Patents

Literature

30 results about "Tube number" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Parallel flow type heat converter

ActiveCN101178273AAdjust heat distributionCooperate wellEvaporators/condensersFluid circulation arrangementEngineeringTube number

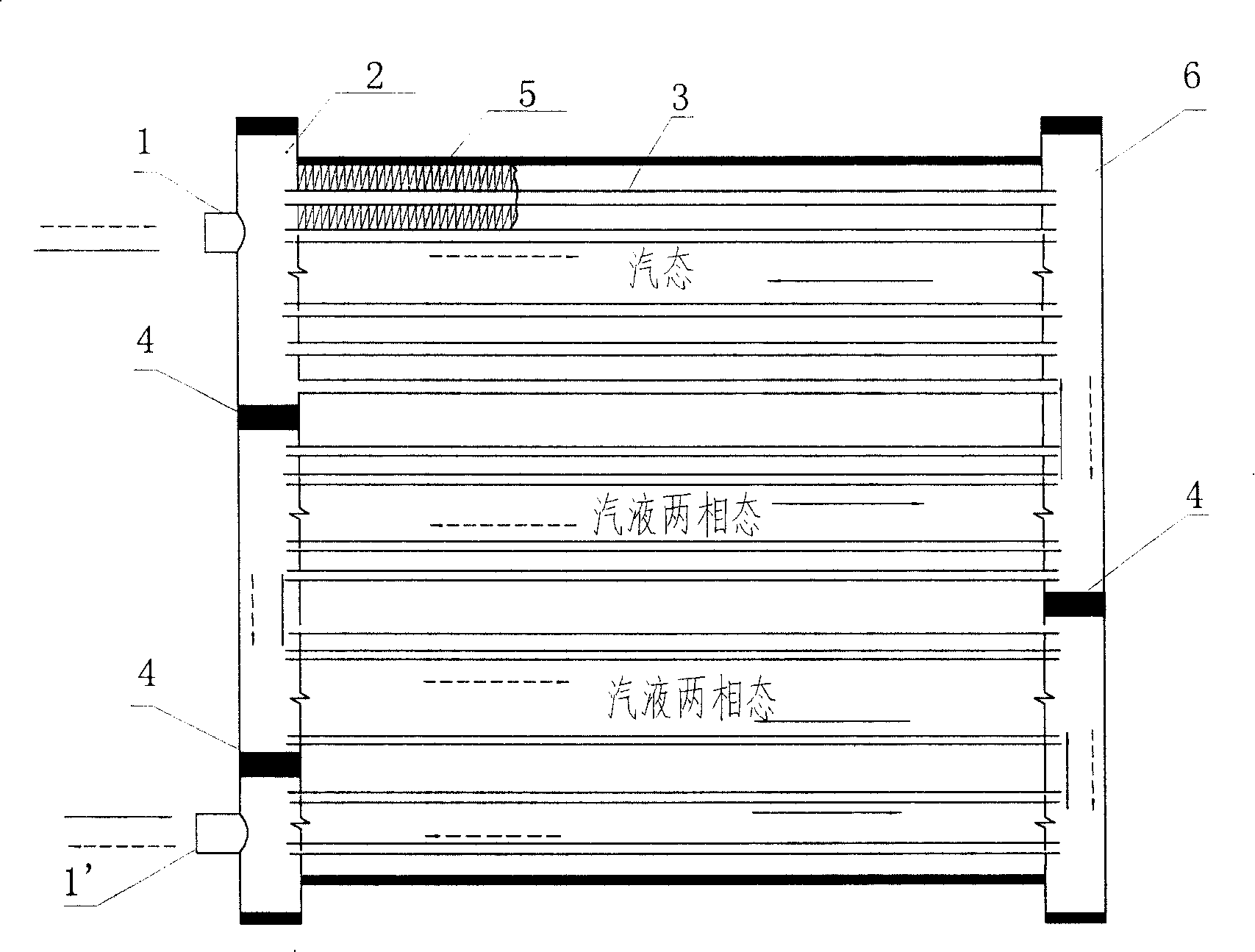

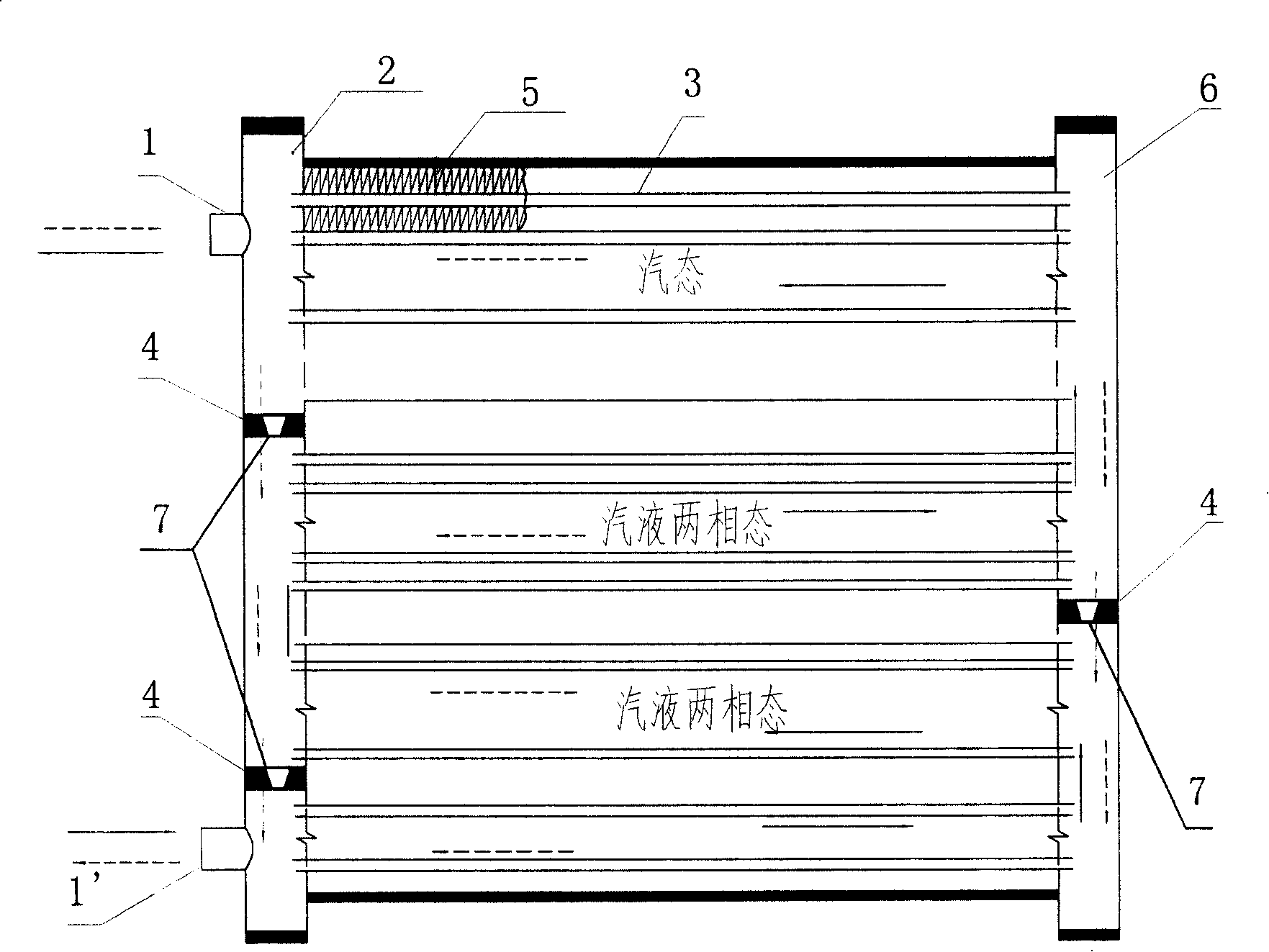

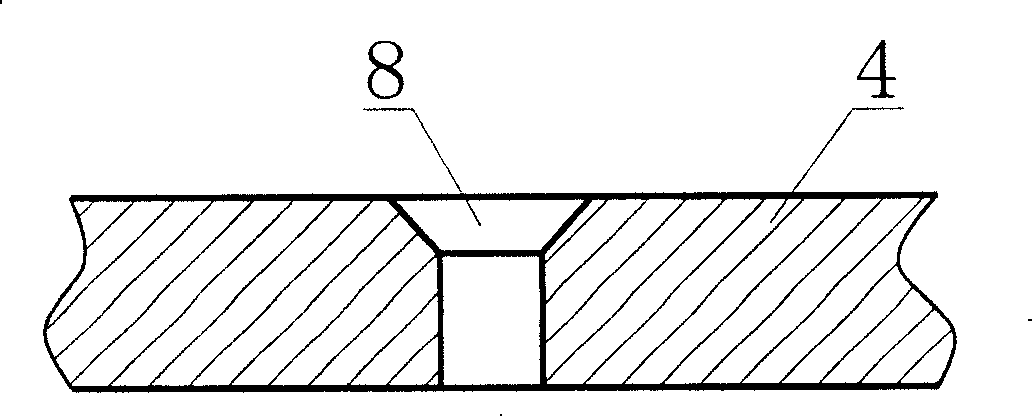

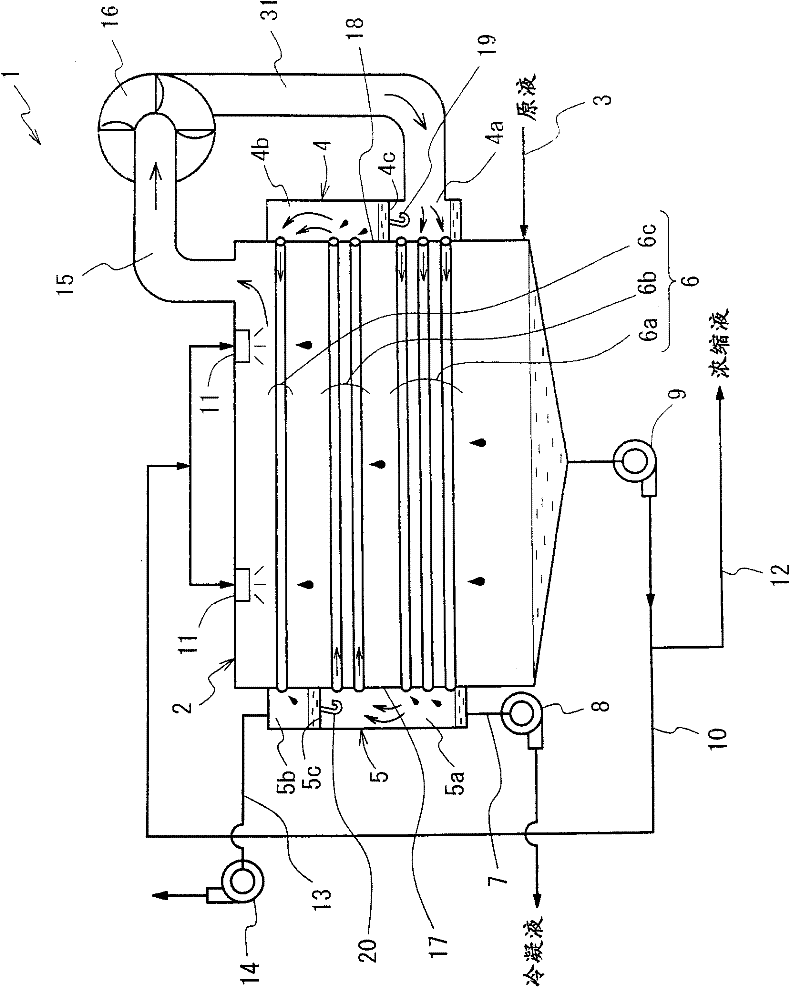

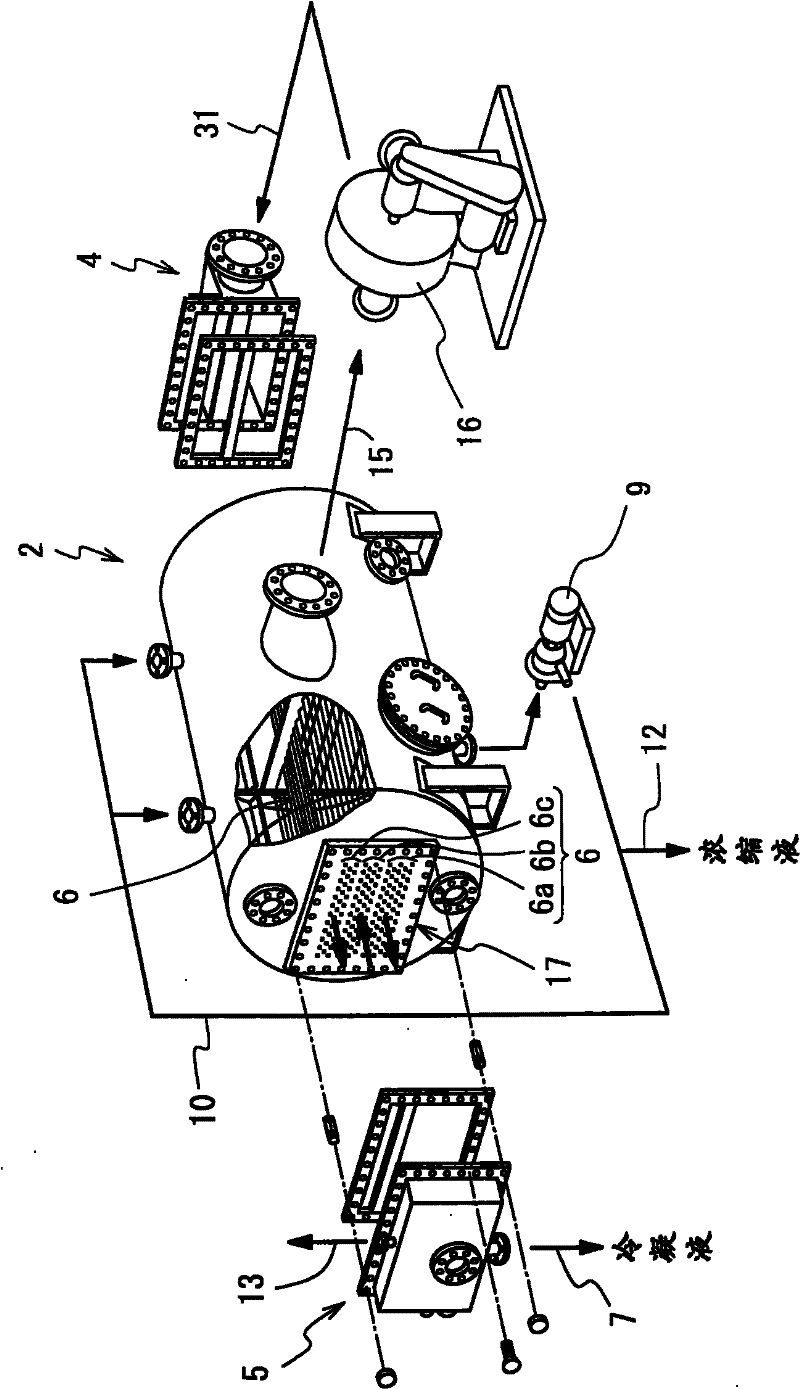

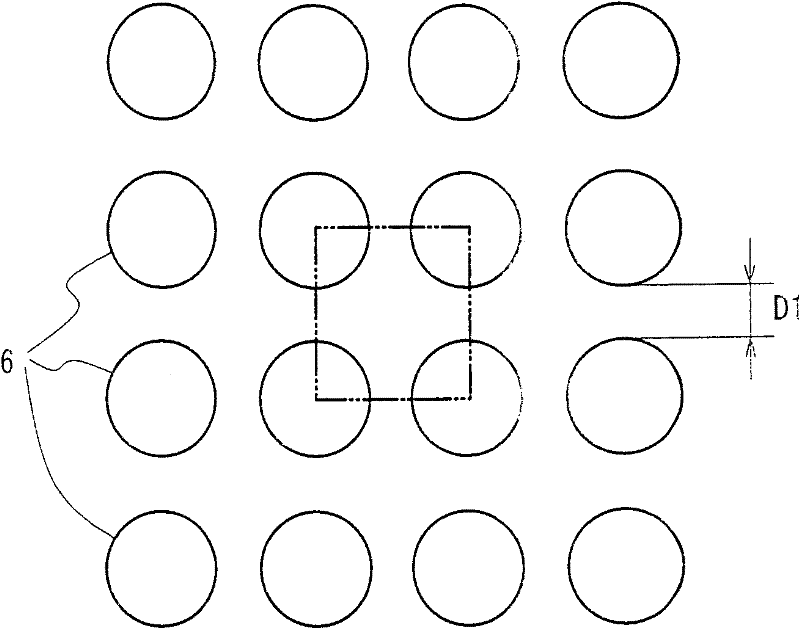

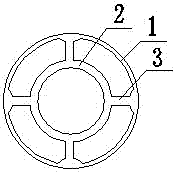

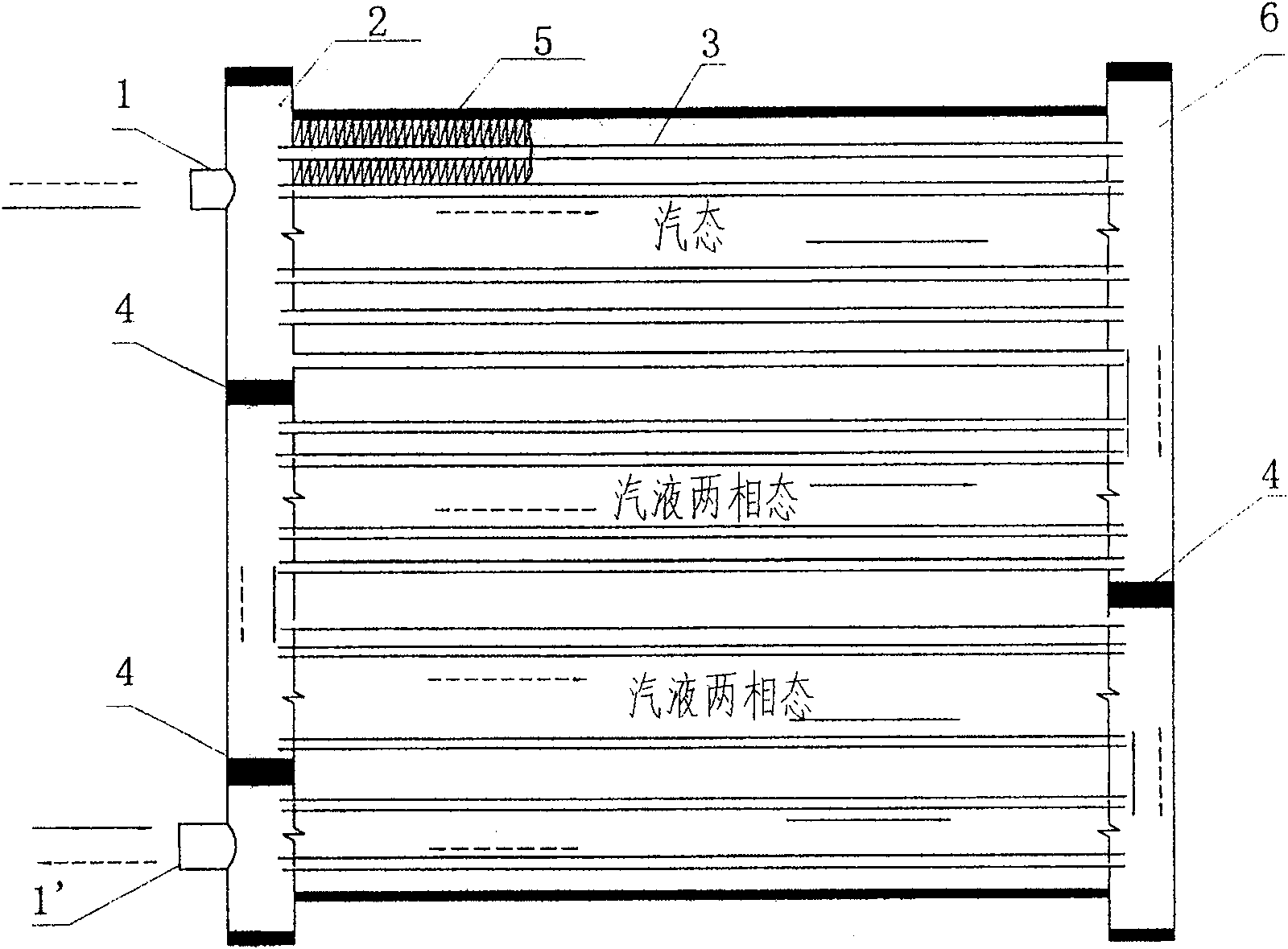

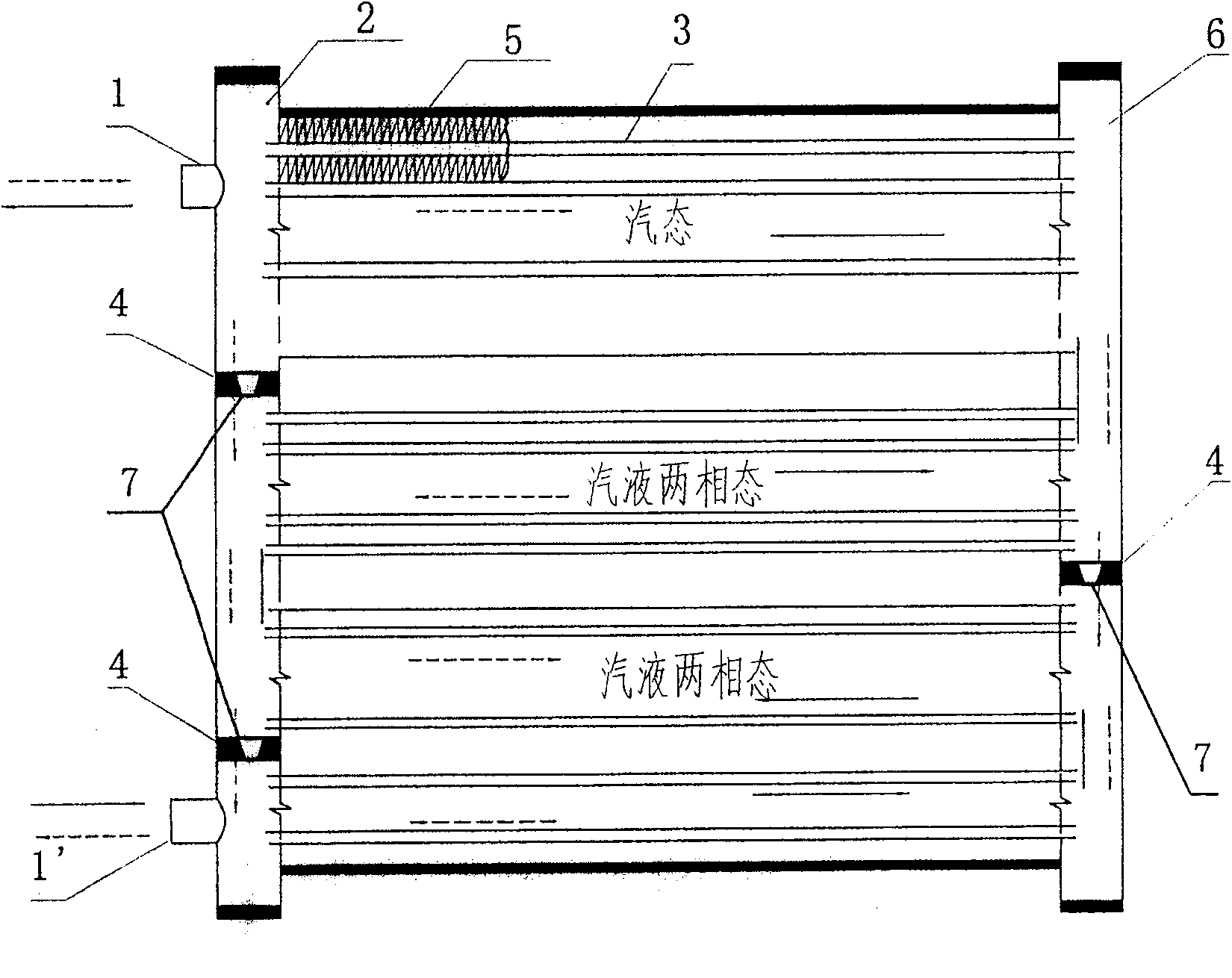

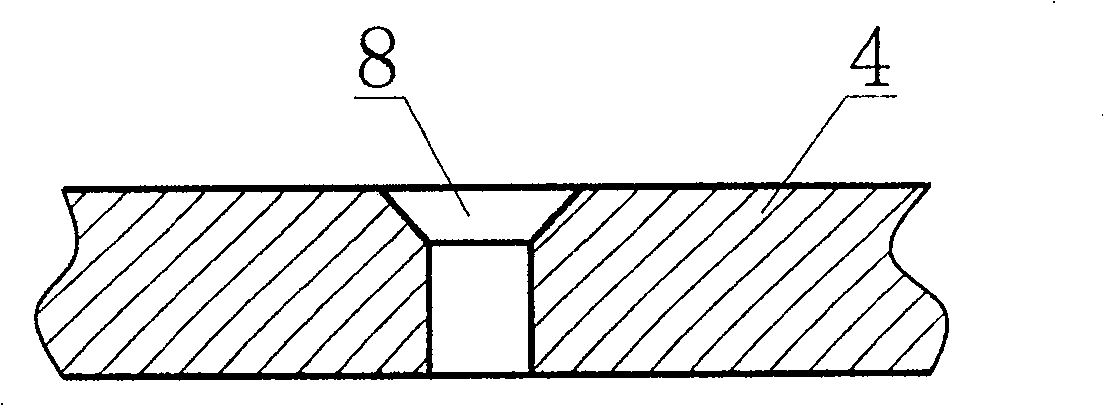

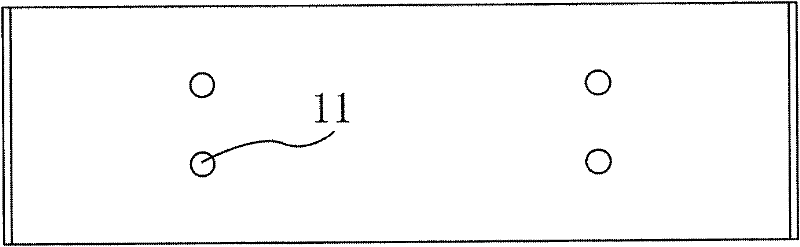

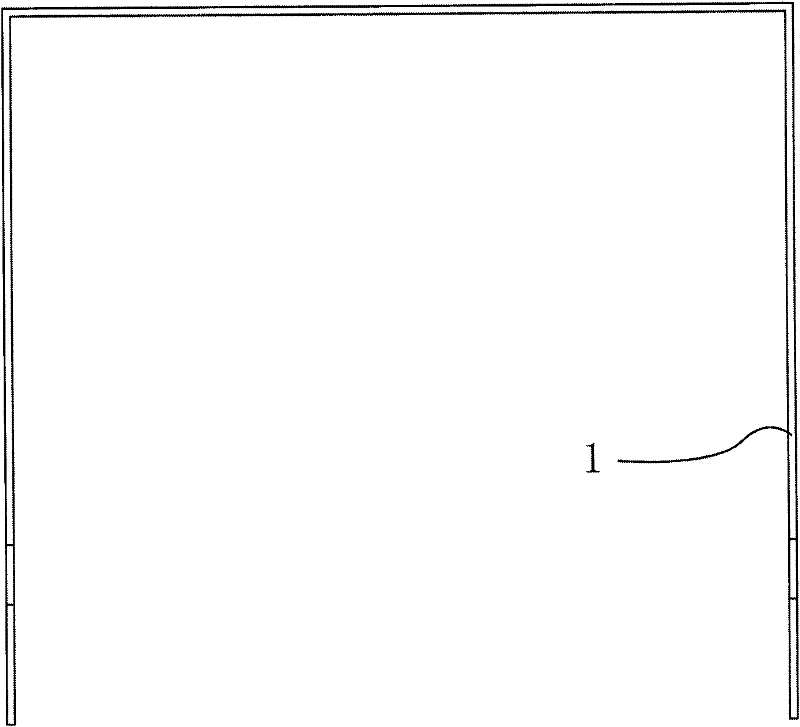

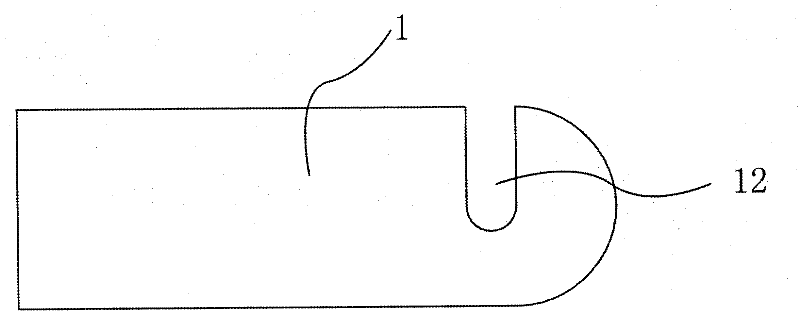

The invention provides a parallel flow heat exchanger, comprising liquid collecting tubes (2, 6), a plurality of flat tubes (3) which are connected between the liquid collecting tubes (2, 6) and communicated with the inner cavities of the liquid collecting tubes (2, 6), fins (5) positioned between flat tubes (3) and clapboards (4) which are arranged inside the liquid collecting tubes (2, 6) to divide the liquid collecting tubes (2, 6) into a plurality of sealed cavities. Connecting tubes (1, 1') are connected with the liquid collecting tubes (2, 6). A throttling device which can change the flow and the flat tube numbers of each flow is arranged at least between two cavities of the liquid collecting tubes. The heat exchanger can regulate the composing proportion of the gas and liquid cooling work mediums so as to realize the regulation of the heat exchanging work states of the heat exchanger, or can form cooling mediums which flows in the heat exchanger to realize the right-direction and reverse-direction flow characteristics so as to adapt to the application of the heat exchanger in the heat pump system and to realize the excellent efficiency balance of cooling and heating and to lead the heat exchanger to perform the biggest benefit.

Owner:SANHUA HANGZHOU MICRO CHANNEL HEAT EXCHANGER

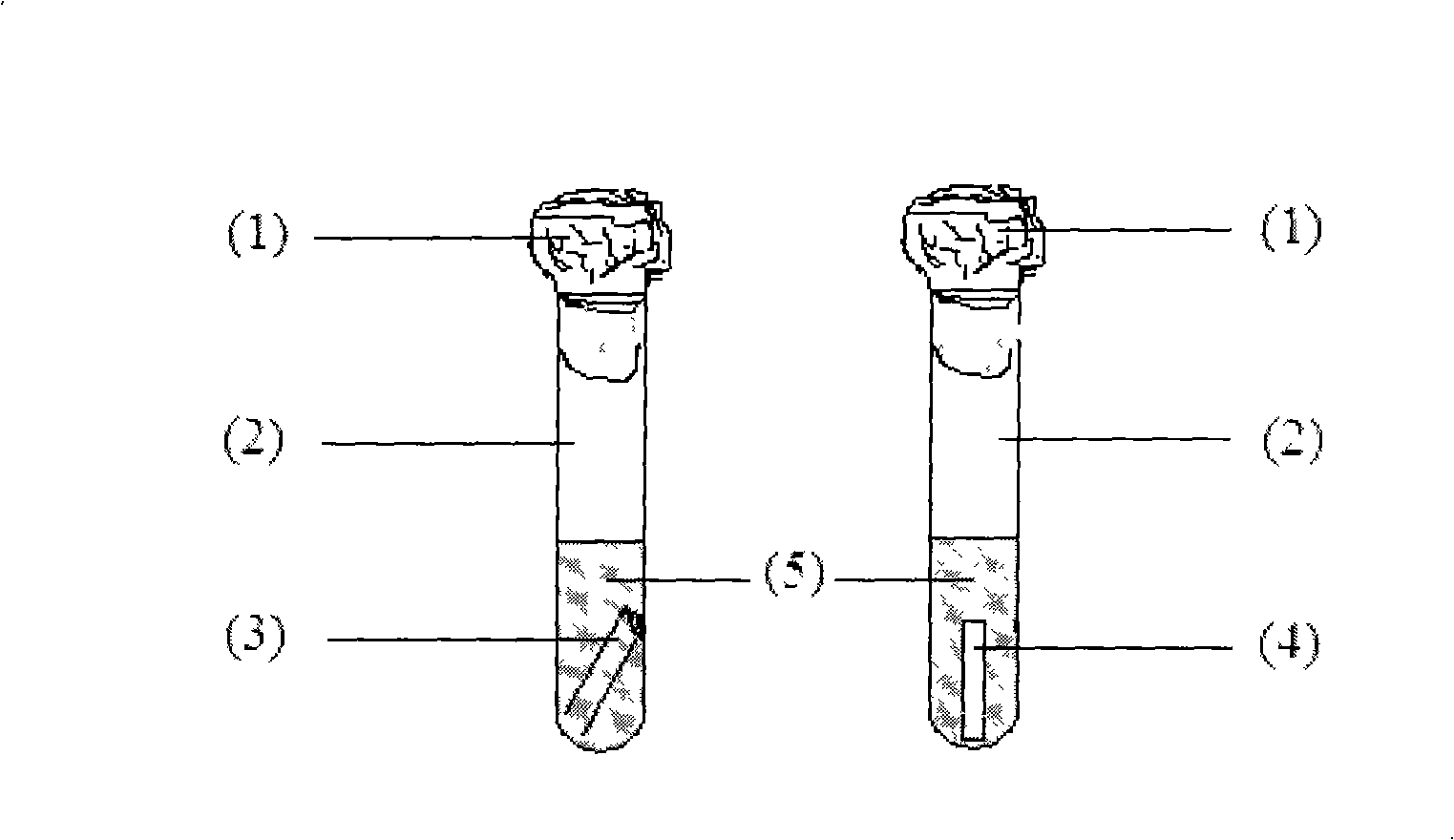

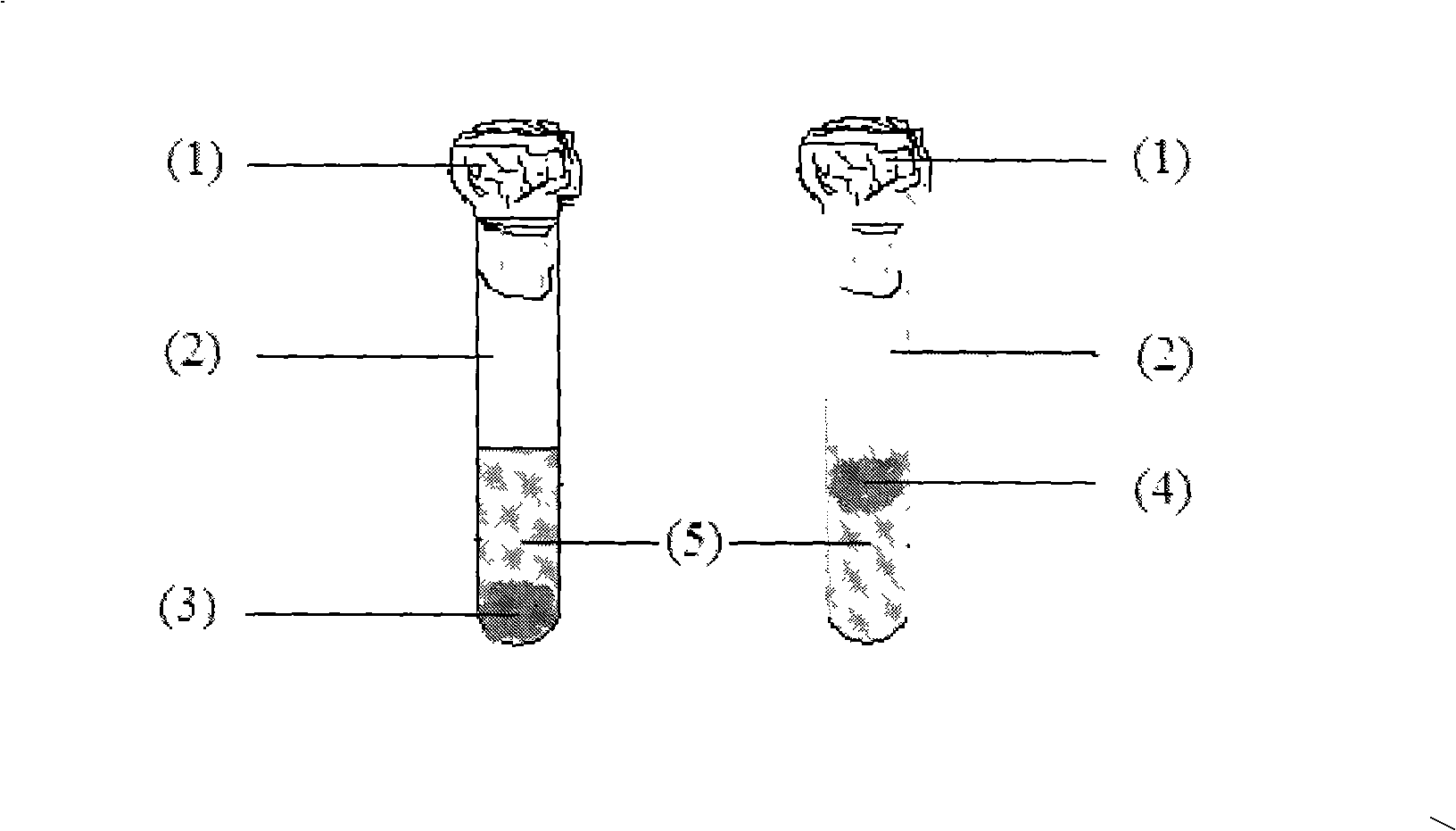

Detecting method for aerogenic bacterium in soy sauce and other condiments

ActiveCN101348826AEasy to detectStrong specificityMicrobiological testing/measurementSoya sauceTube number

The invention discloses a method for detecting aerogen in flavorings such as soybean sauce. The method comprises the following steps that a to-be-detected flavoring sample is diluted and then is inoculate inside a fermentation tube containing a culture medium; when the to-be-detected flavoring sample is cultivated 48+ / -2 hours under a condition of 36+ / -1 DEG C, aerogen is detected according to aerogenesis tube number and aerogenesis characteristic of the fermentation tube. The invention also discloses a culture medium used for aerogen detection. The method can conveniently detect the existence of aerogen in flavorings such as soybean sauce, and has excellent specificity; the detection result of the method has high correlativity with can-swelling leakage, thereby providing an ideal detection method for detecting whether aerogen exists in a product and whether a finished product leaks, and providing a basis for improving manufacturing technique, controlling production quality and improving product quality; moreover, the method also has the advantages of simple step, low cost and easy popularization.

Owner:FOSHAN HAITIAN FLAVOURING & FOOD CO LTD

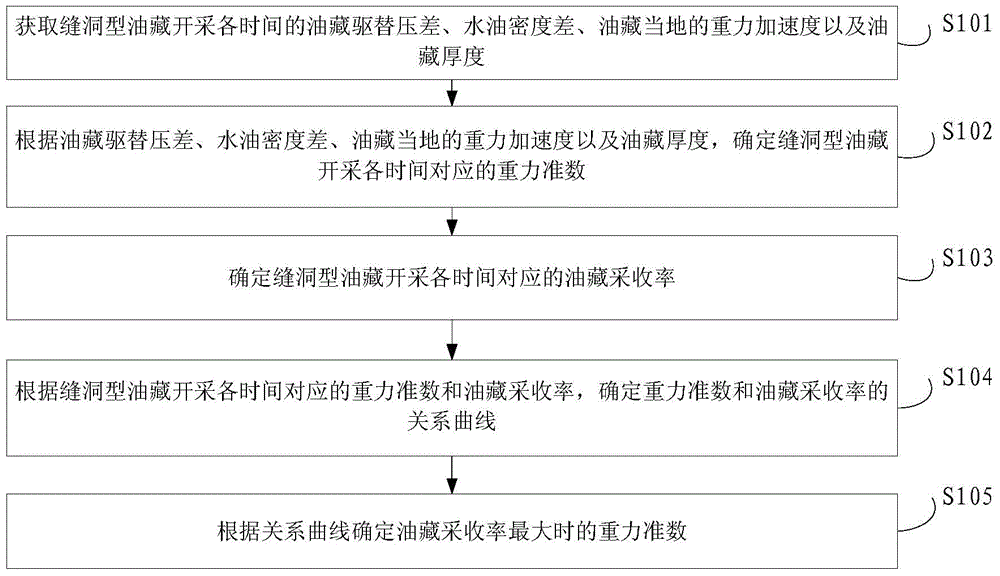

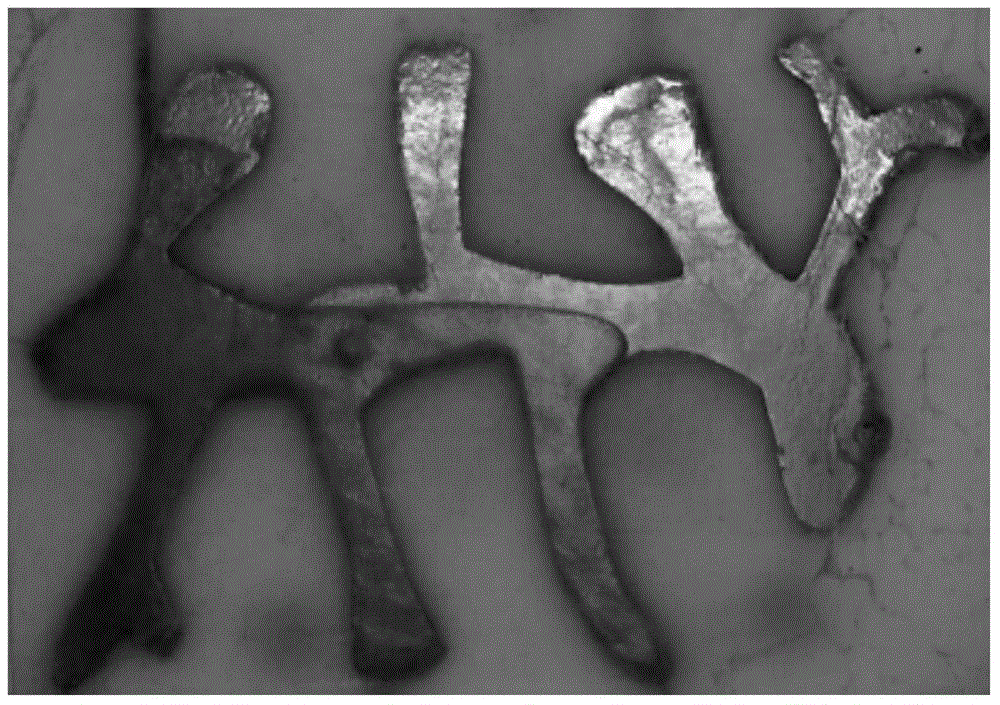

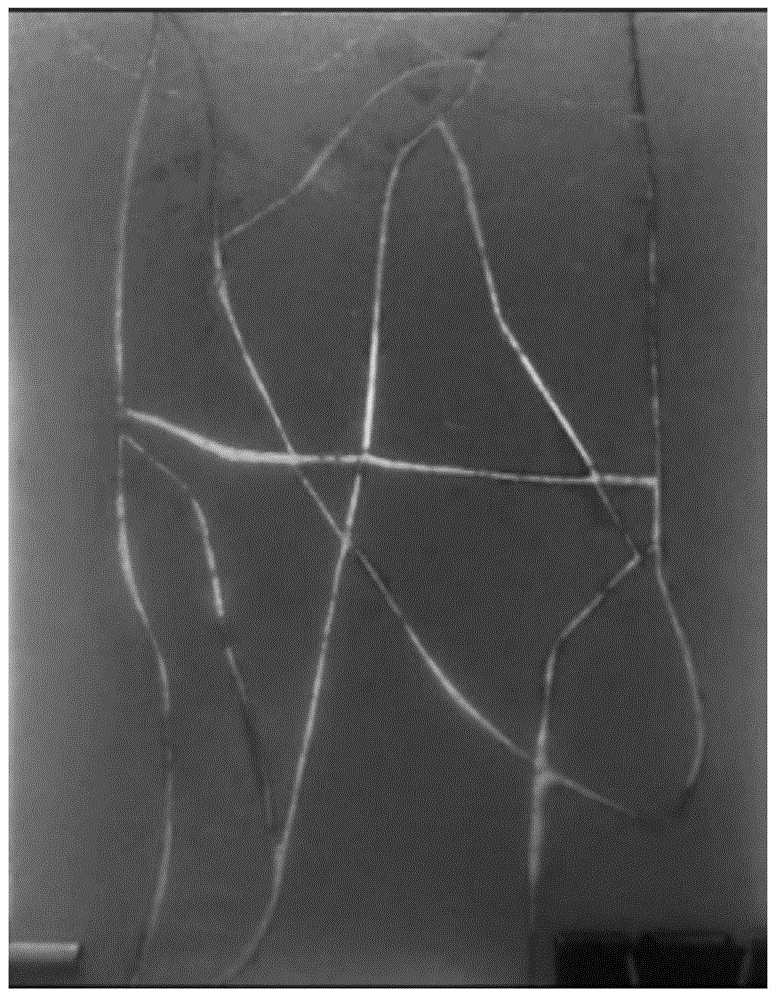

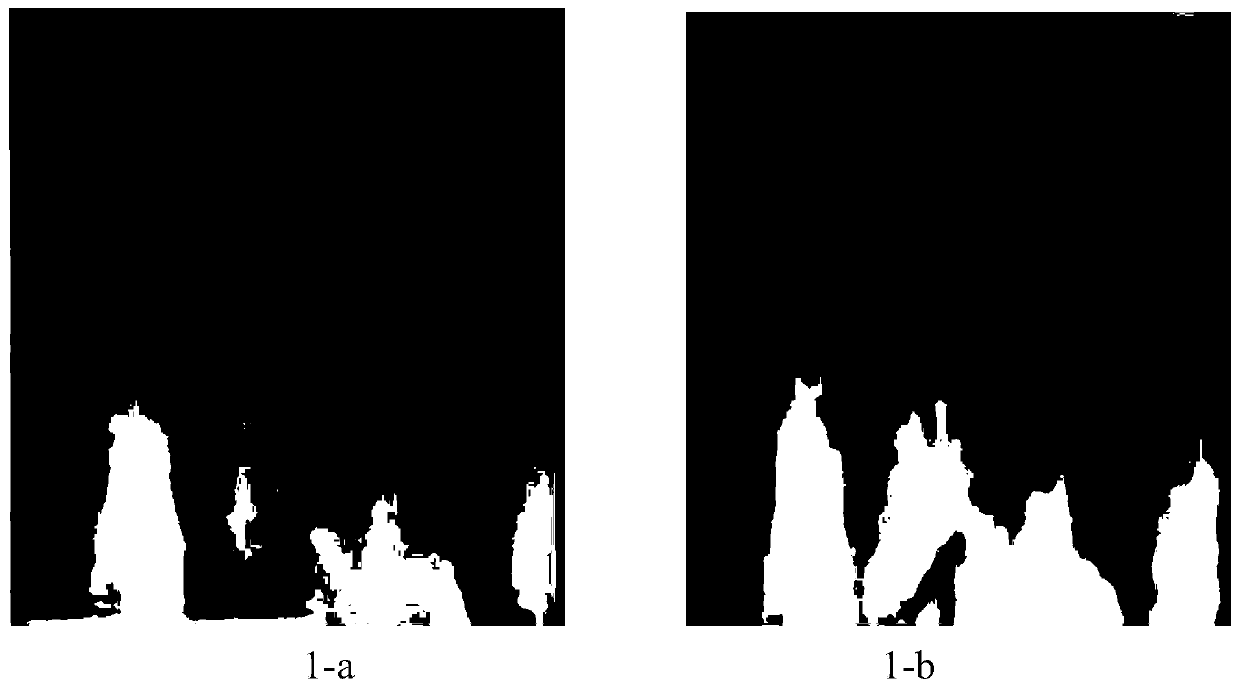

Method for characterizing fracture-cavern type reservoir water-drive recovery effects

ActiveCN105041277ASolve the problem that it is not suitable for the evaluation of the development effect of fracture-cavity reservoirsFluid removalSpecial data processing applicationsDisplacement pressureDensity difference

The invention provides a method for characterizing fracture-cavern type reservoir water-drive recovery effects, and relates to the field of fracture-cavern type reservoir recovery technologies. The method includes acquiring reservoir displacement pressure difference, water and oil density difference, local gravitational acceleration of reservoirs and reservoir thicknesses in fracture-cavern type reservoir recovery time; determining gravitational dimensionless numbers corresponding to the fracture-cavern type reservoir recovery time according to the reservoir displacement pressure difference, the water and oil density difference, the local gravitational acceleration of the reservoirs and the reservoir thicknesses; determining reservoir recovery ratios corresponding to the fracture-cavern type reservoir recovery time; determining relation curves of gravitational dimensionless numbers and reservoir recovery ratios according to the gravitational dimensionless numbers and the reservoir recovery ratios corresponding to the fracture-cavern type reservoir recovery time; determining the gravitational dimensionless numbers under the conditions of maximum reservoir recovery ratios according to the relation curves. The method has the advantage that problems of deficiency of methods for characterizing fracture-cavern type reservoir water-drive recovery effects at present and inapplicability of capillary tube numbers of the traditional sandstone reservoirs to evaluating fracture-cavern type reservoir recovery effects can be solved by the aid of the method.

Owner:CHINA PETROLEUM & CHEM EXPLORATION & PRODION RES INST +1

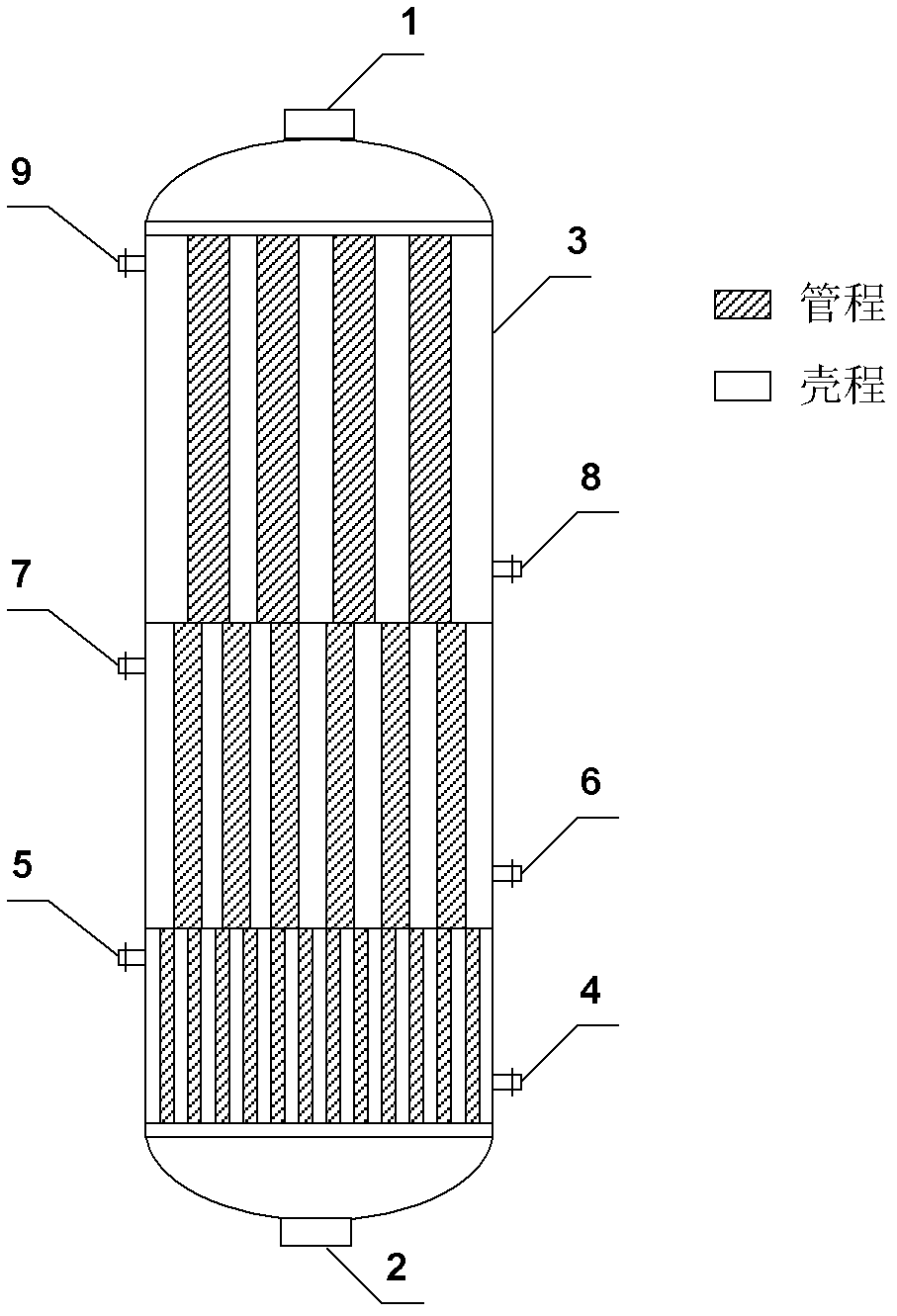

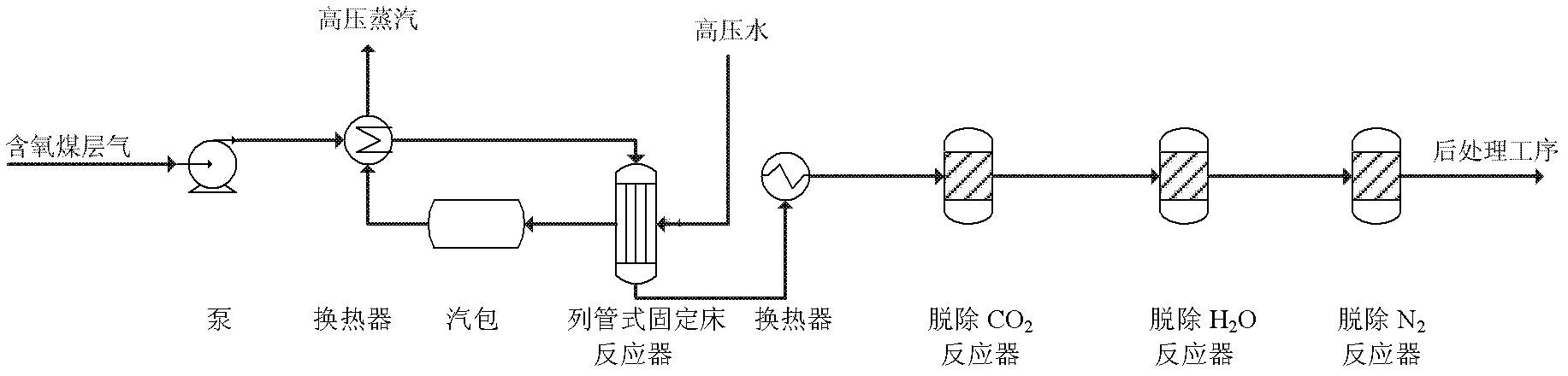

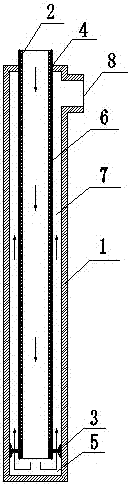

Multitubular fixed bed reactor and coal bed methane deoxidation method

ActiveCN102921355AAvoid Axial Hot SpotsModerate radial temperature differenceGaseous fuelsChemical/physical processesFixed bedProcess engineering

The invention provides a multitubular fixed bed reactor which is characterized in that the reactor comprises a first sealing head, a second sealing head, and a housing, wherein at least one partition plate is disposed in the housing to partition the reactor into at least two sections along an axial direction of the housing; a cooling medium inlet and a cooling medium outlet are disposed on the housing outside each section of the reactor; the tube number of each section of the reactor decreases orderly away from the second sealing head along the axial direction of the housing, and the tube diameters of the tubes increase orderly. The invention also provides a coal bed methane deoxidation method performed in the multitubular fixed bed reactor. Compared with various equipment improvement in the prior art, the multitubular fixed bed reactor of the invention is simple in structure, and low in preparation difficulty. In addition, the method of the invention not only ensures the coal bed methane deoxidation effect, eliminates hot spots in the reactor, but also ensures the processing capacity of the process.

Owner:CHINA PETROLEUM & CHEM CORP +1

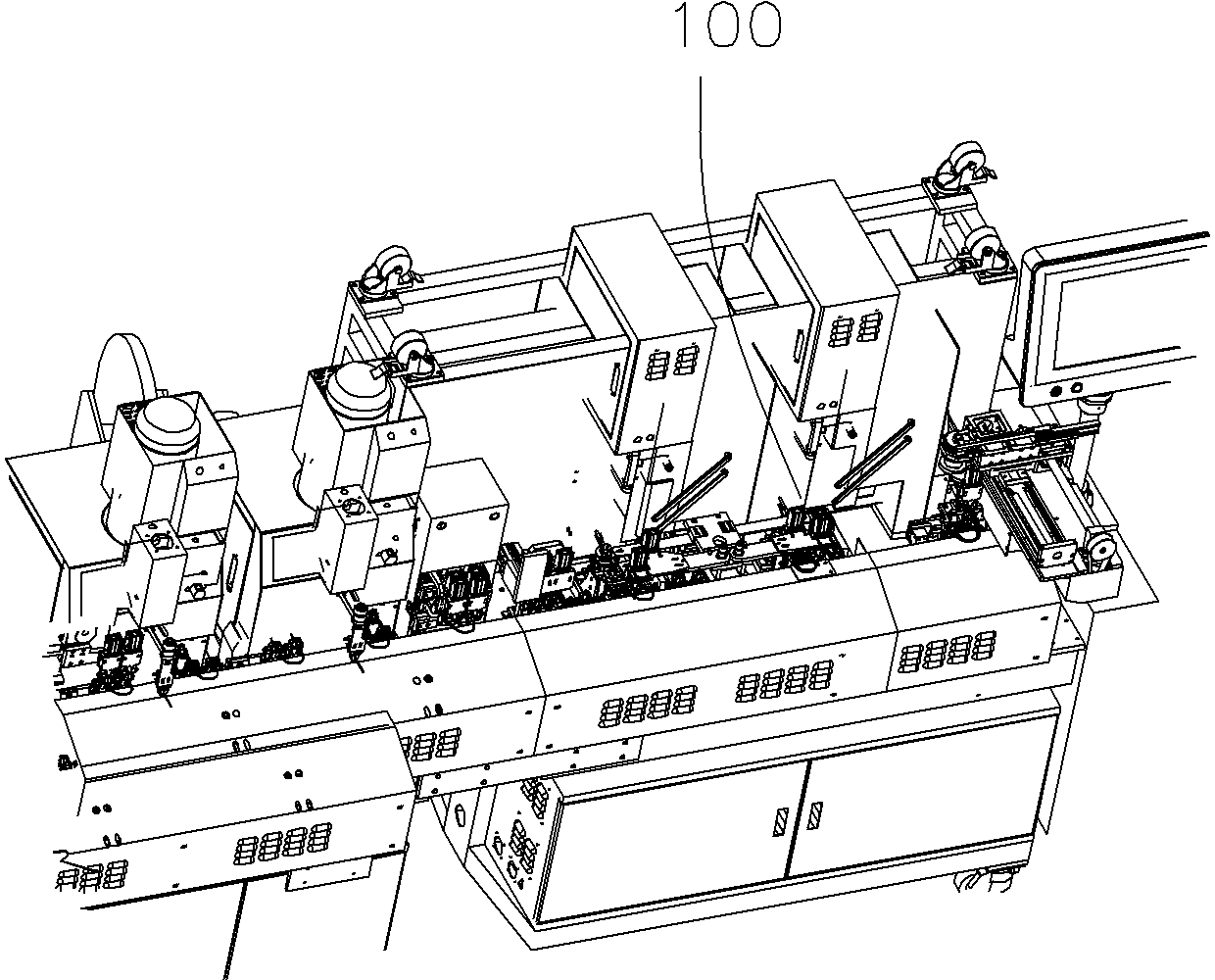

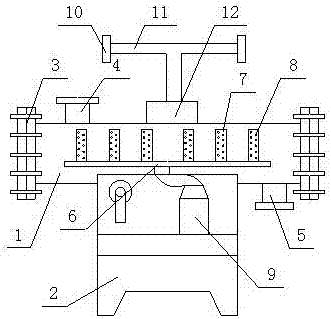

Stepping transferring and carrying system

InactiveCN102556660AEffective controlLoad accuratelyConveyorsControl devices for conveyorsEngineeringMechanical engineering

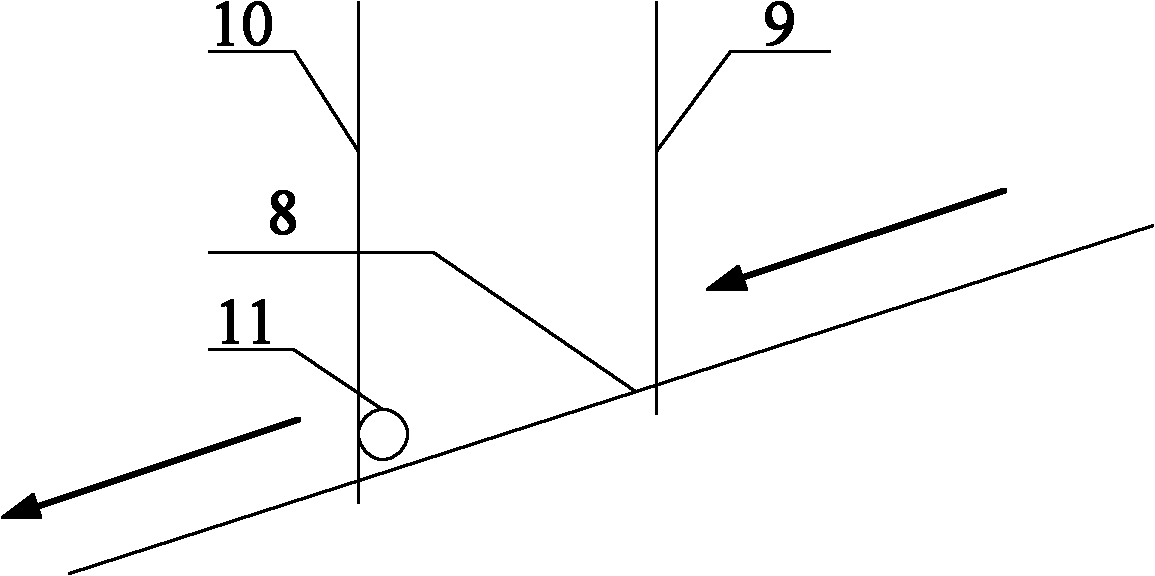

The invention discloses a stepping transferring and carrying system, which belongs to the technical field of solar vacuum tube clip installation. The stepping transferring and carrying system comprises a tube number control device, a transferring and carrying device, a first side conveying belt and a second side conveying belt, the tube number control device is used for controlling the number of tubes and comprises an obliquely arranged tube carrying platform, a first liftable baffle plate and a second liftable baffle plate, the first liftable baffle plate and the second liftable baffle plate are positioned on the tube carrying platform and are arranged side by side at intervals, a gap between the first baffle plate and the second baffle plate is larger than the diameter of each vacuum tube and smaller than 1.5 times of the diameter of each vacuum tube, and a first light sensor for sensing the vacuum tubes is arranged between the first baffle plate and the second baffle plate. The stepping transferring and carrying system is capable of conveying the vacuum tubes into designated positions, so that clips can be accurately mounted in the vacuum tubes.

Owner:SUZHOU ZIGUAN AUTOMATIC EQUIP

Evaporation concentration device

InactiveCN102233193AEvaporate evenlyInhibition of attachmentEvaporators with horizontal tubesEvaporationEngineering

The invention provides an evaporation concentration device. In the invention, a plurality of heat transfer tubes with external diameter of 15mm-26mm are divided into a plurality of heat transfer tube groups in a closed evaporating pot, and the number of the tubes in the heat transfer tube groups sequentially is decreased or increased along the upward direction; heating steam sequentially flows from the heat transfer tube group with the maximum tube number to those with less tube numbers; and a supply dispersion quantity of solution in the heat transfer tube group per horizontal projection area is 10m<3> / h / m<2>-60m<3> / h / m<2>.

Owner:SASAKURA ENG CO LTD

Method for processing tube number winding pipe

InactiveCN101468367ASimple working processReduce processing timeOther chemical processesEngineeringConductor Coil

The invention relates to a method for processing a syphon, and belongs to the field of the method for manufacturing brass instruments. The processing method comprises: filling a mixture of sand and water in a straight pipe; cooling the straight pipe till the mixture of the sand and the water is condensed to a solid; processing the straight pipe of which the inside is filled with the mixture of the sand and the water into the syphon; and unfreezing the processed syphon till the water in the syphon thaws and flows out from the syphon. The method can simplify processing flow, reduce processing time, improve production efficiency and yield, reduce the manufacturing cost of a product, and ensure the quality of a finished product in order to achieve good performing effect in performance.

Owner:TIANJIN JINBAO MUSICAL INSTR

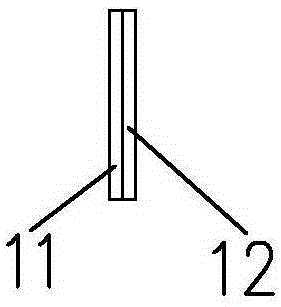

Cast pipe quality management method, cast pipe produced by using above method, and two-dimensional barcode tag

The invention discloses a cast pipe quality management method, a cast pipe and a two-dimensional barcode tag. The method comprises steps: (1) production source information of each cast pipe during the production process is inputted to a two-dimensional barcode management system, and a cast pipe record corresponding to each pipe batch number is generated in the two-dimensional barcode management system; (2) after the cast pipe quality is tested to be qualified, a two-dimensional barcode tag is printed, and the two-dimensional barcode tag is stuck on the corresponding cast pipe which is tested to be qualified; (3) shipping information of the cast pipe which is tested to be qualified is stored to the cast pipe record; and (4) the two-dimensional barcode tag is scanned, if a corresponding cast pipe record is found, the two-dimensional barcode management system displays information of the cast pipe record, and if not, the two-dimensional barcode management system displays false information. The method solves the problems that repeated and wrong numbers appear during the pipe number transmission process and the efficiency is low, and has the advantages that mistakes can be avoided during the cast pipe number transmission process, quality tracing can be realized, and fakeness can be prevented.

Owner:XINXING DUCTILE IRON PIPES CO LTD

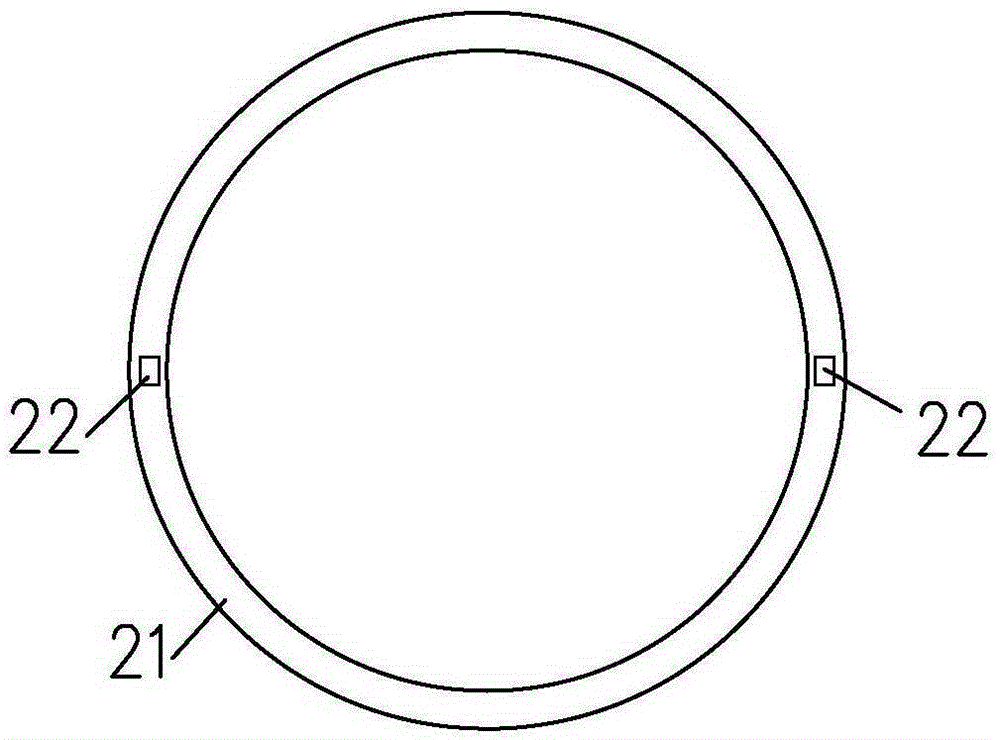

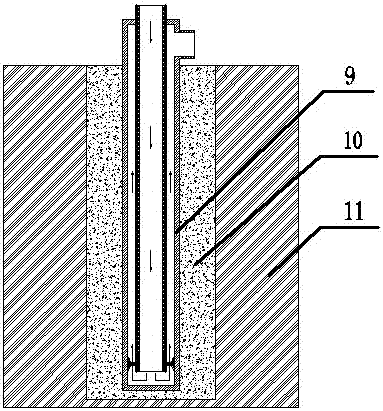

Concentric casing heat exchange tube

PendingCN106885386AReduced drilling costsImprove drilling efficiencyCollector components/accessoriesOther heat production devicesEngineeringTube number

The invention discloses a concentric casing heat exchange tube which comprises a tube body, an inner tube and tube head brackets, wherein a limiting hole is formed in the upper part of the tube body; a water outlet is formed in the upper part of a side of the tube body; the inner tube is inserted into the limiting hole; a gap is formed between the lower part of the inner tube and the lower part of the tube body; the tube head brackets are symmetrically arranged below sides of the inner tube; a thermal-insulating coating is arranged on the outer side of the inner tube; an interlayer is arranged between the outer side of the inner tube and the inner side of the tube body; the tube body is coaxial with the inner tube. The concentric casing heat exchange tube is low in drilling workload, small in heat exchange tube number, low in cost and high in heat exchange efficiency, has remarkable economical efficiency and practicability, and has very wide application prospects.

Owner:JIANGSU GEOLOGY & GEOTHERMAL ENERGY

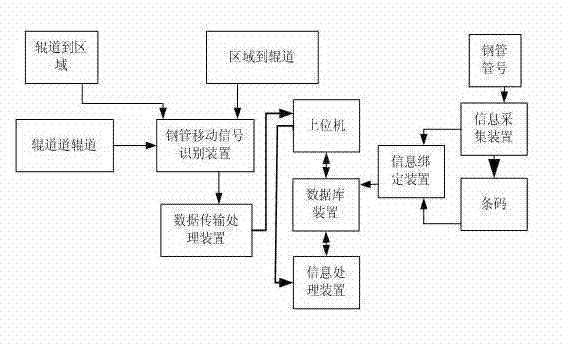

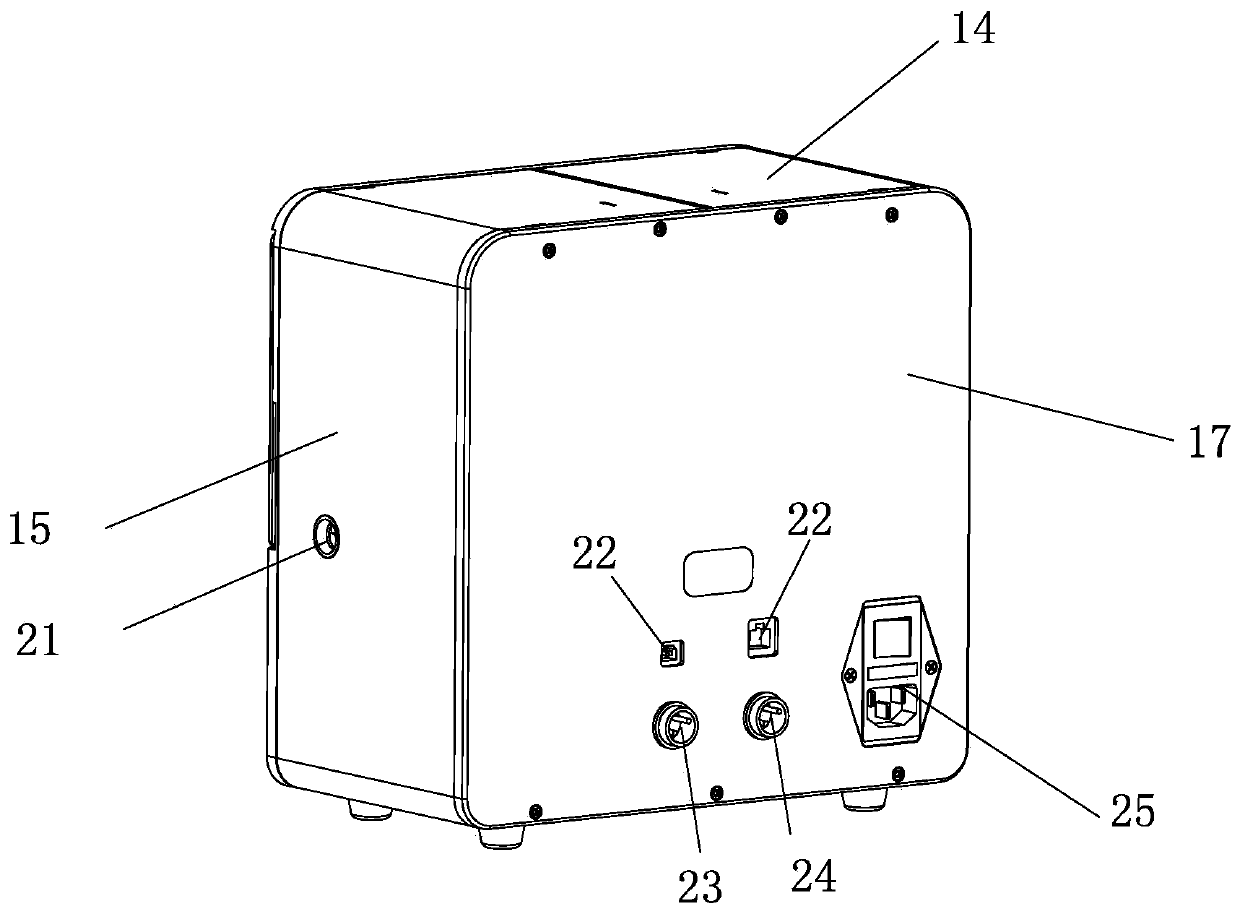

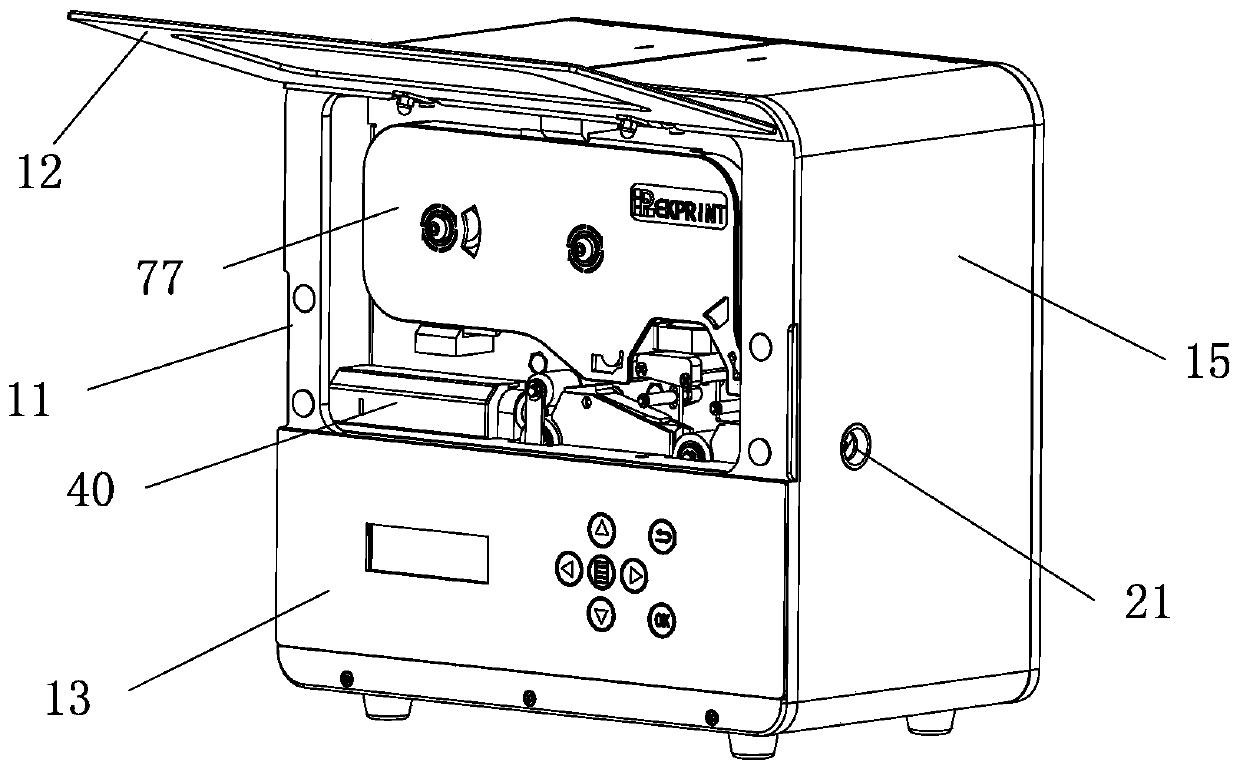

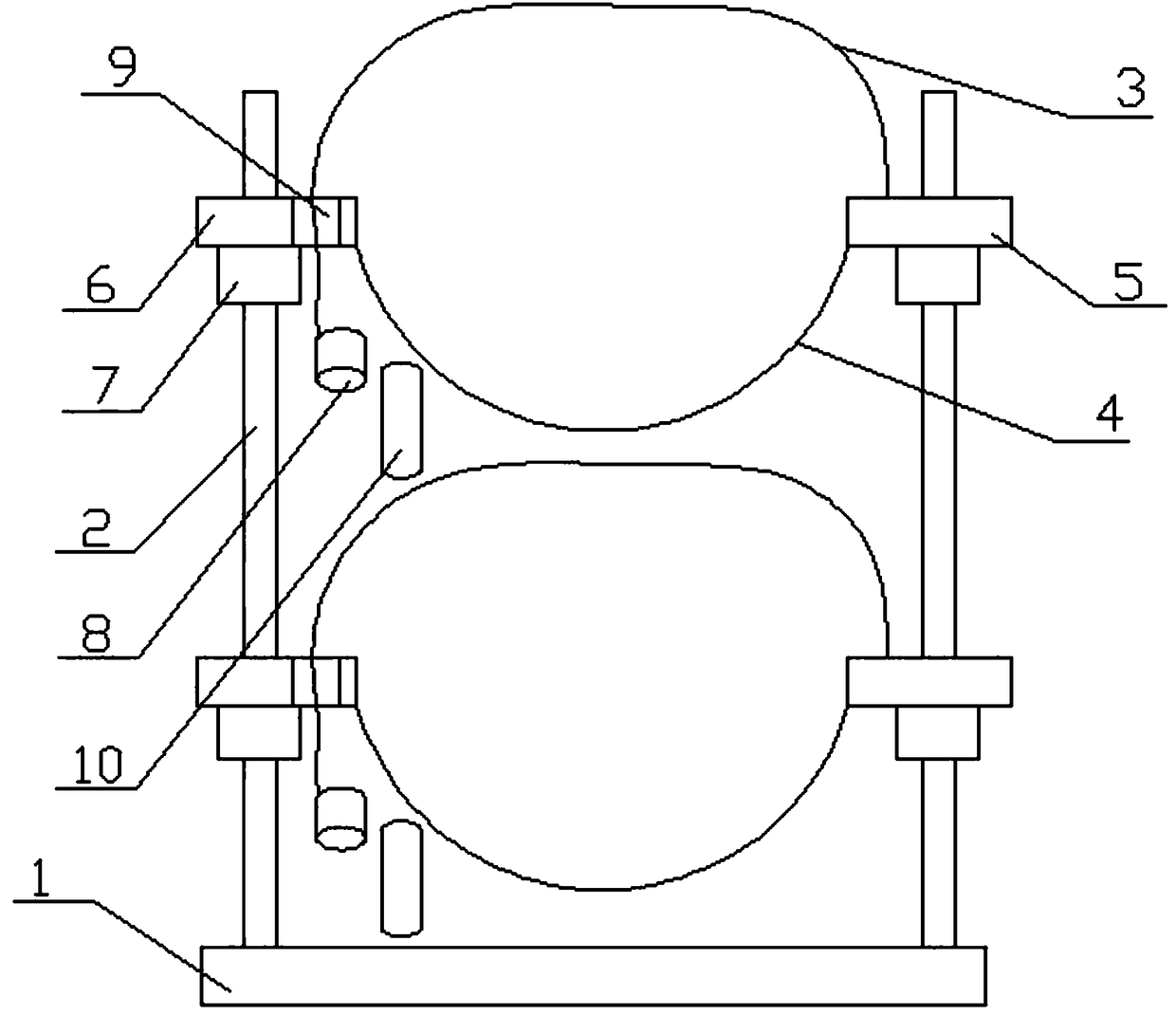

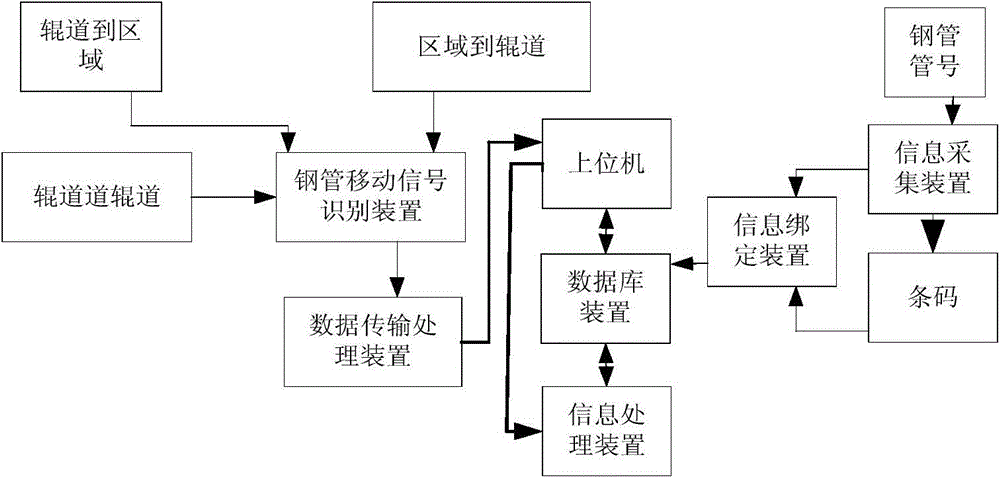

Method for intelligently tracking tube numbers in circulating process of steel tube production line

InactiveCN104751259AImprove efficiencyShorten the timeResourcesSensing by electromagnetic radiationProduction lineEngineering

The invention discloses a method for intelligently tracking tube numbers in a circulating process of a steel tube production line, which comprises the following steps of establishing a database, marking tags, collecting information, processing roller way and buffer area signals, recognizing existence of a steel tube on roller ways, recognizing information that the steel tube is moved from one roller way to another, from the roller way to an area, from the area to the roller way, and the like, and transmitting the information to an upper computer; and binding signals. According to the invention, the tube numbers of the steel tubes are collected into a system through information collecting points, then the steel tube numbers are bound to the steel tubes, and the action signals for entering and exiting from roller ways and the areas are displayed through the upper computer, so that the steel tubes are accurately and visually positioned according to the tube numbers, the number of recognition points is reduced, and the efficiency is improved.

Owner:北海恒久天成技术开发有限公司

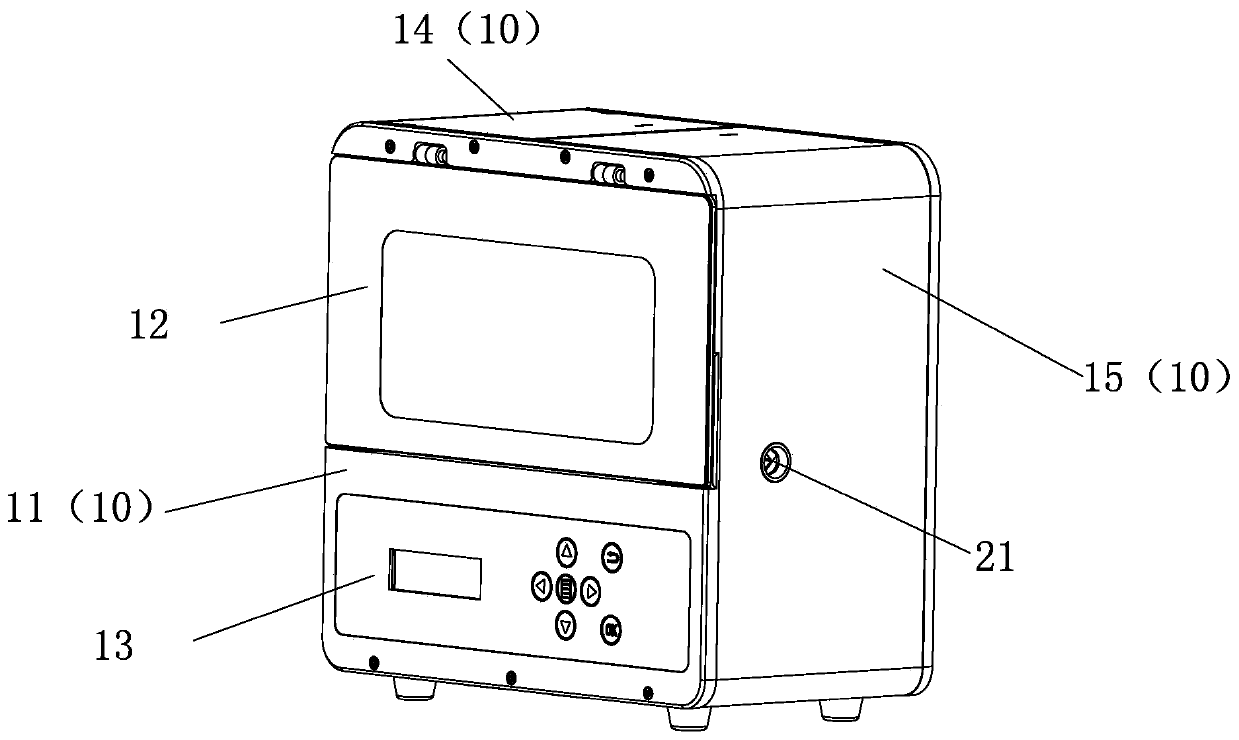

Method for automatically identifying print data for wire tube marking machine

ActiveCN109786045ALow investment costReduce labor costsManufacturing wire harnessesConductor/cable markingData segmentControl system

The invention provides a method for automatically identifying print data for a wire tube marking machine, wherein the wire tube marking machine is networked with a wire harness production control system, and the method can automatically extract wire number data capable of forming the wire tube number from the control system. The method comprises the following steps: parsing a data packet of production data involved in the processing harness and the wire number pipes of a wire harness production enterprise, and acquiring editing rule information of each data segment with independent significance in the data packet; in the data packet, giving a sequence number calibration number to the data segments associated with the wire tube number in the sort position of the data packet; and inputting the editing rule information and the sequence number calibration number into a main control circuit of the wire tube marking machine through the wire tube marking machine to establish an automatic identification screening module. When wire harnesses of related specifications need to be numbered, the automatic identification screening module is used for screening the wire number data related to thewire harnesses of the specifications used for editing corresponding wire tube numbers, and editing the wire number data into the wire tube numbers of a prescribed format. The production of automatic large-batch multi-varieties printing wire tube numbers can be realized.

Owner:SHENZHEN KINGPEK CO LTD

Paper tube classified storage device

InactiveCN108820490APrevent disengagementEasy accessRigid containersInternal fittingsPulp and paper industryTube number

The invention discloses a paper tube classified storage device. The paper tube classified storage device comprises a support base plate; support rods are arranged on the two sides of the upper end surface of the support base plate; more than one paper tube storage units are arranged between the two support rods in the vertical direction; the paper tube storage units comprise rope belts, arc papertube storage baseplates and two fixed pieces; the two fixed pieces are marked as first fixed pieces and second fixed pieces; the two fixed pieces are arranged at the two ends of the paper tube storagebaseplates; the support rods penetrate through positioning through holes formed in the fixed pieces; the fixed pieces are supported on first positioning screw sleeves; the first positioning screw sleeves are connected with the support rods through threads; one ends of the rope belts are connected to the first fixed pieces; and the other ends of the rope belts are connected to second positioning screw sleeves. The paper tube classified storage device is high in paper tube storage quantity, can determine the number of the paper tube storage units according to the paper tube number by people, and is convenient to use.

Owner:旌德县成宇纸管厂(普通合伙)

Method for intelligently tracking tube numbers in circulating process of steel tube production line

InactiveCN104091288AConvenient pipe number changeEasy to integrateData processing applicationsManufacturing computing systemsProduction lineEngineering

The invention discloses a method for intelligently tracking tube numbers in the circulating process of a steel tube production line. The method includes the following steps that areas are obtained through division, and a database is established; information is recorded; signals are recognized; tracking and positioning are performed, and actions of steel tubes correspond to corresponding data processing steps, so that circulating of the steel tubes on the production line with the corresponding tube numbers is tracked and positioned. The tube numbers of the steel tubes are collected into a system through information collecting points, then the steel tube numbers are bound to the steel tubes, and the action signals for entering and exiting from roller ways and the areas are displayed through an upper computer, so that the steel tubes are accurately and visually positioned according to the tube numbers, the number of recognition points is reduced, and efficiency is improved.

Owner:北海恒久天成技术开发有限公司

DNA (Desoxyribonucleic Acid) specimen collection and quality control method for fetus chromosome aneuploid detection

InactiveCN108486217AEasy to operateProcess scienceMicrobiological testing/measurementBlood Collection TubeWhite blood cell

The invention discloses a DNA (Desoxyribonucleic Acid) specimen collection and quality control method for fetus chromosome aneuploid detection. The method comprises the following steps: I, performingspecimen collection, namely collecting 5.0mL of peripheral blood of a pregnant woman by using a blood collection tube I, and after collection is completed, slightly inverting the blood collection tube, placing the blood collection tube in a refrigerator in time, collecting 10.0mL of peripheral blood of the pregnant woman by using a blood collection tube II, after collection is completed, slightlyinverting the blood collection tube, and preserving at a normal temperature; II, pre-cooling a low speed centrifuge, putting into the blood collection tube II, centrifuging for minutes, sucking supernate blood plasma, transferring into an EP (Eppendorf) tube on an ice box, and marking with corresponding sample numbers; III, pre-cooling a high speed centrifuge till a temperature is stabilized, putting into the EP tube, centrifuging, sucking the supernate blood plasma on the ice box with a gun head pointing to non-leukocyte precipitation part, sub-packaging into the EP tube on the ice box, transferring into the blood plasma, marking sample numbers and blood plasma tube numbers, and preserving in the refrigerator; IV, performing quality control and treatment on the sample preserved in the step III. The method is definite in standard, good in practice operation effect and efficient and rigorous.

Owner:CHANGSHA KINGMED MEDICAL DIAGNOSTICS INST

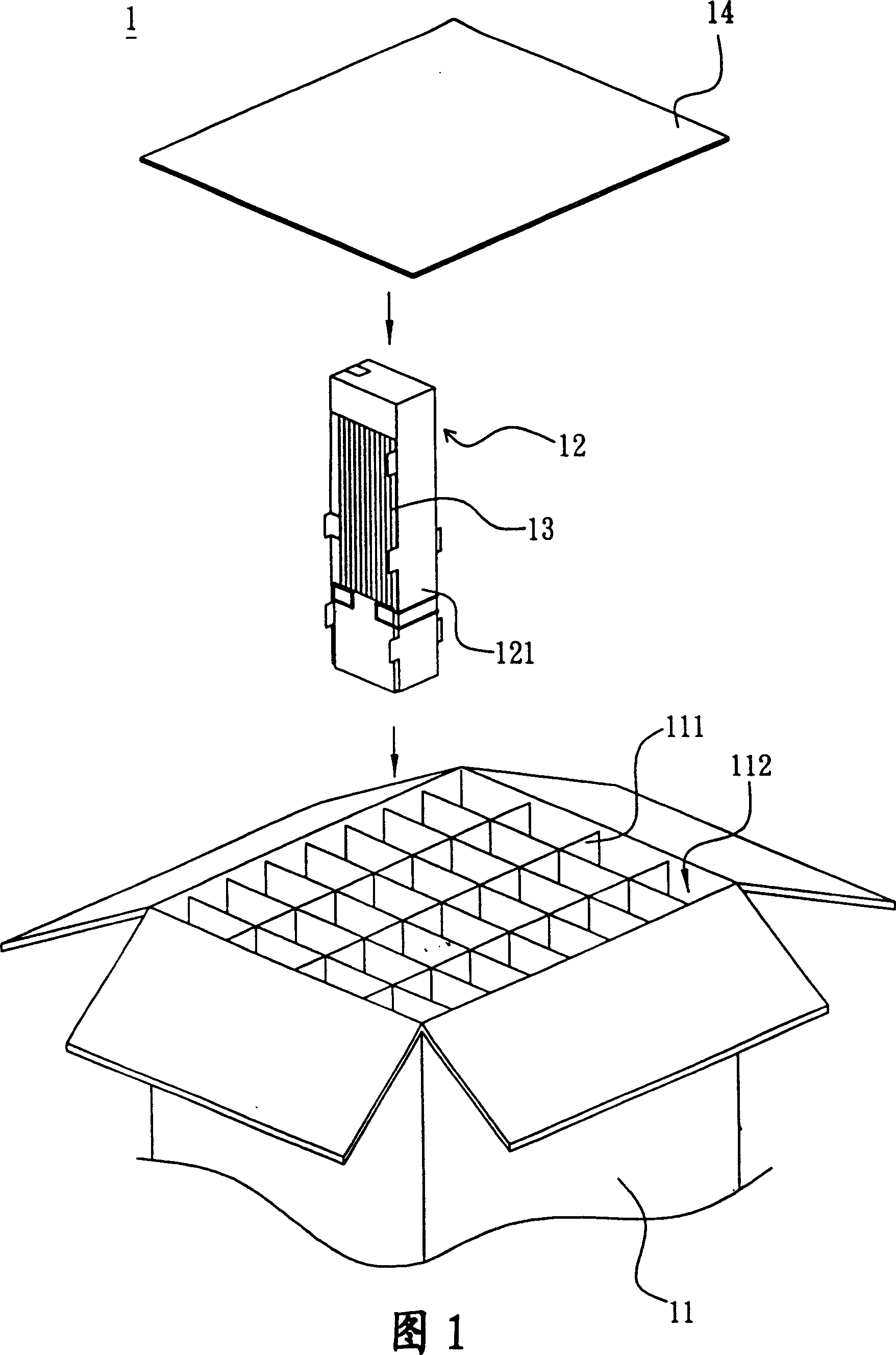

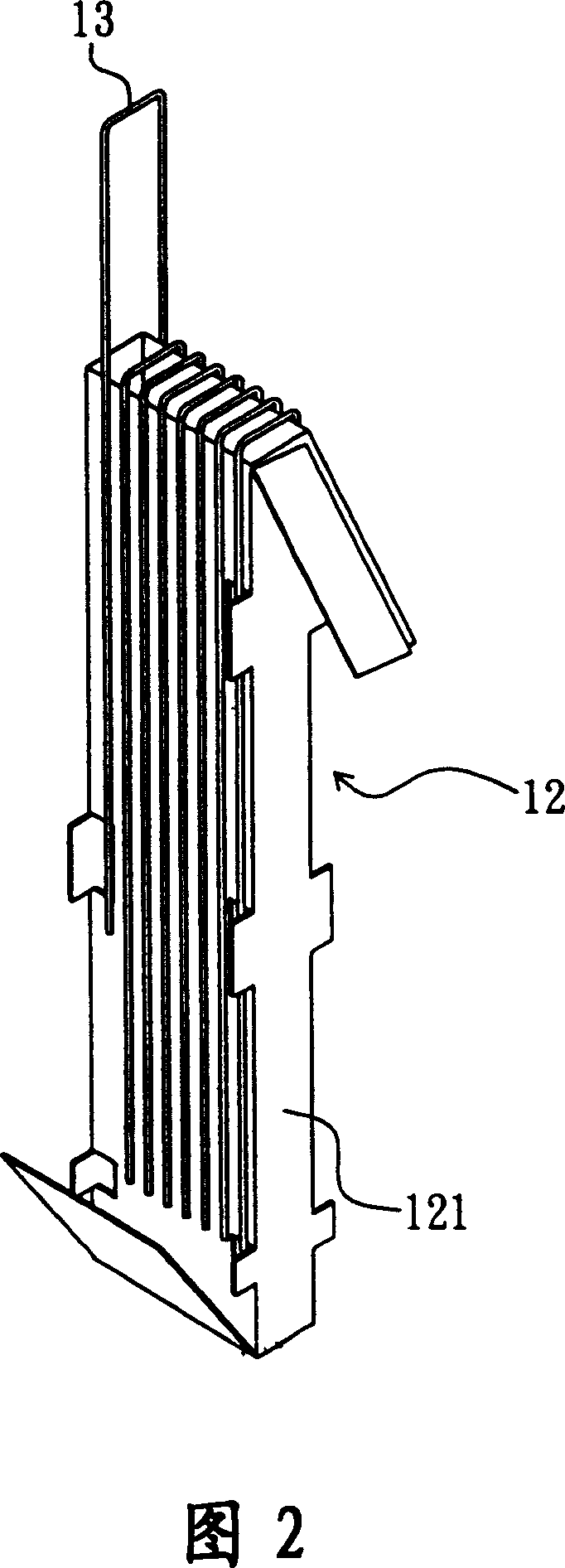

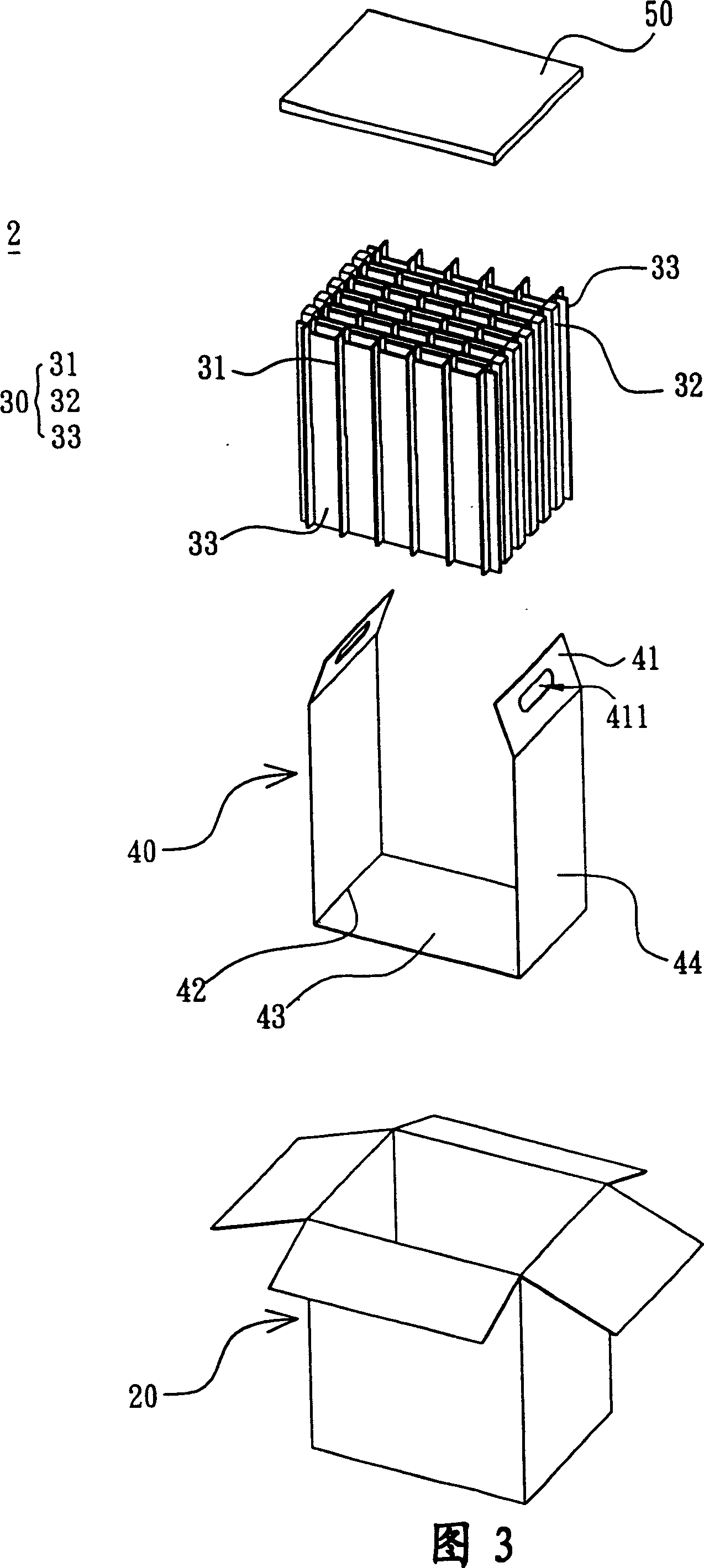

Lamp tube packing set and its lamp tube accommodating structure

InactiveCN101007587ASave man hoursReduce packaging costsContainers to prevent mechanical damageRigid containersCushioningEngineering

The invention relates to a tube packaging group and tube containing structure. The tube containing structure includes at least two supporting elements and one cushioning element; each supporting element is installed in side by side, and is equipped with a first calking groove respectively; the cushioning element is installed crossly with supporting elements, and is embedded in the first calking groove. The tube packaging group includes: a box body; and a tube containing structure installed in the box body, it includes two supporting elements and one cushioning element; said supporting elements is installed relatively and equipped with a first calking groove; the cushioning element is installed crossly with supporting elements and is embedded in the first calking groove. The invention has advantages of convenient packaging, cost saving, more containing tubes number and tube is broken difficultly, it is very suitable for practical application.

Owner:GIGNO TECH CO LTD

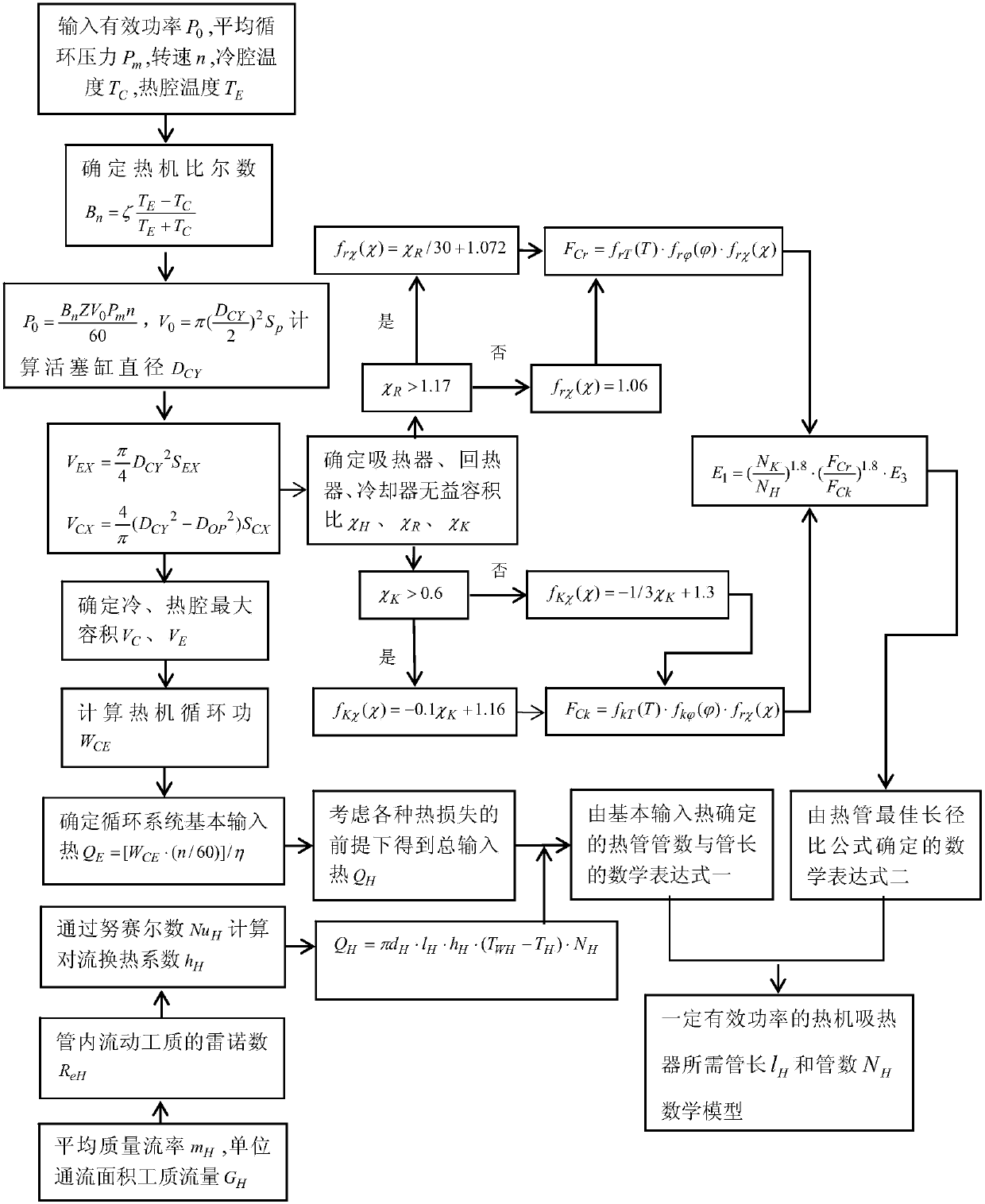

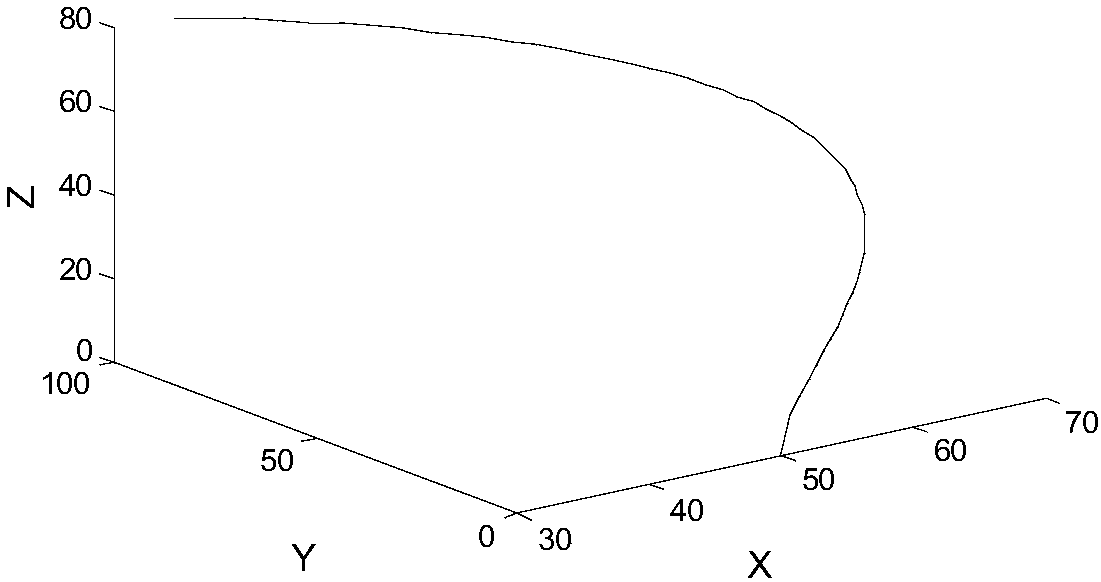

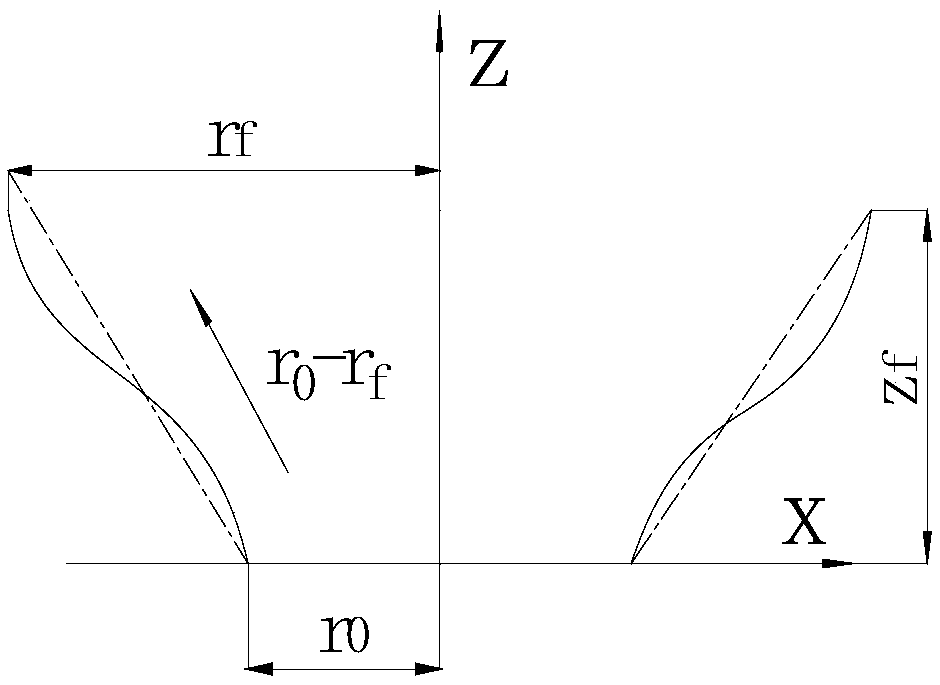

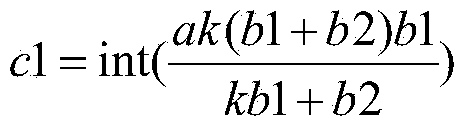

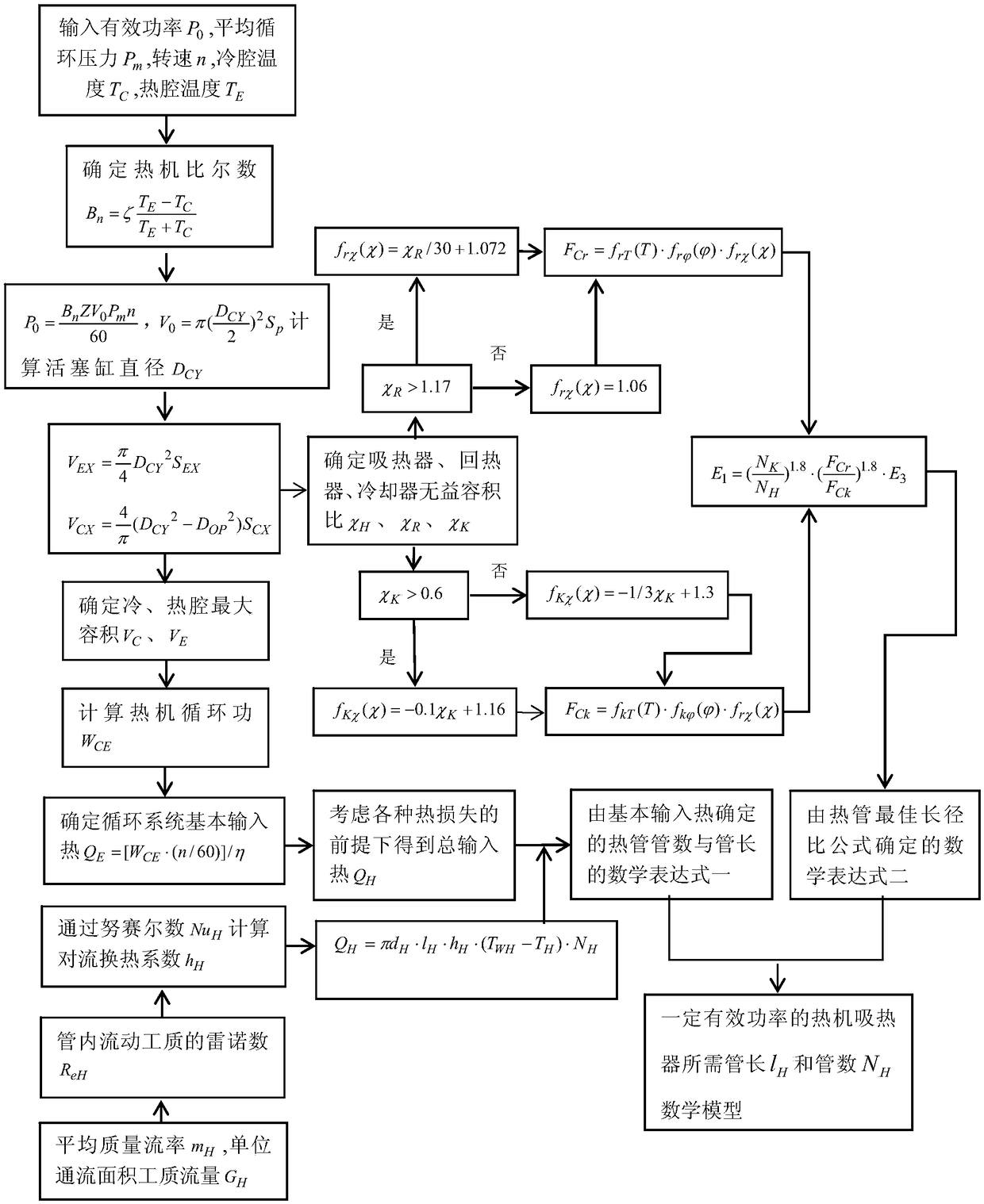

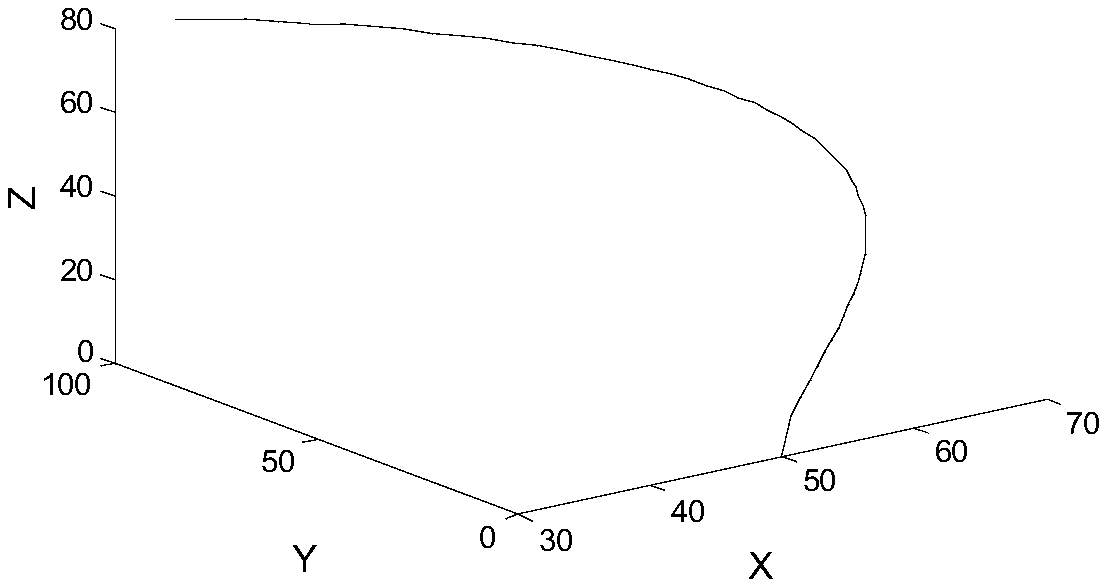

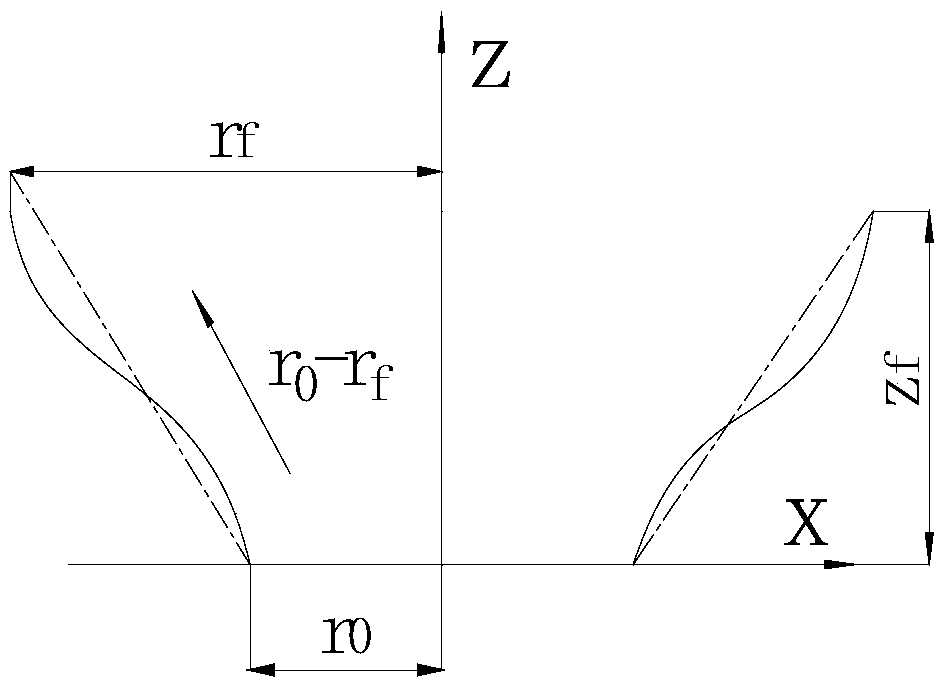

Design method of tube bundle type heat absorber of dish type solar Stirling heat engine

ActiveCN107131073AImprove reliabilityImprove maintainabilityGeometric CADFrom solar energyDiameter ratioEngineering

The invention discloses a design method of a tube bundle type heat absorber of a dish type solar Stirling heat engine. The design method comprises the following steps of (1) determining of calculation of main design parameters of the Stirling heat engine, (2) calculation of the tube number and the tube length of heating tubes of the heat absorber and (3) design of the space positions and shapes of the heating tubes of the tube bundle type heat absorber of the dish type solar Stirling heat engine. The practical calculation method is provided for design of the tube bundle type heat absorber of the dish type solar Stirling heat engine, and starting from the main design parameters of the Stirling heat engine, calculation of the tube number and the tube length of the heating tubes of the tube bundle type heat absorber based on basic input heat and the optimal length-diameter ratio can be provided; and the tube bundle type heat absorber designed through the method is high in reliability and good in maintainability, and it can be guaranteed that the heat exchange amount of heating tube bundles can meet the design requirement.

Owner:HUNAN UNIV OF SCI & TECH

DNA library quantifying and sequencing method

InactiveCN108504724AEasy to operateEasy to operate and flexibleMicrobiological testing/measurementEmulsionWater volume

The invention discloses a DNA library quantifying and sequencing method. The method comprises the steps that step 1, preparation of processing a sheet, a sample and a reagent is performed; step 2, a 1.5-milliliter low-adsorption tube is prepared, 499 microliter of NF water is added, and number and NF water volume are verified; a melt sample is vibrated, evenly mixed and transiently centrifuged tothe bottom of the tube, 1 microliter of sample is added into 499 microliter of NF water, tube number is verified, the diluted sample is vibrated, evenly mixed and transiently centrifuged; MIX is prepared on an ice box, 18 microliter of MIX is put into a 0.2-milliliter PCR plate placed on a metal ice box; number is verified, 2 microliter of sample is extracted and put into 18 microliter of MIX; after film sealing is carried out, centrifugation is carried out, and detection is performed in a PCR instrument; step 3, according to a quantifying detection result in step 2, an instrument-on sheet ismade, and emulsion PCR is carried out; step 4, OT instrument-off processing is carried out; and step 6, instrument-on sequencing is carried out. The DNA library quantifying and sequencing method has the advantages that the operation is simple, convenient and flexible, the sequencing cost is reduced, the sequencing processes are reduced, the labor efficiency is improved, the processes are scientific, the standard is clear, and the practical operation effect is good.

Owner:CHANGSHA KINGMED MEDICAL DIAGNOSTICS INST

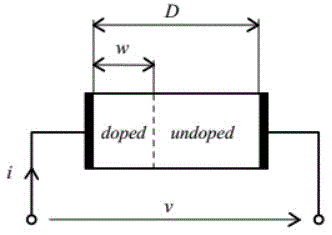

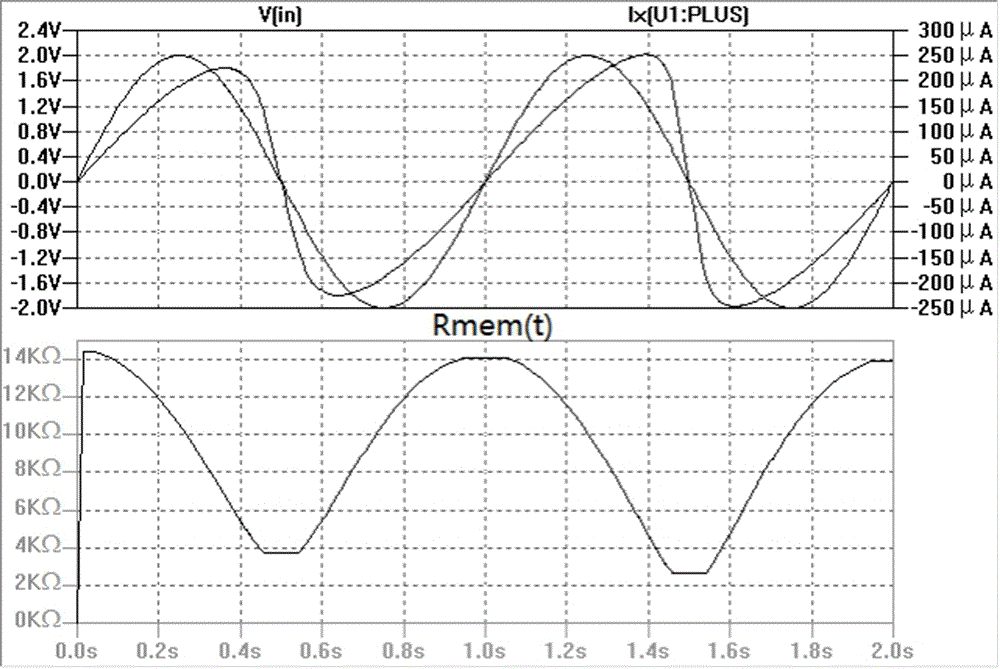

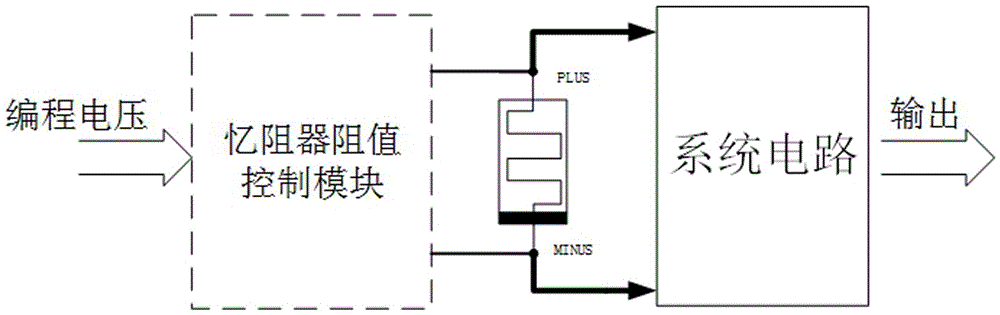

Programmable circuit based on memristor/metal-oxide-semiconductor field-effect transistor (MOSFET) and realization method thereof

The invention relates to a programmable circuit based on a memristor / a metal-oxide-semiconductor field-effect transistor (MOSFET) and a realization method of the programmable circuit. Through using the memiristor and a metal oxide semiconductor (MOS) tube in a combining manner, a programming voltage can generate a stable current which changes the resistance of the memiristor, the changeability and nonvolatility of the resistance of the memirstor are brought into play, and a programming effect is achieved. By the method disclosed by the invention, a memiristor model is successfully built in simulation program with integrated circuit emphasis (SPICE) software, the programmable circuit based on the memristor is put forward by using the model, and simulation validation is performed for the whole circuit. The programmable circuit combined by the memiristor and the MOS tube is simple in structure, small in tube number, high in integration level, and in favor of further developing integrated circuits to nanoscale.

Owner:FUZHOU UNIV

Parallel flow type heat converter

ActiveCN100541057CAdjust heat distributionCooperate wellEvaporators/condensersFluid circulation arrangementVapor liquidEngineering

The invention provides a parallel-flow heat exchanger, which has liquid collecting pipes (2, 6), several flat pipes connected between the liquid collecting pipes (2, 6) and communicated with the inner cavity of the liquid collecting pipes (2, 6). Tubes (3), fins (5) located between the flat tubes (3), and compartments arranged inside the collecting pipes (2, 6) and sealingly dividing the collecting pipes (2, 6) into a plurality of chambers The plate (4), the liquid collecting pipe (2, 6) is connected with the connecting pipe (1, 1'), and the variable number of processes and each process are arranged between at least two chambers of the liquid collecting pipe. Throttling device for the number of flat tubes. The heat exchanger can adjust the composition ratio of the gas-liquid two-state refrigerant, so as to realize the adjustment of the heat exchange condition of the heat exchanger; or realize the forward and reverse directions when forming the flow of the refrigerant in the heat exchanger Different flow characteristics, so as to adapt to the application of the heat exchanger in the heat pump system, to achieve the best efficiency balance of cooling and heating, so that the heat exchanger can maximize its benefits.

Owner:SANHUA(HANGZHOU) MICRO CHANNEL HEAT EXCHANGER CO LTD

A number tube printing support

InactiveCN102259777AEfficient printingSolve the problem of easy entanglement and knottingFilament handlingRotary pressesAxial displacementTube number

The invention relates to a number tube printing bracket, which includes a bracket body and a support rod, at least one end of the support rod is positioned on the bracket body, and the outer diameter of the support rod is suitable for passing through the printed number tube The winding core of the material disk; the two ends of the support rod are provided with limiting parts, and the limiting parts are used to limit the displacement of the placed material disk along the axial direction of the support rod. The printing bracket solves the problem that the number tubes are easily entangled and knotted during the printing process by placing the material tray carrying the number tubes on the bracket cross bar and restricting its displacement. It is conducive to realizing fast and efficient number tube printing, and also reduces the probability of waste products.

Owner:SUZHOU SUZHU IND CONTROL ENG TECH RES CENT CO LTD

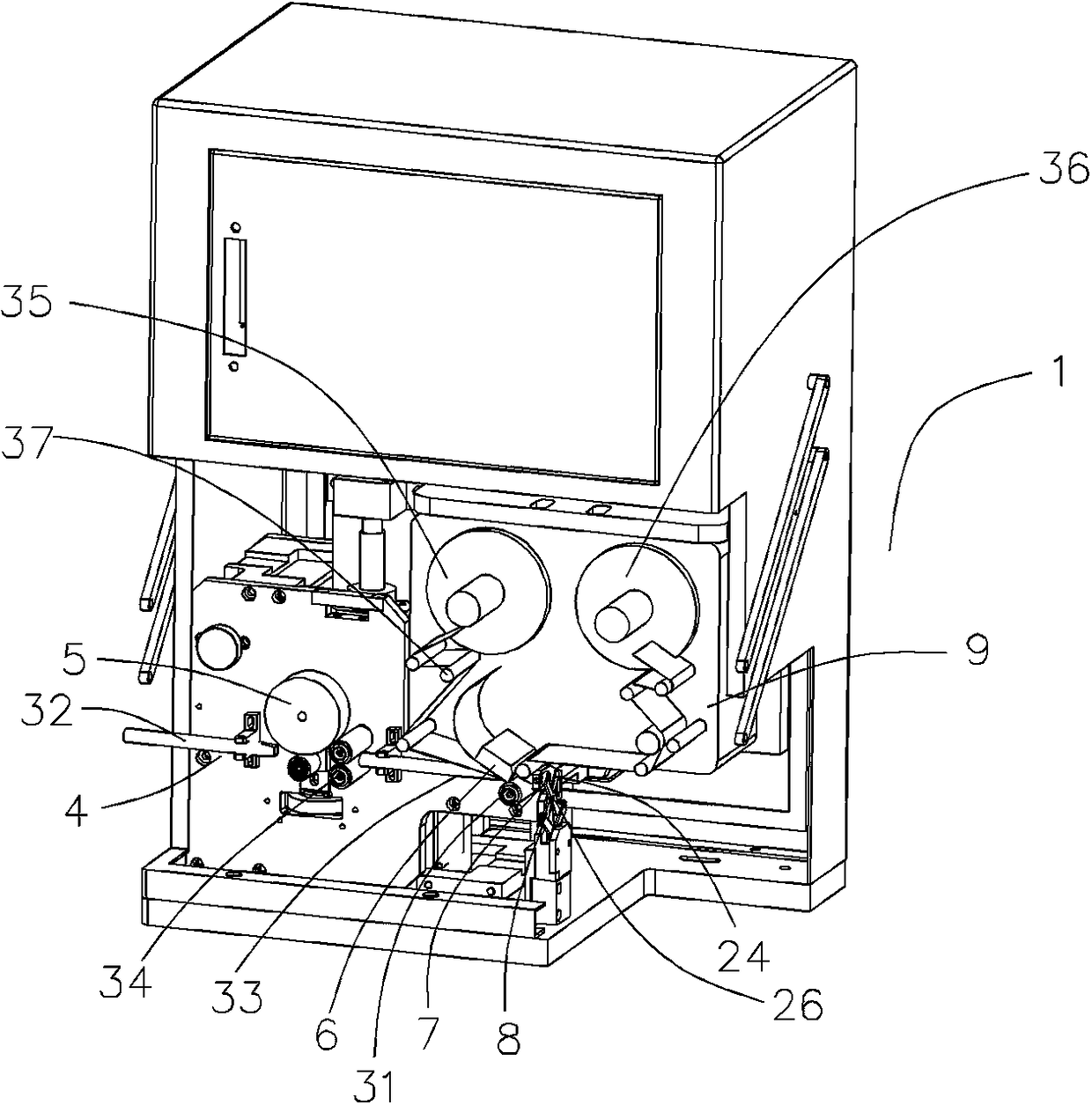

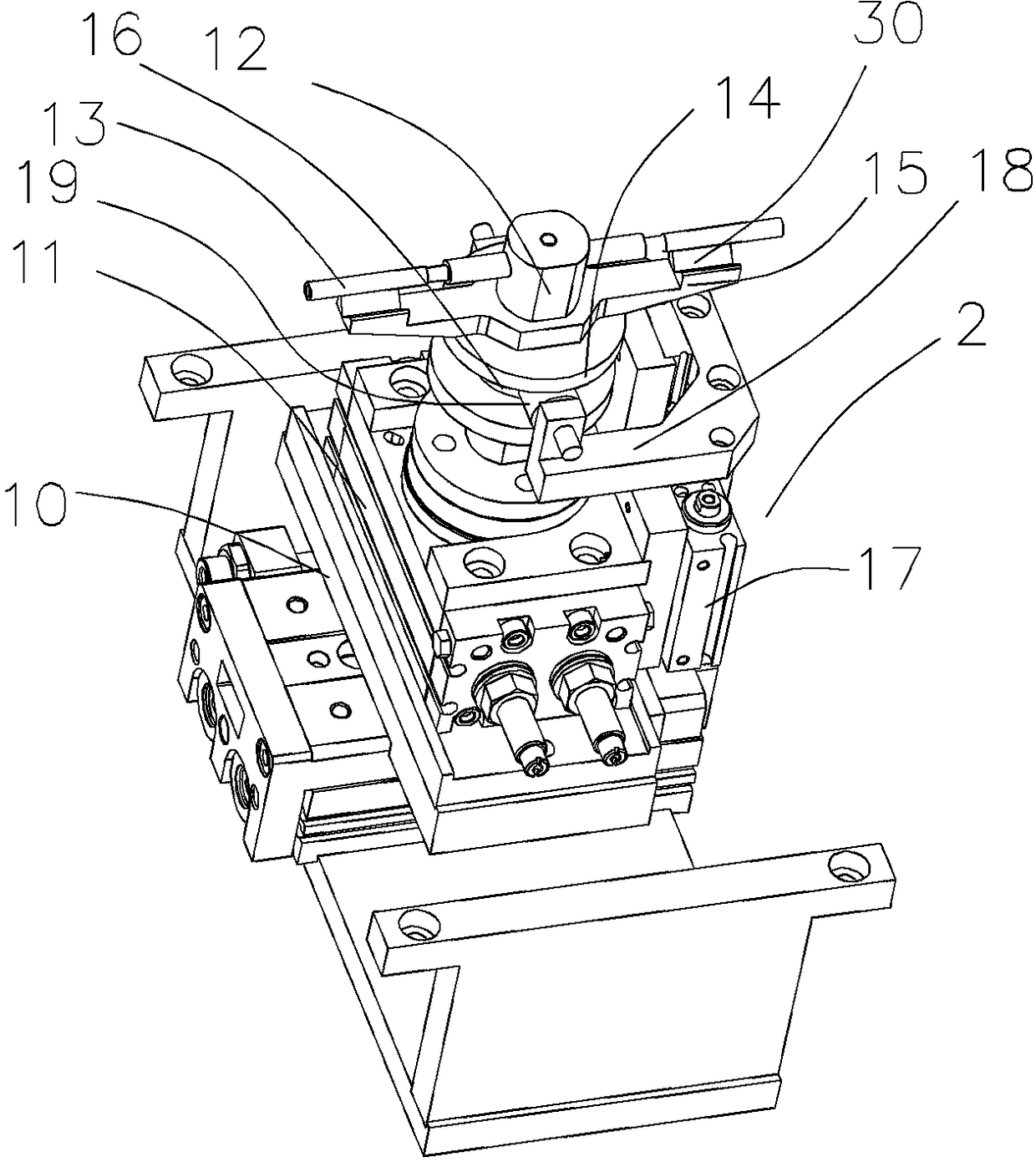

Number marking and number tube penetrating mechanism of double-pressing double-penetrating cable marker

PendingCN109301661AClear codeGood socket stabilityLine/current collector detailsEngineeringTube number

The invention relates to a number marking and number tube penetrating mechanism of a double-pressing double-penetrating cable marker. The number marking and number tube penetrating mechanism comprisesa number tube cutting and number marking device, a number tube moving device and a number tube dialing device; the number tube cutting and number marking device comprises a number tube conveying channel and a number tube conveying wheel providing forwarding power for the number tube, a number tube number marking head, a number tube cutter and a number tube cutter driver for driving the number tube cutter to cut a number tube are arranged in front of the number tube conveying channel, and a band supply system for providing a thermal transfer color band for the number tube number marking head is arranged beside the number tube number marking head. The mechanism has the advantages that (1) a thermal transfer number coding manner is used in the whole mechanism, numbers on the number tubes areclear, and the mechanism is suitable for printing of different types of number tubes; and 2) the number tube sleeves on a cable in an exquisite way, the number tube sleeving stability is high, and the speed is high.

Owner:HONGSHENG MACHINERY EQUIP

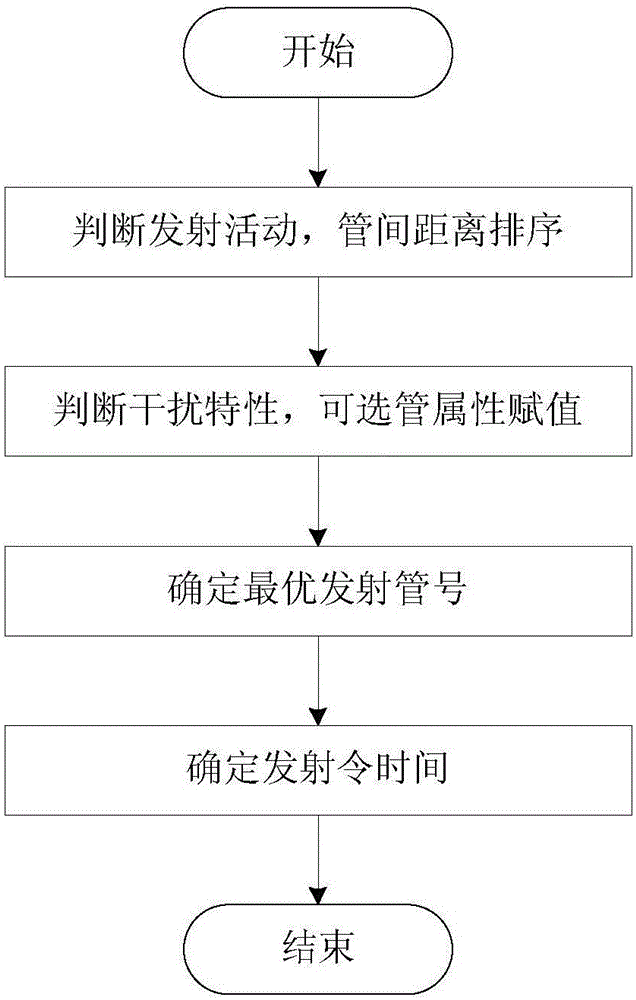

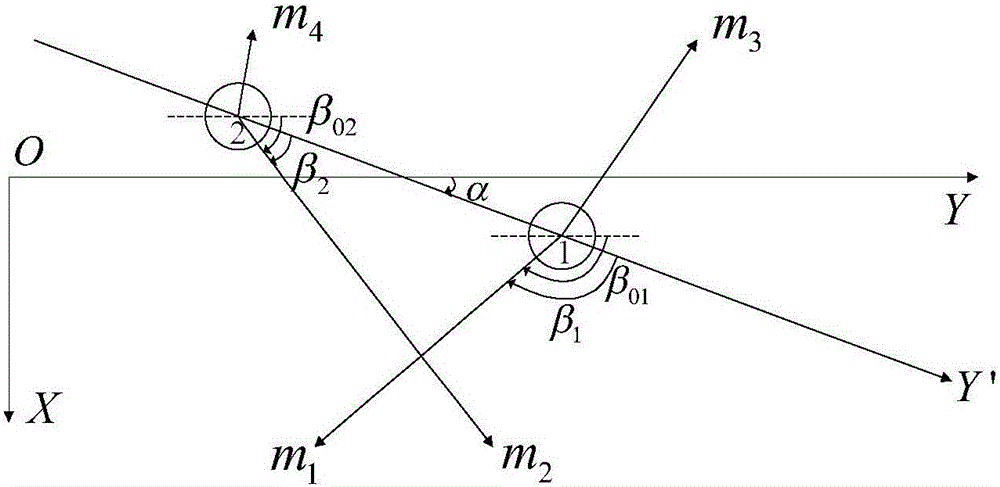

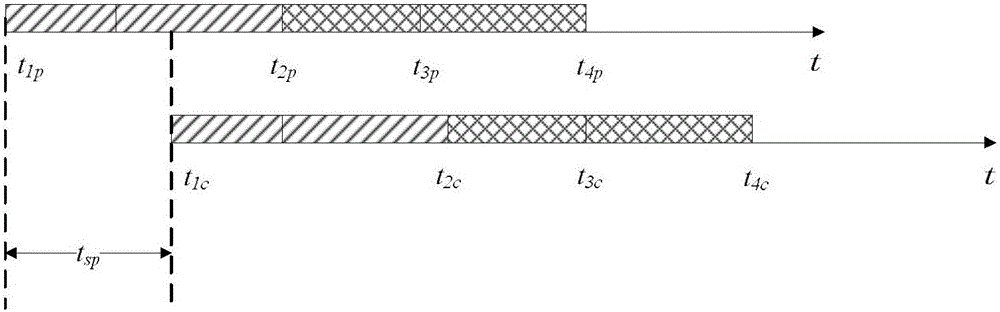

Security control method for multi-tube emission system

InactiveCN106019989AShort interval between launchesIncrease firing rateProgramme control in sequence/logic controllersEngineeringMaster controller

The invention designs a security control method for a multi-tube emission system. The method comprises: whether an emission activity occurs currently is determined; if not, a master controller of a multi-tube emission system selects a tube randomly and sends a tube number and an emission instruction to an emission controller; if so, the master controller of the multi-tube emission system calculates distances between an emission tube and all selectable tubes and sorts the distances in a descending order; interference characteristics between the emission tube and all selectable tubes are determined, attribute assignment is carried out on all selectable tubes based on the interference characteristics, and the master controller of the multi-tube emission system determines an optimal emission tube pipe according to a certain tube selection strategy; and the master controller of the multi-tube emission system determines emission order time of the selected tube numbers based on the differences of the interference characteristics and transmits the optimal emission tube number and the emission order time data to the emission controller. According to the invention, the emission rate of the system can be increased to the greatest extent and the system is also suitable for various launchers automatically.

Owner:NAVAL UNIV OF ENG PLA

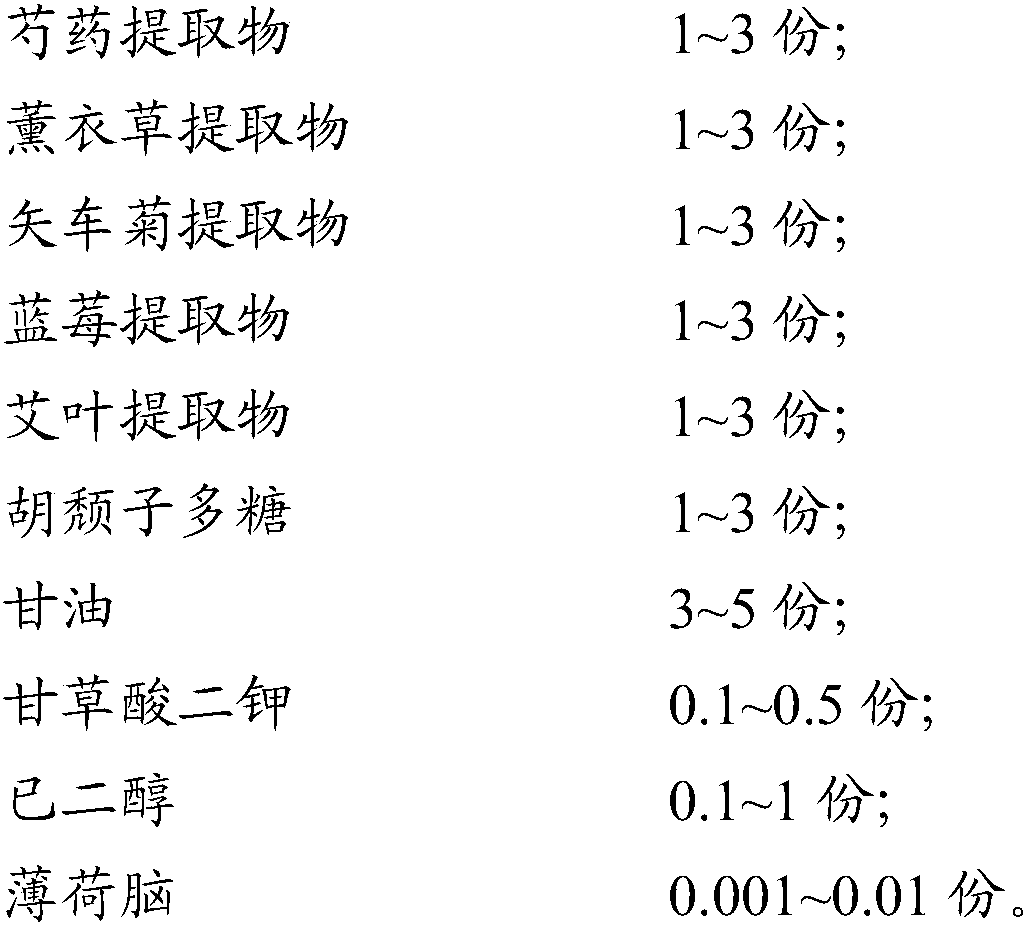

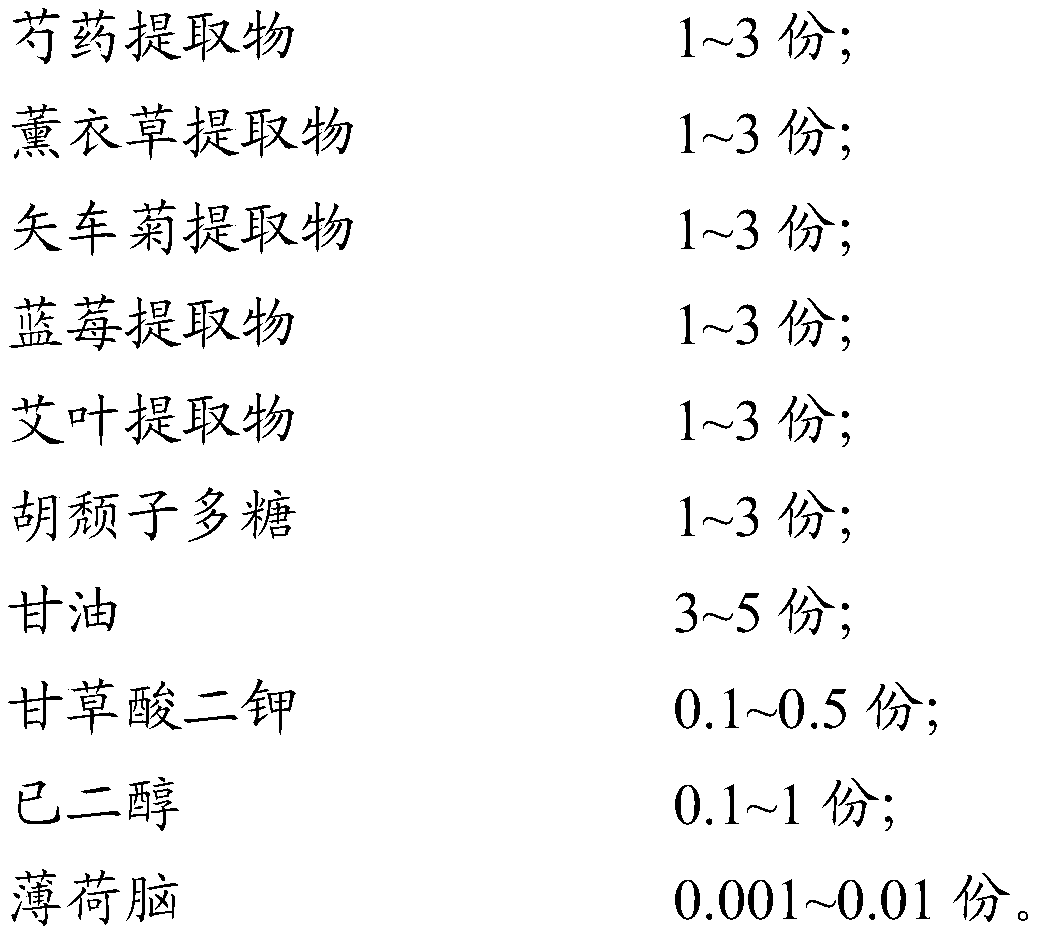

Composition and application of composition to preparing fatigue relieving cosmetics

ActiveCN108379169ASuppress generationImprove microcirculationCosmetic preparationsToilet preparationsMedicineTyrosinase

The invention relates to the technical field of cosmetics, in particular to a composition and application of the composition to preparing fatigue relieving cosmetics. The composition and the application have the advantages that extract components of diversified plants are compounded with one another to form the composition, accordingly, generation of tyrosinase can be obviously inhibited by the formed composition, microcirculation can be improved, and excellent anti-oxidation effects can be realized by the composition; as shown by detection, the tube numbers and the blood flow and velocities of human subjects can be obviously changed after the cosmetics prepared from the composition are used, various indexes can be effectively improved, the tube numbers can be increased, the input / output branch tube diameters, top diameters and tube lengths can be increased, and the blood velocities can be obviously increased; the sharpness of tubes can be improved along with prolonging of the eye maskclinging time of the human subjects, blood colors can be darkened, the input / output branch tube diameters can be expanded, and the microcirculation of the human subjects can be improved to a certainextent.

Owner:INFINITUS (CHINA) CO LTD

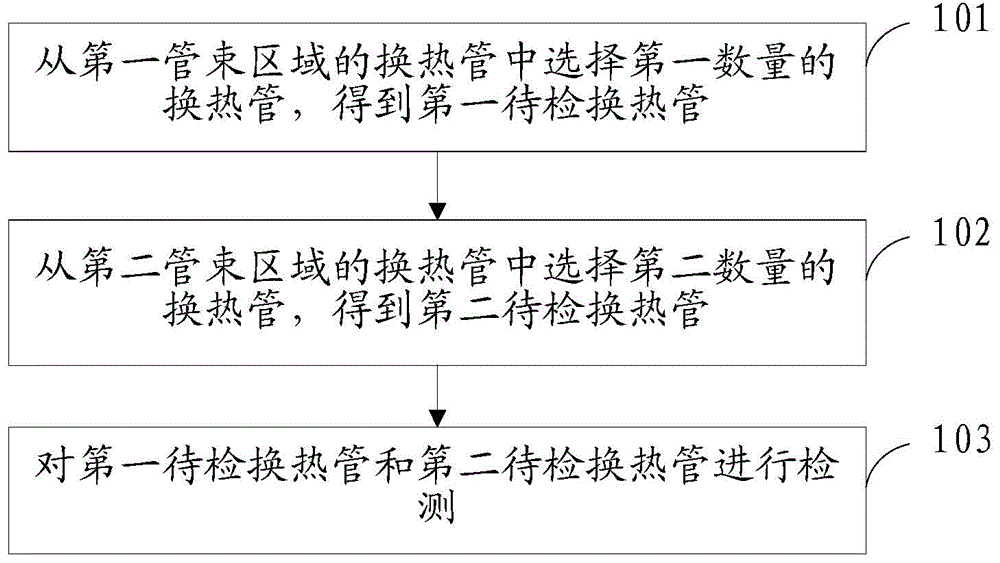

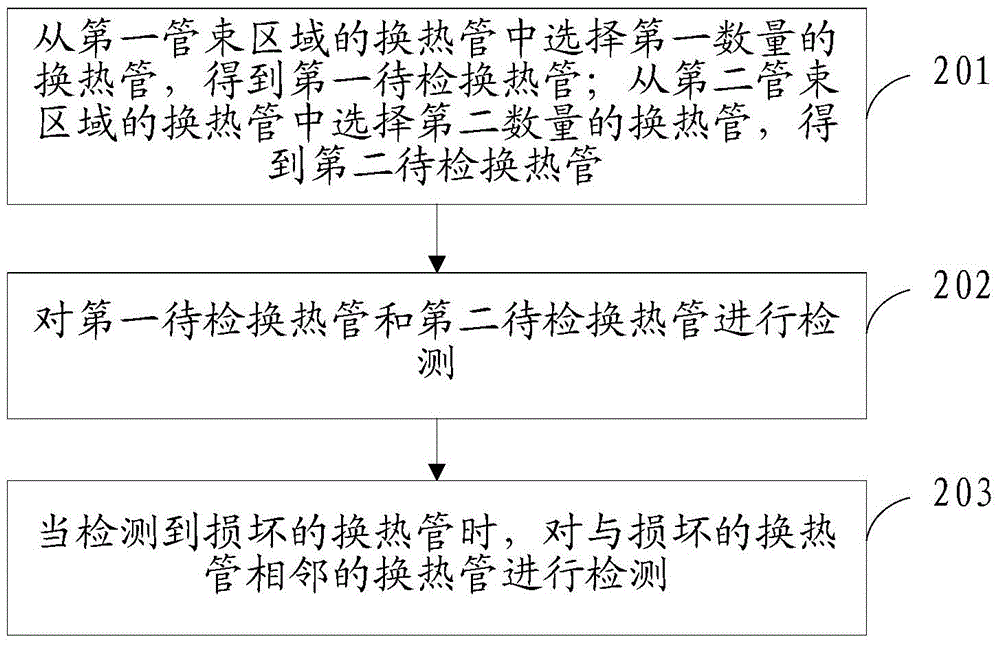

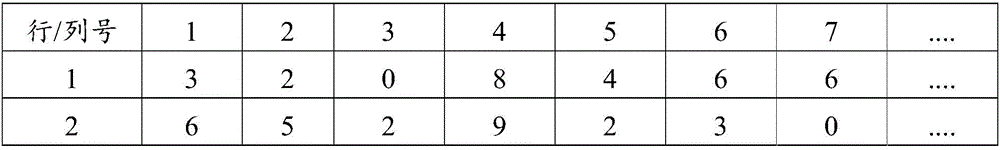

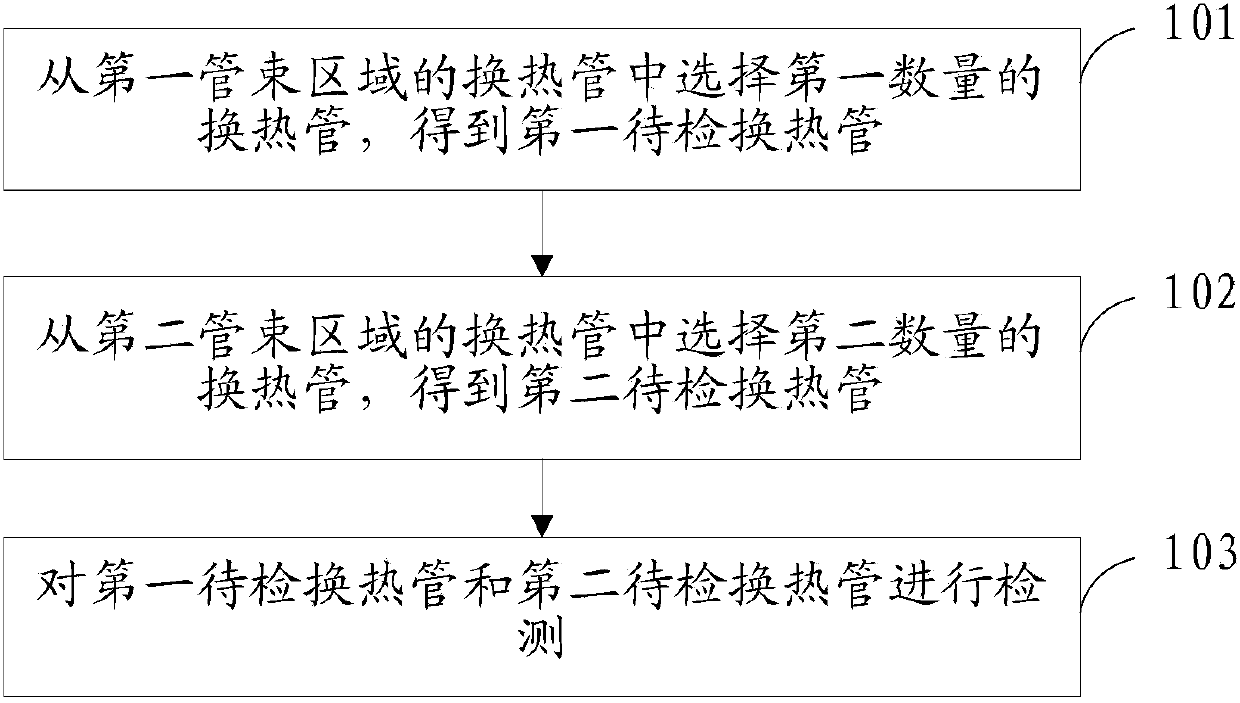

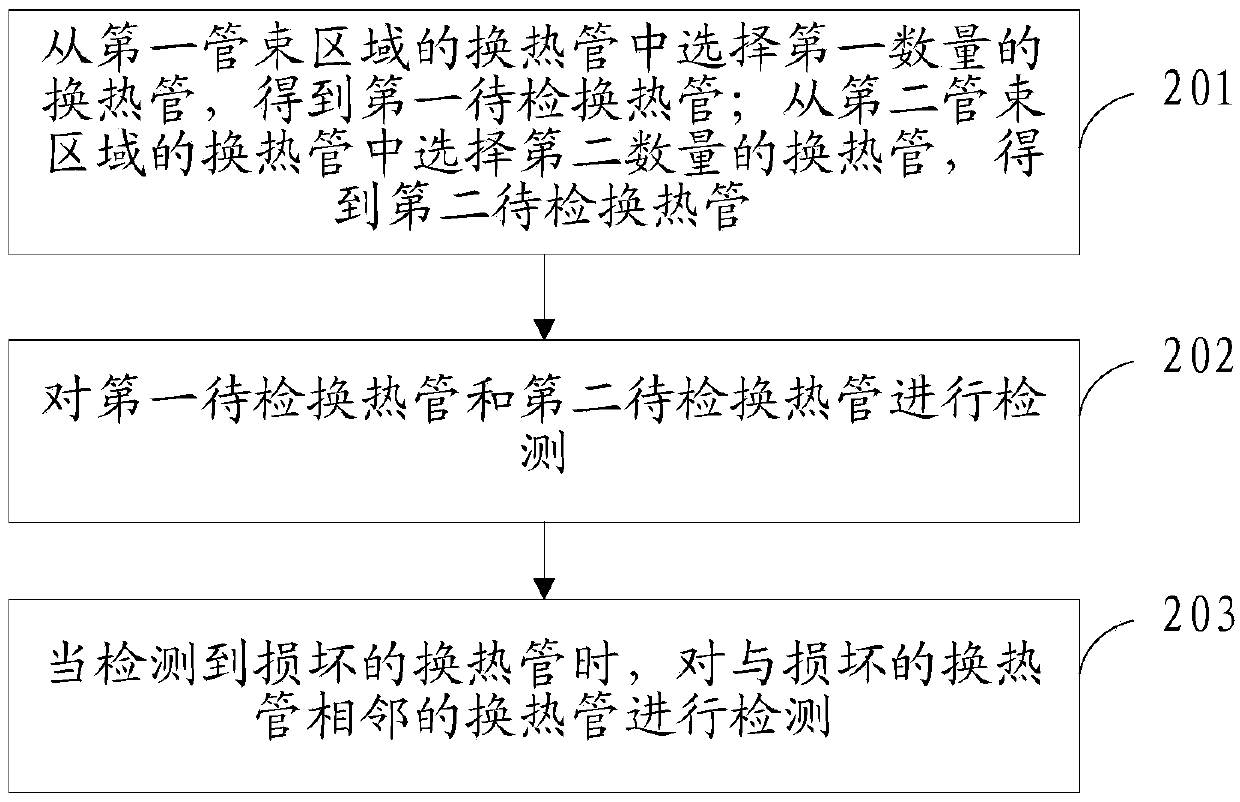

A detection method of heat exchanger tube bundle

ActiveCN103743813BReduce the sampling ratioThe damage is realMaterial magnetic variablesEngineeringTube number

The invention discloses a detection method for a heat exchanger tube bundle, which belongs to the field of heat exchanger detection. The method includes: selecting a first number of heat exchange tubes from the heat exchange tubes in the first tube bundle area to obtain the first heat exchange tubes to be inspected, and the heat exchange tubes in the first tube bundle area include at least the outermost two turns of the heat exchanger. Heat pipe; select a second number of heat exchange tubes from the heat exchange tubes in the second tube bundle area to obtain a second heat exchange tube to be checked, and the second tube bundle area is the area of the heat exchanger tube bundle area other than the first tube bundle area Area; detect the first heat exchange tube to be inspected and the second heat exchange tube to be inspected; the ratio of the sum of the first number and the second number to the total number of tubes of the heat exchanger is a predetermined value, and the predetermined value is less than 1 Positive number; the ratio of the first number to the number of heat exchange tubes in the first tube bundle area is the first ratio, the second number to the number of heat exchange tubes in the second tube bundle area is the second ratio, and the ratio of the first ratio to the second ratio is the set value, and the set value is a positive number greater than 1. The detection result of the present invention is true.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

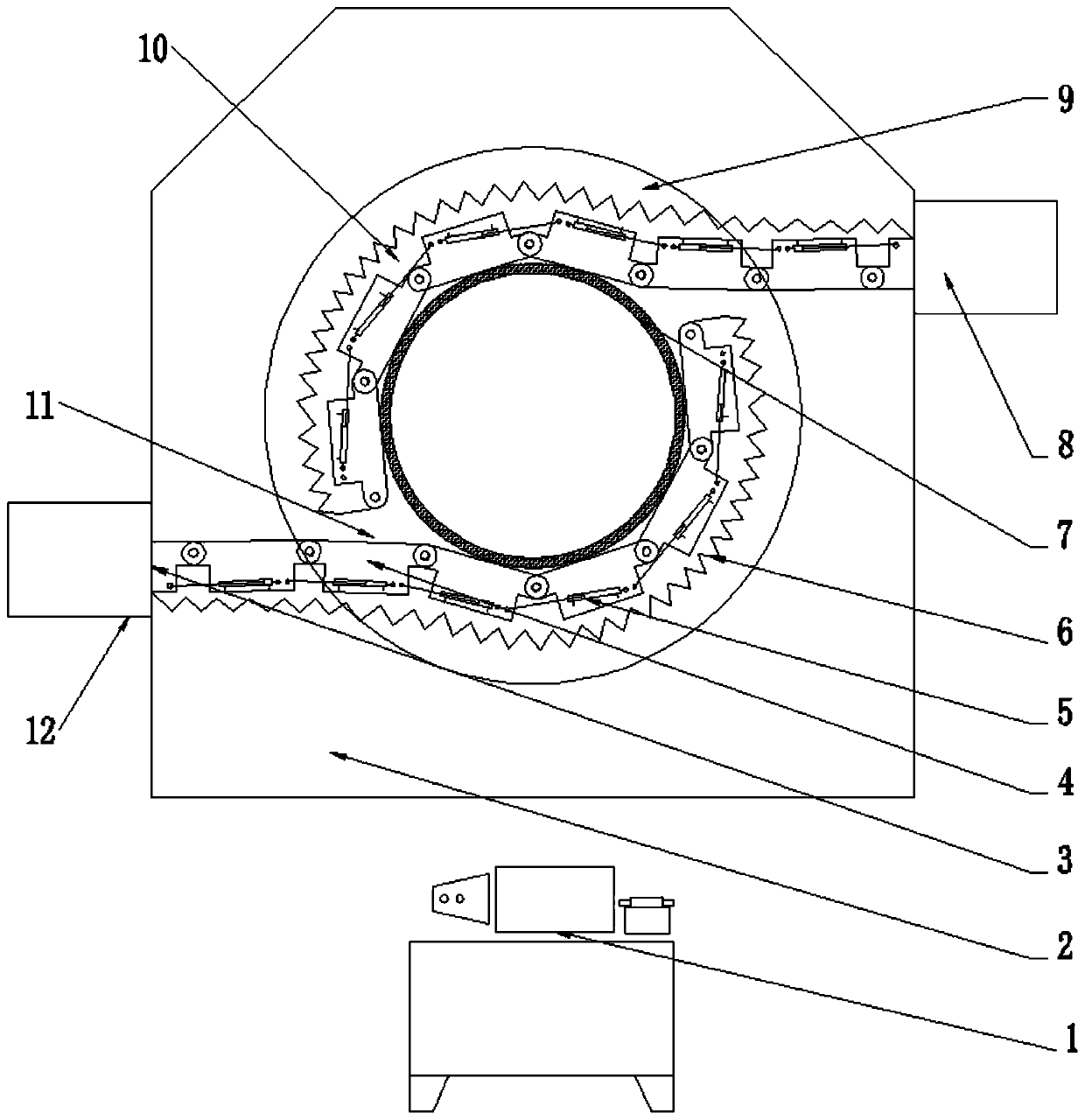

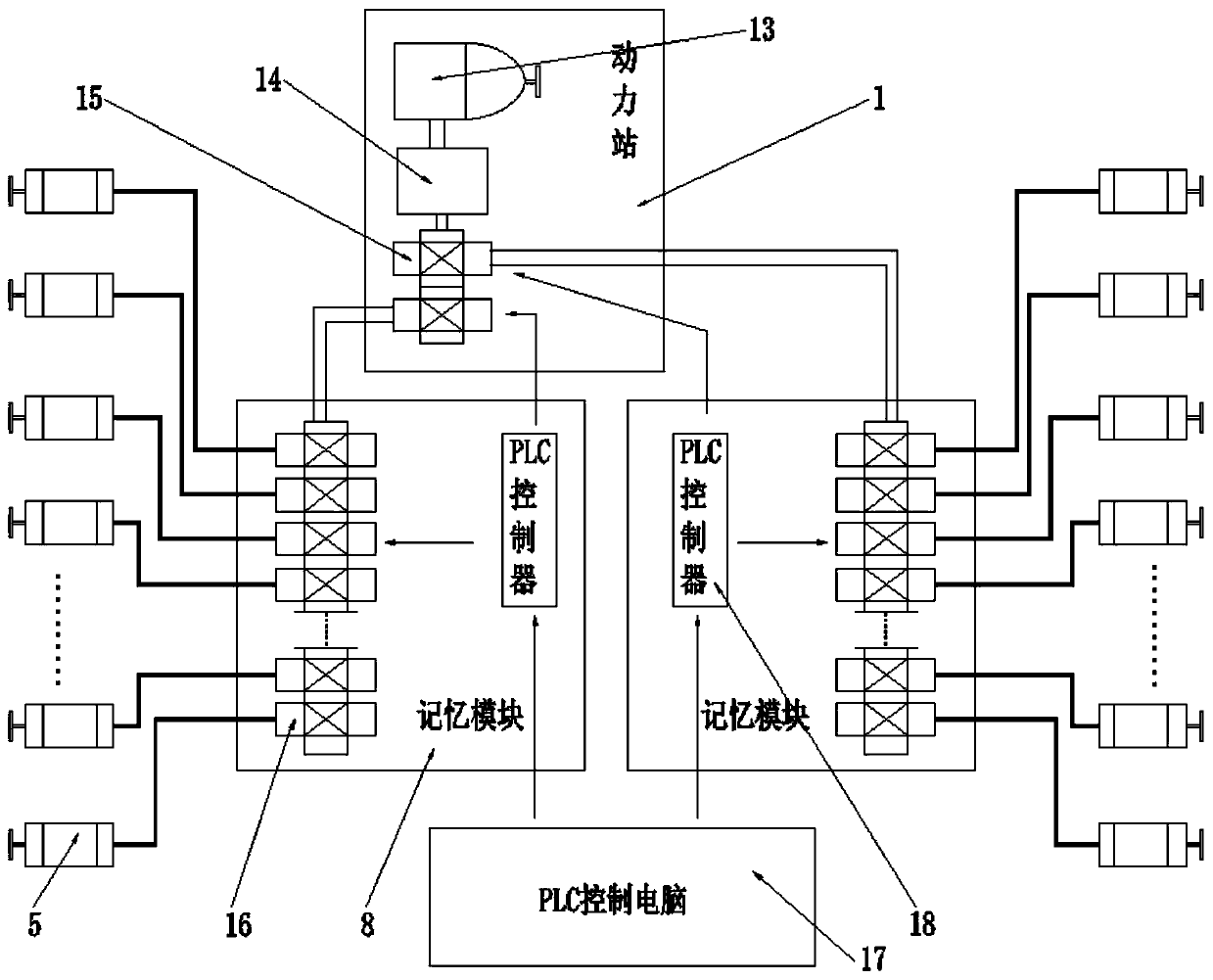

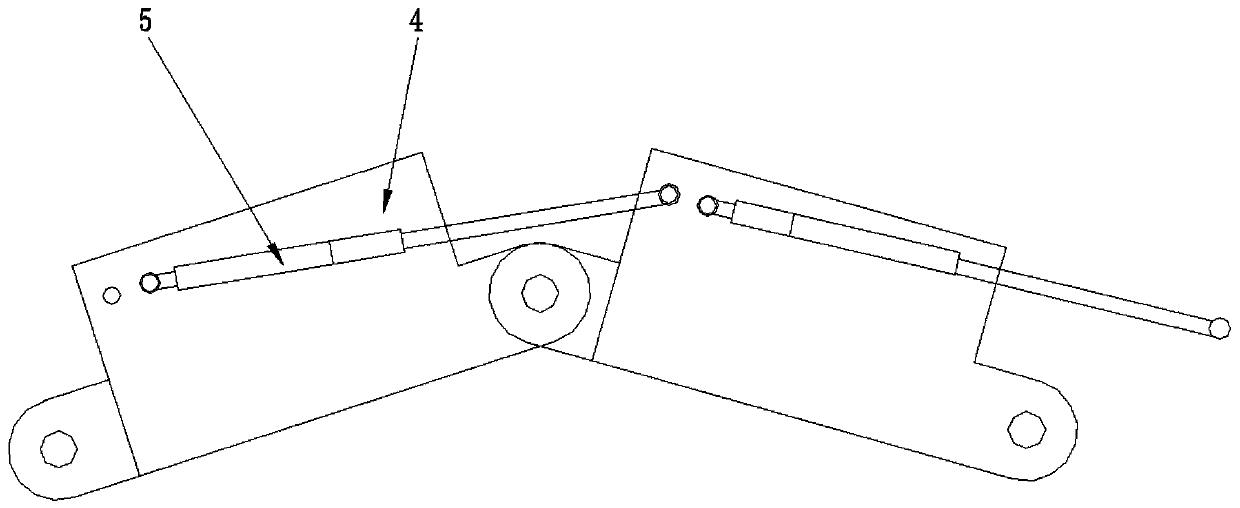

Flexible mechanical arm holding device

InactiveCN110039564AImprove the blessing effectSolve the problem of manually adjusting the Harbin Fu mechanismGripping headsMetal working apparatusPower stationRobotic arm

The invention discloses a flexible mechanical arm holding device. The holding device comprises a power station, a fixed wallboard, a first memory module, a first flexible arm structure, a second flexible arm structure and a second memory module, wherein the power station is arranged below the fixed wallboard, flexible joints are hinged to the inner part of a flexible arm fixing seat, the first memory module is fixed on the right side of the fixed wallboard, a pipe hole is formed in the fixed wallboard, and a holding pipe is arranged in the pipe hole; the inner section of the power station comprises an oil pump, a second linkage rod filter and a total electromagnetic valve set, and the total electromagnetic valve set is connected with an oil cylinder electromagnetic valve set inside the first memory module through a pipeline. According to the flexible mechanical arm holding device, when a pipe diameter needs to be replaced, only a corresponding tube number or memory symbol needs to be input on a computer, an articulated type octopus arm can be adjusted to a corresponding tube diameter, and the problem of manually adjusting a half mechanism when changing the pipe diameter of the heatpreservation pipe is solved.

Owner:青岛巨天机械有限公司

Efficient gas dissolving pipe

InactiveCN107304073AGood effectImprove efficiencyWater/sewage treatment by flotationMelting tankEngineering

The invention discloses a high-efficiency gas-dissolving pipe, which comprises an air-dissolving pipe and an air control cabinet. The air-dissolving pipe is horizontally arranged above the air-control cabinet. Both ends of the air-dissolving pipe are respectively sealed by flanges. Water inlet, the bottom of the other end is provided with a water outlet, the inner bottom of the dissolved gas pipe is provided with a pipe frame, the pipe frame is vertically provided with several uniformly arranged air distribution pipes, and several air outlet holes are uniformly arranged on the air distribution pipe, so An air control device is provided in the air control cabinet, and the air control device is connected to each air distribution pipe through a pipeline. A spray head is provided on the top of the air-dissolving pipe, and a spray pipe is connected to the spray head. One end of the spray pipe is connected to the spray pipe. The tube is connected, and the other end is connected with a nebulizer. The air-dissolving water of the present invention has good effect, simple debugging, convenient operation and maintenance, can replace the traditional pressure-dissolving air tank, improves the processing capacity by more than 30%, greatly improves the efficiency and effect of the dissolved air water, and has a good external Dust removal effect.

Owner:戴祖清

Detection method for heat exchanger tube bundle

ActiveCN103743813AReduce the sampling ratioThe damage is realMaterial magnetic variablesEngineeringTube number

The invention discloses a detection method for a heat exchanger tube bundle, and belongs to the field of heat exchanger detection. The method comprises the following steps: selecting a first number of heat exchange tubes from heat exchange tubes in a first tube bundle area to obtain first heat exchange tubes to be detected, wherein the first heat exchange tubes in the first tube bundle area at least comprise the outmost two circles of heat exchange tubes of a heat exchanger; selecting a second number of heat exchange tubes from heat exchange tubes in a second tube bundle area to obtain second heat exchange tubes to be detected, wherein the second heat exchange area is the area except for the first tube bundle area; detecting the first heat exchange tubes to be detected and the second heat exchange tubes to be detected, wherein the ratio of the summation of the first number and the second number to the total tube number of the heat exchanger is a preset value I, and the preset value Iis a positive number smaller than 1, the ratio of the first number to the number of the heat exchange tubes in the first tube bundle area is a first ratio, the ratio of the second number to the number of the heat exchange tubes in the second tube bundle area is a second ratio, the ratio of the first ratio to the second ratio is a preset value II, the preset value II is a positive number greater than 1. The detection result of the detection method is true.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A design method of dish solar Stirling heat engine tube cluster heat absorber

ActiveCN107131073BImprove reliabilityImprove maintainabilityGeometric CADFrom solar energyMaintainabilityDiameter ratio

Owner:HUNAN UNIV OF SCI & TECH

A composition and its application in the preparation of cosmetics for relieving fatigue

ActiveCN108379169BSuppress generationImprove microcirculationCosmetic preparationsToilet preparationsMedicineTyrosinase

The invention relates to the technical field of cosmetics, in particular to a composition and application of the composition to preparing fatigue relieving cosmetics. The composition and the application have the advantages that extract components of diversified plants are compounded with one another to form the composition, accordingly, generation of tyrosinase can be obviously inhibited by the formed composition, microcirculation can be improved, and excellent anti-oxidation effects can be realized by the composition; as shown by detection, the tube numbers and the blood flow and velocities of human subjects can be obviously changed after the cosmetics prepared from the composition are used, various indexes can be effectively improved, the tube numbers can be increased, the input / output branch tube diameters, top diameters and tube lengths can be increased, and the blood velocities can be obviously increased; the sharpness of tubes can be improved along with prolonging of the eye maskclinging time of the human subjects, blood colors can be darkened, the input / output branch tube diameters can be expanded, and the microcirculation of the human subjects can be improved to a certainextent.

Owner:INFINITUS (CHINA) CO LTD

Ductile iron pipe with two-dimensional code pipe number pattern, spraying system and production method

ActiveCN104948847BPrecise deliveryImprove the level ofElongated constructional elementsTypewritersRead throughEngineering

The invention discloses a nodular cast iron pipe with a two-dimension code pipe number pattern, a spraying system and a production method. The method comprises the following steps that a nodular cast iron pipe body is moved to a code spraying station to wait for being sprayed; a control system is operated to control mechanisms on a cross sliding table and framework to move, a two-dimension code spray printing machine is moved to the pipe number spraying position along a horizontal sliding table, the vertical position of the two-dimension code spray printing machine is adjusted, the spraying distance is made to be proper, then automatically increased pipe numbers are sprayed, and finally spraying control software in the two-dimension code spray printing machine controls the two-dimension code spray printing machine to spray the automatically generated two-dimension code pattern to the outer surface of the nodular cast iron pipe body; the two-dimension code pipe number information is read through a two-dimension code reading device and is transmitted to a nodular cast iron pipe quality information management database to be stored. The outer wall of the nodular cast iron pipe is coated with the two-dimension code pipe number pattern, so that the requirement for automatically collecting the pipe numbers by a computer is met, and the quality management and control level of the nodular cast iron pipe is improved.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com