Reaming method and tool thereof for small-diameter deep holes

A small-diameter, deep-hole technology, applied in the direction of drilling/drilling equipment, drilling tool accessories, manufacturing tools, etc., can solve the problems of surface roughness and straightness that are difficult to guarantee, and achieve high straightness and strong economic applicability , good surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

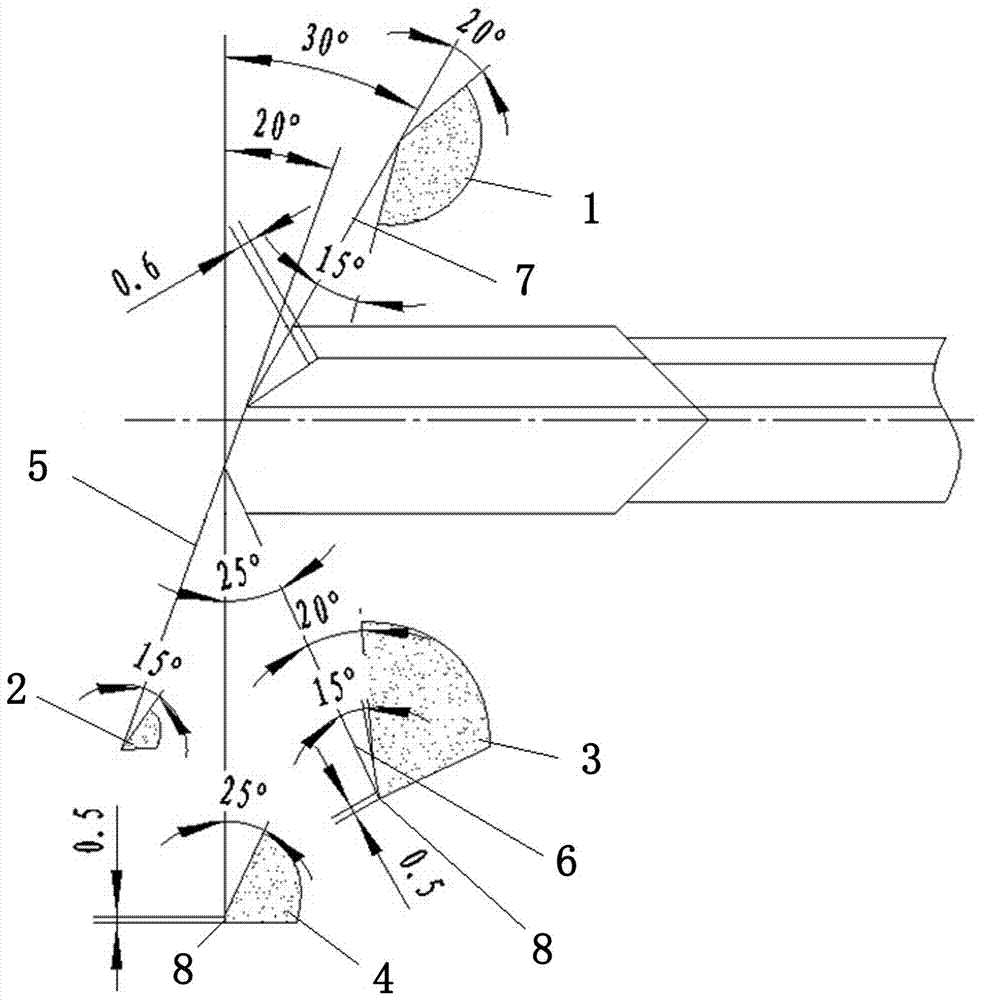

[0017] The small-diameter deep hole reaming method improves the cutting process on the basis of the gun drilling processing method, and is characterized in that it includes the following steps:

[0018] (1) The rough machining of the outer circle of the workpiece is processed by the double top inner hole machining method;

[0019] (2) Using the first step benchmark, process the gun drill guide hole at one end of the workpiece, and process the thread at the other end;

[0020] (3) Block the other end of the workpiece by using the threaded plug of the existing auxiliary tool;

[0021] (4) Start processing, adopt the method of one clip and one top, and the processing and feeding process is as follows: use the macro program to control the drill to advance 0.08mm, then rewind 3mm, then fast forward 2.99mm, and then feed 0.08mm, the above Step cycle feed to the end of processing.

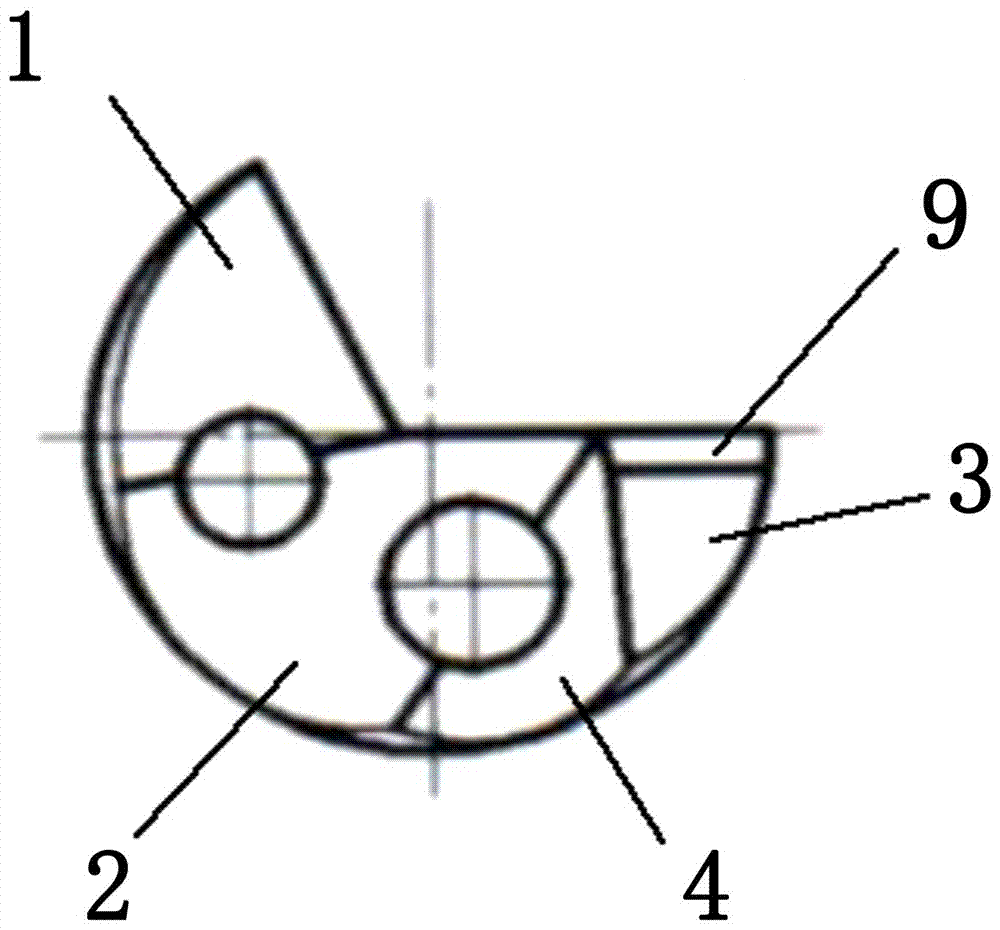

[0022] The small-diameter deep hole reaming tool is specifically to use the existing gun drill, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com