A design method of dish solar Stirling heat engine tube cluster heat absorber

A design method and technology of solar energy, applied in the direction of solar thermal power generation, mechanical power generated by solar energy, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

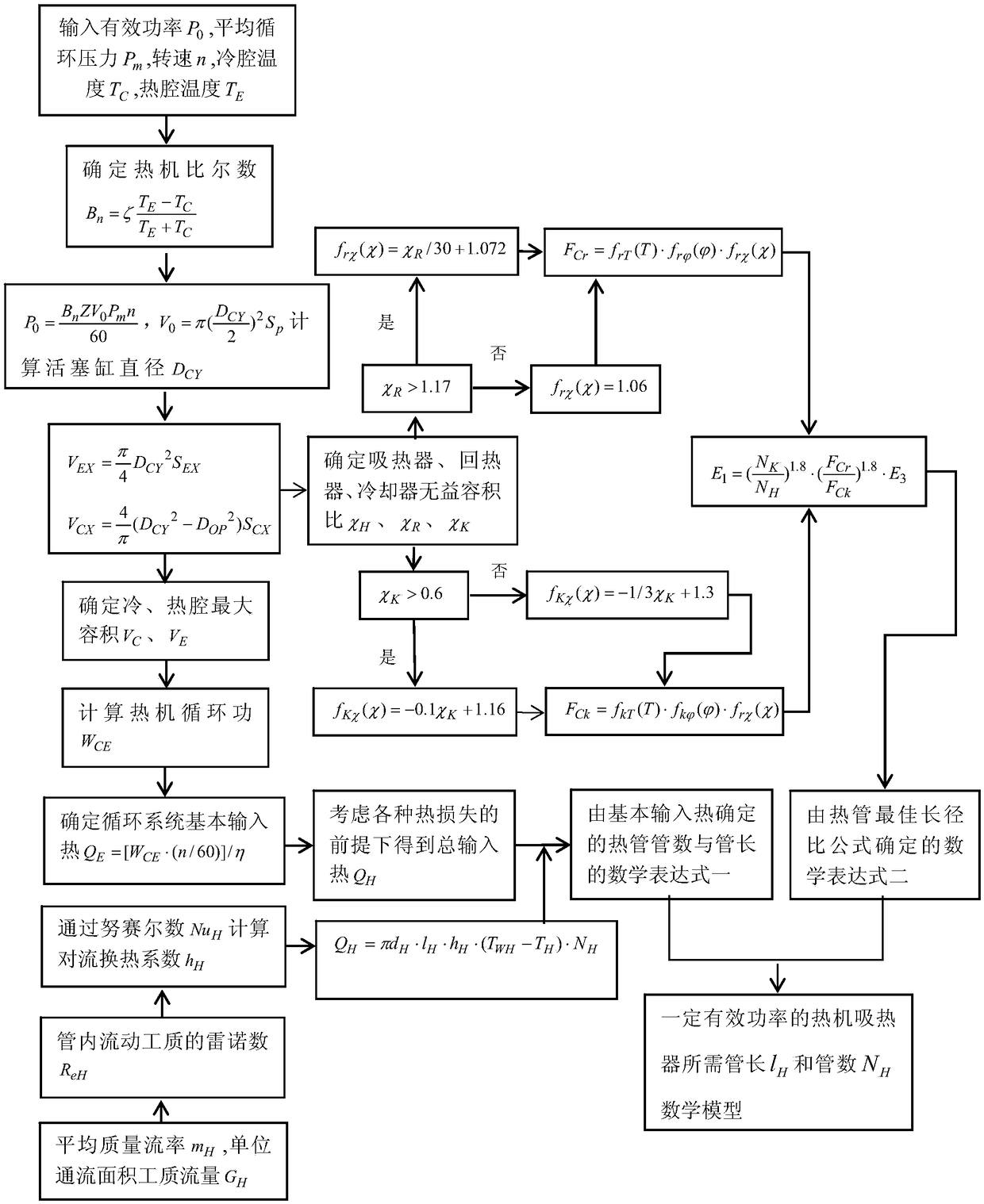

Method used

Image

Examples

Embodiment

[0086] 1: known parameter effective power P 0 1Kw, P m is 2MPa, the rotational speed n is 500r / min, the working fluid power conversion coefficient ζ is 0.34, the swash plate inclination θ is 20°, the temperature of the hot chamber T E is 700 degrees, the cold chamber temperature T C is 45 degrees; calculated to get B n =0.168,D CY =5.62cm, V E =88.67cm 3 , V C =77.36cm 3 .

[0087] 2: First calculate Stirling heat engine cycle work W CE =2.676Kw, basic input heat Q E =4.048, calculate the total basic heat input as Q H =4.448kW; M fhmax =0.3453, M fhmin =0.1230,F ht =0.284, m H = 1.545g / s, then the calculation formula for the number of heat absorber tubes and tube length based on the basic input heat can be obtained as

[0088] 3: First calculate the regenerator volume flow rate correction factor F Cr =0.65, cooler volume flow rate correction factor F Ck = 0.717. Then calculate the four intermediate variables Finally, the formula for calculating the numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com