Reinforcement cage seepage drainage pipe for quickly lowering seepage line in side slope body

A technology of steel cages and soaking lines, applied in the field of soil slope drainage, can solve the problems of reducing slope safety and stability, increasing investment costs, and limited number of pipe wall openings, so as to optimize the slope treatment plan and reduce the number of boreholes. Cost, the effect of enhancing the drainage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better describe the present invention, a steel cage drainage pipe for rapidly reducing the infiltration line in the slope body of the present invention will be further described in detail below in conjunction with the accompanying drawings.

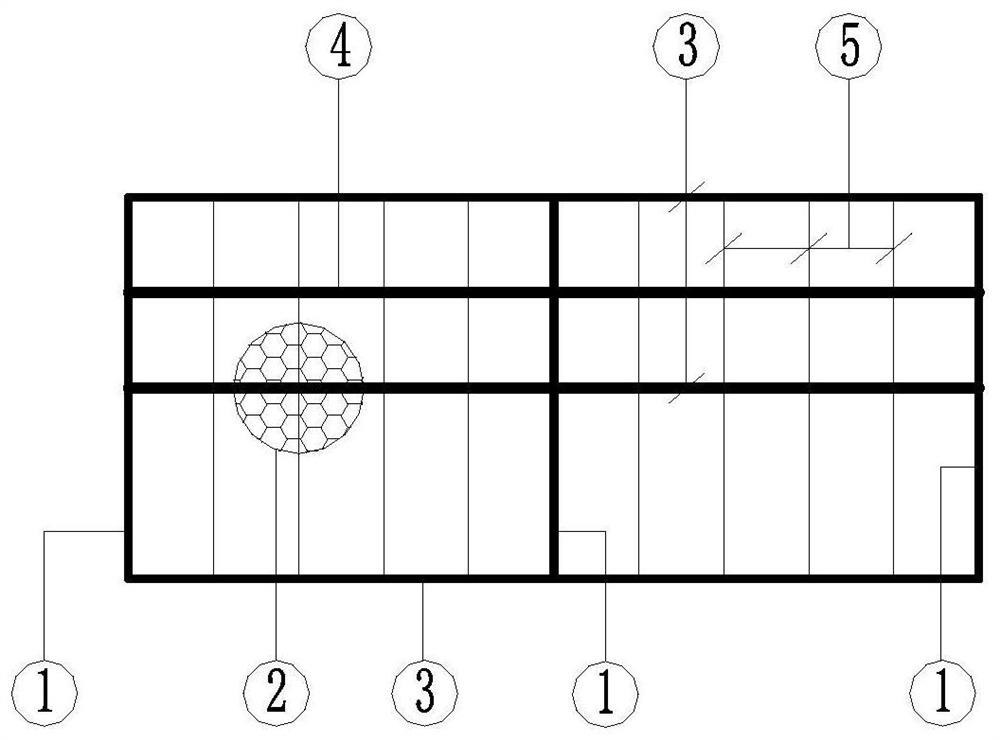

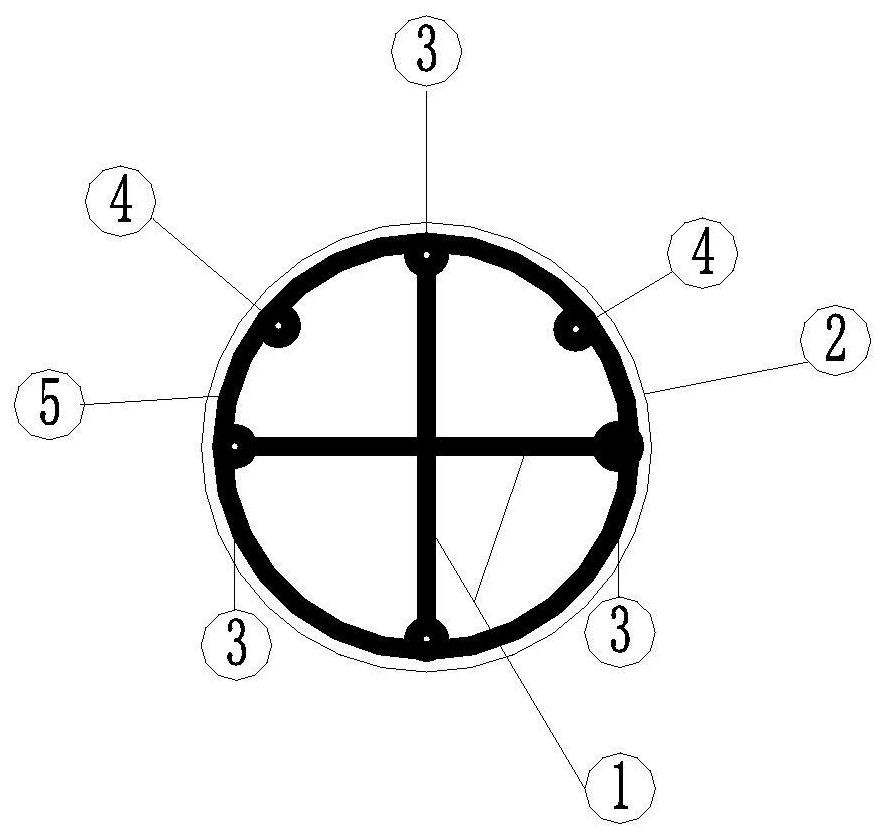

[0022] Depend on figure 1 A longitudinal section view of a reinforced cage seepage pipe structure for rapidly reducing the infiltration line in the slope body shown in the present invention and combined with figure 2 , image 3 , Figure 4 It can be seen that a kind of steel cage drainage pipe for quickly reducing the infiltration line in the slope body of the present invention is composed of a combination of geotextile 2 wrapped outside the steel cage pipe, which plays the role of reverse filtration drainage and prevents soil from entering the pipe. The steel cage tube includes 4 equal-length longitudinal support bars 3, 2 longitudinal reinforcing ribs 4, equally spaced horizontal support discs 5, equally spaced tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com