Calculation method for parameter design of inverted-triangle rotor engine

A rotary engine and parameter design technology, applied in combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of shortening the research and development cycle, complex and complicated theories of rotor and cylinder profile creation, and saving design time. , simplified math expressions, powerful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

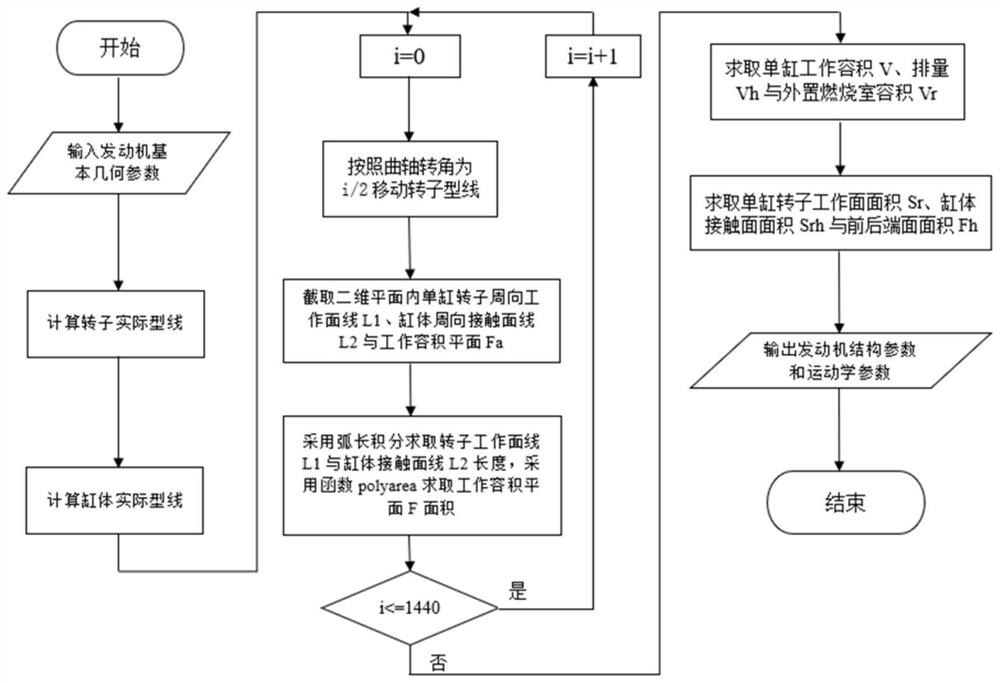

Method used

Image

Examples

Embodiment 1

[0094] Such as figure 2As shown, a calculation method for parameter design of an inverse triangular rotor engine. After the calculation module is loaded, it can be switched in the tabs at the top of the form. The tabs include the geometric data of the rotor engine, the solution of the cylinder translation equation, the intake and exhaust phase Translation distance and program instructions to meet different computing needs. After inputting the basic parameters, the graph will be drawn in a newly opened window, and the resulting parameters will be displayed in a dialog box.

[0095] Such as image 3 As shown, enter the basic parameters of the rotor engine in the value box of the geometric data tab of the rotor engine in sequence e=12mm, creation radius R=76mm, cylinder thickness B=50mm, translational distance a=1.45mm, rotor cylinder After the distance Δ=0.3mm, the actual compression ratio ε=11 and the rated engine speed n=7000rpm, calculate and draw. Drawn curves such as cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com