Number marking and number tube penetrating mechanism of double-pressing double-penetrating cable marker

A technology of number tube and docking, which is applied in the field of turning and bending mechanism, which can solve the inconvenience and other problems, and achieve the effect of fast speed, clear characters and good socket stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

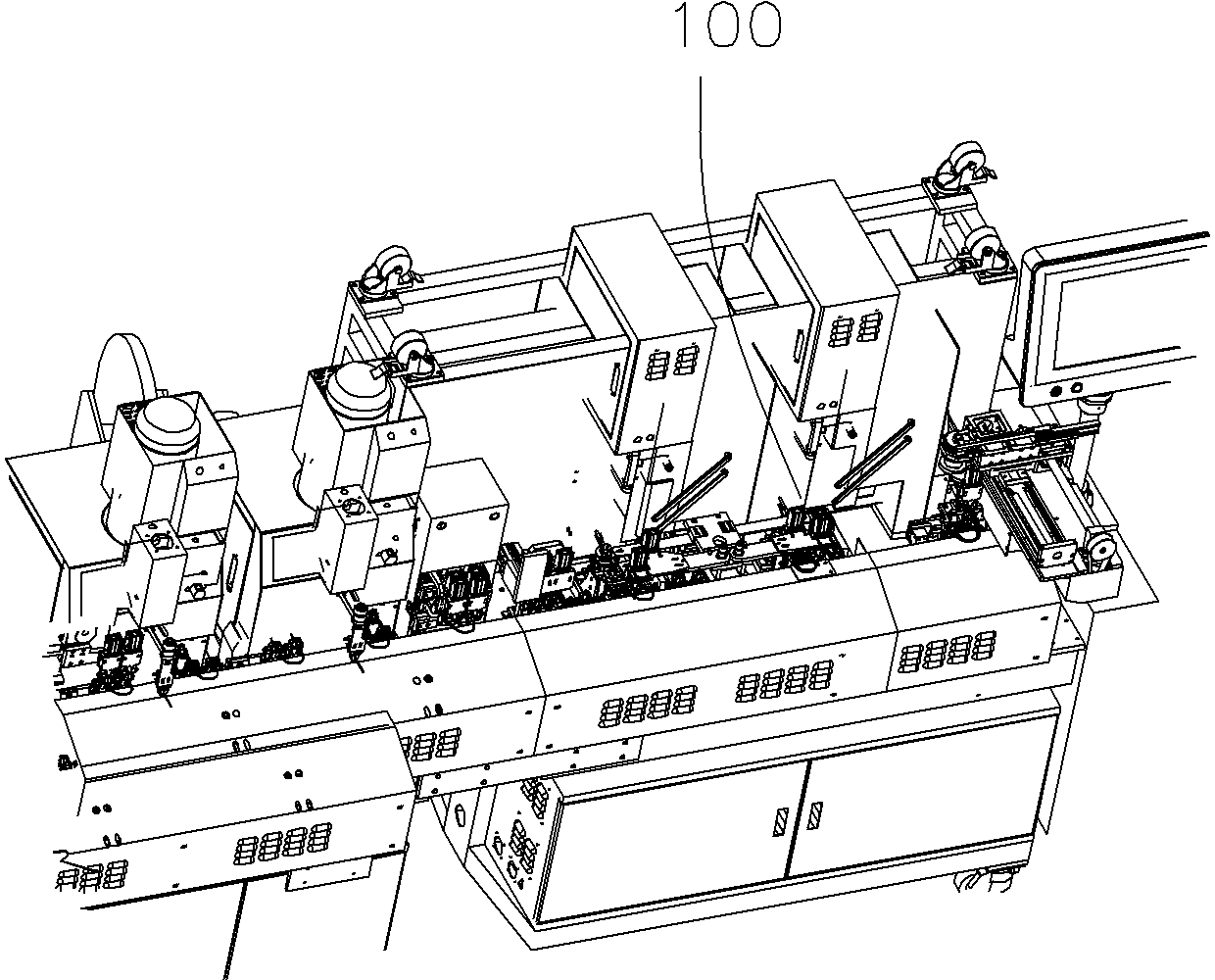

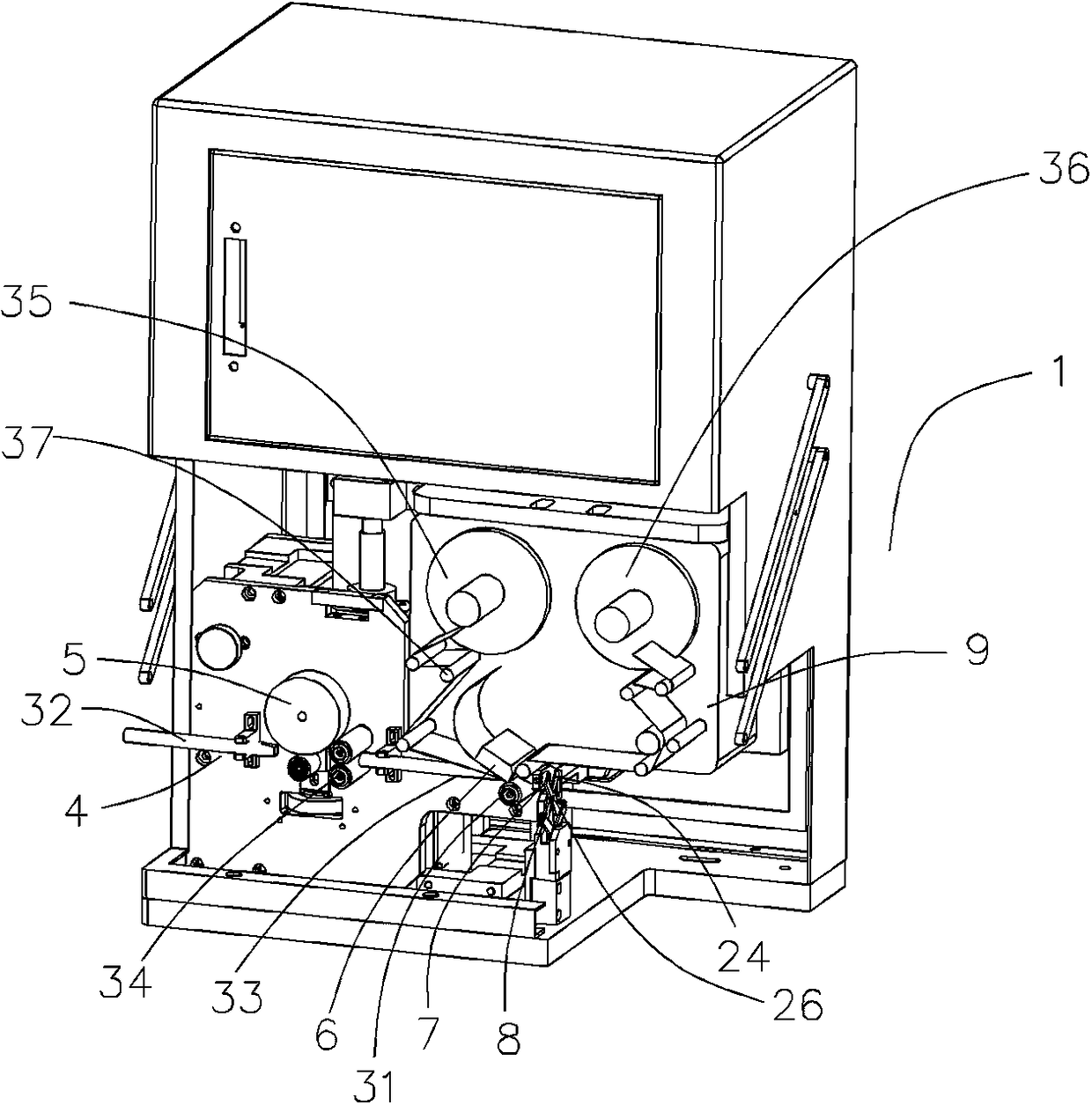

[0024] combined with Figures 1 to 4 , a double-pressure double-piercing number tube machine for coding and number tube threading mechanism 100, comprising a number tube cutting and coding device 1, a number tube transfer device 2, and a number tube toggle device 3;

[0025] The number tube cutting and coding device 1 includes a number tube conveying path 4 and a number tube conveying wheel 5 that gives the number tube forward power. 7 and the number tube cutter drive device 8 for driving the number tube cutter 7 to cut the number tube; the number tube punching pier 6 is provided with a belt supply system 9 for providing the number tube punching pier 6 with a thermal transfer ribbon. ;

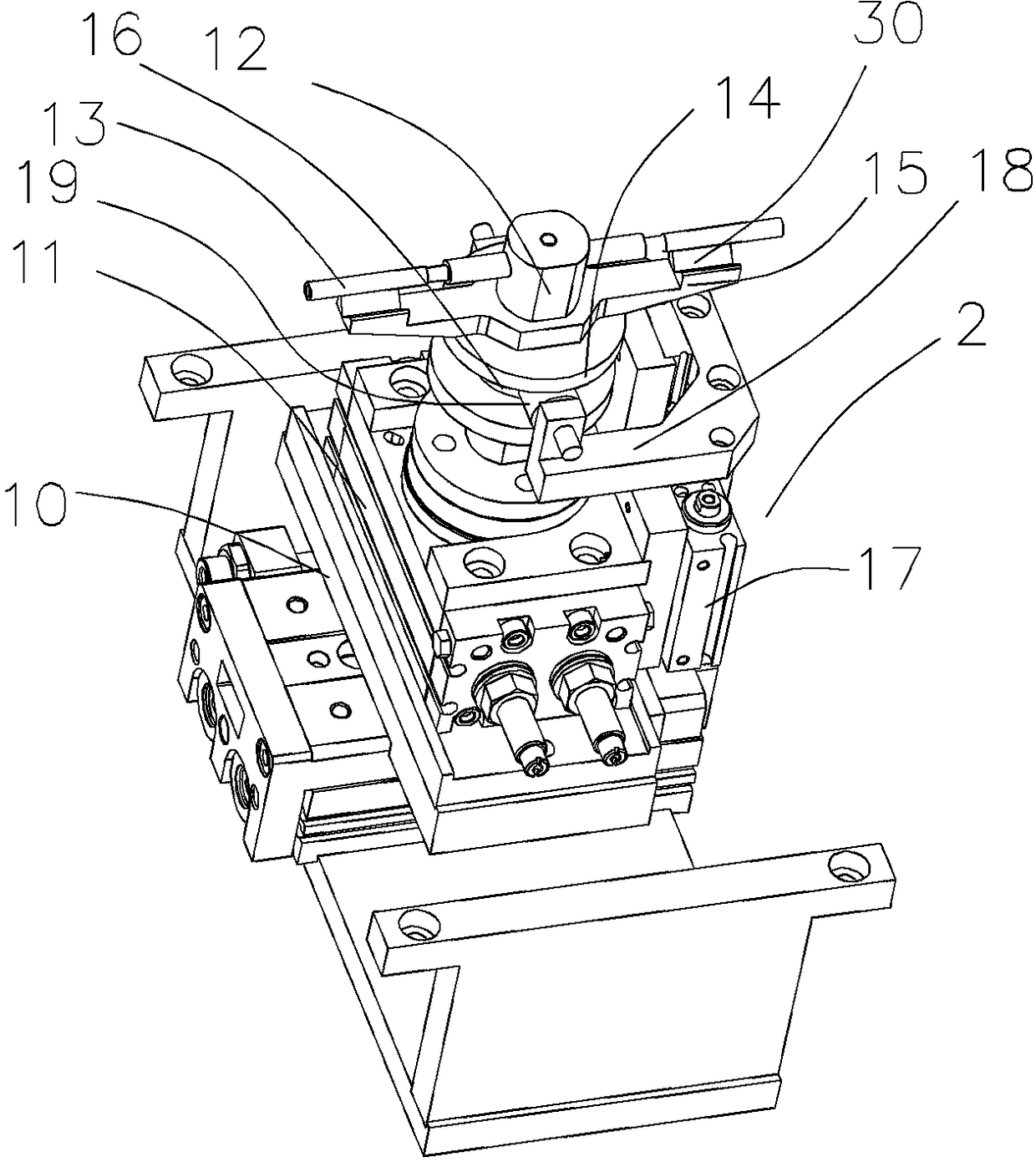

[0026] The number tube transfer device 2 includes a horizontal displacement table 10 driven by a cylinder, a rotary cylinder 11 is arranged on the horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com