Concentric casing heat exchange tube

A technology of concentric sleeves and heat exchange tubes, applied in geothermal energy, heating fuel, household heating, etc., can solve the problems of increased construction cost, increased construction difficulty and cost, and affected heat exchange efficiency, etc., to achieve the cost of backfill materials The effect of reducing and reducing the number of heat exchange tubes and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

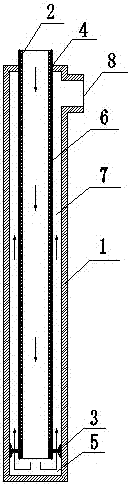

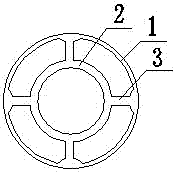

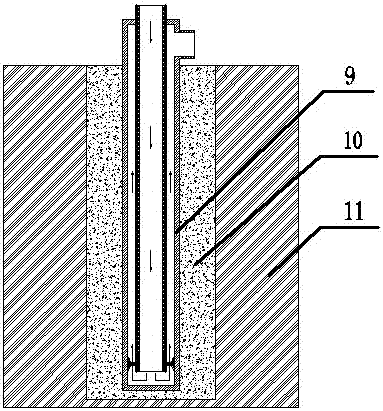

[0029] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

[0030] As shown in the figure, a concentric casing heat exchange tube according to the present invention is made of HDPE (high density polyethylene) 100 type, with a pressure bearing capacity of 1.6MPa and a long service life; the inner side of the inner tube 2 is a water inlet tube , when the water flows to the bottom of the concentric sleeve type heat exchange tube, it return...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com