Application of novel aluminum profile in direct type backlight

An aluminum profile, straight-down technology, applied in optics, nonlinear optics, instruments, etc., can solve the problem of inability to prevent fool-proof positioning, achieve good socket stability, convenient and fast fool-proof installation and positioning, and reduce processing procedures and costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

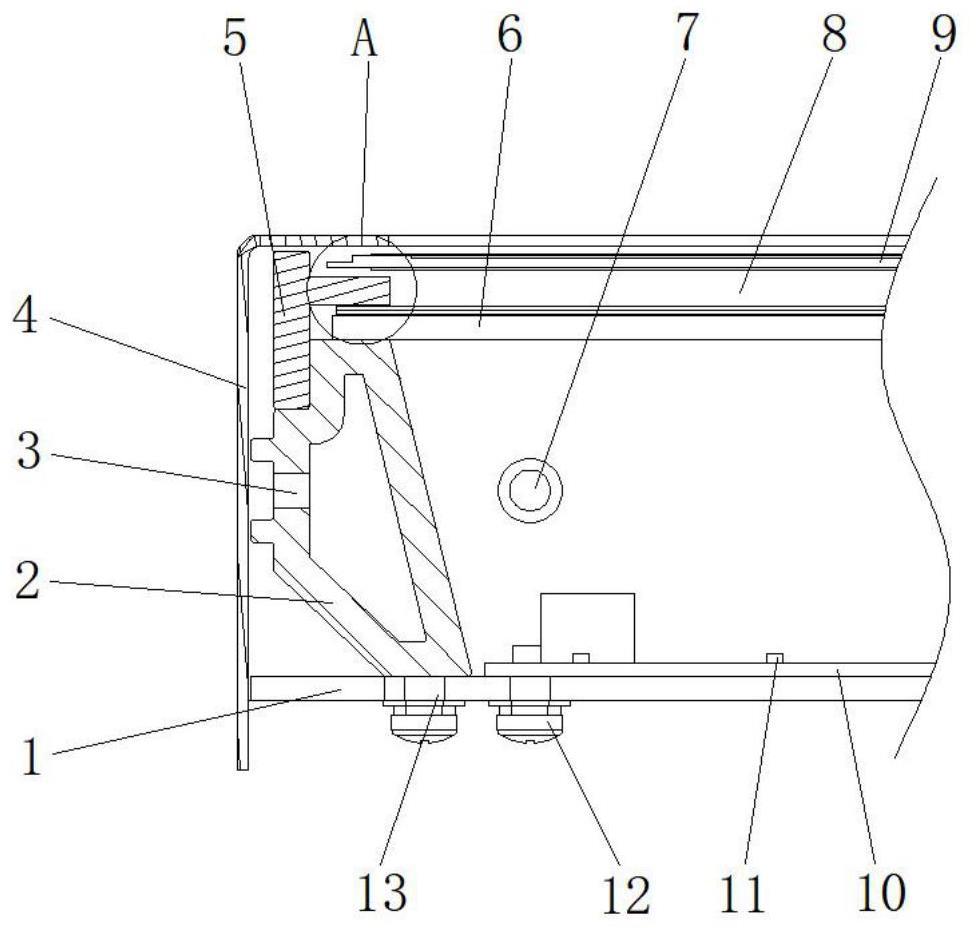

[0026] Example 1: See Figure 1-6 , an application of a new type of aluminum profile in a direct-lit backlight, including a base plate 1, a front frame 4 is provided at one end of the base plate 1, a lamp panel 10 is provided on one side of the top of the base plate 1, and a light panel 10 is provided on one end of the front frame 4. The light-mixing middle frame 2 is provided with a counterbore 7 on one side of the inner rear end of the front frame 4, and the top of the inner side of the front frame 4 is provided with a bearing middle frame 5, and the top of the inner rear end of the front frame 4 is fixedly connected with an optical part 6 and a lamp The two ends of the top of the board 10 are fixedly connected with positioning and fixing blocks 11, and the positioning and fixing blocks 11 are respectively arranged at equal intervals at both ends of the top of the lamp board 10, and the top of one end inside the front frame 4 is fixedly connected with OC9, OC9 and optical par...

Embodiment 2

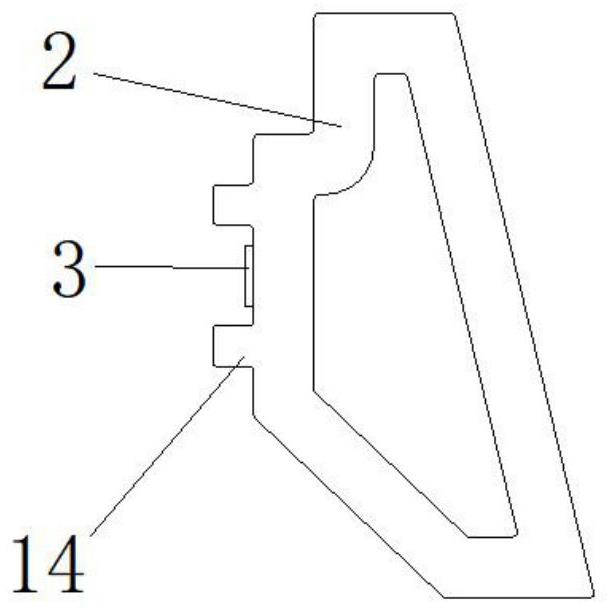

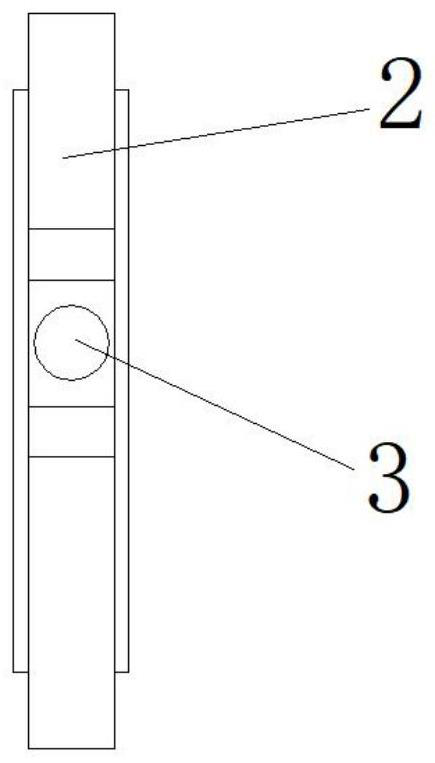

[0029] Embodiment 2: The light-mixing middle frame 2 is hollow, the bottom of one side of the light-mixing middle frame 2 is inclined, and the inclination angle of the slope is 45°, and the bearing middle frame 5 is in the shape of a "T";

[0030] Specifically, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, and the "T"-shaped side is plugged into the socket groove 8 provided between the OC9 and the optical part 6, and the OC9 is carried by the bearing middle frame 5, and then the polygonal mixed The light middle frame 2 is sleeved on one side of the front frame 4 from top to bottom, and the two ends of one side of the light mixing middle frame 2 are respectively provided with step blocks 14 and the bottom of one side of the light mixing middle frame 2 is inclined at 45° It can be perfectly nested under the carrying middle frame 5 inside the front frame 4, so as to achieve the purpose of conveniently and quickly inserting the carrying middle frame 5 and the ...

Embodiment 3

[0031] Embodiment 3: One side of the bottom plate 1 is respectively provided with socket holes 13, and the inside of the socket holes 13 are respectively pierced with pressure riveting studs 12;

[0032] Specifically, such as figure 1 and Figure 5 As shown, in the process of processing the bottom plate 1, two sets of socket holes 13 are set on one side of the interior, and the diameter of the socket holes 13 is 4.5 mm, and the processing of the socket holes 13 inside the bottom plate 1 does not require Further machining the threaded holes reduces the man-hours for processing the workpiece, and the installation and fixation of the aluminum profile parts through the riveting stud 12 and the sleeve hole 13 can effectively reduce the processing when the parts are processed and manufactured The process greatly shortens the processing time and effectively reduces its production cost, making the production cost of the optical component parts of the aluminum profile used in the back...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com