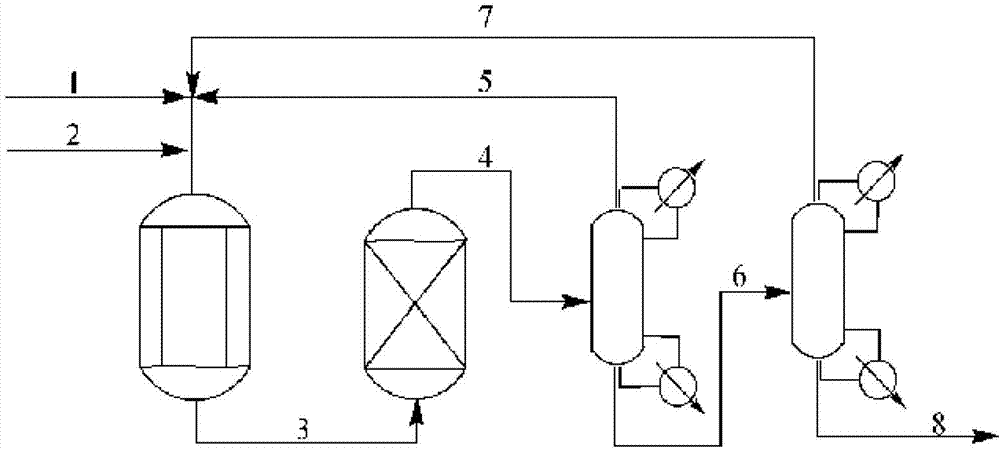

Method for continuous production of polyformaldehyde dimethyl ether

A technology of polyoxymethylene dimethyl ether and paraformaldehyde, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of environmental pollution, corrosion of liquid acid catalysts, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 30 ml of Nafion resin with a particle size of 0.5 to 1.0 mm in a reaction tube with an inner diameter of 2.5 mm. The reaction temperature is controlled at 140 °C, the reaction pressure is 3 MPa, and the liquid volume hourly space velocity (LHSV) is 1 hr. -1 , the mass ratio of methylal and paraformaldehyde is 2.0, the reaction product is sampled after cooling, and analyzed by gas chromatography, wherein DMM 32.2%, MeOH 4.0%, DMM 2 20.6%, DMM 3-8 27.0 %, DMM n (n>8) not detected.

Embodiment 2

[0032] Add 30 ml of Nafion resin with a particle size of 0.5 to 1.0 mm in a reaction tube with an inner diameter of 2.5 mm. The reaction temperature is controlled at 160 °C, the reaction pressure is 3 MPa, and the liquid volume hourly space velocity (LHSV) is 1 hr. -1 , the mass ratio of methylal and paraformaldehyde is 2.0, the reaction product is sampled after cooling, and analyzed by gas chromatography, wherein DMM 30.6%, MeOH 3.9%, DMM 2 20.2%, DMM 3-8 26.7 %, DMM n (n>8) not detected.

Embodiment 3

[0034] Add 30 ml of Nafion resin with a particle size of 0.5 to 1.0 mm in a reaction tube with an inner diameter of 2.5 mm. The reaction temperature is controlled at 140 °C, the reaction pressure is 3 MPa, and the liquid volume hourly space velocity (LHSV) is 0.5 hr. -1 , the mass ratio of methylal and paraformaldehyde is 2.0, the reaction product is sampled after cooling, and analyzed by gas chromatography, wherein DMM 26.2%, MeOH 4.0%, DMM 2 18.4 %, DMM 3-8 30.0 %, DMM n (n>8) not detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com