a wetting agent

A technology of sizing agent and auxiliary agent, which is applied in the field of sizing agent coated on the glass surface. It can solve the problems of affecting glass fiber, sizing agent can not fully meet the protection effect of glass fiber, and single fiber breakage, so as to solve the problem of broken wire , Improve physical and chemical properties, increase the effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

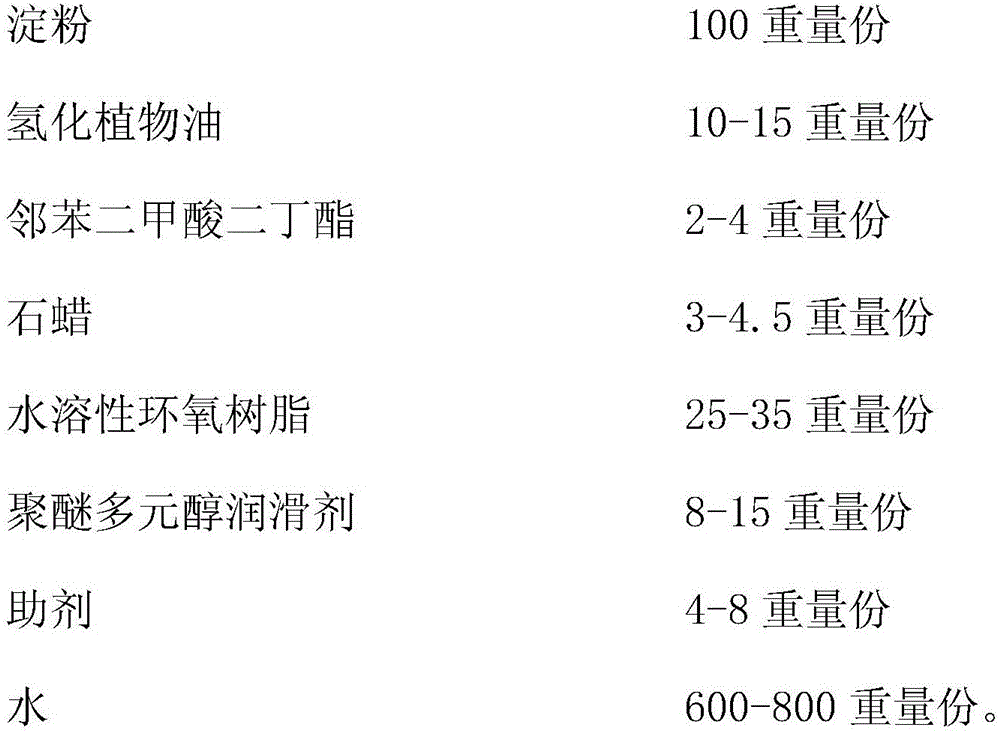

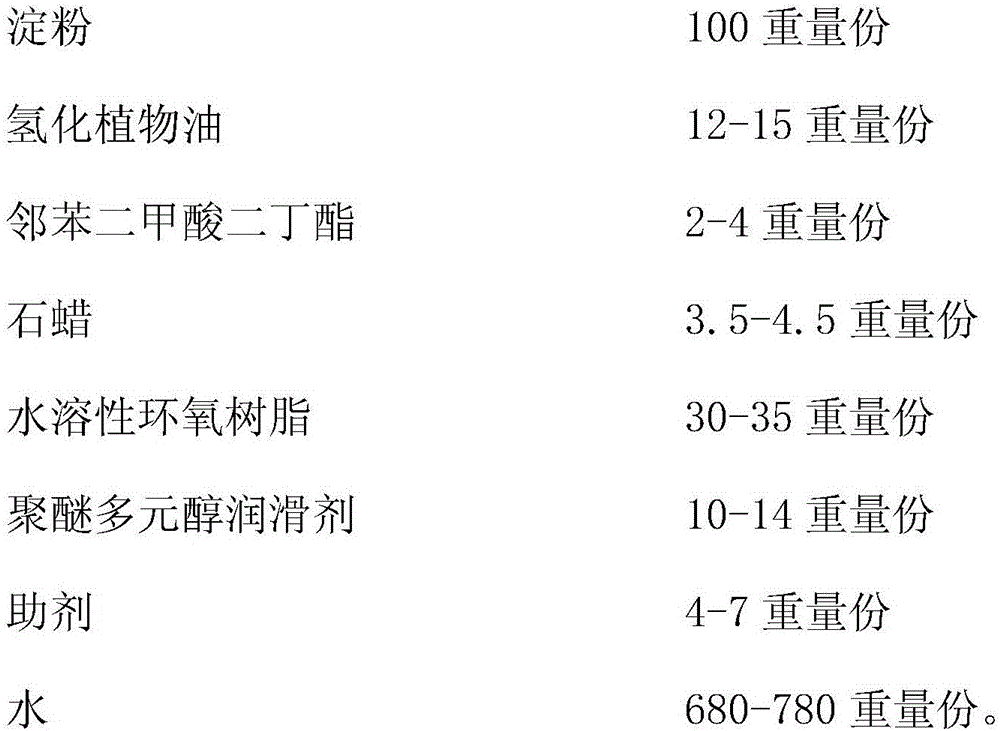

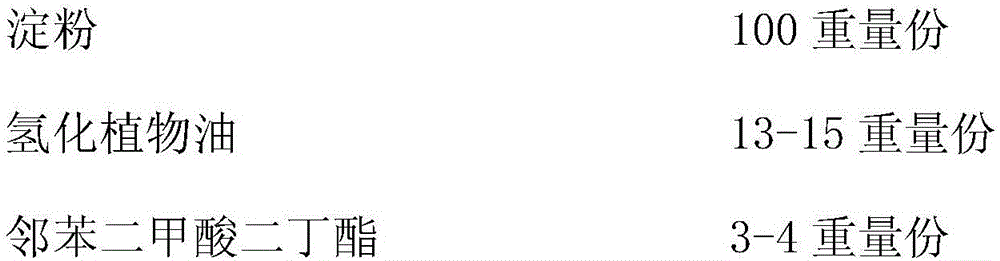

Method used

Image

Examples

Embodiment 1

[0021] Raw materials: 62.5 parts by weight of modified amylose, 37.5 parts by weight of modified amylopectin, 12.5 parts by weight of hydrogenated vegetable oil, 3.2 parts by weight of dibutyl phthalate, 3 parts by weight of paraffin, 30 parts by weight of water-soluble epoxy resin , 10 parts by weight of polyether polyol lubricant, 650 parts by weight of water, 3 parts by weight of fatty alcohol polyoxyethylene ether, 2 parts by weight of silane coupling agent, and 2 parts by weight of phosphate defoamer.

[0022] The preparation method is as follows: add amylose and amylopectin to water, heat to 85°C, and gelatinize the starch; prepare emulsion, hydrogenated vegetable oil, dibutyl phthalate, paraffin, water-soluble epoxy resin, polyether The polyol lubricant, antistatic agent, coupling agent and crosslinking agent are mixed, stirred evenly to form an emulsion, added to the gelatinized starch, stirred and mixed evenly to obtain a wetting agent.

Embodiment 2

[0024] 70 parts by weight of modified amylose, 30 parts by weight of modified amylopectin, 14 parts by weight of hydrogenated vegetable oil, 2.5 parts by weight of dibutyl phthalate, 4 parts by weight of paraffin, 28 parts by weight of water-soluble epoxy resin, 12 parts by weight of Parts by weight of polyether polyol lubricant, 800 parts by weight of water, 1 part by weight of fatty alcohol polyoxyethylene ether, 1 part by weight of silane coupling agent, and 4 parts by weight of phosphate defoamer.

[0025] The preparation method is as follows: add amylose and amylopectin to water, heat to 85°C, and gelatinize the starch; prepare emulsion, hydrogenated vegetable oil, dibutyl phthalate, paraffin, water-soluble epoxy resin, polyether The polyol lubricant, antistatic agent, coupling agent and crosslinking agent are mixed, stirred evenly to form an emulsion, added to the gelatinized starch, stirred and mixed evenly to obtain a wetting agent.

Embodiment 3

[0027] 65 parts by weight of modified amylose, 35 parts by weight of modified amylopectin, 14.5 parts by weight of hydrogenated vegetable oil, 3.5 parts by weight of dibutyl phthalate, 4.2 parts by weight of paraffin, 32 parts by weight of water-soluble epoxy resin, 13 parts by weight Parts by weight of polyether polyol lubricant, 780 parts by weight of water, 2 parts by weight of fatty alcohol polyoxyethylene ether, 2 parts by weight of silane coupling agent, and 2 parts by weight of phosphate defoamer.

[0028] The preparation method is as follows: add amylose and amylopectin to water, heat to 85°C, and gelatinize the starch; prepare emulsion, hydrogenated vegetable oil, dibutyl phthalate, paraffin, water-soluble epoxy resin, polyether The polyol lubricant, antistatic agent, coupling agent and crosslinking agent are mixed, stirred evenly to form an emulsion, added to the gelatinized starch, stirred and mixed evenly to obtain a wetting agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com