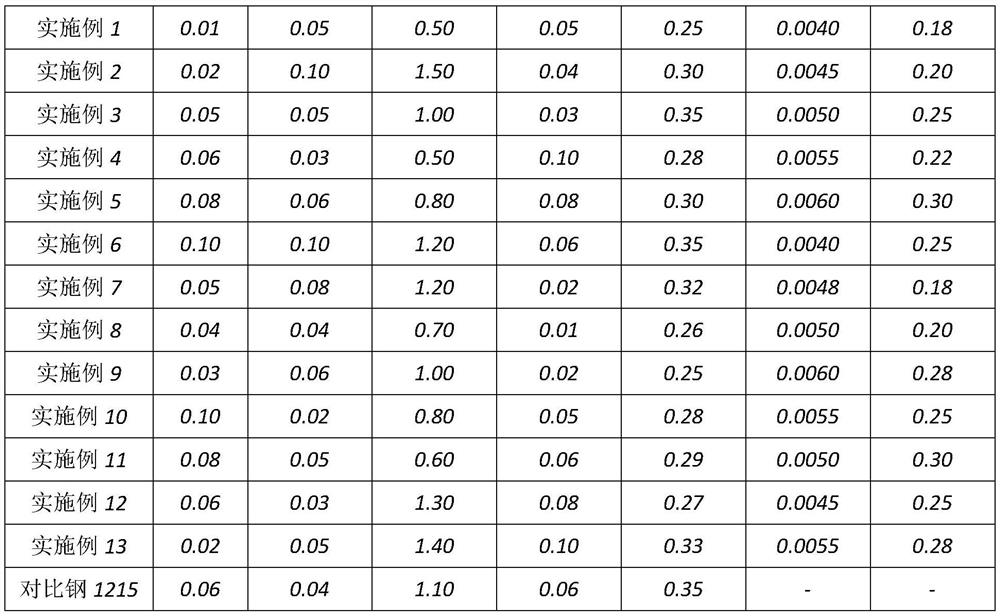

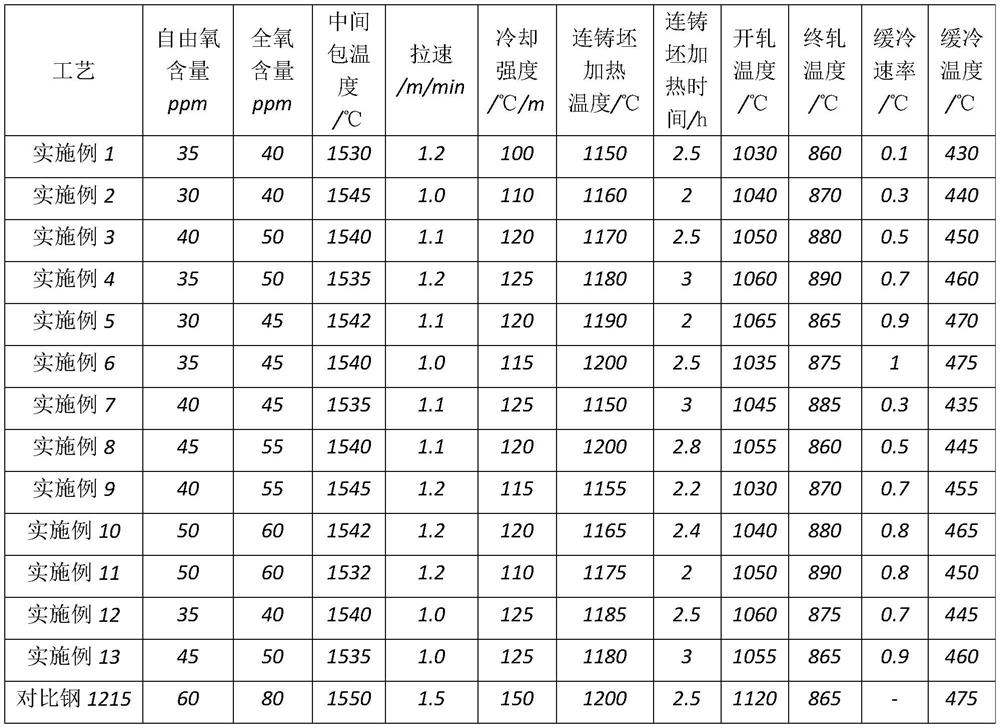

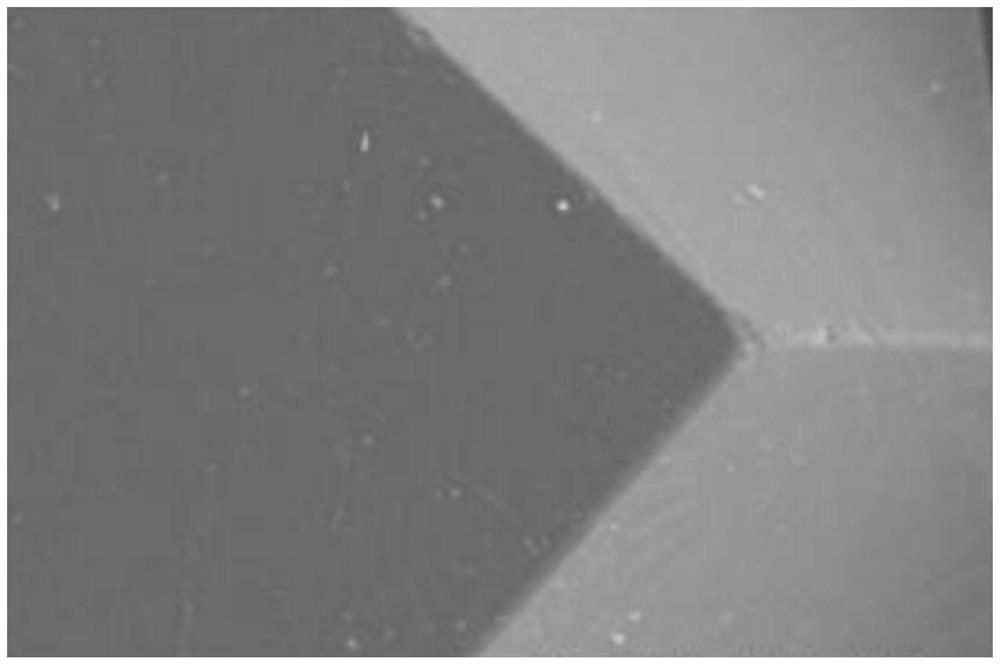

The invention relates to the technical field of free-cutting steel, in particular to a low-carbon selenium-containing free-cutting steel for instruments and meters and a manufacturing method thereof. It consists of the following chemical components in weight percentage: C: 0.01% to 0.10%, Si: 0.01% to 0.10%, Mn: 0.50% to 1.50%, P: 0.01% to 0.10%, S: 0.25% to 0.35% %, Se: 0.18% to 0.30%, O: 0.0040% to 0.0060%, the ratio of selenium to sulfur Se / S is 0.2 to 2, the ratio of oxygen to selenium to O / Se is 0.016 to 0.17, and the balance is iron and unavoidable impurities. The present invention reduces cutting resistance and cutting heat in the cutting process through a certain ratio of manganese and selenium and a certain combination of selenium and sulfur, protects the cutting tool, lubricates the cutting tool at the same time, and obtains good machining surface roughness.

Owner:ANGANG STEEL CO LTD

Preparation method of modified diamond abrasive particles

PendingCN114634796AGood surface roughnessGood for grindingOther chemical processesCermetNitrogen gas

Owner:厦门雷昂科技有限公司

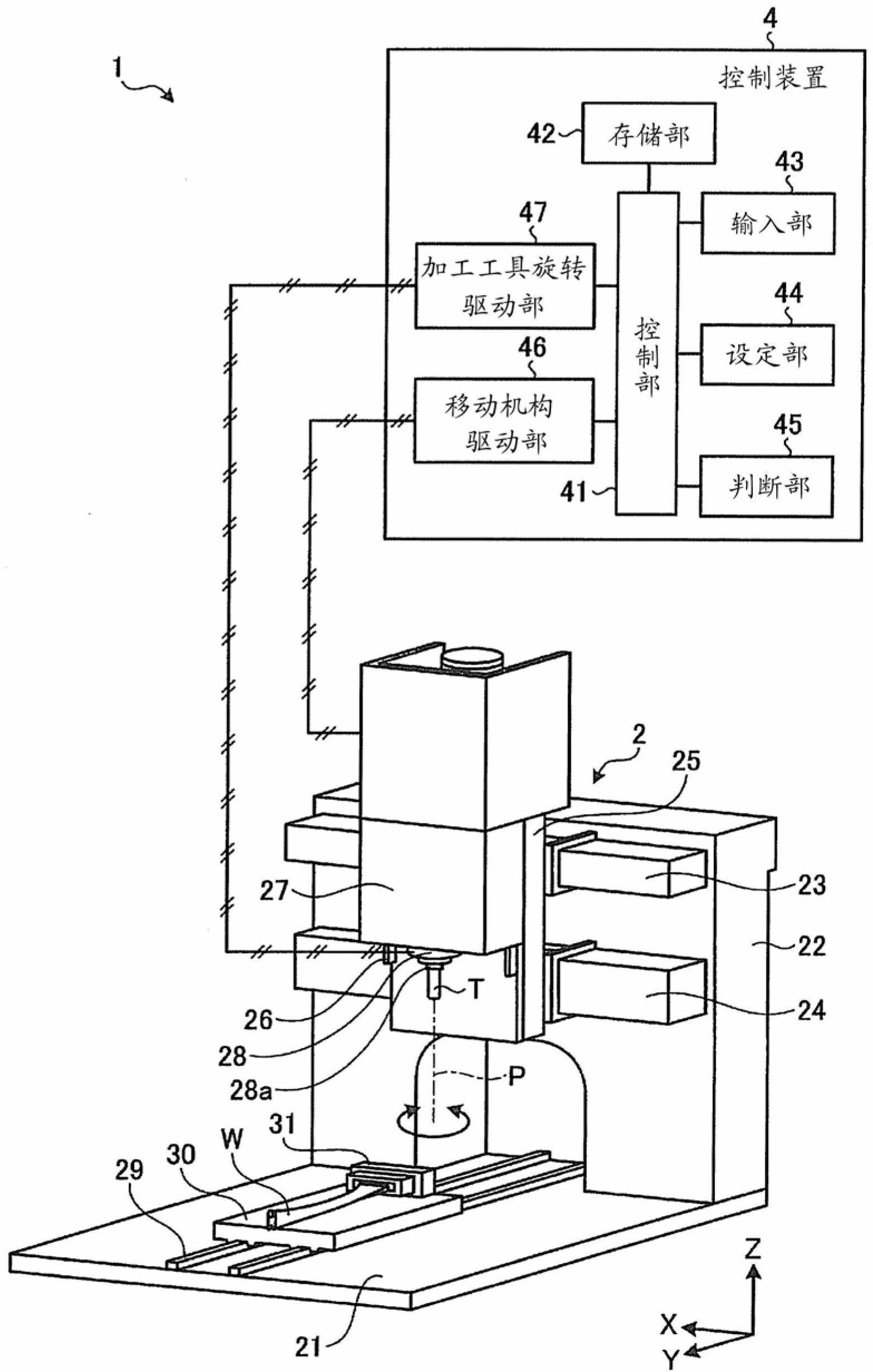

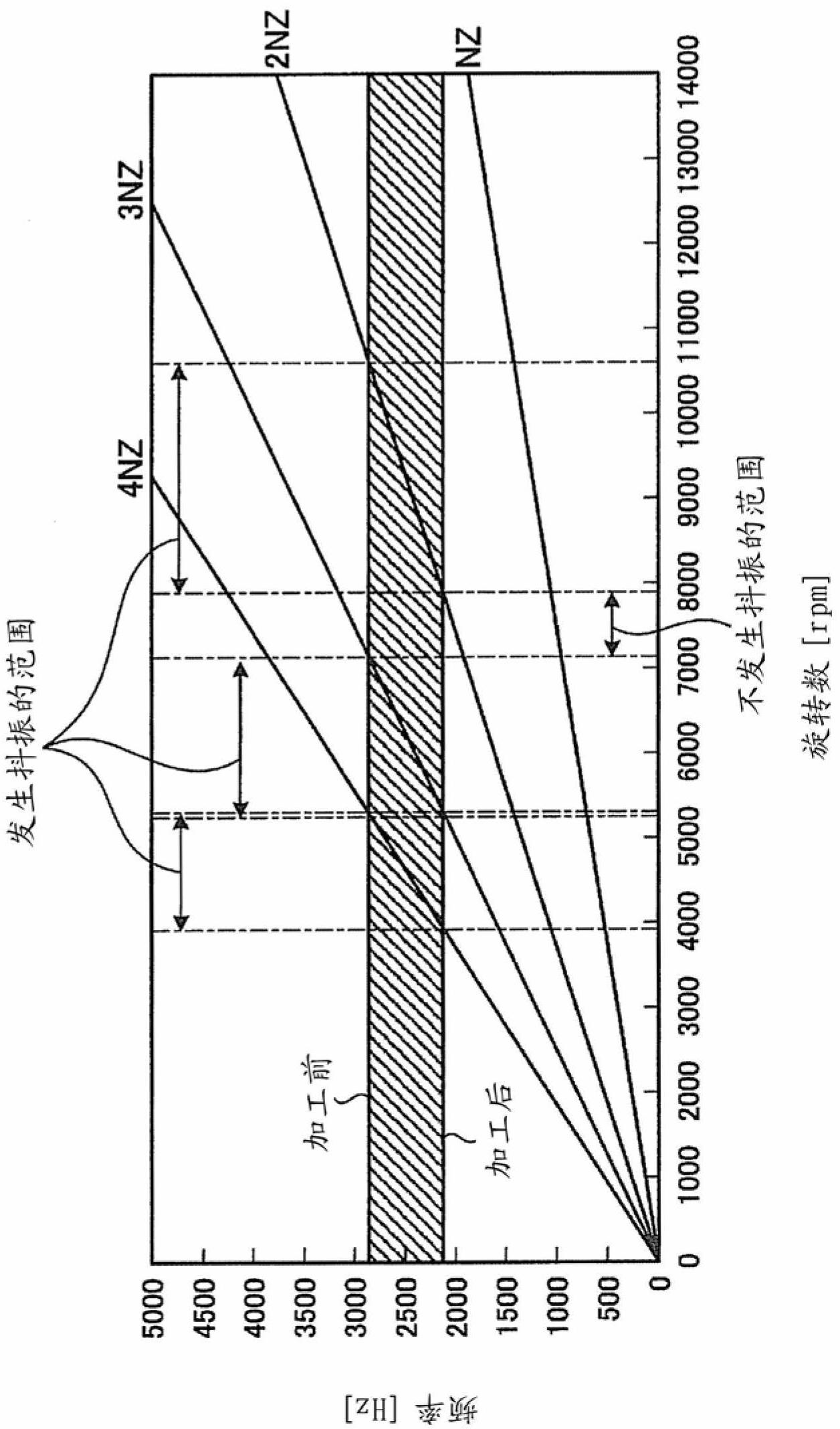

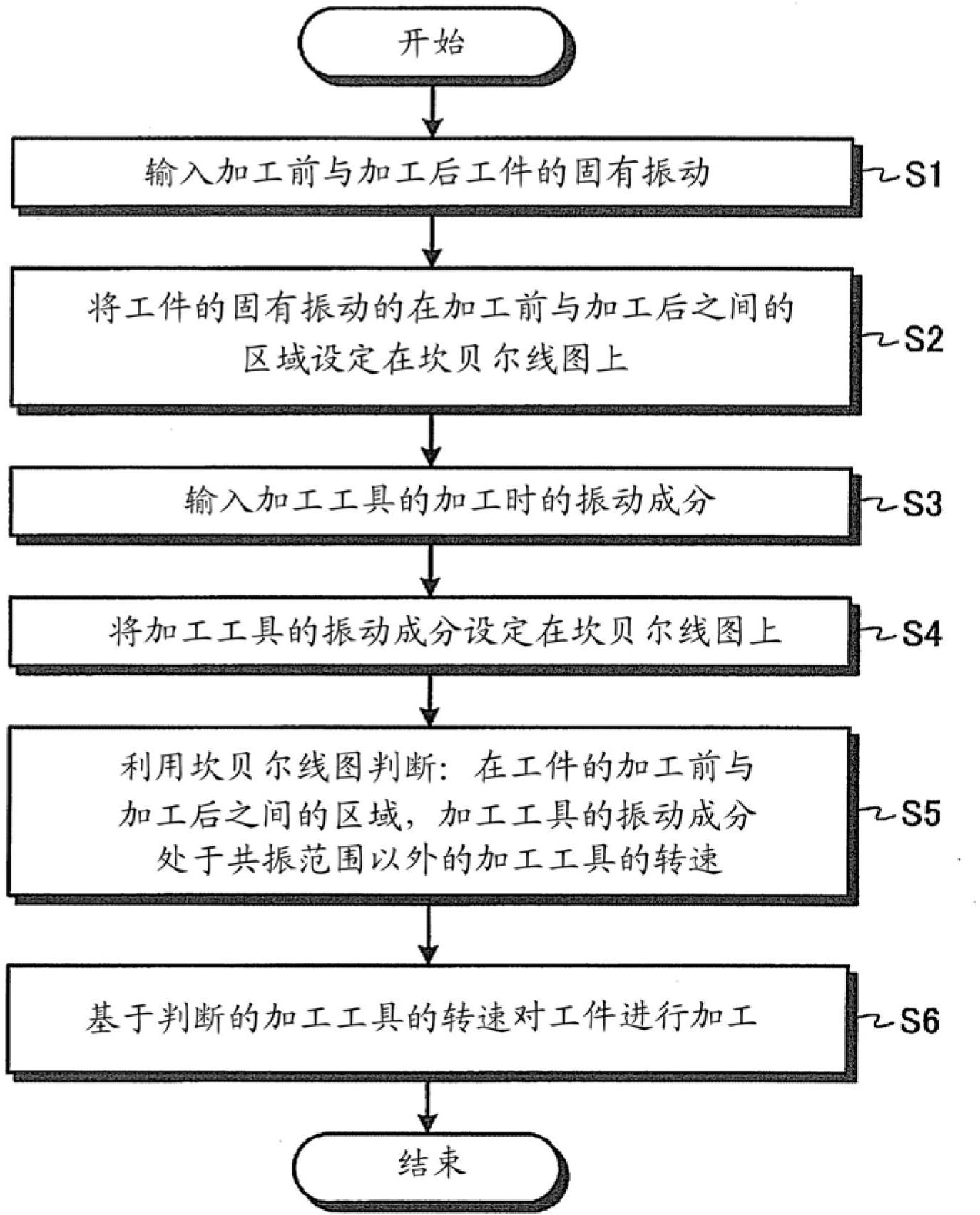

Machine tool control method and control device

InactiveCN102596495AGood surface roughnessCircumstances that change working conditionsAutomatic control devicesMeasurement/indication equipmentsMachined surfaceMachine tool control

In the first place, the characteristic frequency of a workpiece before machining and the one at after machining are input (Step S1). In the next place, a region between the characteristic vibration of a workpiece before machining and the one after machining is set in a Campbell diagram (Step S2). Furthermore, the vibration components of a machining tool during machining are input (Step S3). Subsequently, the vibration components of a machining tool during machining are set in the Campbell diagram (Step S4). Thereafter, with respect to the region between the characteristic vibration of a workpiece before machining and the one after machining, the Campbell diagram is used to determine the rotational speeds (operating condition) of the machining tool outside the ranges where the vibration components of the machining tool resonate (Step S5). In the last place, workpiece machining is executed on the basis of the rotational speeds (operating condition) of the machining tool (Step S6). For this reason, the machined surface roughness of the workpiece can be improved, and the machining cost can be reduced.

Owner:MITSUBISHI HEAVY IND LTD

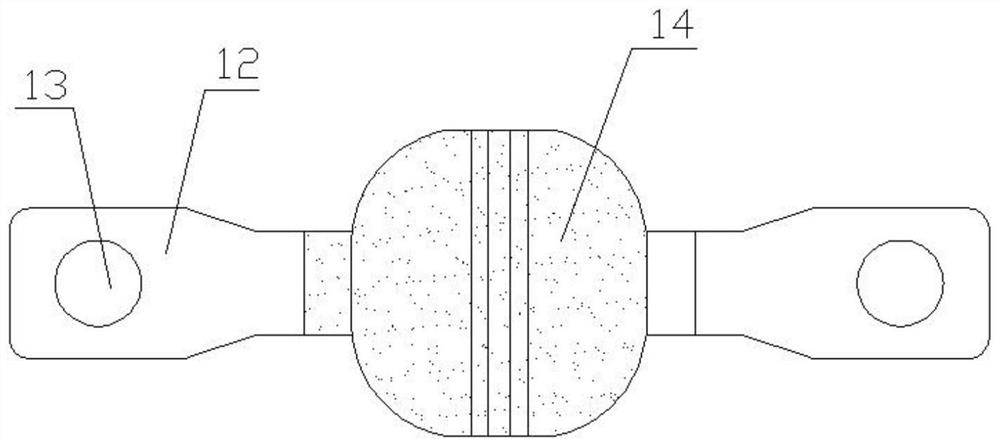

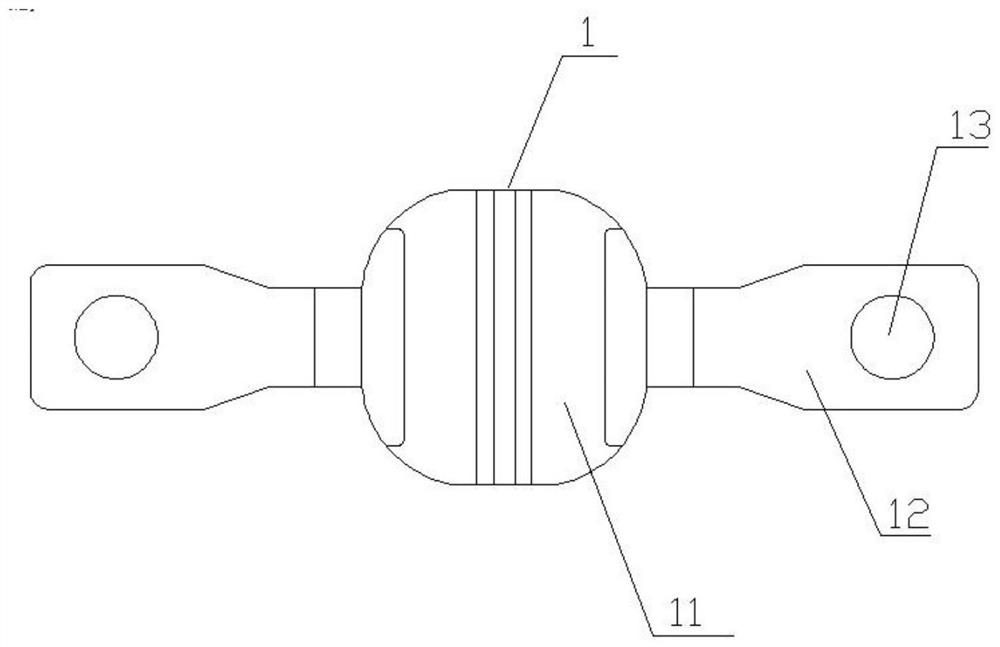

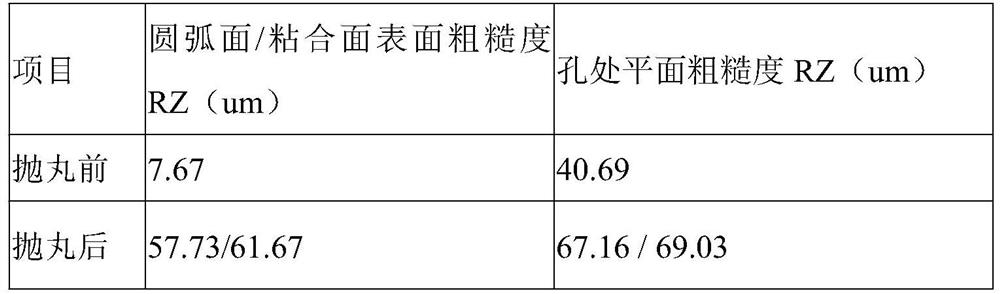

Machining process of ball pin for automobile

The invention provides a machining process of a ball pin for an automobile, and relates to the technical field of ball pin machining. The machining process of the ball pin comprises the following steps of forging and heat treatment, wherein a 40Cr steel material is adopted, forging and heat treatment are adopted to obtain a ball pin framework, and the surface hardness of the ball pin framework reaches HRC25-30; finish machining, wherein a ball pin body is turned to form an arc surface, and an end cover is turned to form a cylindrical surface; hole milling, wherein a mounting hole is milled in the end cover; shot blasting, wherein shot blasting treatment is carried out on the ball pin framework by using a shot blasting machine; and adhesive coating, vulcanizing and flash removing, wherein the outer portion of the ball pin body is coated with an adhesive, rubber adheres to the surface of the ball pin body, and flashes are removed after high-temperature vulcanizing to obtain a rubber sleeve. According to the machining process of the ball pin for the automobile, after machining, the roughness value of the arc surface / bonding surface and the roughness value of the plane at the hole are close to or even better than the roughness value in the prior art; and the shot blasting time is saved, the good plane roughness is achieved, and the production efficiency is greatly improved.

Owner:ANHUI ZHONGDING NVH

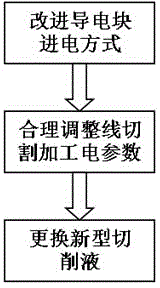

Wire cut electrical discharge machining (WEDM) processing aluminium alloy technology improved method

InactiveCN104959686AThe process improvement method is simple and reasonableSolve the broken wire problemElectricityMetallurgy

The invention provides a wire cut electrical discharge machining (WEDM) processing aluminium alloy technology improved method comprising the following steps: a, improving conducting block current input mode; b, reasonably adjusting linear cutting processing electric parameters; c, replacing novel cutting fluid. The technology improved method is simple and reasonable, can effectively solve fracture wire problem, obtains better processing surface roughness quality, improves processing efficiency, and ensures product quality requirements.

Owner:SUZHOU BAOMA NUMERICAL CONTROL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com