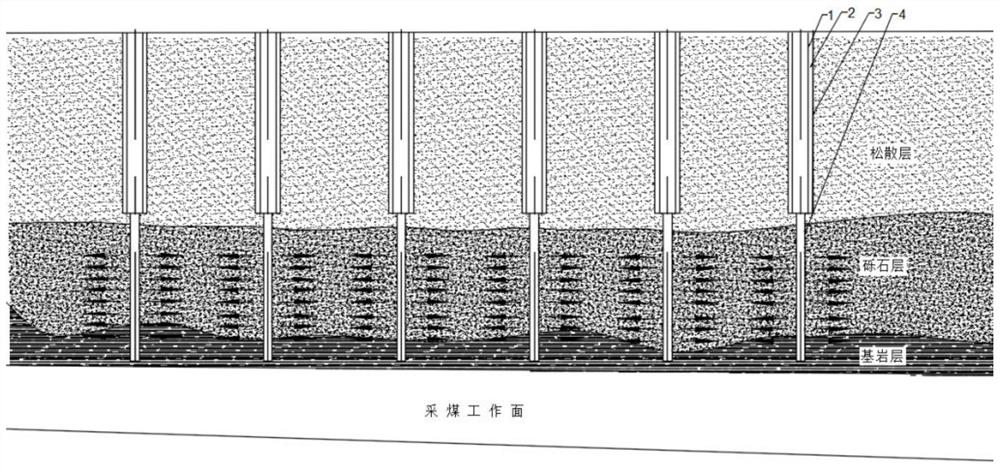

A water-separation method for grouting reinforced water-rich gravel layer on the roof of coal mining face

A coal mining face and grouting reinforcement technology, which is applied to mining equipment, earthwork drilling, shaft equipment, etc., can solve the problems of dense drilling, large changes in water content, and immaturity, so as to reduce construction costs and improve construction efficiency. Efficiency and usage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

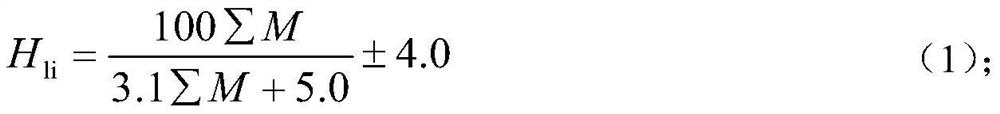

Method used

Image

Examples

Embodiment 1

[0025] A coal mine temporarily arranges 8 boreholes for the anomalous water-rich area and the suspected water-rich anomalous area of a coal seam roof aquifer detected by transient electromagnetic survey, arranged in a straight line, and the drill holes are arranged at a distance of 30m. Among them, Drill 1, Drill 2, Drill 3, and Drill 4 are the inspections of suspected water-rich anomaly areas and non-water-rich anomaly areas. The coordinates of each hole are shown in Table 1:

[0026] Table 1 Hole position coordinates of each drilling hole

[0027] Hole number Longitude latitude Ground elevation (estimated) Drill 1 38369572.3 3828237.5 190.4 Drill 2 38369620.2 3828240.3 189.1 Drill 3 38369693.7 3828243.6 189.6 drill 4 38369742.4 3828232.7 193.1 drill 5 38369791.2 3828212.8 193.5 Drill 6 38369840.0 3828210.9 194.1 drill 7 38369888.8 3828200.0 195.3 drill 8 38369945.5 3828190.4 195.3

[0028]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com