Method for intelligently tracking tube numbers in circulating process of steel tube production line

A technology of intelligent tracking and steel pipes, applied in data processing applications, instruments, manufacturing computing systems, etc., can solve problems such as looseness, uncleanness, and difficulty in protecting barcodes, and achieve the effects of improving efficiency and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

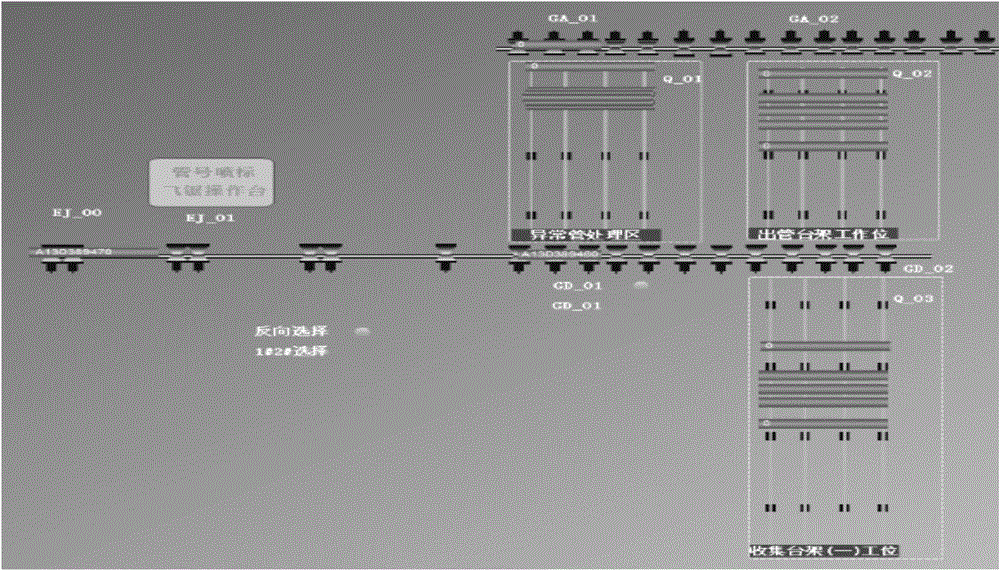

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

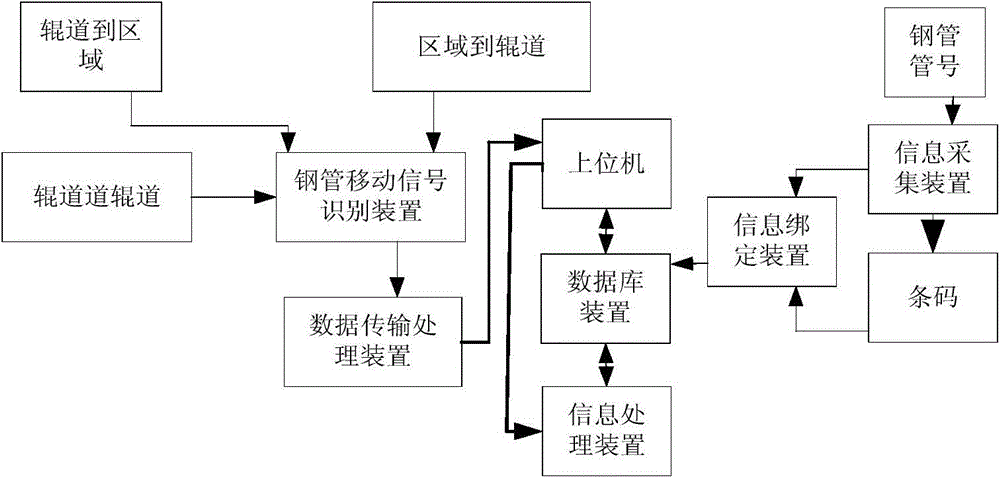

[0028] The method of the present invention for intelligently tracking the pipe number during the circulation of the steel pipe production line includes the following steps:

[0029] In the area division step, the steel pipe production line is divided into at least one area according to the steel pipe production process, each area includes a plurality of sub-areas, each sub-area is equipped with an object detector, and the initial position of the area is equipped with a label identifier;

[0030] Database building step: building a model of the steel pipe production line in a database, the model is divided into at least one virtual area, and each virtual area includes a plurality of virtual sub-areas;

[0031] Marking step: setting an identification tag for the steel pipe, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com