A ground grouting filling method with one hole and multiple openings above the coal pillar

A coal pillar and grouting technology, which is applied in the fields of filling, earth-moving drilling, mining equipment, etc., can solve the problems of high grouting cost, hidden dangers of construction safety, and application restrictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

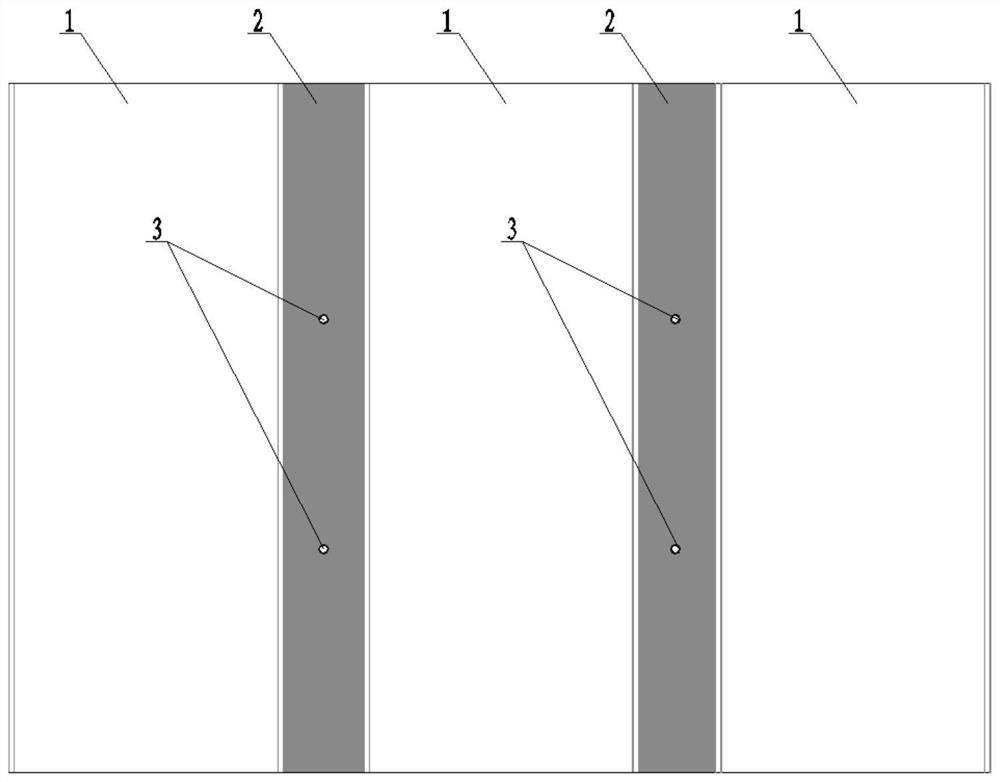

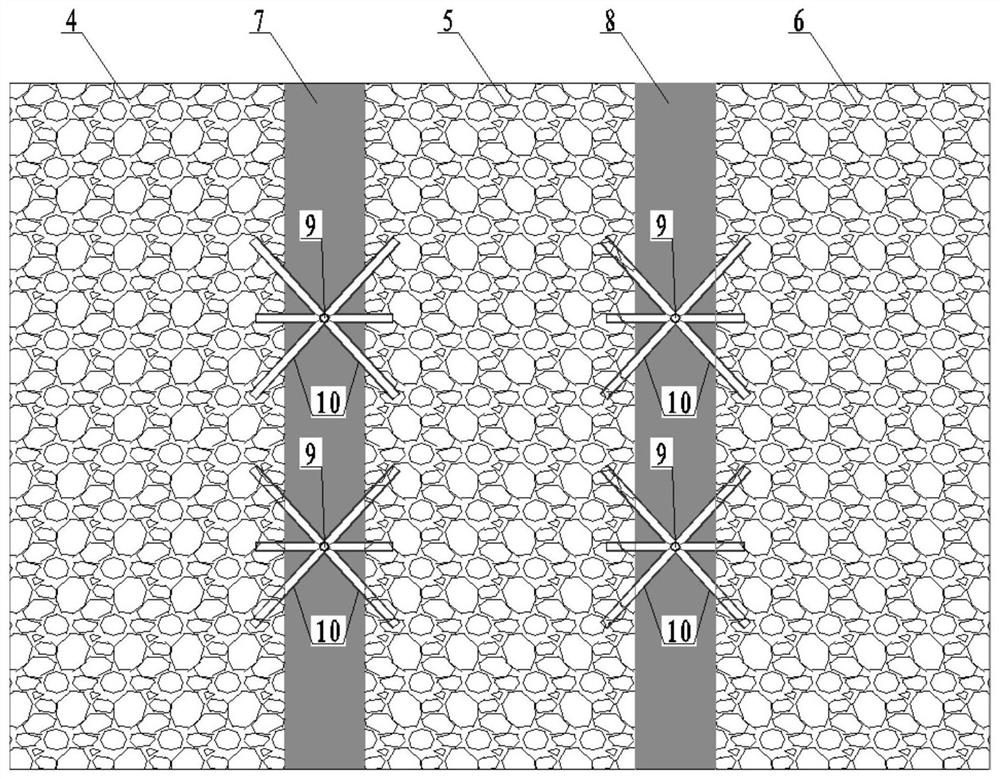

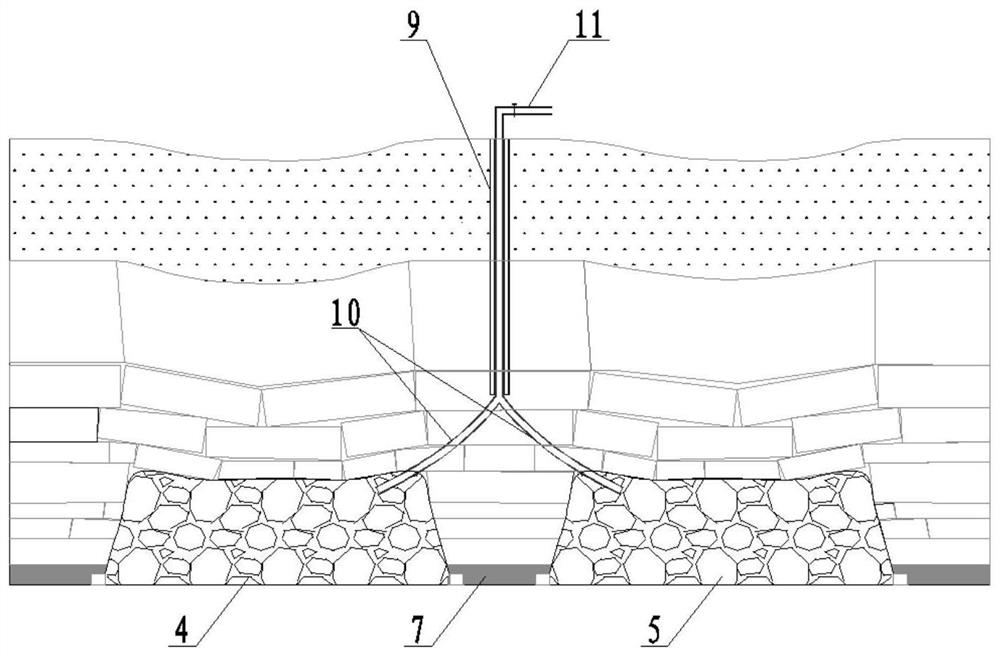

[0028] Such as Figure 1 to Figure 3 As shown, the present invention provides a ground grouting filling method with one hole and multiple openings above the coal pillar. According to the traditional layout of coal mining face 1, a section of coal is reserved between two adjacent coal mining faces 1. Column 2, after two adjacent coal mining working faces 1 are mined sequentially, grouting filling is carried out on the goaf of the working face on both sides of the coal pillar 2 by arranging the grouting borehole 3 on the ground above the coal pillar 2; The grouting borehole 3 comprises a top-down connected grouting main borehole 9 and a secondary grouting borehole 10; specifically comprises the following steps;

[0029] a. According to the traditional layout of coal mining face, the mining operations are carried out on No. 1 working face 4, No. 2 working face 5 and No. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com