Detecting method for aerogenic bacterium in soy sauce and other condiments

A detection method and condiment technology, applied in the direction of biochemical equipment and methods, microbial measurement/inspection, etc., can solve the problems of gas production, tank leakage and other problems, achieve low cost, improve production process, and control production quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Culture medium composition and fermentation tube preparation:

[0023] 1. Medium composition: glucose 20g, peptone 10g, beef extract 10g, yeast powder 5g, Tween-801mL, ammonium citrate 2g, dipotassium hydrogen phosphate 2g, magnesium sulfate heptahydrate 0.58g, sodium thioglycolate 0.1g, Distilled water 1000mL.

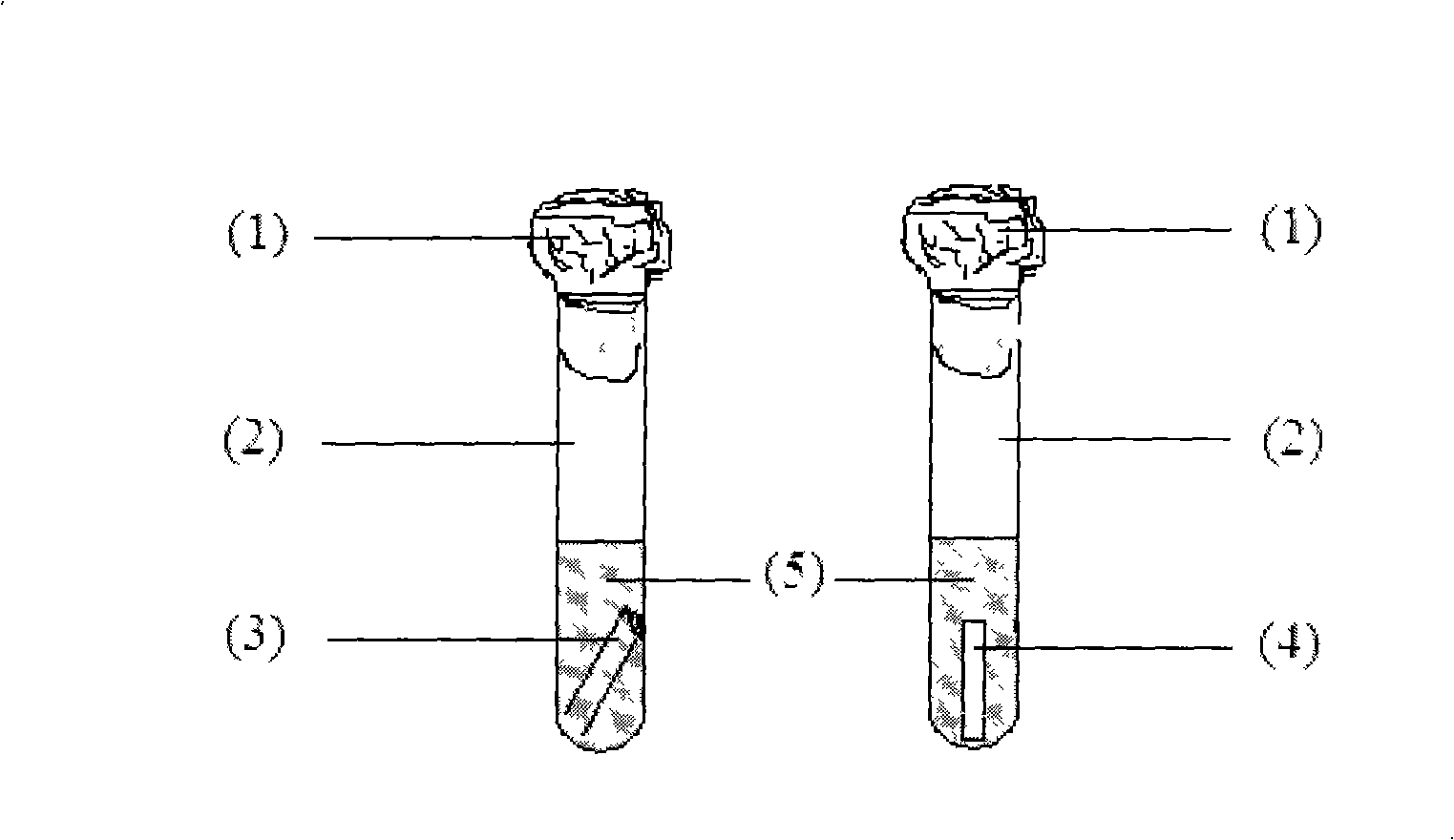

[0024] 2. Fermentation tube preparation method:

[0025] Preparation method: Dissolve the above medium components into distilled water, heat to dissolve, divide into 10ml tubes, put them into an inverted Duchenne tube, autoclave at 121°C for 15-20min, cool at room temperature, and store in a refrigerator at 4°C for use .

[0026] 3. Dilution of sample to be tested:

[0027] Aseptically place 10 mL of the test sample in 90 mL of sterilized saline to make a uniform dilution of 1:10.

[0028] Draw 1mL of the 1:10 dilution with a 1mL sterile pipette, inject it into a test tube containing 9mL of sterilized normal saline or other diluents, shake the test tube to ...

Embodiment 2

[0038] 1. Medium composition: glucose 20g, peptone 10g, beef extract 10g, yeast powder 5g, Tween-801mL, ammonium citrate 2g, dipotassium hydrogen phosphate 2g, magnesium sulfate heptahydrate 0.58g, sodium thioglycolate 0.1g, Distilled water 1000mL.

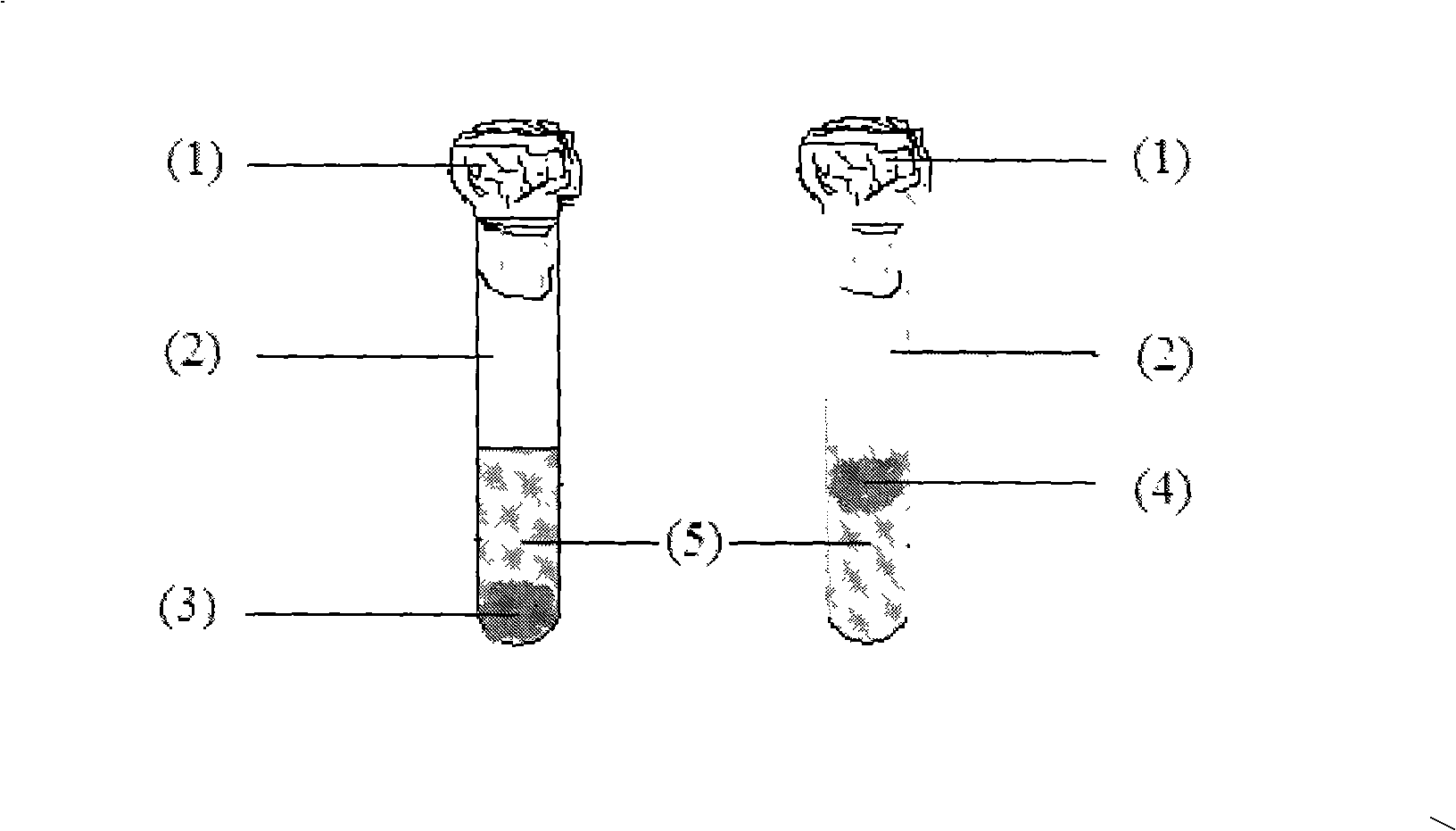

[0039] 2. Fermentation tube preparation method: Dissolve the above medium components into distilled water, heat to dissolve, fill each tube with 10ml, put a small ball of cotton or a small piece of sponge, autoclave at 121°C for 15-20min, and cool at room temperature At this time, the sponge or cotton ball sinks to the bottom of the test tube, and put it in the refrigerator at 4°C for use.

[0040] 3. Dilution of sample to be tested:

[0041] Aseptically place 10 mL of the test sample in 90 mL of sterilized saline to make a uniform dilution of 1:10.

[0042] Draw 1mL of the 1:10 dilution with a 1mL sterile pipette, inject it into a test tube containing 9mL of sterilized normal saline or other diluents, shake the test tube to mix...

Embodiment 3

[0051] 1. Medium composition: glucose 20g, peptone 10g, beef extract 10g, yeast powder 5g, Tween-801mL, ammonium citrate 2g, dipotassium hydrogen phosphate 2g, magnesium sulfate heptahydrate 0.58g, sodium thioglycolate 0.1g, Distilled water 1000mL.

[0052] 2. Fermentation tube preparation method: Dissolve the above medium components into distilled water, heat to dissolve, fill each tube with 10ml, put a small ball of cotton or a small piece of sponge, autoclave at 121°C for 15-20min, and cool at room temperature At this time, the sponge or cotton ball sinks to the bottom of the test tube, and put it in the refrigerator at 4°C for use.

[0053] 3. Dilution of sample to be tested:

[0054] Aseptically put 10 g of the test sample into 90 mL of sterilized physiological saline to make a uniform dilution of 1:10.

[0055] Draw 1mL of the 1:10 dilution with a 1mL sterile pipette, inject it into a test tube containing 9mL of sterilized normal saline or other diluents, shake the tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com