Multitubular fixed bed reactor and coal bed methane deoxidation method

A fixed-bed reactor and reactor technology, which are applied in chemical instruments and methods, gas fuels, petroleum industry, etc., can solve the problems of decreased process capacity, complex reactor structure, increased investment cost, etc., to improve efficiency and economy. high stability, simple structure, avoiding the effect of axial hot spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment is used to illustrate the coalbed methane deoxidation method of the present invention.

[0053] The composition of oxygen-containing coalbed methane OM-1 is shown in Table 1, and the gas volume is 30Nm 3 / h, the temperature is 5°C, and the pressure is 0.6MPa (gauge pressure).

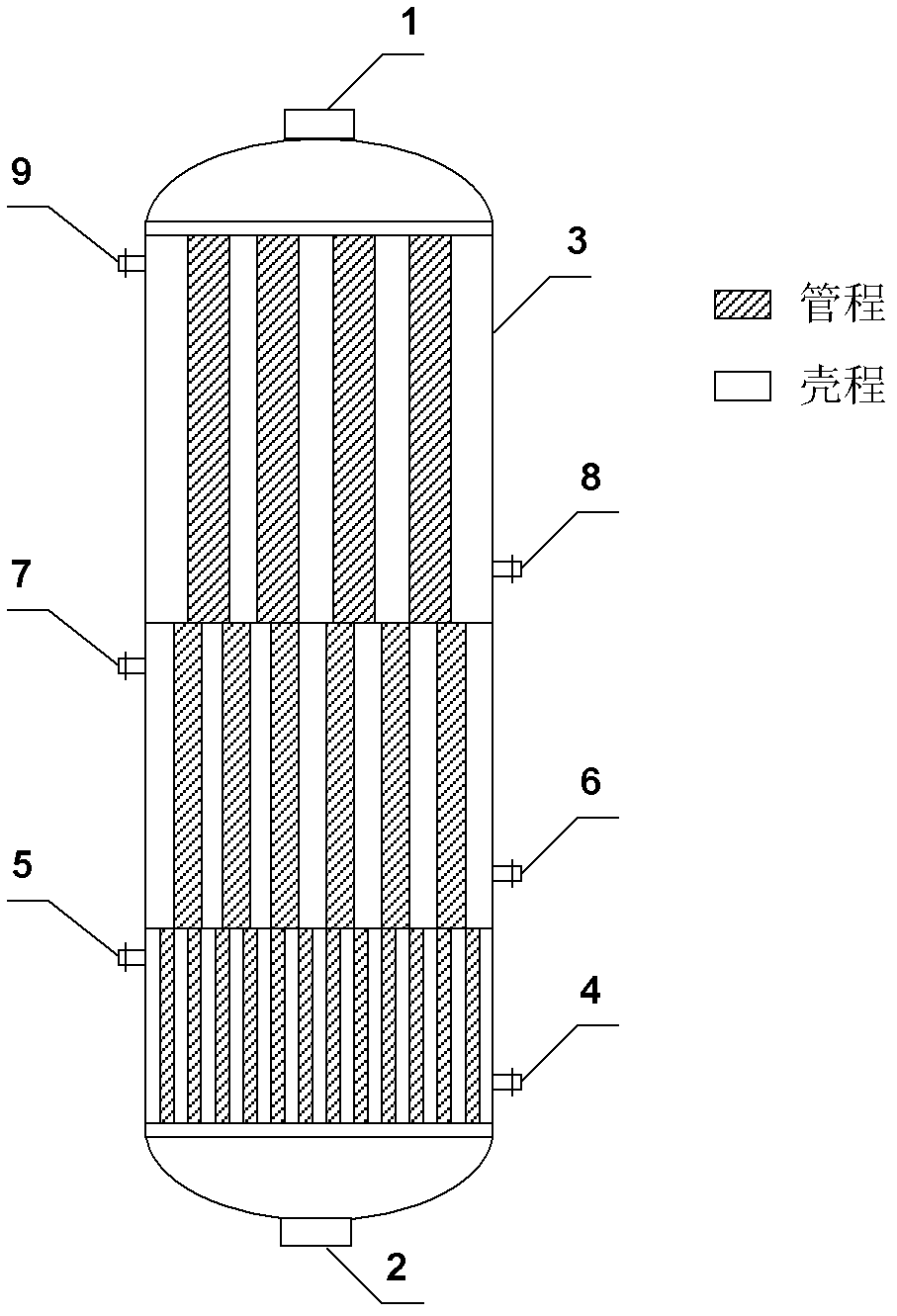

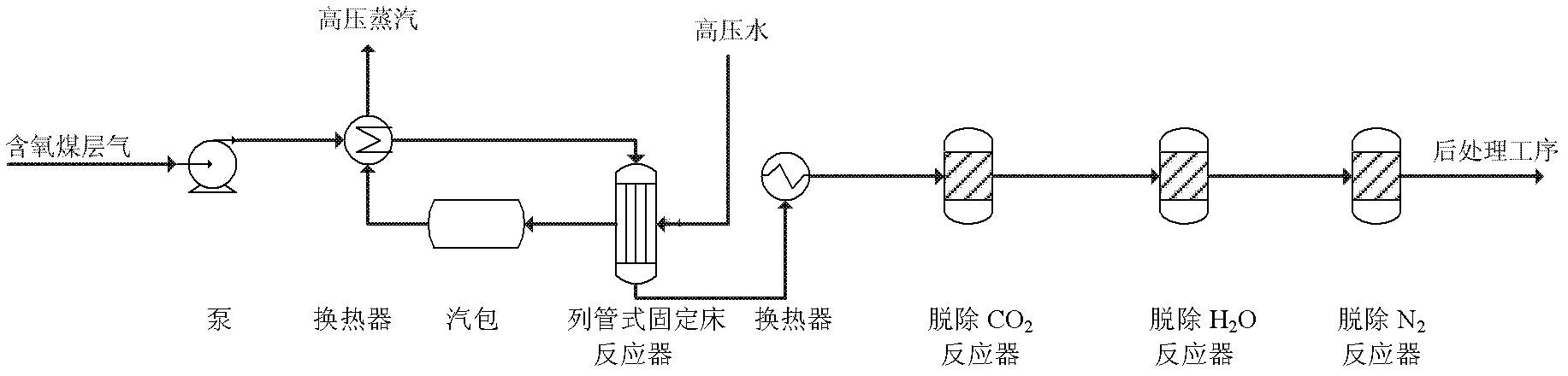

[0054] After the oxygen-containing coalbed gas is heated to 310°C through the heat exchanger, it enters from the second head 2 such as figure 1 Shown is a tubular fixed-bed reactor, and leaves the reactor from the first head 1. Among them, the shell 3 has a height of 100 cm, and the tube-and-tube fixed-bed reactor is divided into three sections. Among them, along the flow direction of coalbed methane, 16 reactors with a diameter of 0.6 cm and a height of 25 cm are uniformly distributed in the first-stage reactor. Centimeter tubes filled with Mn / Al to a height of 20 cm 2 o 3 Catalyst (based on catalyst weight, Mn content is 12% by weight), evenly distributed with 8 diameters in...

Embodiment 2

[0059]This embodiment is used to illustrate the coalbed methane deoxidation method of the present invention.

[0060] The composition of oxygen-containing coalbed methane OM-2 is shown in Table 2, and the gas volume is 30Nm 3 / h, the temperature is 25°C, and the pressure is 0.6MPa (gauge pressure).

[0061] After the oxygen-containing coalbed gas is heated to 300°C through the heat exchanger, it enters from the second head 2 such as figure 1 Shown is a tubular fixed-bed reactor, and leaves the reactor from the first head 1. Among them, the height of the shell 3 is 120 cm, and the tube-and-tube fixed-bed reactor is divided into three sections. Among them, along the flow direction of the coalbed methane, 24 reactors with a diameter of 0.4 cm and a height of 20 cm are evenly distributed in the first-stage reactor. Centimeter tubes filled with Mn / Al to a height of 15 cm 2 o 3 Catalyst (based on catalyst weight, Mn content is 12% by weight), evenly distributed with 12 diameters...

Embodiment 3

[0066] This embodiment is used to illustrate the coalbed methane deoxidation method of the present invention.

[0067] The composition of oxygen-containing coalbed methane OM-3 is shown in Table 3, and the gas volume is 30Nm 3 / h, the temperature is 15°C, and the pressure is 0.8MPa (gauge pressure).

[0068] After the oxygen-containing coalbed gas is exchanged to 280°C through the heat exchanger, it enters the tubular fixed-bed reactor from the second head 2 and leaves the reactor through the first head 1 . The tube-and-tube fixed-bed reactor is divided into four sections, among which, along the flow direction of coalbed methane, 32 tubes with a diameter of 0.4 cm and a height of 20 cm are evenly distributed in the first-stage reactor, and the filling height of the tubes is 15 cm. cm Mn / Al 2 o 3 Catalyst (based on catalyst weight, Mn content is 12% by weight), evenly distributed with 16 diameters in the second stage reactor is 1.2 centimeters, height is 30 centimetres, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com