A slope shallow drainage system

A drainage system and slope technology, applied in waterway systems, sewage removal, soil drainage, etc., can solve the problems of a small number of drainage pipes, inability to discharge rainfall and infiltration of groundwater in time, affecting the drainage effect of the slope body, etc., to prevent scouring. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

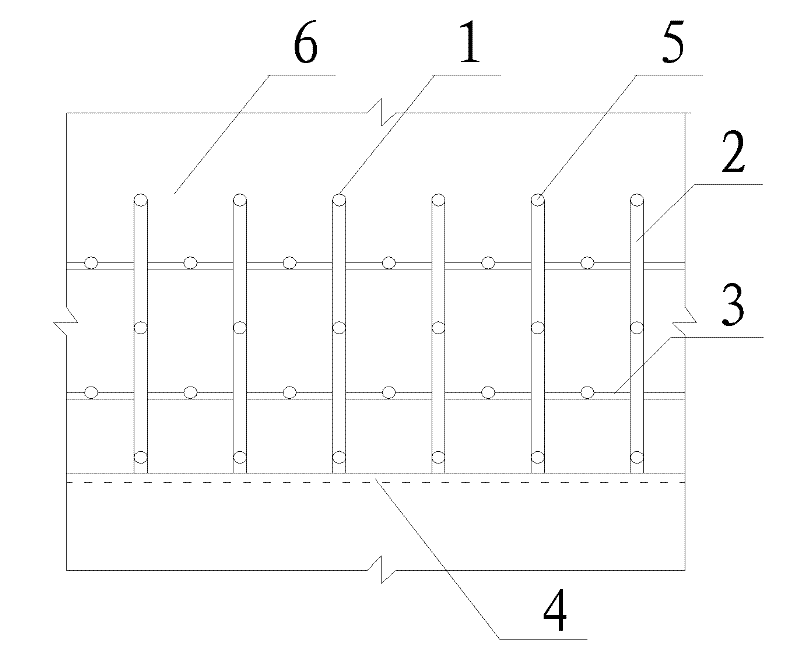

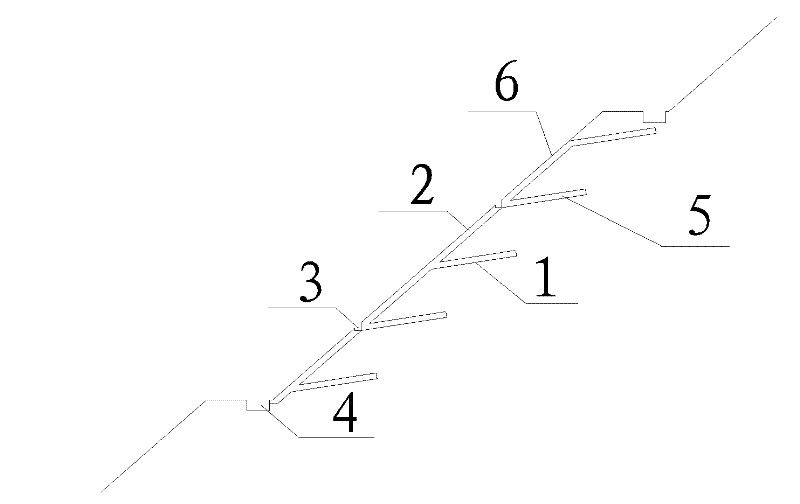

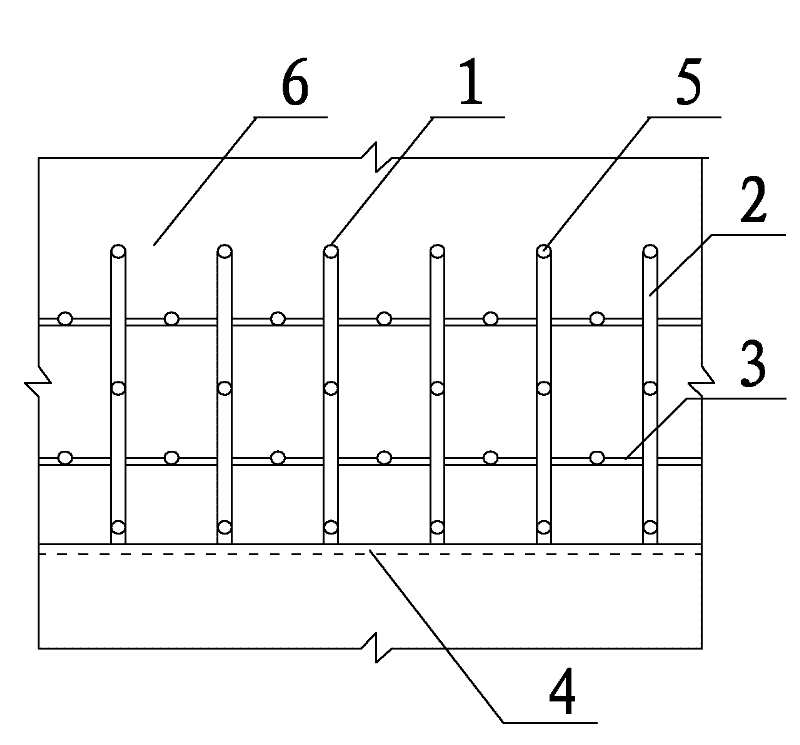

[0017] see figure 1 with figure 2 , the bottom platform of the side slope 6 is provided with drainage ditches 4, on the side slope 6, rows and rows of drainage boreholes 1 are densely arranged, the upper and lower rows of drainage boreholes 1 are staggered, and the drainage holes 1 are arranged in a staggered manner. The distance of the drainage borehole 1 is 2-3m, the depth of the drainage borehole 1 is 3-4m, the diameter of the drainage borehole 1 is 75-110mm, the elevation angle of the drainage borehole 1 is 0-10°, and the best elevation angle is 5-10°. A high-porosity drainage pipe 5 is arranged in each drainage borehole 1, and the high-porosity drainage pipe 5 on the bottom layer of the side slope 6 is 20-30 cm higher than the bottom platform, and the slope surface of the side slope 6 is arranged with longitudinal micro-collectors. Ditc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Elevation angle | aaaaa | aaaaa |

| Elevation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com