Method for automatically identifying print data for wire tube marking machine

A technology for automatic identification and printing of data, which is applied in the field of marking machines, can solve problems such as inability to realize automatic batch printing, inability to correspond to wire harness cutting processes, and error-prone, etc., to achieve automatic mass production of multi-variety printing wire tube numbers , Reduce the effect of fixed asset investment and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

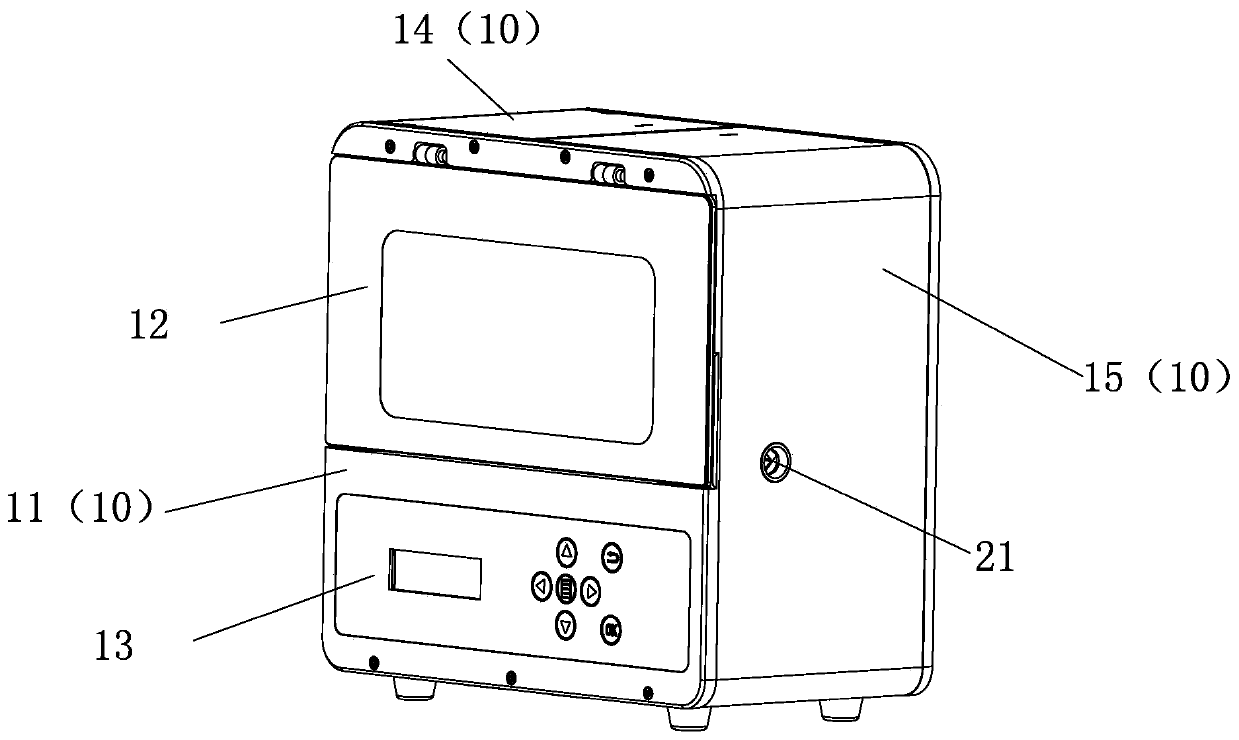

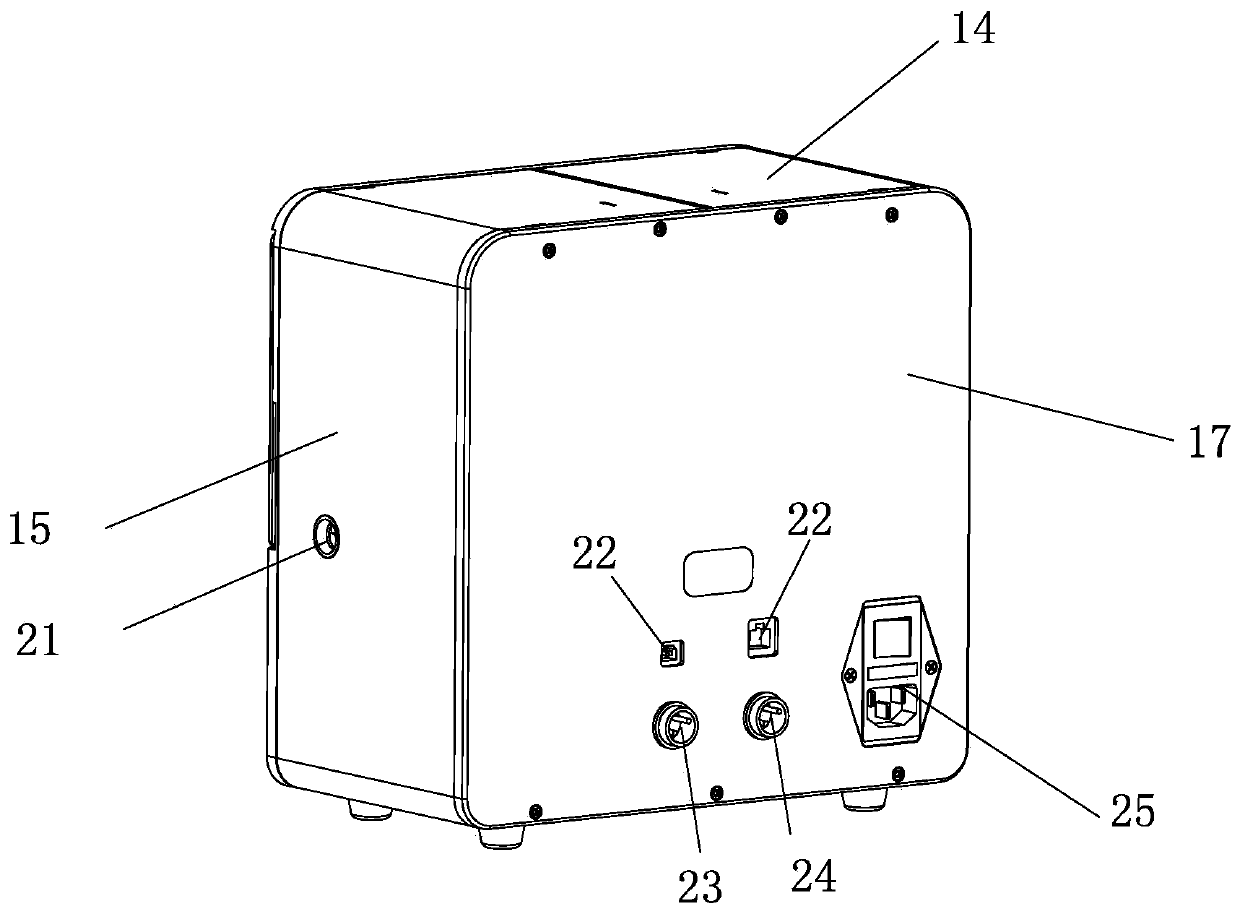

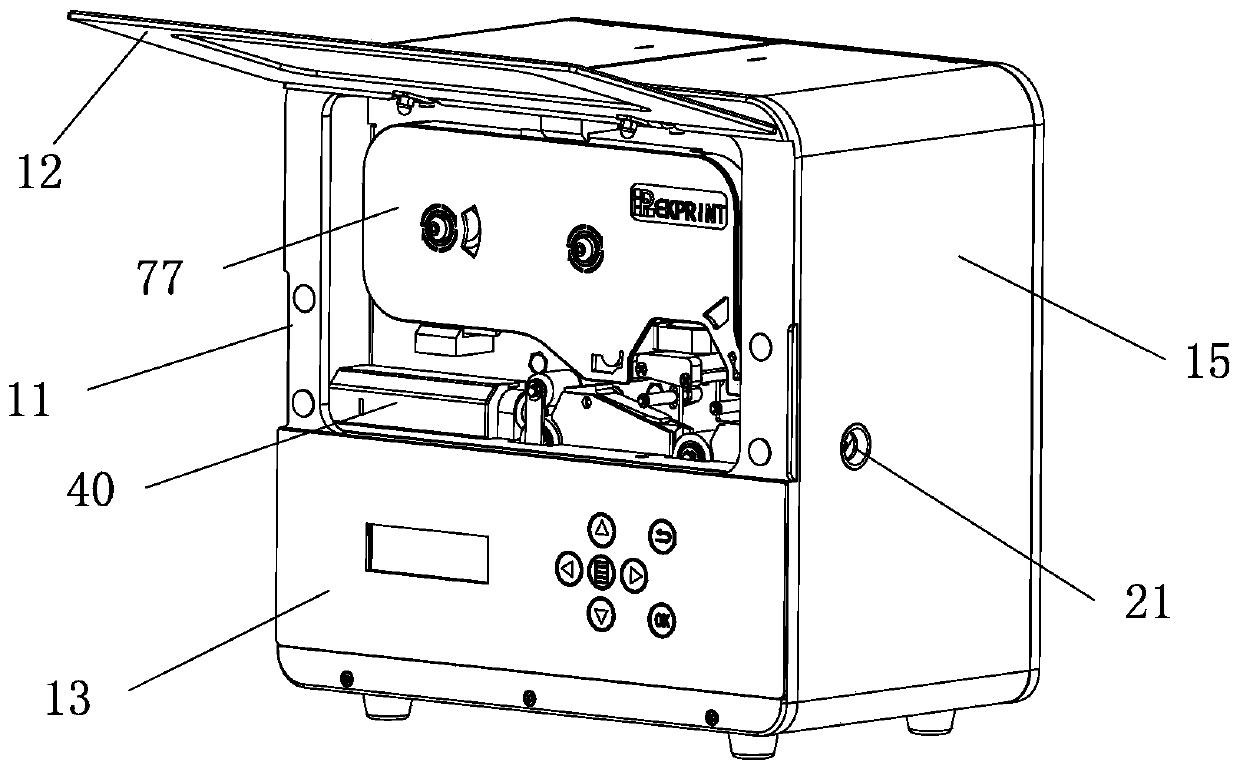

[0040] The method for automatically identifying and printing data of the wire pipe marking machine of the present invention is applied to the wire pipe marking machine that can be networked with the wire harness production control system. The main control circuit of the wire pipe marking machine is equipped with an automatic An identification and screening module, the automatic identification and screening module can automatically filter the data related to the wire tube number from the production data of the wire harness production control system, so that the wire tube marking machine can print these data on the wire tube numbering machine In terms of performance, it can not only improve the production efficiency of wire harness and wire number tube production and processing enterprises, but also effectively reduce their production costs. At the same time, it can realize wire harness production, wire number tube cutting, wire tube number printing and wire number tube The autom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com