A device for reducing the diameter of low melting point welding wire and its application

A processing device and low melting point technology, applied in the field of electronic packaging and welding materials, can solve the problems of stuck mold, can not meet production requirements, easy to break, etc., achieve slow deformation, not easy to break wire, and solve the effect of broken wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

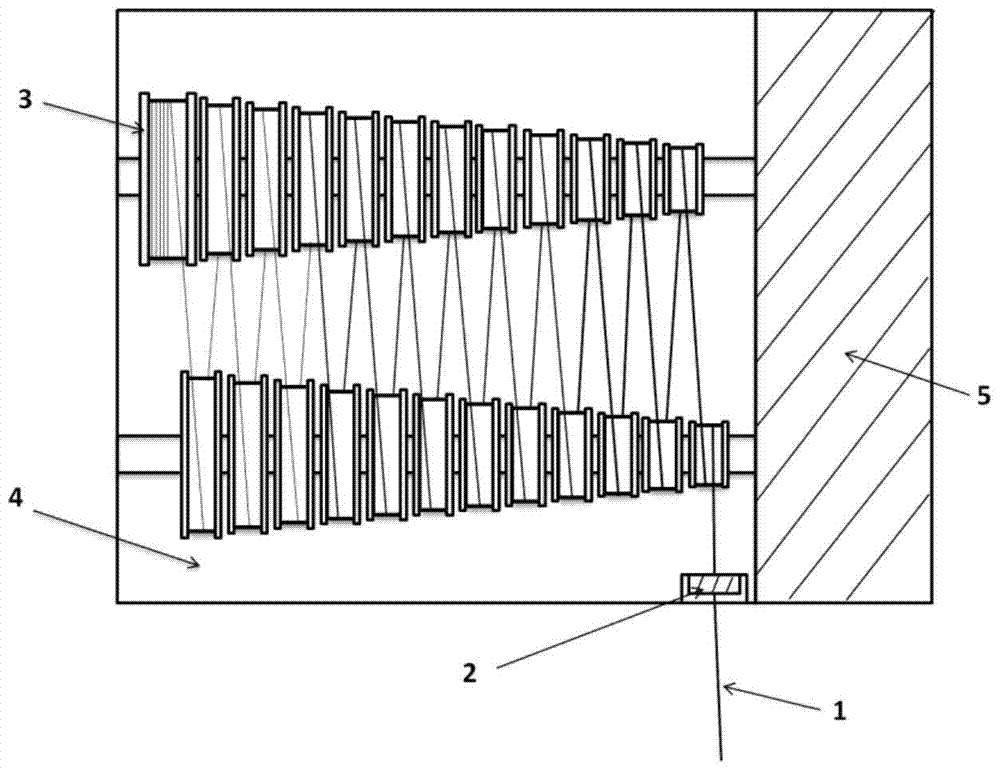

[0021] A low-melting point welding wire diameter reduction processing device, comprising: a pre-drawing die 2, a roller 3, a constant temperature oil bath 4 and a motor 5; the low-melting point welding wire 1 passes through the pre-drawing die 2 and is cross-wound in two rows arranged in parallel. On the roller group consisting of twenty-four-pass rollers 3; the low melting point welding wire 1 is wound at the largest roller 3; the roller group is arranged in the constant temperature oil bath 4 and is driven by the motor 5 and The speed is the same.

[0022] The Sn-58Bi welding wire with a low melting point diameter of 2mm passes through a pre-drawing die with an inner diameter of 1.94mm, and then continuously crosses around two parallel rows of roller groups. The diameter of the rollers gradually increases. The entire roller group is immersed in a constant temperature oil bath. When the two parallel roller groups rotate at the same speed, the wire is collected at the largest ...

Embodiment 2

[0024] The Sn-42Bi welding wire with a low melting point diameter of 2mm passes through a pre-drawing die with an inner diameter of 1.92mm, and then continuously crosses around two parallel rows of roller groups. The diameter of the rollers gradually increases. The entire roller group is immersed in a constant temperature oil bath. When the two parallel roller groups rotate at the same speed, the wire is collected at the largest roller. The temperature of the constant temperature oil bath is 100°C. The diameter of the rollers in each pass is 4% larger than the diameter of the previous rollers. The rotation speed of the roller group is 7r / min. The final diameter of the welding wire was 1.65mm, and no wire breakage occurred during the wire drawing process.

Embodiment 3

[0026] The Sn-30Bi welding wire with a low melting point diameter of 2mm passes through a pre-drawing die with an inner diameter of 1.90mm, and then continuously crosses around two rows of parallel roller groups. The diameter of the rollers gradually increases. The entire roller group is immersed in a constant temperature oil bath. When the two parallel roller groups rotate at the same speed, the wire is collected at the largest roller. The temperature of the constant temperature oil bath is 110°C. The diameter of the rollers in each pass is 5% larger than that of the previous rollers. The rotation speed of the roller group is 5r / min. The final diameter of the welding wire was 1.48mm, and no wire breakage occurred during the wire drawing process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com