Wire cut electrical discharge machining (WEDM) processing aluminium alloy technology improved method

A technology for cutting processing and process improvement, which is applied in the field of processing process improvement and wire electric discharge processing aluminum alloy, which can solve the problem of light and dark spots and stripes on the surface of the processed workpiece, affecting the surface roughness and processing efficiency of the workpiece, and the selection of discharge parameters Inappropriate and other problems, to achieve the effect of simple and reasonable process improvement method, good processing surface roughness quality, and product quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

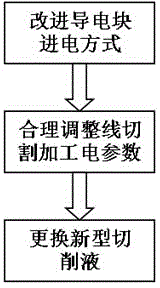

Image

Examples

Embodiment 1

[0019] The specific processing method is as follows:

[0020] a) Improve the power supply mode of the conductive block, and use the aluminum cutting component to improve the power supply mode of the conductive block. The aluminum cutting component uses the DC motor armature power supply mode, and uses the carbon brush to supply high-frequency power to the wire drum of the wire feeding system, thereby avoiding The phenomenon of wire clamping and broken wire in the conductive block is eliminated.

[0021] b) Reasonably adjust the electrical parameters of wire cutting processing. The voltage selected for wire cutting processing is normal pressure, and the discharge waveform is rectangular wave pulse. The electrical parameters are adjusted as follows: pulse width 18, pulse gap 16, power tube number 5, gap voltage 4, Feed rate 50.

[0022] c) Replace the new cutting fluid. The selected new cutting fluid contains the following components and weight percentages: 10% compound lubrica...

Embodiment 2

[0024] The specific processing method is as follows:

[0025] a) Improve the power supply mode of the conductive block, and use the aluminum cutting component to improve the power supply mode of the conductive block. The aluminum cutting component uses the DC motor armature power supply mode, and uses the carbon brush to supply high-frequency power to the wire drum of the wire feeding system, thereby avoiding The phenomenon of wire clamping and broken wire in the conductive block is eliminated.

[0026] b) Reasonably adjust the electrical parameters of wire cutting processing. The voltage selected for wire cutting processing is normal pressure, and the discharge waveform is rectangular wave pulse. The electrical parameters are adjusted as follows: pulse width 20, pulse gap 18, power tube number 6, gap voltage 4, Feed rate 55.

[0027] c) Replace the new cutting fluid. The selected new cutting fluid contains the following components and weight percentages: 10% compound lubrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com