Electroplating CBN grinding wheel for efficient and precise gear profile grinding and manufacturing method of electroplating CBN grinding wheel for efficient and precise gear profile grinding

A precision forming and grinding wheel technology, applied in the direction of bonding grinding wheels, abrasives, manufacturing tools, etc., can solve the problems of simple shape and low precision of electroplated CBN grinding wheels, and achieve the effect of load reduction, optimized mass distribution, and accelerated penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

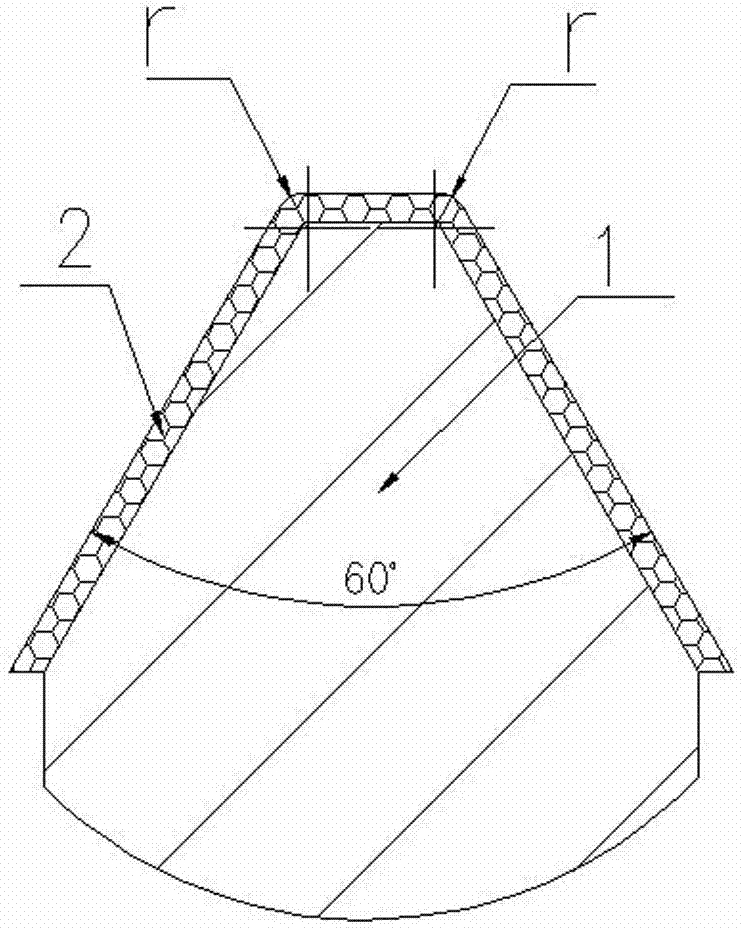

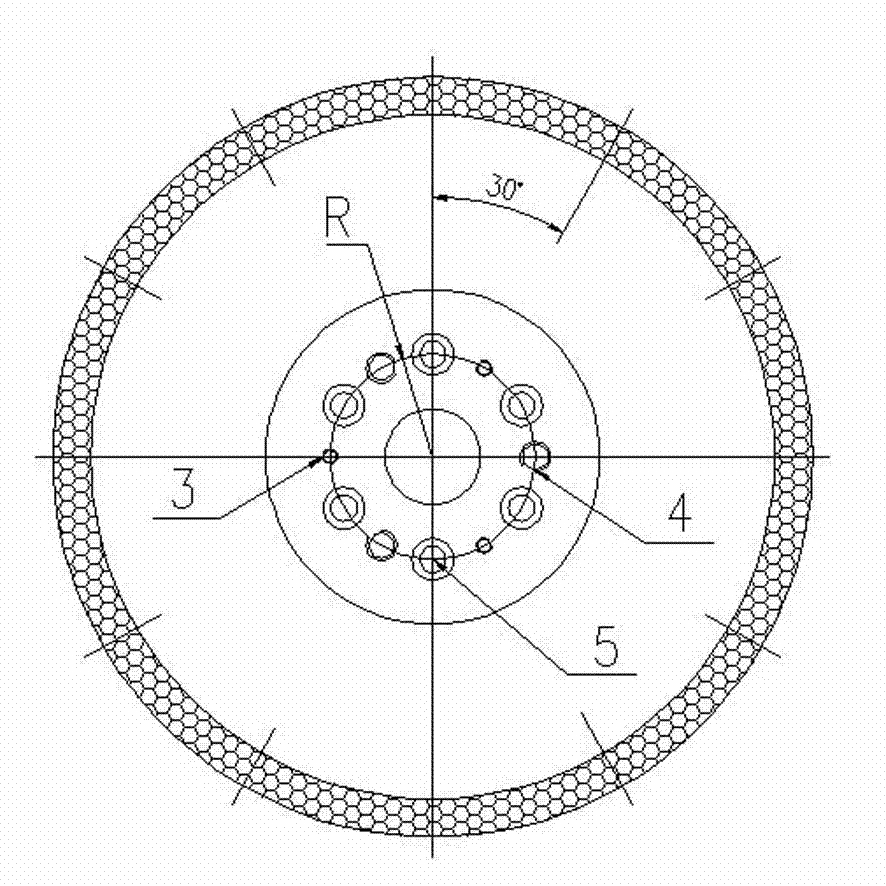

[0024] Such as figure 1 and figure 2 As shown, the electroplated CBN emery wheel used for high-efficiency precision profile grinding of gears includes a dish-shaped substrate 1 and an abrasive zone on its edge, the quality of the abrasive zone accounts for 4% of the total mass of the substrate, and the abrasive layer on the abrasive zone 2 The cross-sectional shape is an isosceles trapezoid with rounded corners between the upper bottom and the two waists, and the angle between the two waists and the lower bottom is 60°. The fillet radius r is 0.3. There are thread holes and circular holes evenly distributed on the concentric arc of the grinding wheel base body from the center R27mm, the thread holes include 3 thread holes I3 and 3 thread holes II4, and there are 6 circular holes 5, which are used to fasten the grinding wheel and Avoid wheel runout. The abrasive used in the grinding wheel is CBN, the particle size is 70 / 80, and the embedding rate of the coating is 60%.

[...

Embodiment 2

[0034] For post-treatment of the electroplated grinding wheel, the arc abrasive layer of the grinding wheel is divided into 4 areas on average, each area is immersed in the activation solution successively, the depth is 3mm, and the current density is 1A*dm -2 , and the time was 10 minutes; then the grinding wheel was taken out for cleaning and drying, and the edge height deviation on the arc and on the plane was 14.8%, and the other steps were the same as in Example 1.

Embodiment 3

[0036] For the post-treatment of the electroplated grinding wheel, the arc abrasive layer of the grinding wheel is divided into 20 areas on average, and each area is immersed in the activation solution successively with a depth of 1mm and a current density of 1A*dm -2 , the time was 3min; then the grinding wheel was taken out for cleaning and drying, and the deviation of the blade height on the arc and on the plane was 5.6%, and the other steps were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com