Large-area soft soil foundation duplex negative pressure consolidation processing method

A technology of soft soil foundation and treatment method, which is applied in infrastructure engineering, soil protection, construction, etc., can solve problems such as the inability of roadbeds, the inability to directly use large-scale construction vehicles, and the inability to directly meet the needs of high-standard construction sites. Increase the impact depth, improve vertical drainage and transfer negative pressure, and improve drainage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

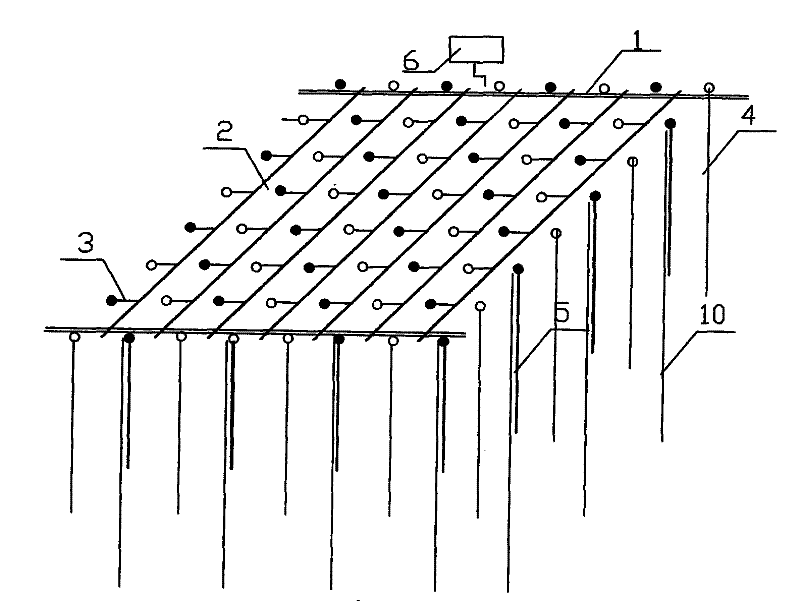

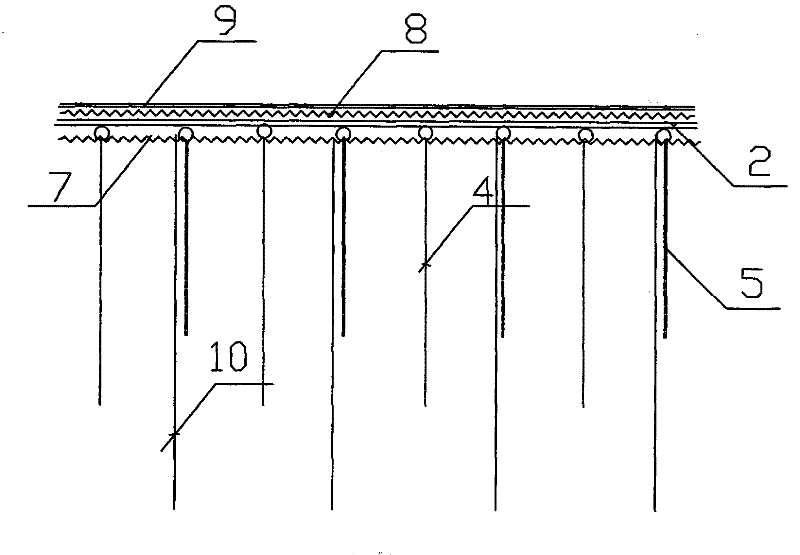

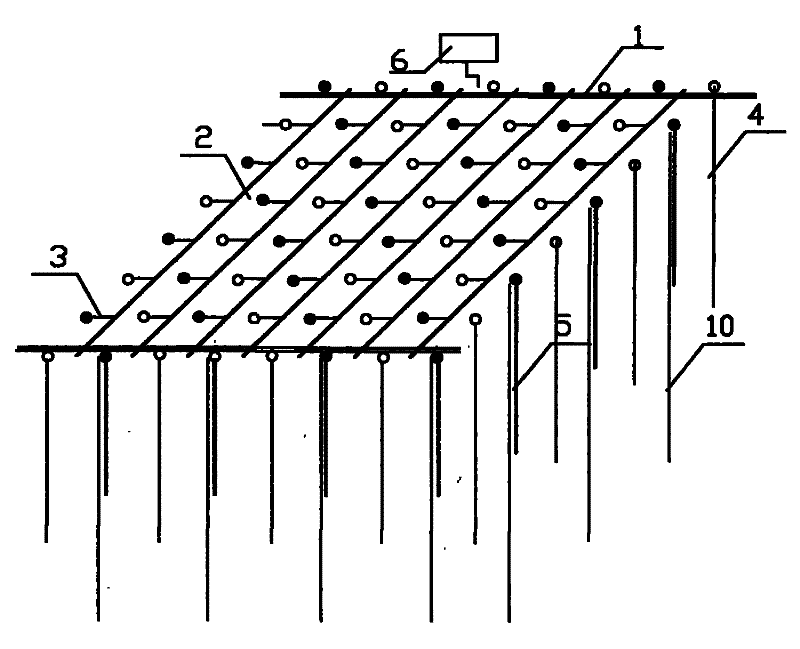

[0042] The present invention relates to a kind of large-area soft ground " compound negative pressure consolidation " treatment method, described method comprises following process (referring to figure 1 with figure 2 ):

[0043] Step 1. Negative pressure consolidation

[0044] a) Cover the area to be treated with plastic woven cloth, and use a light-duty beater on the mud to lay a vertical plastic drainage board and manually lay a vertical plastic seepage pipe. Vertical plastic seepage pipes and vertical plastic drainage boards are arranged at intervals. The spacing of the vertical plastic drainage boards is 1.2-2.0m, and the insertion depth of the vertical plastic drainage boards is determined according to the required reinforcement depth, generally 5-10m. The spacing of the vertical plastic seepage pipes is 1.2-2.0m, the diameter of the vertical plastic seepage pipes is 3-3.5cm, the length of the vertical plastic seepage pipes is 3-4m, the vertical plastic seepage pipes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com