A ground pressure sensor based on three-dimensional space monitoring

A three-dimensional space and sensor technology, applied in the direction of instruments, measuring forces, measuring devices, etc., can solve problems such as inability to monitor incoming pressure, unreasonable force, and complicated installation, so as to reduce monitoring data drift and ensure accuracy and accuracy , The effect of ensuring the safety of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

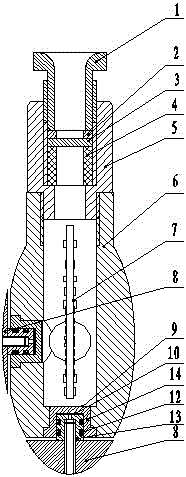

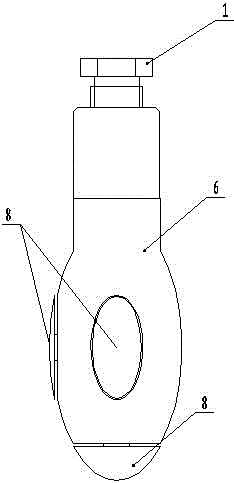

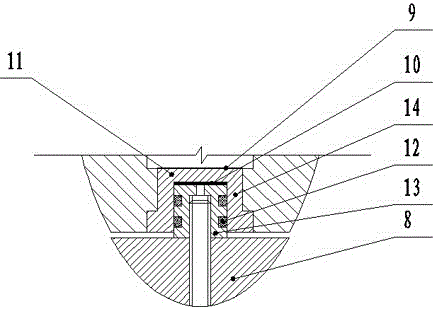

[0017] According to the accompanying drawings, a ground pressure sensor based on three-dimensional space monitoring consists of an oval housing 6, an outlet device, a circuit board 7 and three mutually perpendicular ground pressure monitoring heads. The upper end of the elliptical shell 6 is equipped with an outlet device, which includes A0 compression nut 1, A0 porous pad 2, A0 non-porous pad 3, A0 sealing ring 4 and Unicom joint 5. This device can effectively ensure that mud, sand, Substances such as water will not enter the inside of the elliptical shell 6 to ensure the safety of the internal components of the elliptical shell 6 and provide a good environment for its work. There is a circuit board 7 inside the elliptical shell. The components of the circuit board 7 are patch type, which has the advantages of low power consumption and small size. A high-precision potentiometer is used to ensure the accuracy and accuracy of data adjustment. Reduce monitoring data drift. Thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com