A kind of low-carbon selenium-containing free-cutting steel for instruments and meters and its manufacturing method

A technology of free-cutting steel and instrumentation, applied in the field of free-cutting steel, can solve the problems of unfavorable suppression, limited improvement effect, and reduced production efficiency, and achieve advanced cutting performance and surface quality level, good processing surface roughness, cutting performance Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing low-carbon selenium-containing free-cutting steel for instrumentation, specifically comprising the following steps:

[0035] 1) Converter smelting: Converter molten iron does not desulfurize, but only decarburizes and phosphorus; deoxidizes when 1 / 5~1 / 4 of the steel is tapped, and the total oxygen content is controlled at 40~60ppm. In the smelting of the present invention, the total oxygen content must be controlled within this range, which is the key to the nucleation thermodynamic environment for the formation and precipitation of selenium and sulfur elements in the present invention. If the total oxygen content exceeds this range, the precipitation effect of selenium will be weakened. When the total oxygen is lower than When the concentration is 55ppm, the selenium element cannot be diffusely distributed. When the concentration is higher than 75ppm, the precipitation grows rapidly and the sulfide cannot be wrapped. This is one of the innovations...

Embodiment

[0041] The chemical composition of the embodiment of the present invention is shown in Table 1; the manufacturing process parameters of the corresponding embodiment steel and comparative steel are shown in Table 2; the slab end cracking, surface scarring, bubble defects and relative cutting coefficient Kr and chips of the corresponding embodiment The types are shown in Table 3.

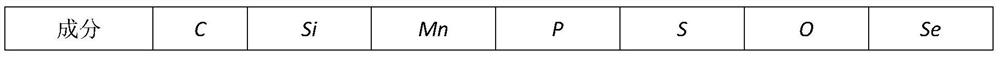

[0042] The composition wt% of table 1 embodiment steel of the present invention, comparative example steel

[0043]

[0044]

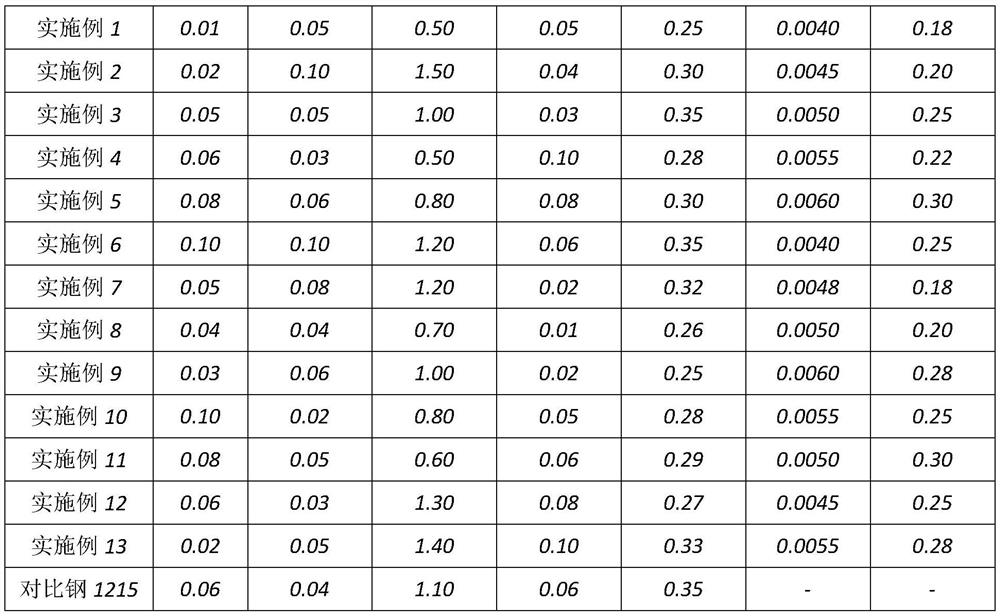

[0045] Table 2 The manufacturing process parameters of the embodiment steel of the present invention and comparative example steel

[0046]

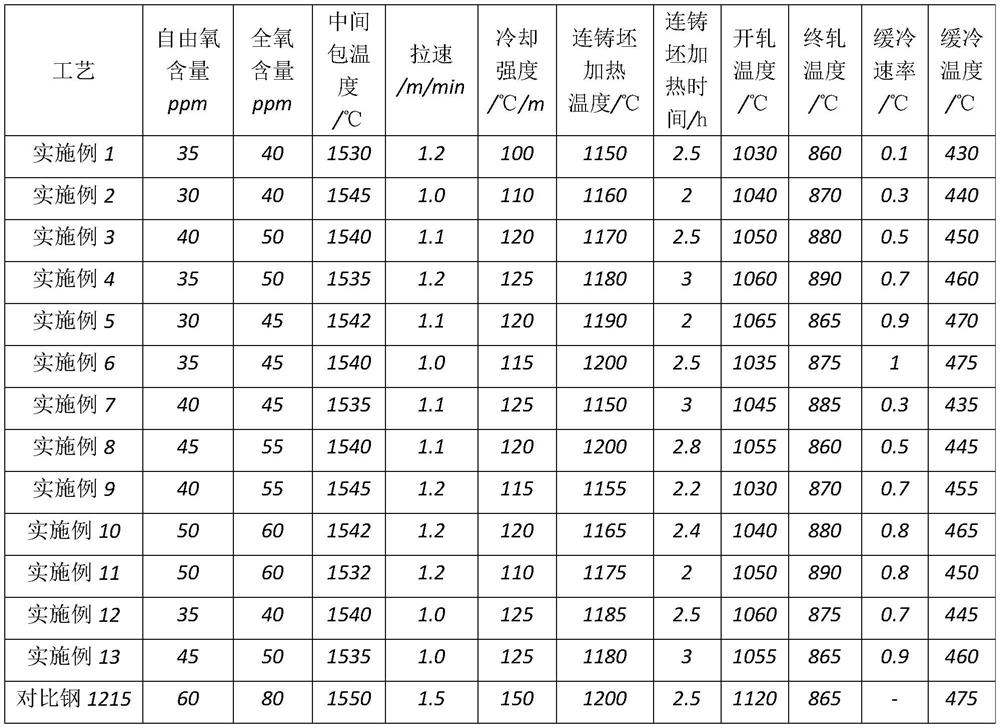

[0047] Table 3 Statistics of slab end cracking, surface scarring, bubble defects, relative cutting coefficient Kr and chip types

[0048]

[0049] The present invention is created by the above-mentioned technology, evaluates the continuous casting slab hot rolling continuity and stability of different composition designs (se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com