Cast pipe quality management method, cast pipe produced by using above method, and two-dimensional barcode tag

A two-dimensional code label and quality management technology, which is applied to the quality management of cast pipes, cast pipes produced by the above, and the field of two-dimensional code labels, can solve the problems that the pipe number cannot be automatically recognized by the computer, and the efficiency is low, so as to facilitate quality traceability , Avoid repeated numbers and wrong numbers, and the effect of convenient scanning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is a cast pipe quality management method, which method comprises the following steps:

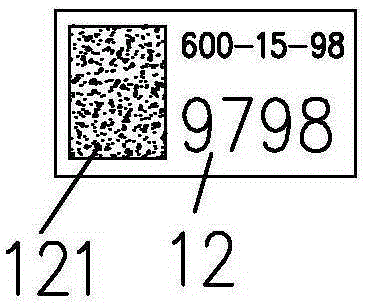

[0023] (1) Input the production source information of each cast pipe in the production process into the two-dimensional code management system, and the two-dimensional code management system assigns each cast pipe a pipe batch number, and establishes a relational code in the two-dimensional code management system. In the database, the production plan is first issued according to the order, and then the cast pipe is produced according to the production plan, so that the order and production plan correspond to the pipe batch number, and the cast pipe record corresponding to each pipe batch number is generated in the two-dimensional code management system. When the cast pipe is passed on the production line, the production source information of the cast pipe includes the measured value of the wall thickness of the cast pipe, the hydraulic pressure qualification reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com