Method for intelligently tracking tube numbers in circulating process of steel tube production line

An intelligent tracking, steel pipe technology, applied in data processing applications, electromagnetic radiation induction, resources, etc., can solve the problems of cumbersome, multi-time and labor, and achieve the effect of improving efficiency and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

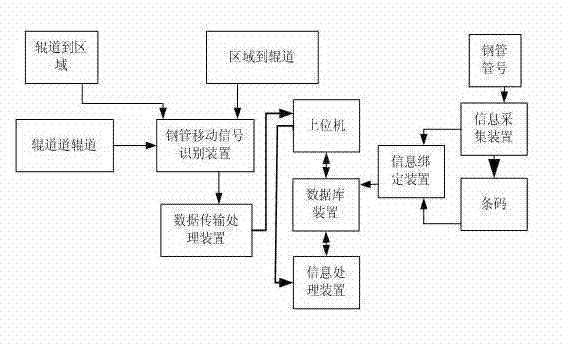

[0015] Such as figure 1 As shown, before the steel pipe enters the identification area, read the pipe number and print the barcode, and paste the barcode on the steel pipe to facilitate future calibration; install sensors at the entry and exit positions of the roller table and the area to detect that the steel pipe is in the production area The flow, the signal of the moving tracking sensor, the judgment of the steel pipe from the roller table to the roller table, from the roller table to the area, from the area to the roller table, etc., are processed through the corresponding queue in the database, and adjusted in the host computer in real time show.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com