Swivel nut combination unit

A combined unit and rotating nut technology, applied in the direction of belts/chains/gears, mechanical equipment, transmission devices, etc., can solve the problem that the rotation transmission mode of the screw cannot meet the design requirements of the machine tool, so as to save design, reduce the moment of inertia, improve The effect of limit speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

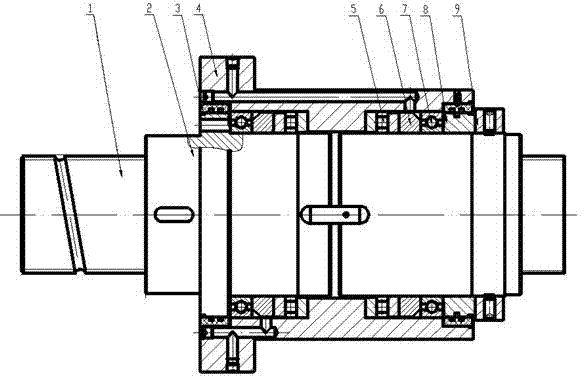

[0011] The rotating nut combination unit includes a ball screw 1, a rolling nut 2, a rolling bearing and a housing. The ball nut 2 is screwed with the ball screw 1. The housing 4 is covered outside the rolling nut by the rolling bearing. When the rolling screw 1 rotates, the ball nut Drive the housing to move linearly along the axial direction of the ball screw 1. The end of the ball nut 2 is provided with a preload adjusting device and a dustproof device 3 . The preload adjusting device is composed of spacer ring 6, spacer sleeve 8 and radial lock nut 9 nuts. Rolling bearings include deep groove ball bearings 7 and thrust roller bearings 5 .

[0012] The present invention directly installs the bearing outside the ball nut pair, which saves the design of the transition sleeve and greatly reduces the radial dimension. The ball screw is fixed in place. The driving motor drives the ball nut pair to rotate and move linearly along the raceway. Thereby driving the housing to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com