Net-shaped taper sleeve self-compensating centrifugal expansion high-speed cutter handle

A centrifugal expansion and self-compensation technology, applied in the field of machining, can solve the problems of uneven contact of the cone surface, low strength stiffness, poor radial stiffness, etc. The effect of alleviating manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

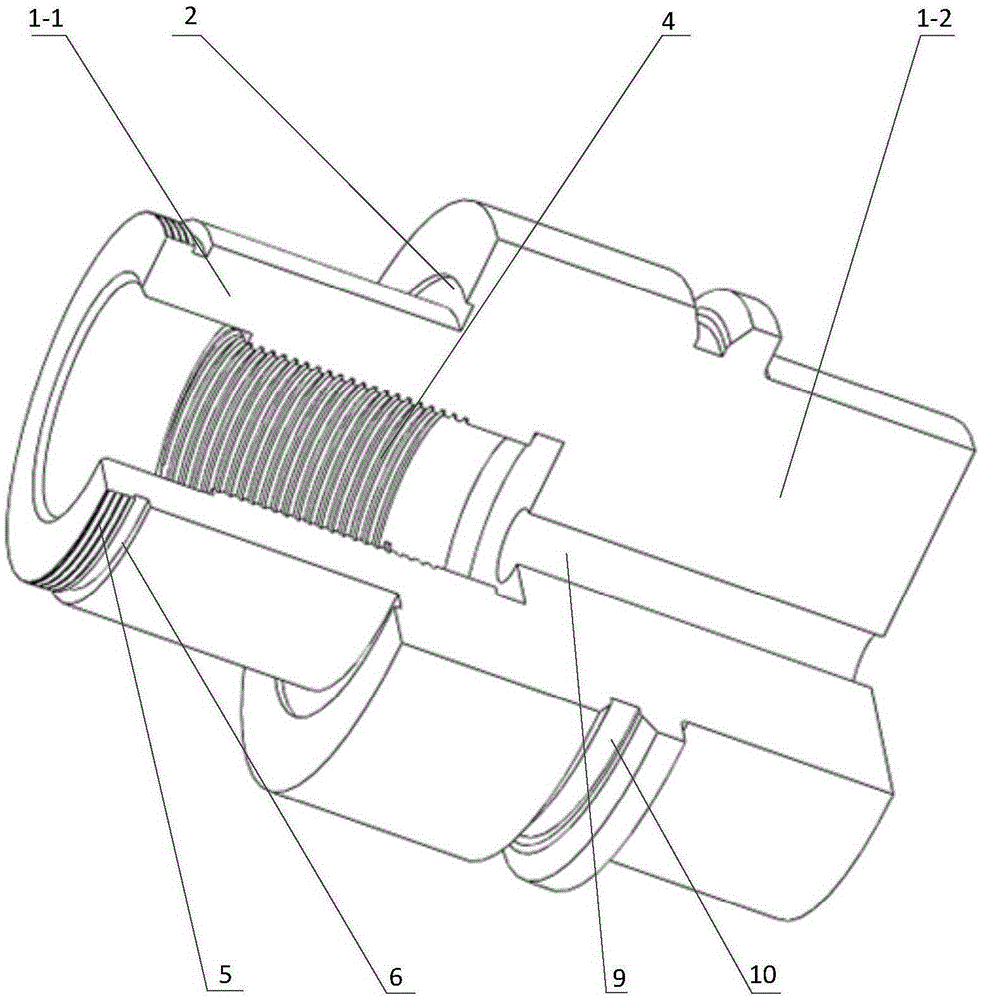

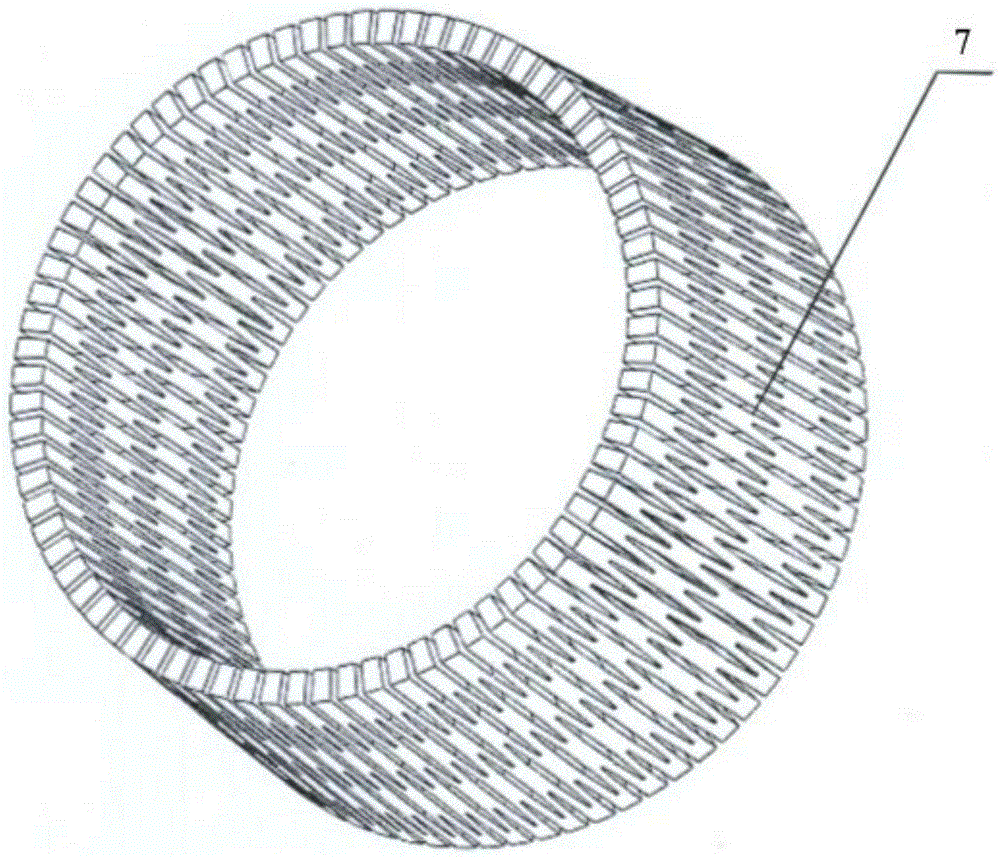

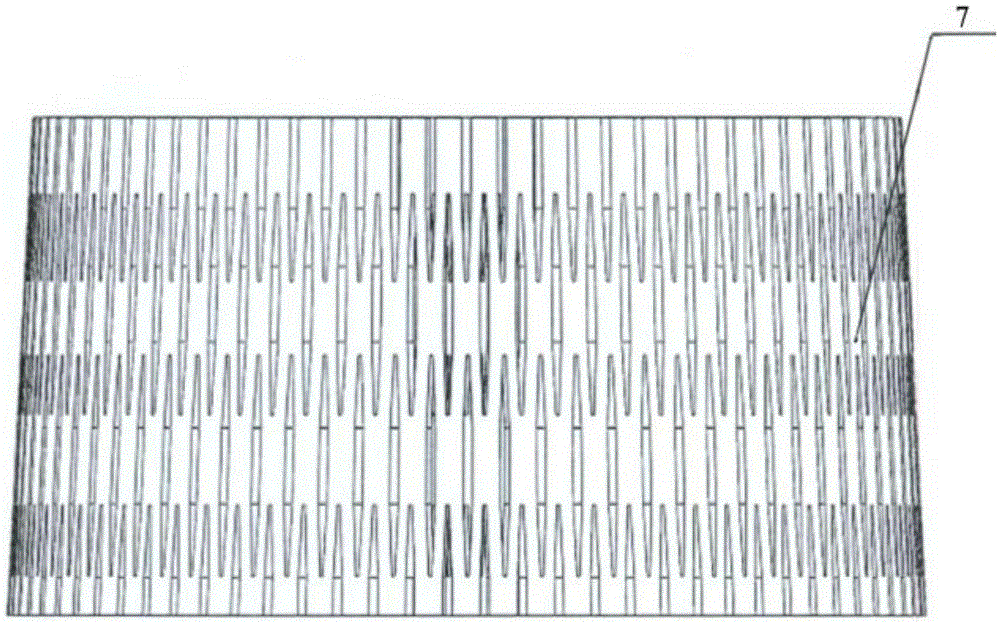

[0024] Such as figure 1 and 4 As shown, the present invention mainly includes a handle body 1, which is an integral solid structure composed of a front handle body 1-1 and a rear end handle body 1-2, and the rear end handle body is in accordance with DIN69893-HSK- E401996-01 tool handle has the same shape and size, the front handle body and the rear end handle body are coaxial cylinders, and the diameter of the front end handle body is smaller than the rear end handle body, and the end surface of the rear end handle body surrounds the junction of the front end handle body Process a circle of groove 2, install disc spring 3 in the groove; open thread groove 4 from the end surface of the front handle body along the axis to the direction of the rear end handle body, for tensioning connection with the pull rivet; The front end of the body is processed with a shoulder and is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com