Patents

Literature

39results about How to "Avoid point contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

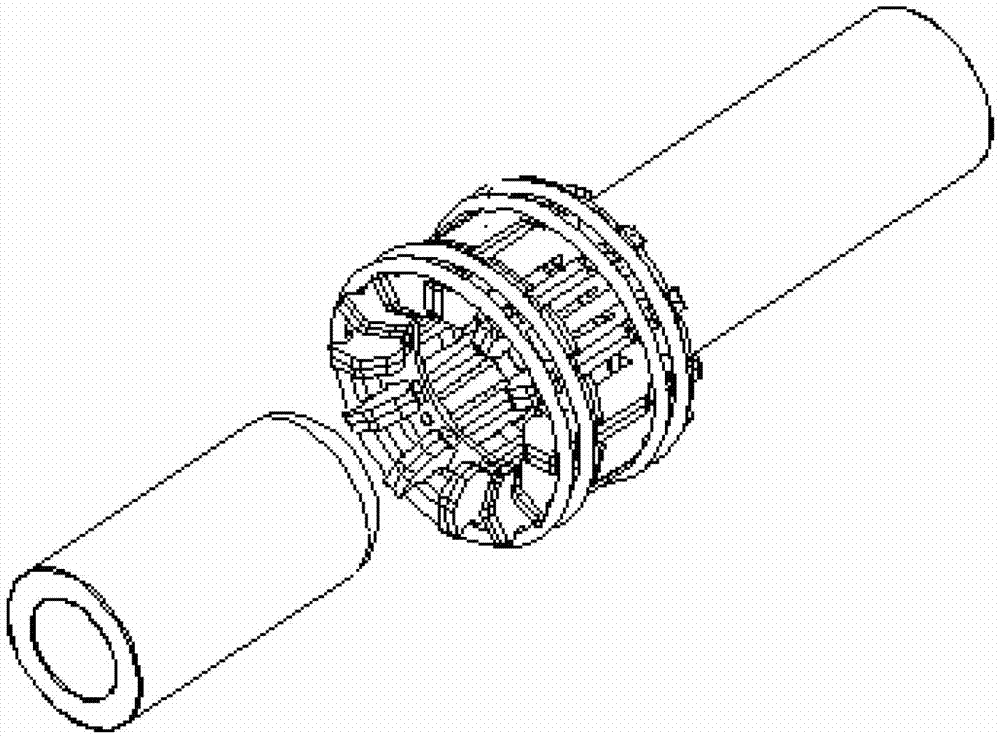

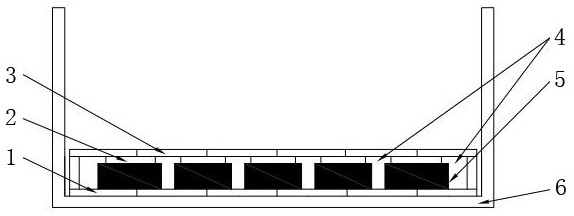

Rotary tulip contact and contact system for switching device

InactiveCN103208376AImprove securityAvoid point contactContact surface shape/structureContacts heating/coolingContact systemPoint contact

The invention relates to a rotary tulip contact. The rotary tulip contact comprises a closed ring support and a ring spring. A plurality of contact blade holes are uniformly and annularly distributed in the support. The ring spring is used for fixing contact blades in the contact blade holes. A plurality of movable and fixed contact blades forming the tulip contact are arranged in the contact blade holes. A semispherical raised part at the bottom of each movable contact blade is arranged in a U-shaped sunken groove on the top of the corresponding fixed contact blade, and is movably connected with the sunken groove in a rotating way. The rotary tulip contact has the advantages that contact surfaces between the contact blades and conducting rods are annular surfaces, so that the conventional point contact is avoided; and moreover, when fixed conducting rods are inserted into the ends of the movable contact blades, the raised parts of the movable contact blades can rotate to a certain degree in the sunken grooves, and the movable contact blades can return to original positions under the action of the external spring, so that the problem of suspension of a part of contact blades during the use of the tulip contact is solved, and the safety of high / low-voltage switches is effectively improved.

Owner:CIXI CITY HECHANG ELECTRIC APPLIANCE

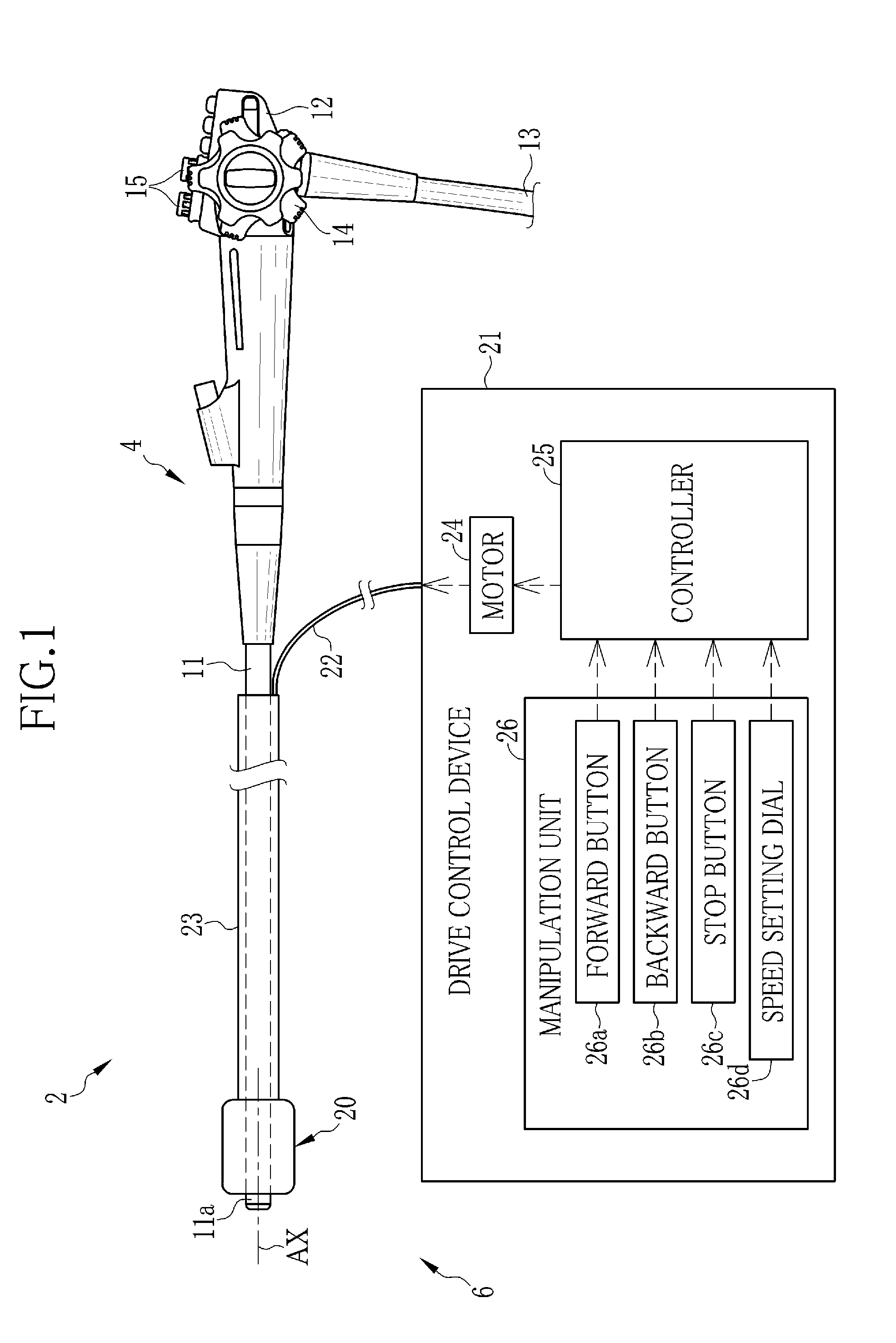

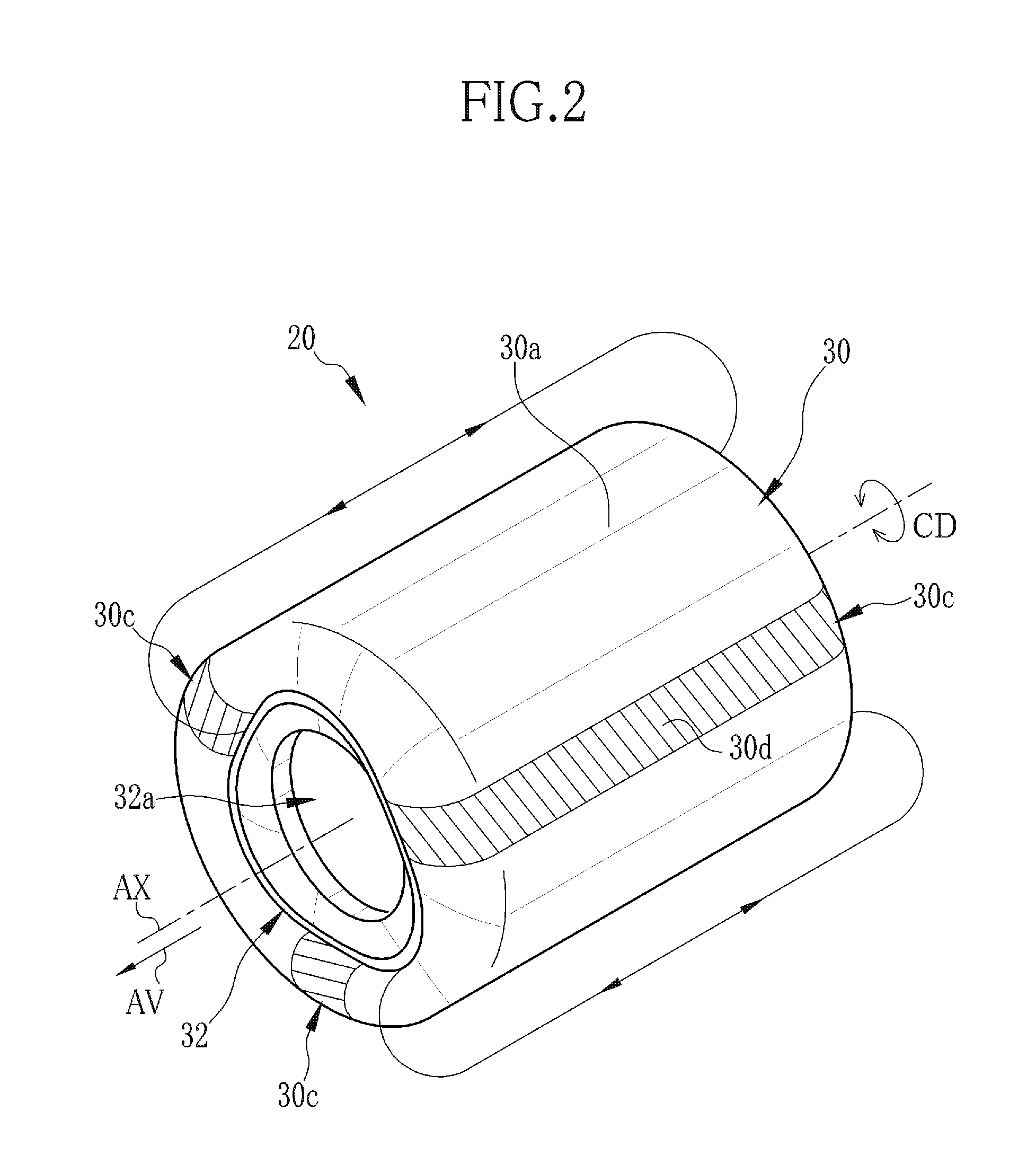

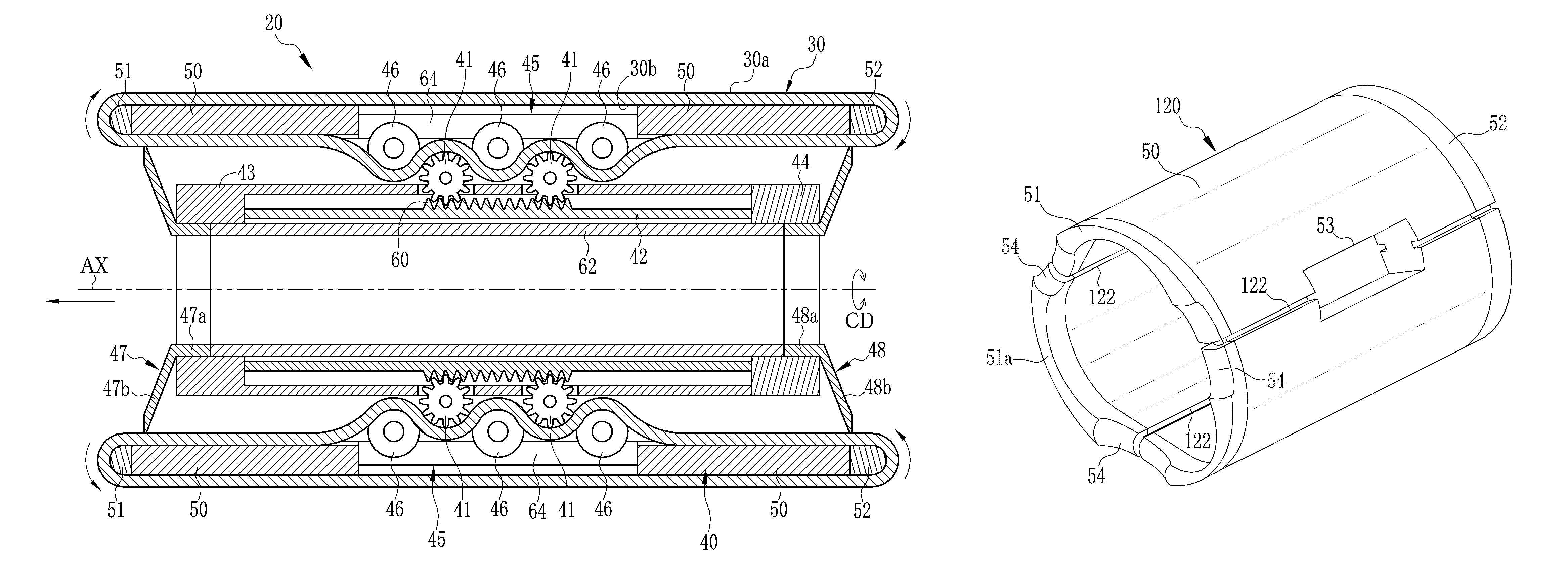

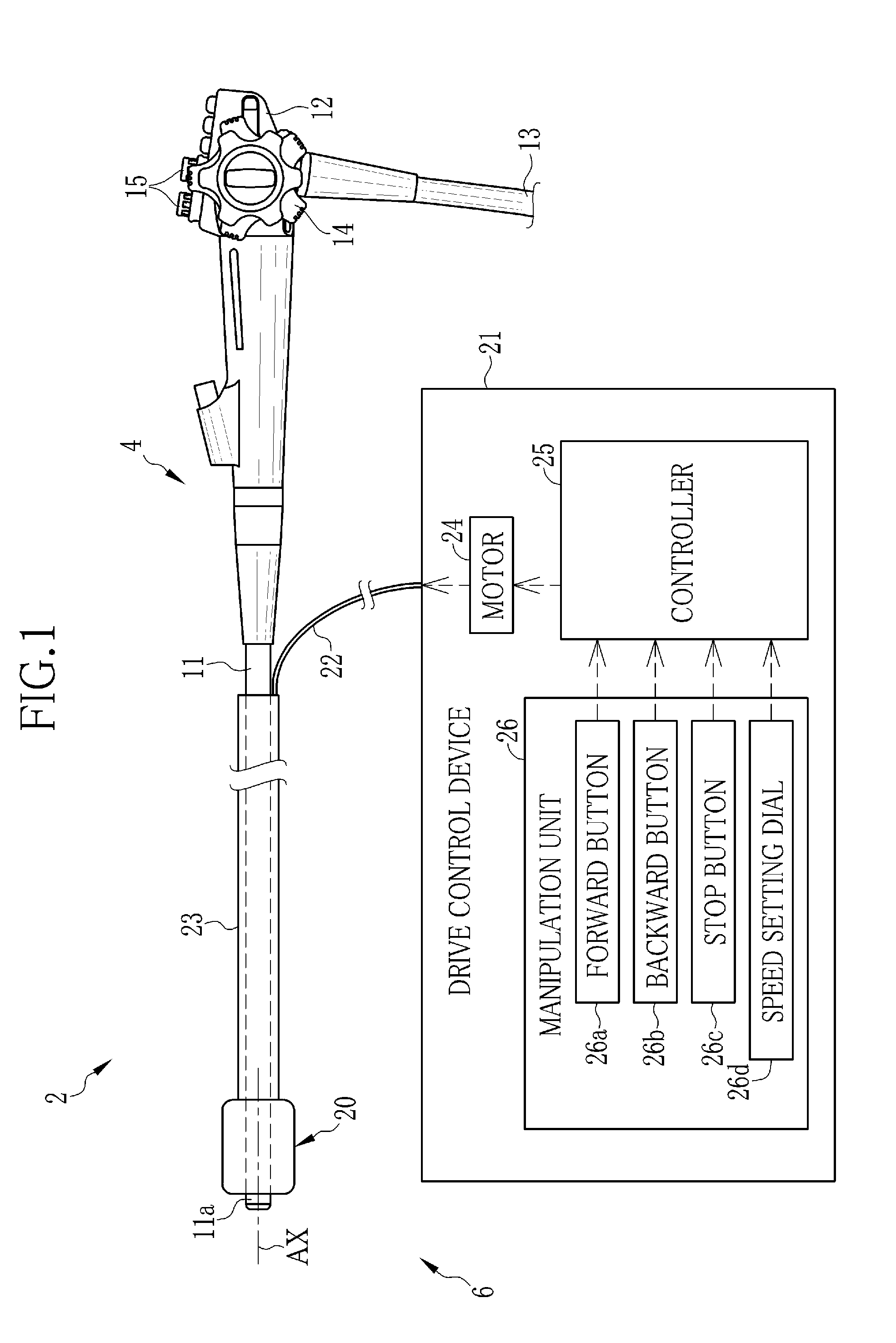

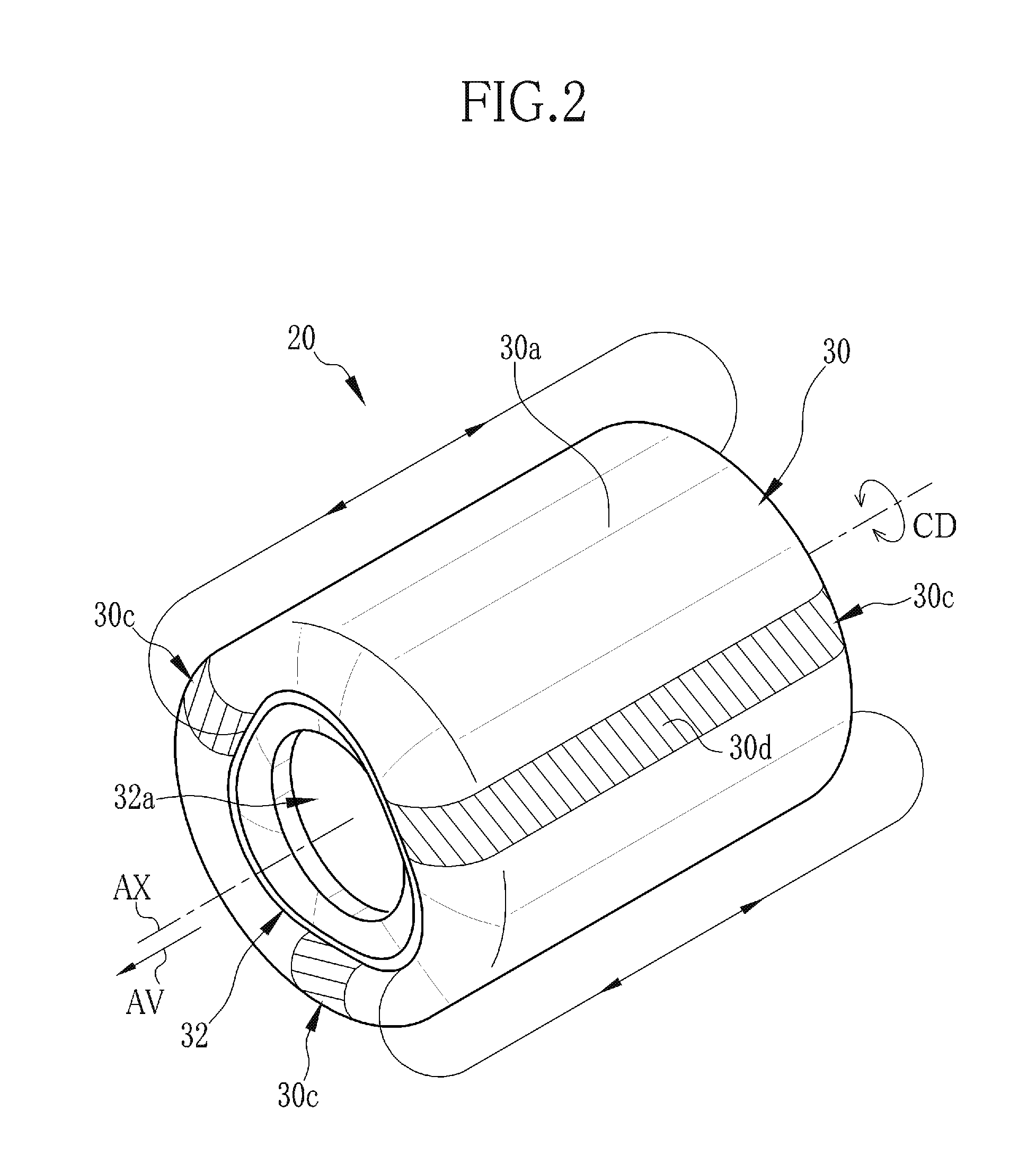

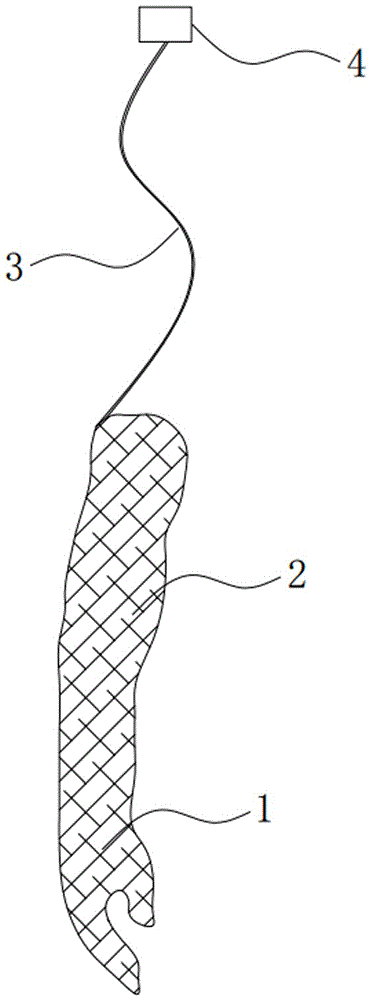

Endoscope insertion assisting device

ActiveUS20120277530A1High strengthIncrease flexibilitySurgeryEndoscopesEngineeringUltimate tensile strength

An insertion assisting device includes a rotary body in the form of toroid, and a support and drive part for supporting the rotary body in a rotatable manner and rotating it. The support and drive part has an approximately cylindrical supporting member for supporting the rotary body in a rotatable manner. The rotary body is provided with a convex portion for increasing the thickness to improve the strength thereof. A concave portion having a shape corresponding to the shape of the convex portion is formed on a portion of a front end surface of the supporting member, which is made in contact with the convex portion. The concave portion prevents the rotary body from stopping rotating, which may be caused by point contact between the convex portion and the supporting member.

Owner:FUJIFILM CORP

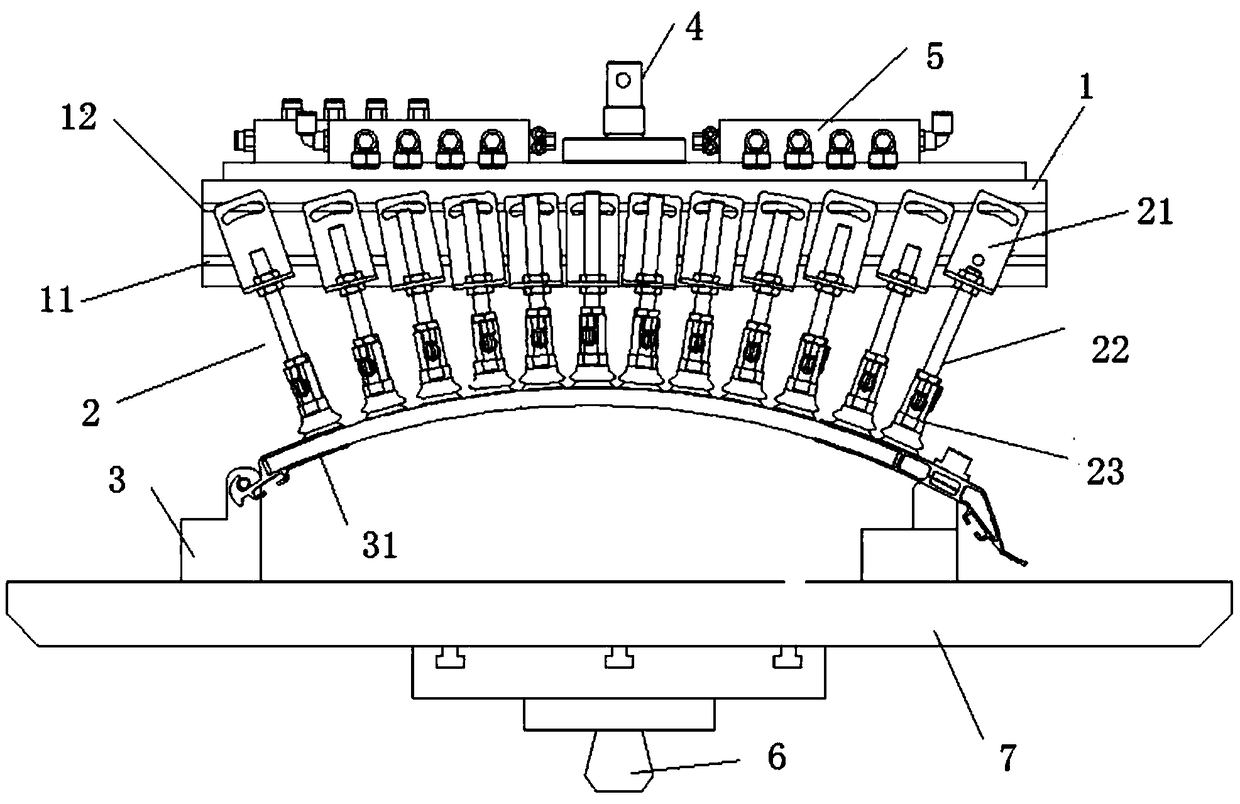

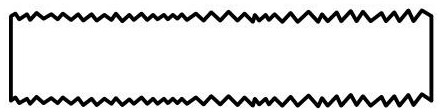

Curved-surface type fatigue sample strip detecting device

PendingCN108827667AGuaranteed accuracyAvoid point contactMachine part testingStands/trestlesSurface typePulp and paper industry

The invention provides a curved-surface type fatigue sample strip detecting device, which comprises a loading pressure head, fixed blocks, adjusting brackets, adjusting screw rods, vacuum suction cupsand supporting blocks, wherein the loading pressure head is fixed above the fixed blocks; each adjusting bracket is roatably connected with the corresponding fixed block; the adjusting screw rods areL-shaped components; each vacuum suction cup is arranged at one end, away from the corresponding adjusting bracket, of the corresponding adjusting screw rod, so as to absorb a sample strip from above; and the two supporting blocks are arranged, and are used for fixing the sample strip from two ends. Compared with the prior art, the curved-surface type fatigue sample strip detecting device has thebeneficial effects that the vacuum suction cups are arranged under the adjusting screw rods, the curved-surface type fatigue sample strip is absorbed by means of the vacuum suction cups, thus the curved-surface type fatigue sample strip can be stretched and compressed alternately in the measuring process, thereby avoiding the compression in a single direction, and ensuring the accuracy of the measurement result.

Owner:NEWTRY COMPOSITE

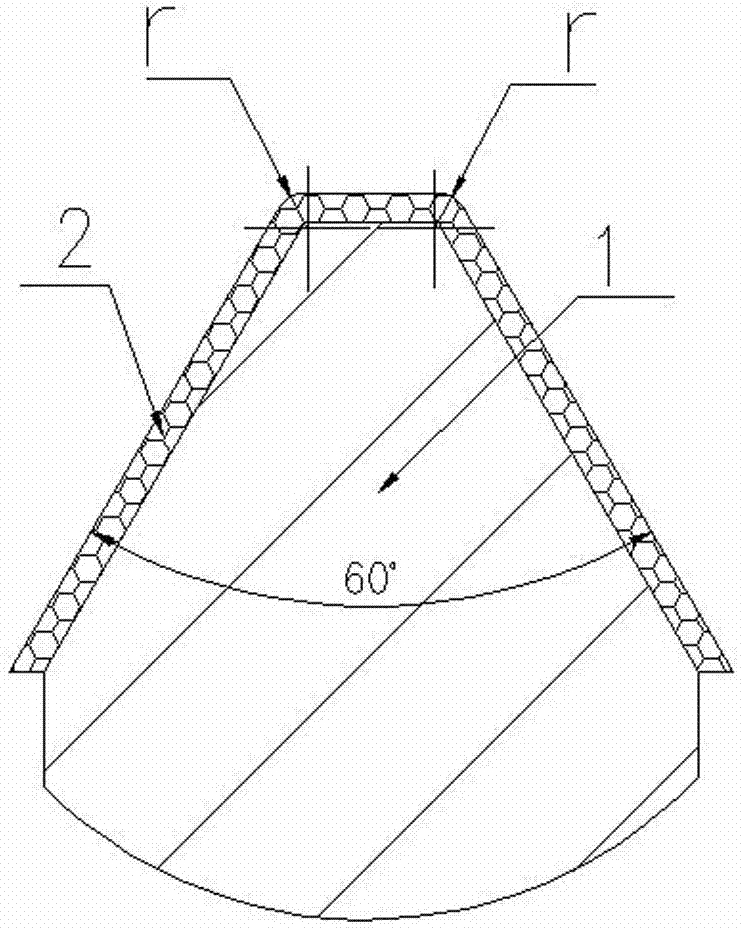

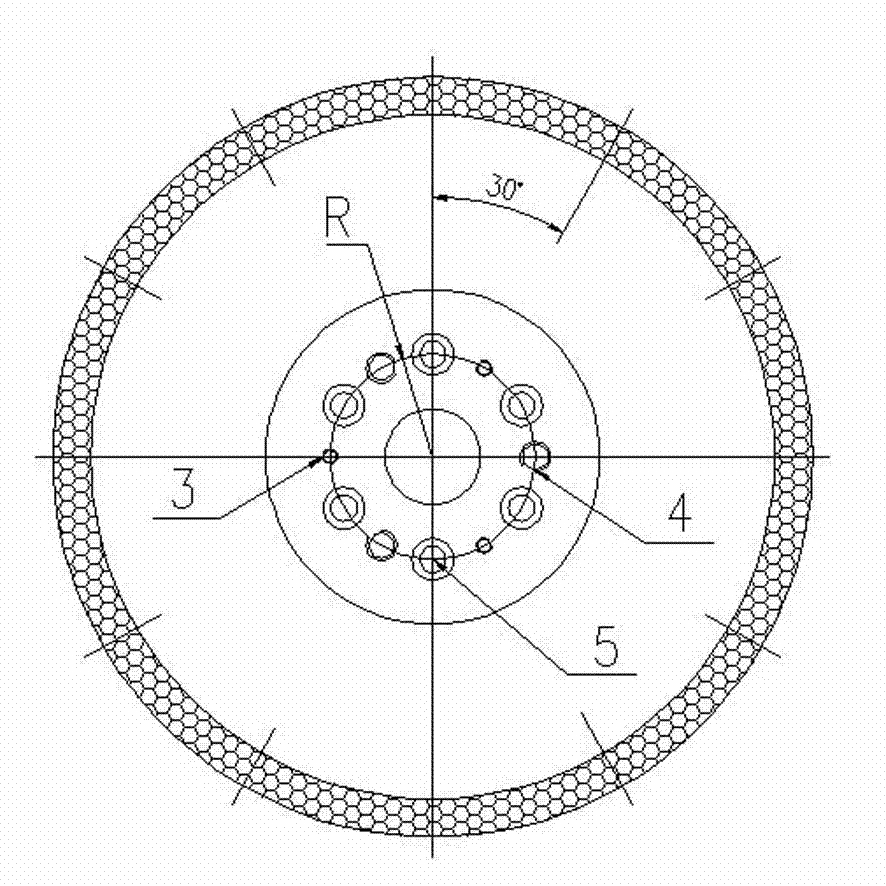

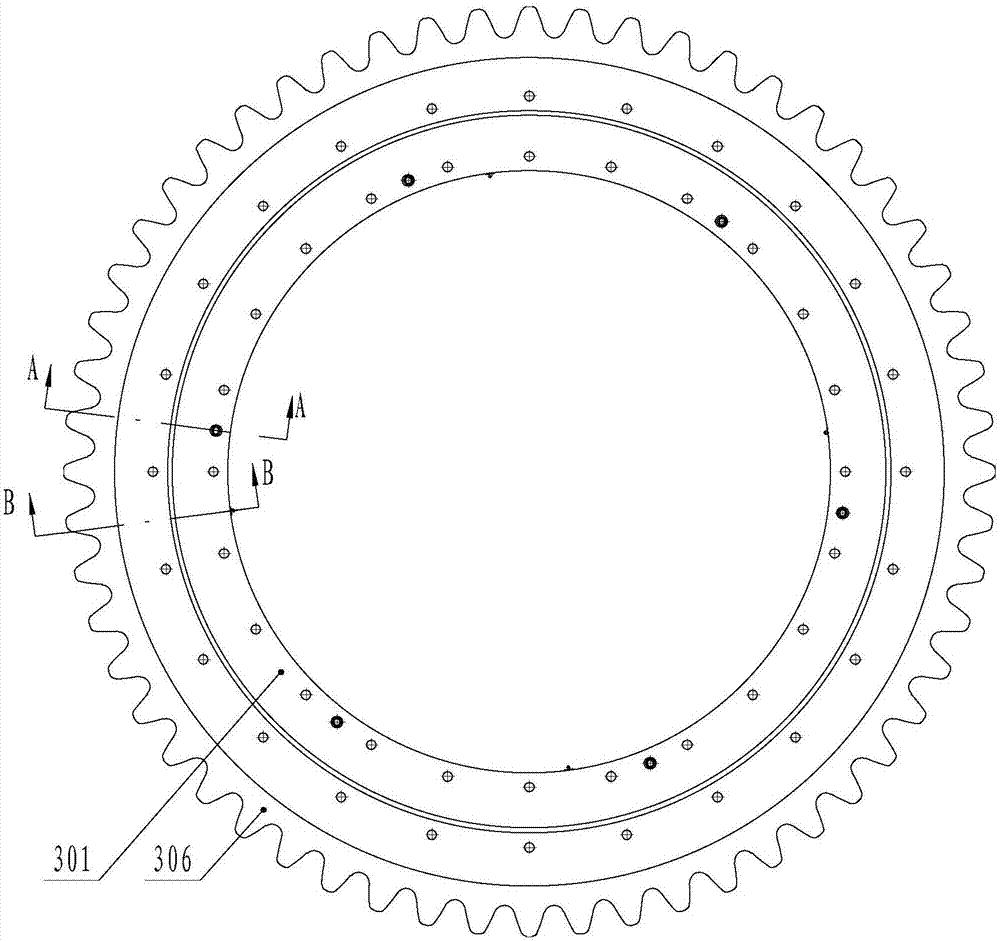

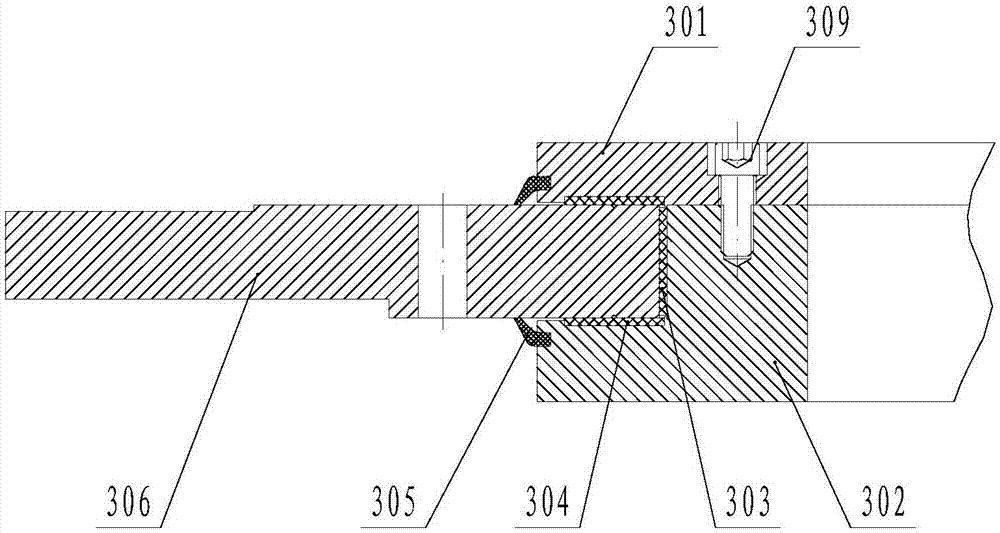

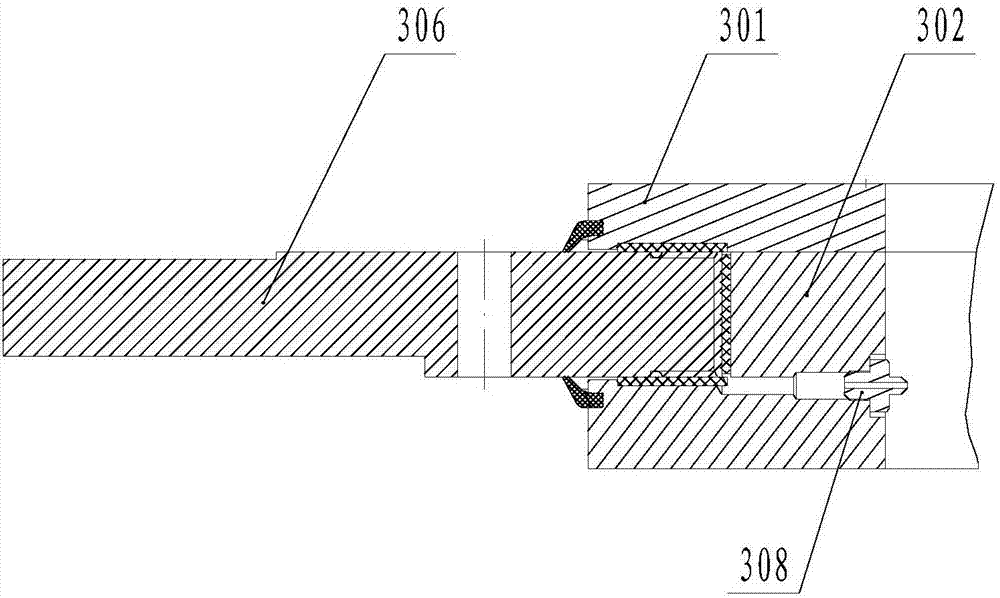

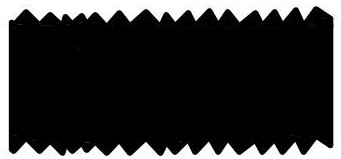

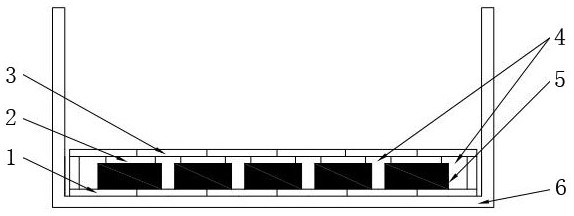

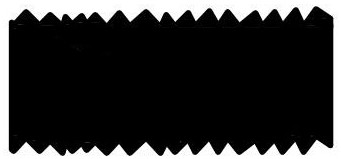

Electroplating CBN grinding wheel for efficient and precise gear profile grinding and manufacturing method of electroplating CBN grinding wheel for efficient and precise gear profile grinding

ActiveCN103878705AImprove mass distributionIncrease limit speedBonded abrasive wheelsIsosceles trapezoidAdsorptive membrane

The invention relates to an electroplating CBN grinding wheel for efficient and precise gear profile grinding. The electroplating CBN grinding wheel comprises a dish-shaped base body and a material grinding area at the edge of the dish-shaped base body, the mass of the material grinding area is 4%-15% of the total mass of the base body, the cross-section of a material grinding layer on the material grinding area is in an isosceles trapezoid shape, and the upper bottom and the two lateral edges are chamfered. A manufacturing method of the electroplating CBN grinding wheel includes the steps of firstly machining the base body of the grinding wheel, and then sequentially conducting negative and positive pole alternative electrochemistry oil removing, clamp and electrostatic adsorption film insulation assembling, negative and positive pole alternative electrolytic treatment, ballistic method preplating, grinding material assembling, thickening and grinding wheel electroplating on the base body of the grinding wheel. The using linear velocity of the electroplating CBN grinding wheel can achieve 250 m / s, and the grinding feeding amount achieves 4 m / min-10 m / min and is much higher than that of a common grinding wheel. The roughness Ra can achieve 0.4 micrometers, the surface quality requirement of a workpiece can be met, and gear efficient and precise gear profile grinding can be successfully achieved.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

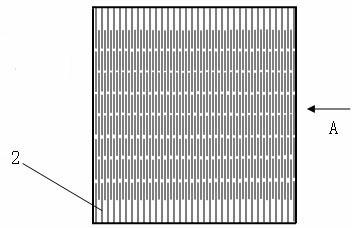

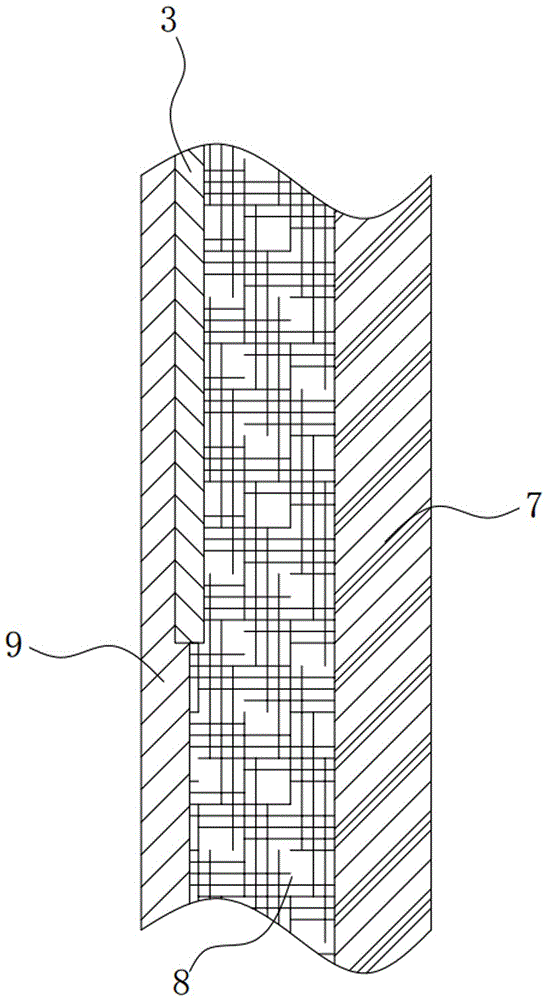

Scrimber comprising wood wool rod units and manufacturing method

ActiveCN102581917ASolve resource problemsSolve Exhaust ProblemsWood working apparatusDomestic articlesSolid woodBrick

The invention discloses a scrimber comprising wood wool rod units and a manufacturing method. Wood wool rods with identical specifications are directionally laid on a cushion plate in a stepped stacking mode or a brick wall type stacking mode after being selected, straightened, dried and glued, then the cushion plate is conveyed into a lower mold of an opening type mold mounted on a hot press, and single wood wool slabs are manufactured by means of thickness limiting mold pressing, pressure relieving, mold releasing and sanding processing; or the wood wool rods are directionally laid in a stepped stacking mode or a brick wall type stacking mode on the cushion plate placed at the bottom of a mold pressing box, and a wood wool mold pressing material is manufactured by means of mold pressing, pressure relieving and mold releasing. The scrimber has the advantages that characteristics of natural solid wood are kept, gluing area and gluing strength are improved, the problem that products including plywood, technical wood and the like need to be formed by single plates manufactured by means of rotationally cutting straight logs of large-diameter tree trunks is solved, and the problem of strain on resources and resource exhaustion of raw materials for producing the man-made board products is also solved.

Owner:TONGXIANG BEITE TECH CO LTD

Endoscope insertion assisting device

Owner:FUJIFILM CORP

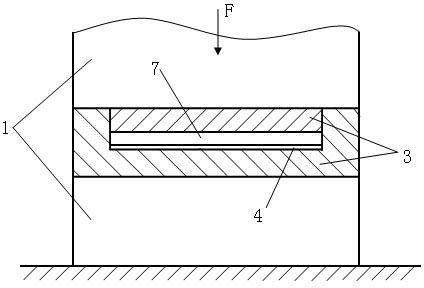

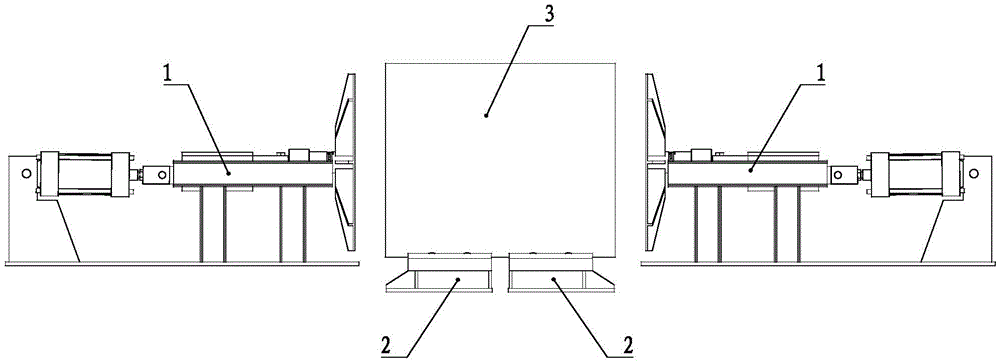

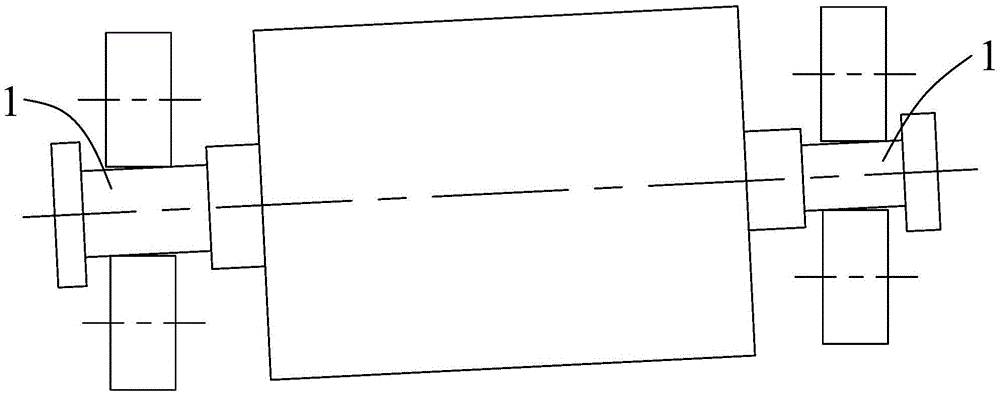

Tower-shaped repairing device of hotly-rolled steel coil

The invention provides a tower-shaped repairing device of a hotly-rolled steel coil and relates to the technical field of steel coil defect correction. The tower-shaped repairing device comprises lateral pushing mechanisms, a saddle, a power system and a control system, wherein the saddle is used for storing the steel coil; the lateral pushing mechanisms are arranged on the two sides of the saddle respectively. Each lateral pushing mechanism comprises an air cylinder base, an air cylinder, a trolley, a guide rail, a guide rail support, a push plate and a base plate. A cylinder body of the air cylinder is hinged to the air cylinder base; a piston rod of the air cylinder is hinged to the trolley through a U-shaped connector; the trolley can move along the guide rail; an arm of the trolley is connected with the push plate through a floating connection piece. According to the tower-shaped repairing device provided by the invention, the floating connection piece is additionally arranged between the push plate and a driving part, so that point contact between the push plate and the steel coil can be avoided, and the push plate can be completely filled with a convex part of the steel coil all the time in a repairing process, and a movement track of the steel coil is completely fitted; a condition that part abrasion is caused by the fact that a twisting force is transmitted to the driving part is avoided, and labor is saved in a use process of the tower-shaped repairing device.

Owner:SHANDONG IRON & STEEL CO LTD

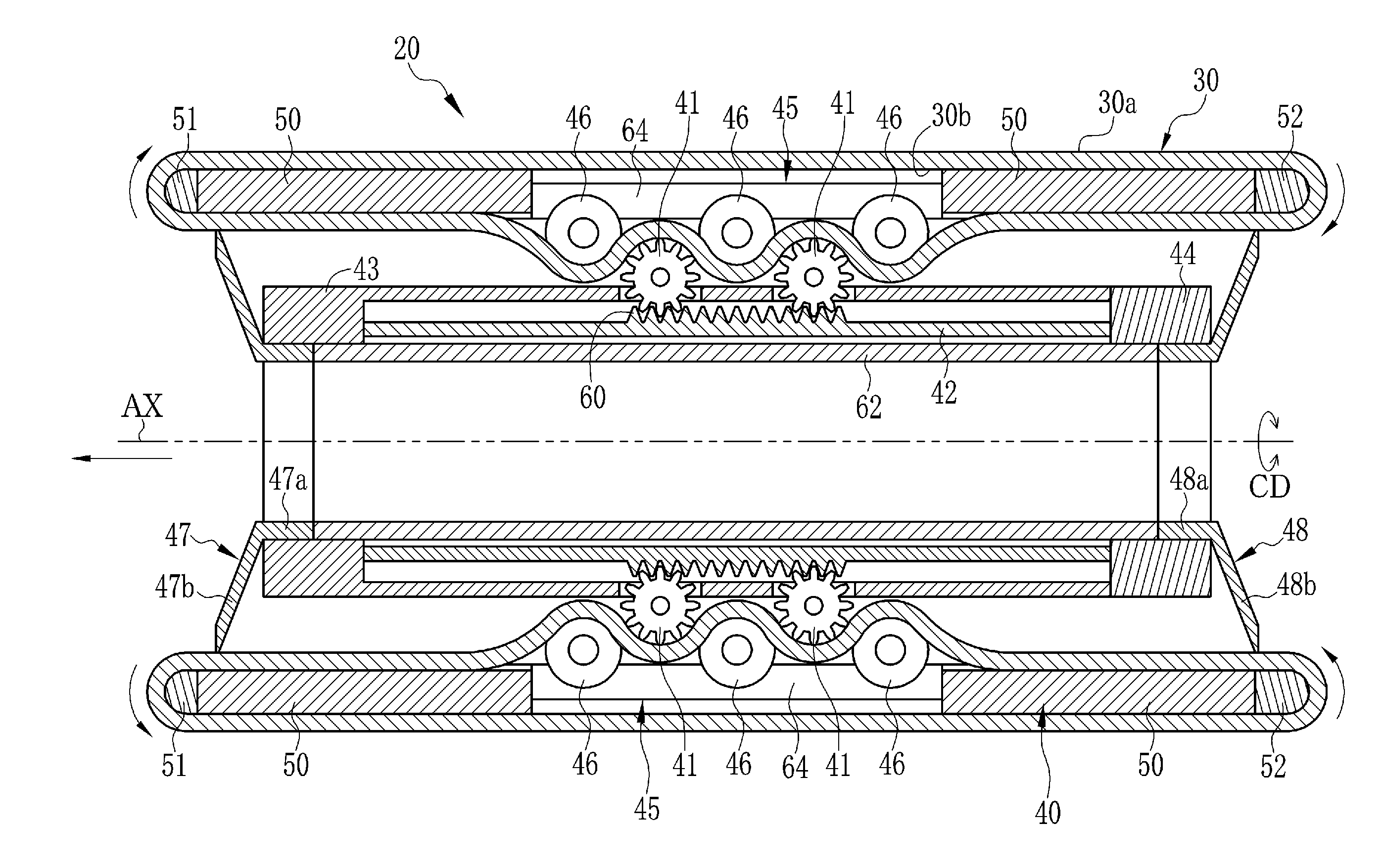

Rolling disc type working device and slide revolving support thereof

PendingCN107574850AFully lubricatedWell formedMechanical machines/dredgersAgricultural rollersLubricationPlain bearing

The invention discloses a rolling disc type working device and a slide revolving support thereof, and belongs to the field of engineering machinery. The device mainly comprises an upper fixed plate and a lower fixed plate; a slide gear ring is arranged between the upper fixed plate and the lower fixed plate; composite slide bearings II and sealing rings are arranged above and below the slide gearring and between the upper fixed plate and the lower fixed plate; a composite slide bearing I is arranged between the inner side of a slide outer gear ring and the lower fixed plate; lubricating oil tanks are respectively formed in the side surfaces, contacted with the upper fixed plate and the lower fixed plate, of the slide gear ring; lubricating holes are formed in the lower fixed plate, and communicate with the lubricating oil tanks; and lubricating oil cups are arranged in the lubricating holes. A sliding end and a fixed end are in surface contact; a lubricating oil film is easier to form; the lubrication is more sufficient; the replacement cost is low; and failed parts are only replaced. The device is mainly applied to a land leveler.

Owner:SHANDONG LINGONG CONSTR MACHINERY

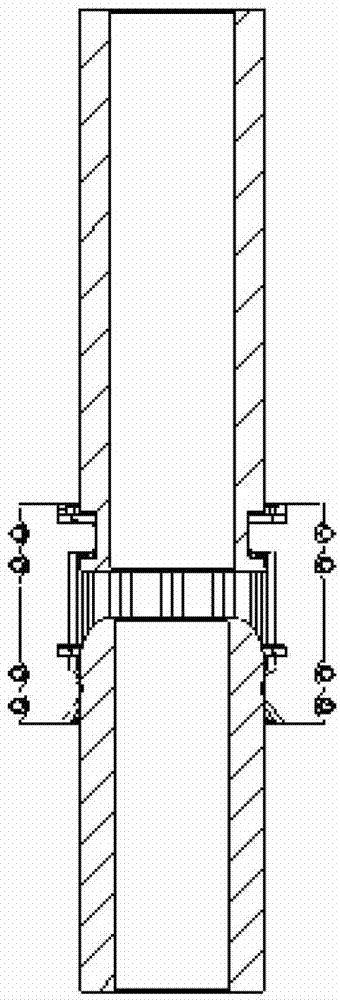

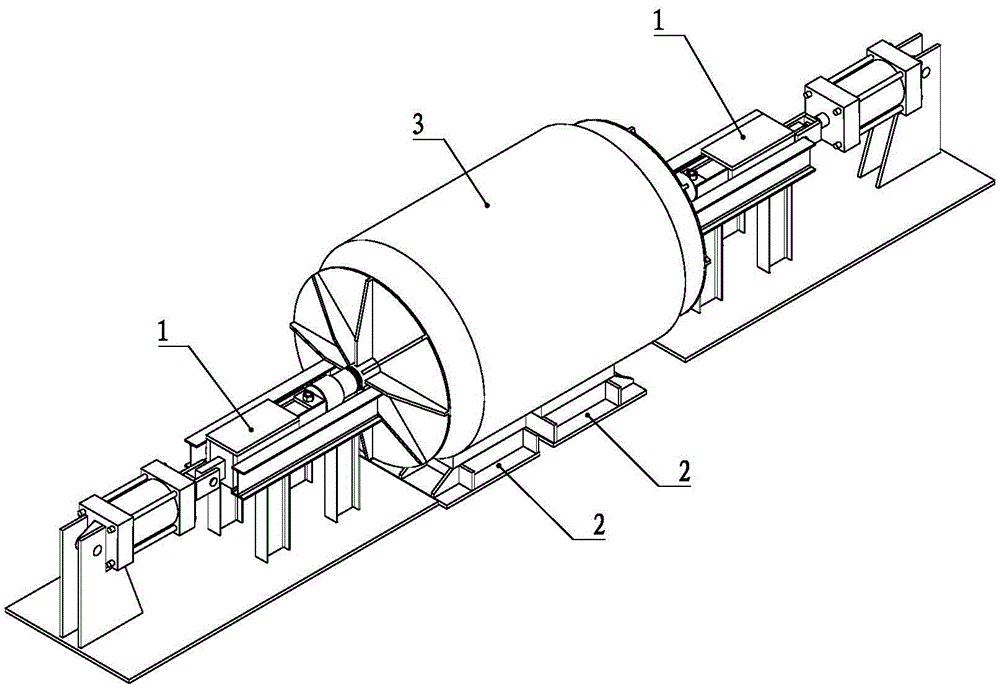

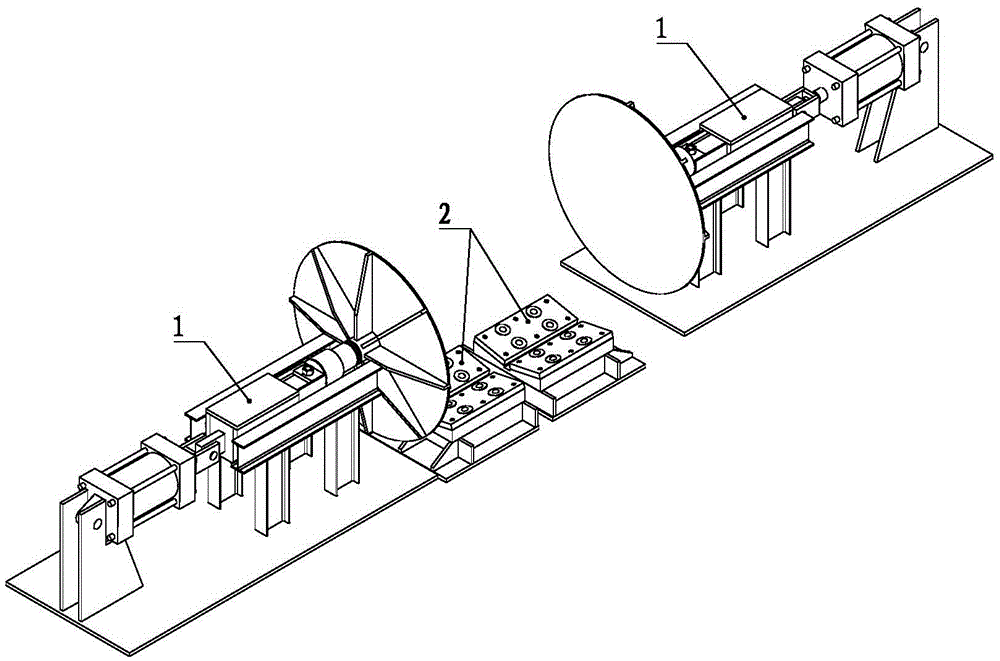

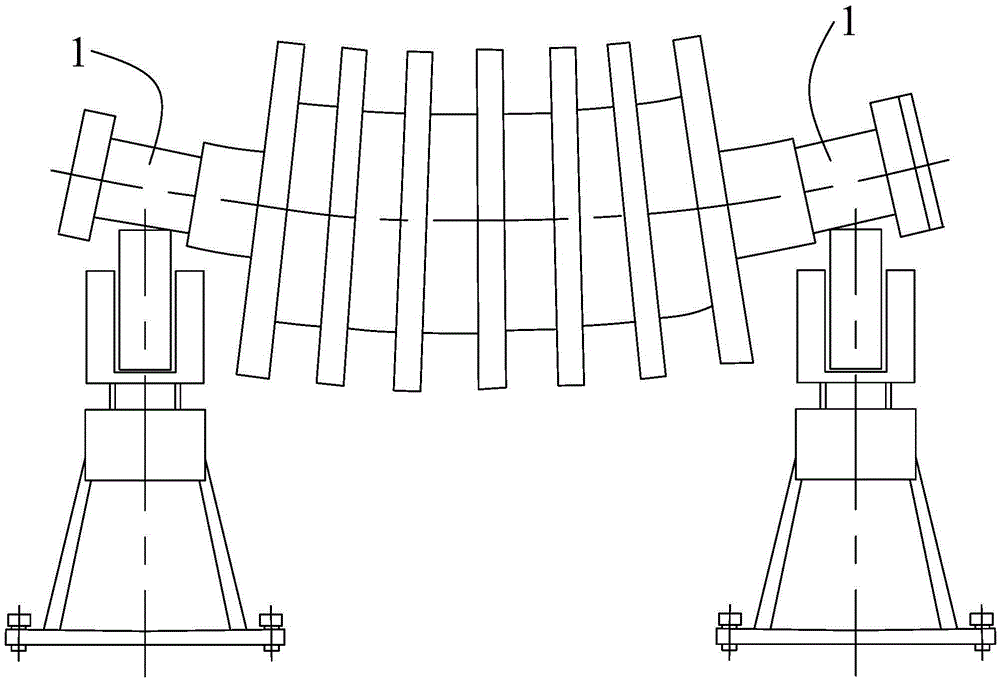

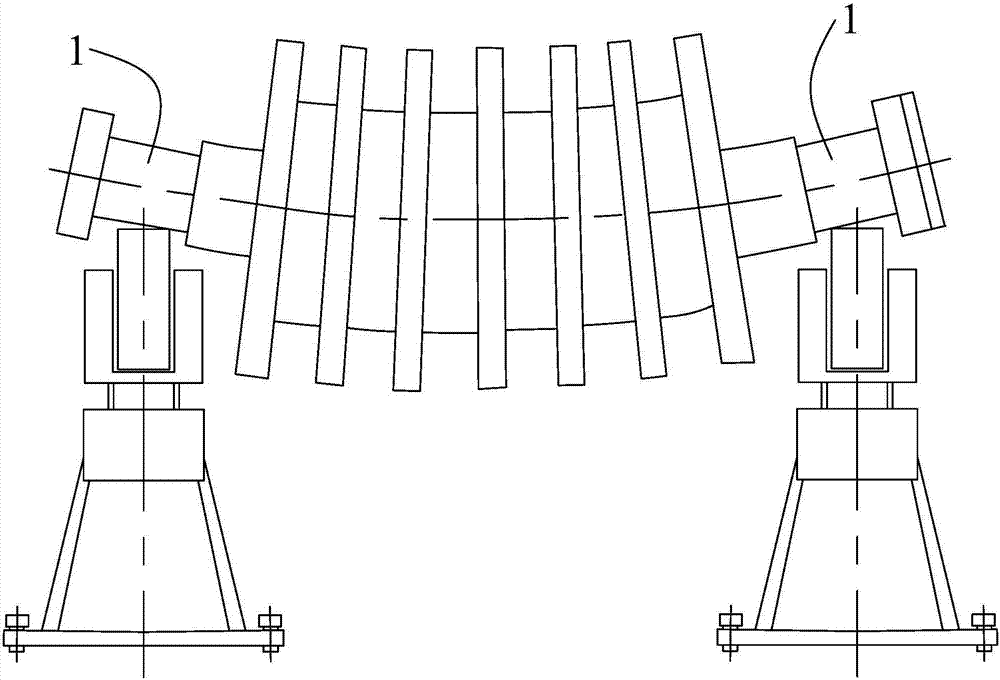

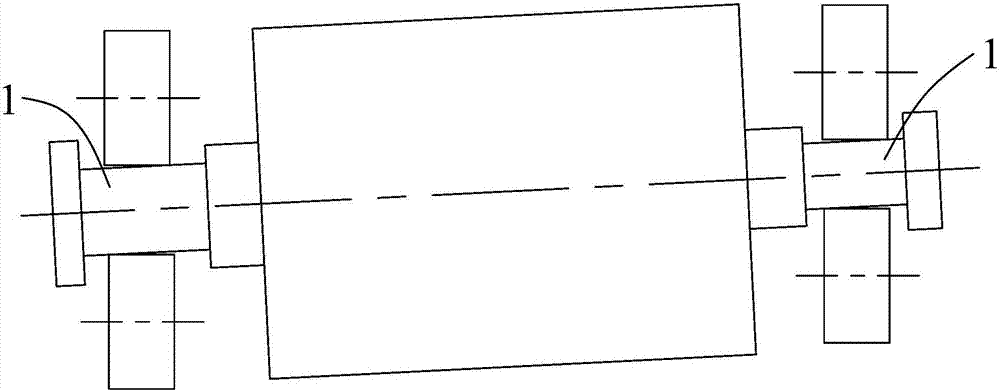

Novel roller bracket for steam turbine rotor

ActiveCN105583794AEliminate stress concentrationAvoid destructionWork benchesEngineeringStress concentration

The invention provides a novel roller bracket for a steam turbine rotor. The novel roller bracket comprises a base, a roller bracket body located above the base, and two supporting rollers arranged in a left-right symmetry mode. The two supporting rollers are both mounted in the roller bracket body in a rotatable mode. After the rotor is placed on the novel roller bracket for the steam turbine rotor, the two supporting rollers are located on the left side and the right side of a rotor journal respectively, and the outer circumferential faces of the supporting rollers make contact with the outer circumferential face of the rotor journal. The supporting rollers can rotate along the vertical radial line of the rotor journal, and swing front and back along the transverse radial line of the rotor journal. After the rotor is placed on two novel roller brackets, oppositely arranged front and back, for the steam turbine rotor, the supporting rollers can rotate and swing front and back automatically through pressure of the rotor on the supporting rollers, so that the outer circumferential faces of the supporting rollers are always in line contact with the outer circumferential face of the rotor journal, point contact between the supporting rollers and the rotor journal is avoided, and therefore the phenomenon of stress concentration is avoided, and burring of the outer circumferential face of the rotor journal and damage to the rotor are prevented.

Owner:SHANGHAI HAIYE ELECTROMECHANICAL EQUIP CO LTD

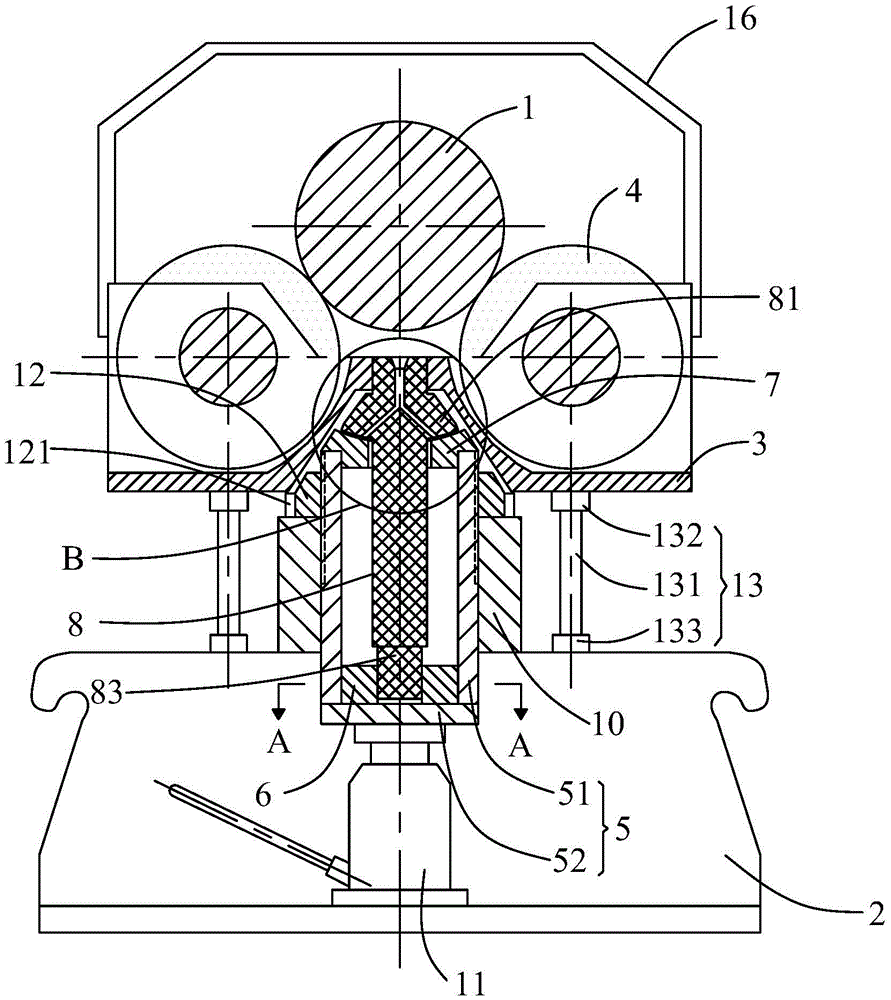

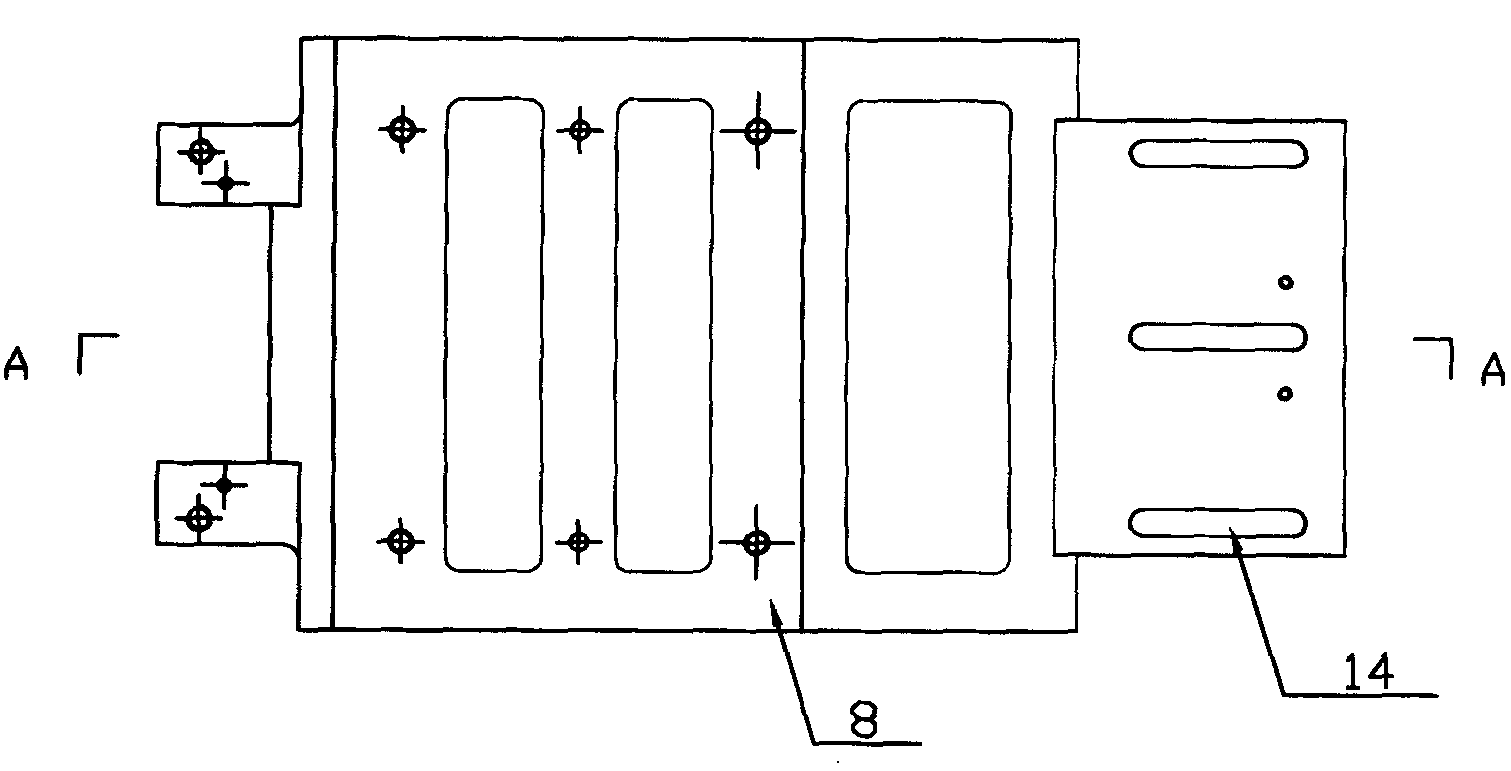

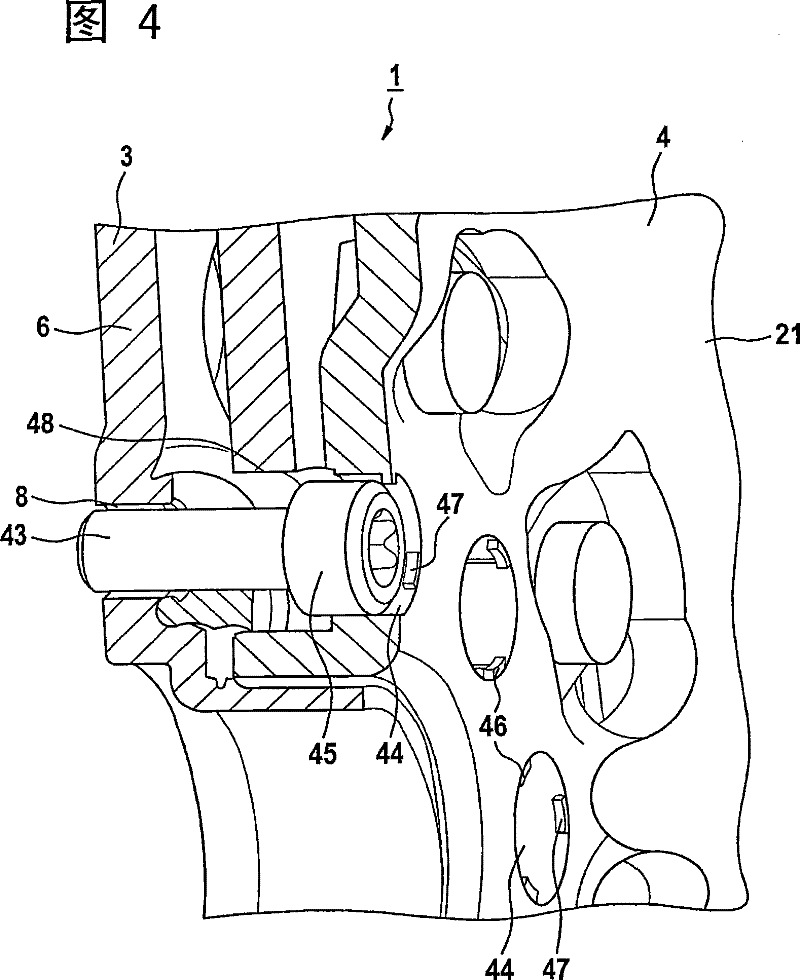

Contact mechanism of switching device capable of realizing three states

ActiveCN104576092ALarge rotation angleLittle electrical wearContact engagementsContact pressureState switching

The invention provides a contact mechanism of a switching device capable of realizing three states. The contact mechanism comprises multiple contact units sequentially arranged in parallel, wherein each contact unit comprises a movable contact group and a static contact group; mirror images on the two sides of the central part of the movable contact group symmetrically extend out of a movable contact plate part; each movable contact plate part further comprises a beat type contact and an arc-shaped knife type inserting contact which are fixedly arranged on the two sides of the external end part of the movable contact plate part respectively and have the same orientation; each static contact group comprises two finger-type beat type static contacts and one knife type inserting static contact, and the two finger-type beat type static contacts are arranged on the two sides of the central part of the movable contact group respectively. According to the invention, the contact mechanism can effectively reduce electrical wear generated when a contact is closed or disconnected, enables the rotating angle of the movable contact group to be enlarged to an angle nearly 180 degrees, is very suitable for the switching device capable of switching among three states, effectively avoids the point contact phenomenon caused by machining error and other cumulative errors, ensures contact pressure, and enables a movable contact and a static contact to keep excellent surface contact.

Owner:SCHNEIDER WINGOAL TIANJIN ELECTRIC EQUIP

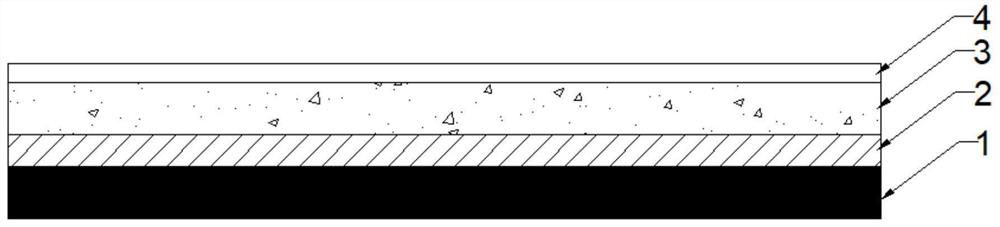

Negative electrode, and preparation method and application thereof

InactiveCN113224263AAvoid point contactReduce irreversible capacityNegative electrodesElectrode collector coatingMetallic lithiumElectrical battery

The invention provides a negative electrode, and a preparation method and application thereof. The negative electrode comprises a current collector, a negative electrode active material layer, a slow-release layer and an active lithium layer which are sequentially stacked, the slow-release layer comprises inorganic particles and a binder, and the ionic conductivity of the slow-release layer is smaller than 10<-4> S / cm. The slow-release layer with the inorganic particles is added between the active lithium layer and the negative electrode active layer, so that direct contact between metal lithium and a negative electrode active material before a lithium supplementing process is avoided, and the effect of improving the safety performance of the battery is further achieved.

Owner:SUZHOU QINGTAO NEW ENERGY TECH CO LTD

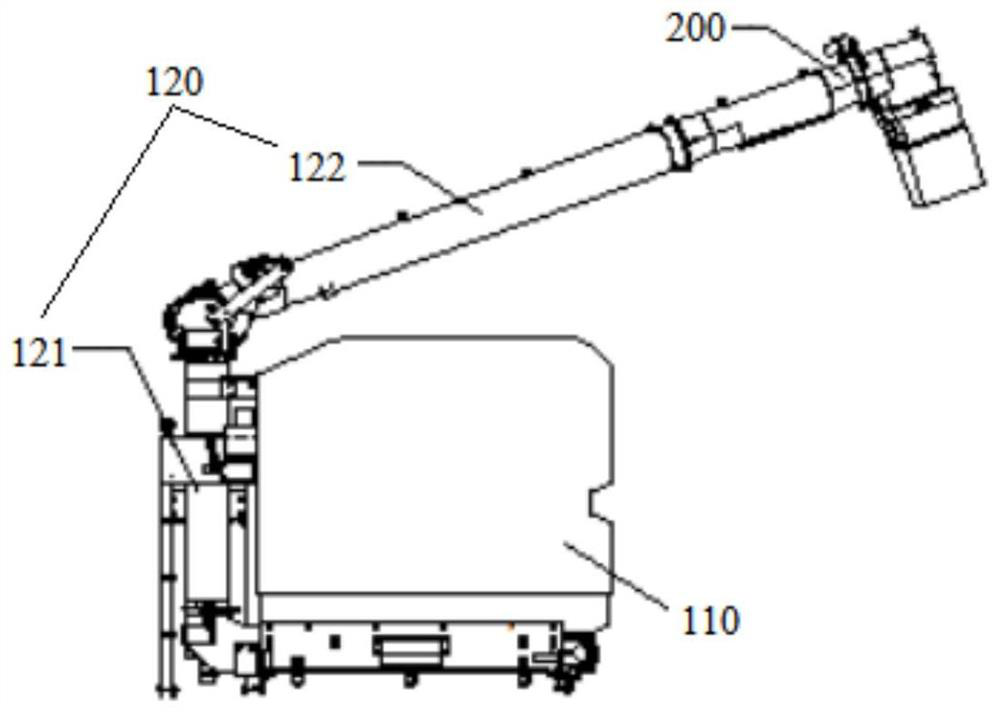

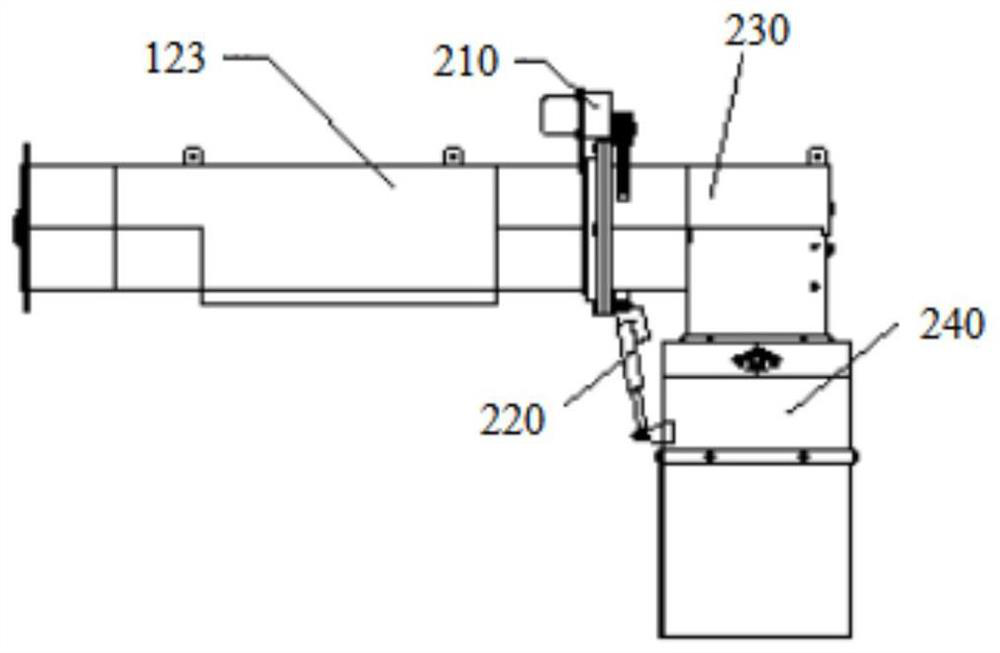

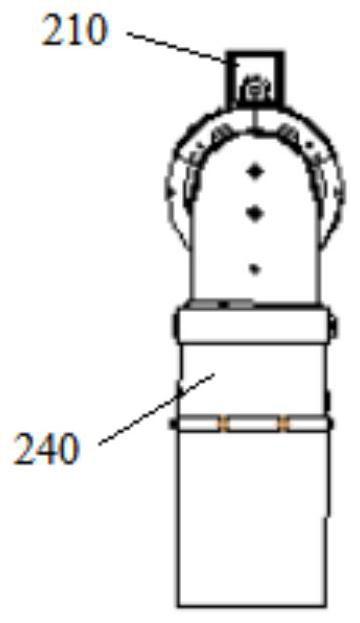

Movable grain unloading opening mechanism of combine harvester, grain unloading device and harvester

PendingCN113575100AImprove the efficiency of grain unloading operationsReduce operating costsMowersAgricultural engineeringStructural engineering

The invention discloses a movable grain unloading opening mechanism of a combine harvester, a grain unloading device and a harvester, and belongs to the technical field of harvesters. The movable grain unloading opening mechanism of the combine harvester is installed at the tail end of a grain unloading horizontal auger assembly and comprises a radial rotating assembly and an axial swinging assembly. The radial rotating assembly can rotate around the axis of the horizontal grain unloading auger assembly, and the axial swing assembly can swing in the axis direction of the horizontal grain unloading auger assembly. According to the movable (vector) grain discharging opening mechanism, during grain discharging operation, a grain discharging opening can be freely adjusted in the 360-degree direction on the horizontal projection plane, the grain discharging direction can be freely changed, grains can be evenly discharged to all corners of a dragging box of a grain transporting vehicle, the grain discharging operation efficiency of the harvester is greatly improved, the operation cost of the harvester is saved, and potential safety hazards during grain unloading are further eliminated. The movable grain unloading opening mechanism of the combine harvester is simple in principle, reasonable in structural design and convenient to popularize and use.

Owner:苏州久富农业机械有限公司

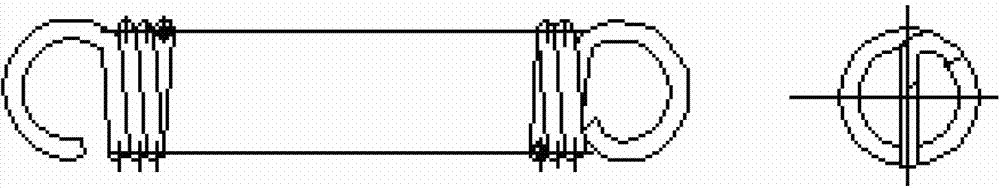

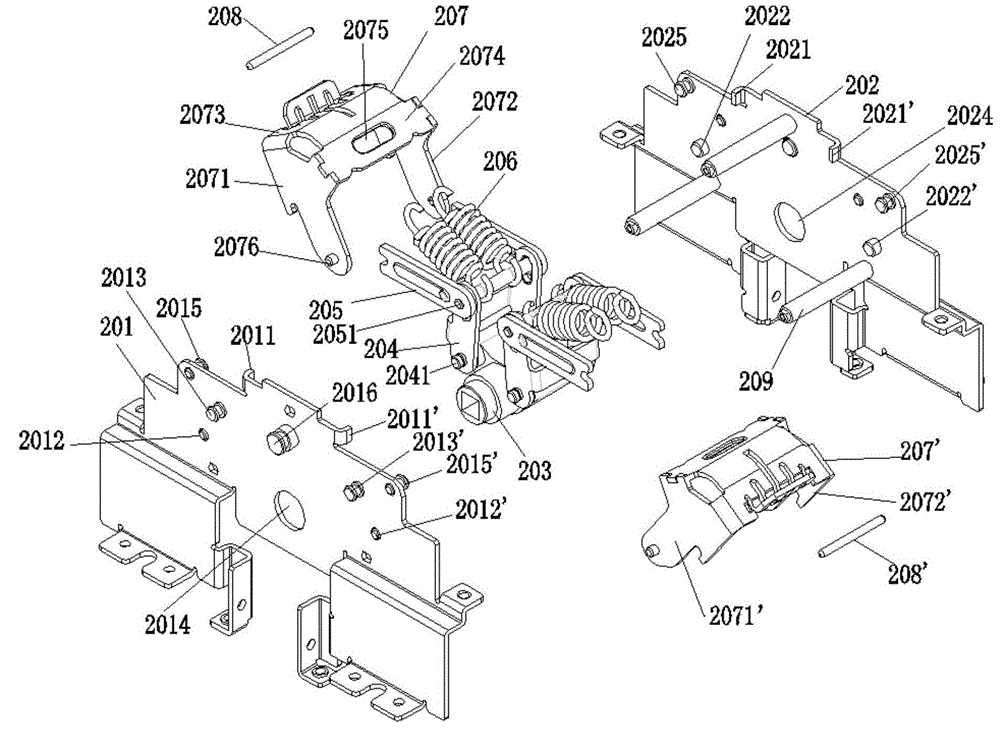

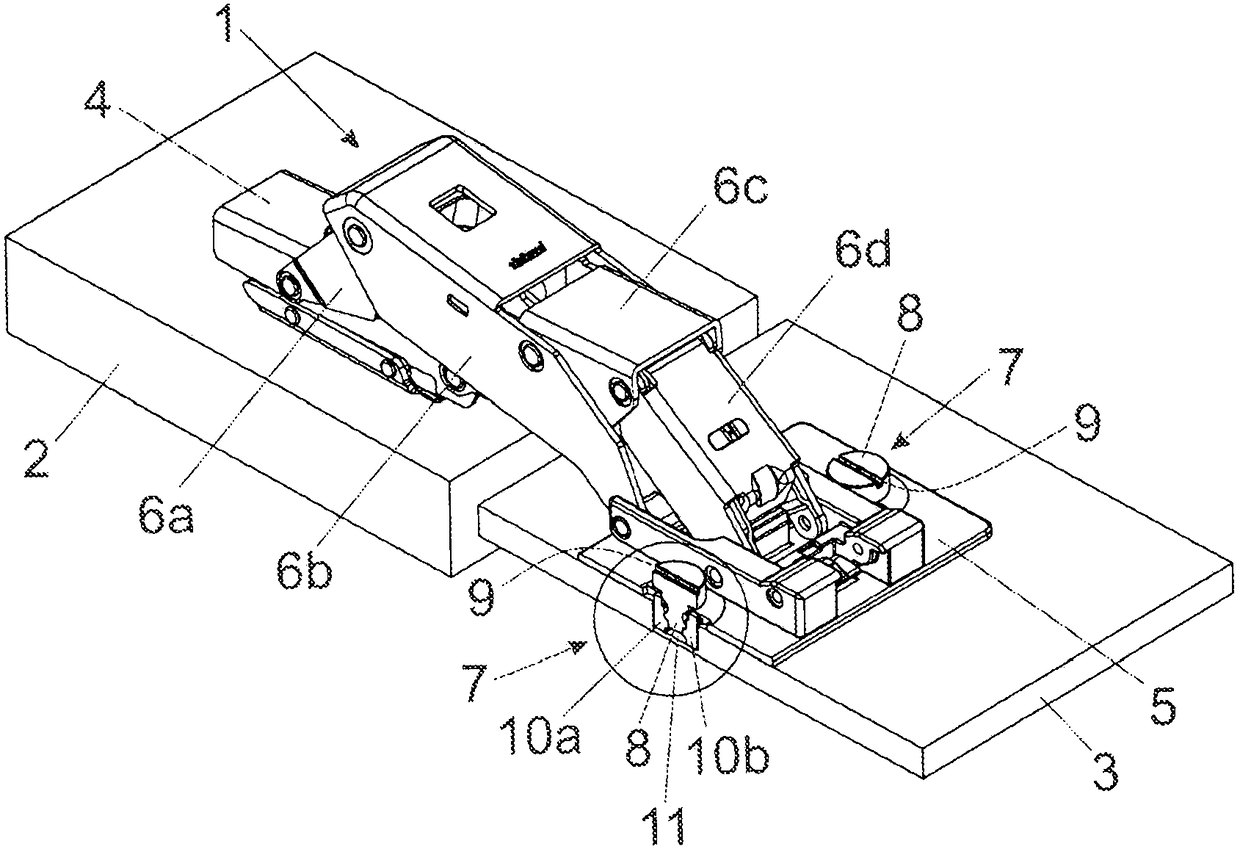

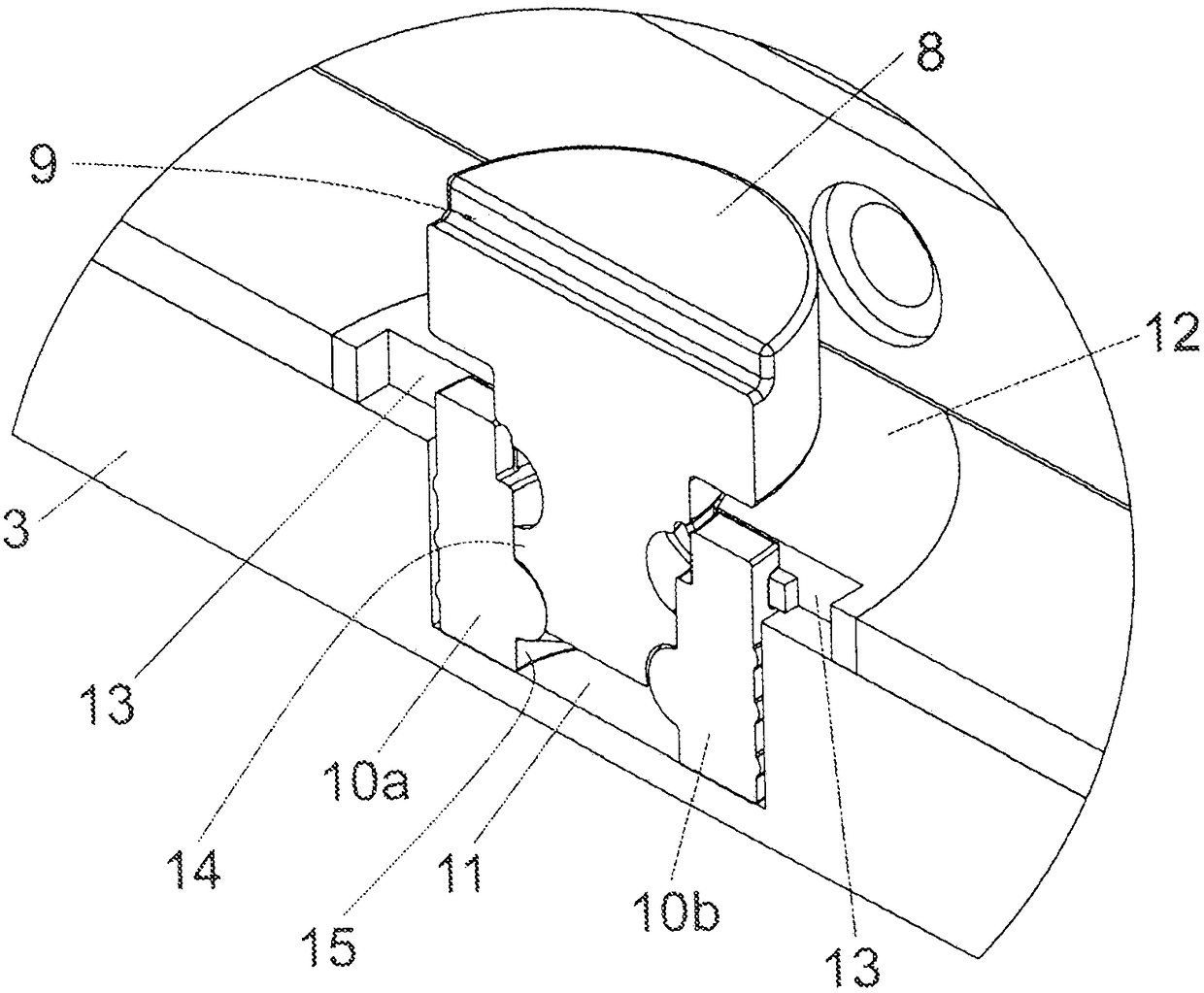

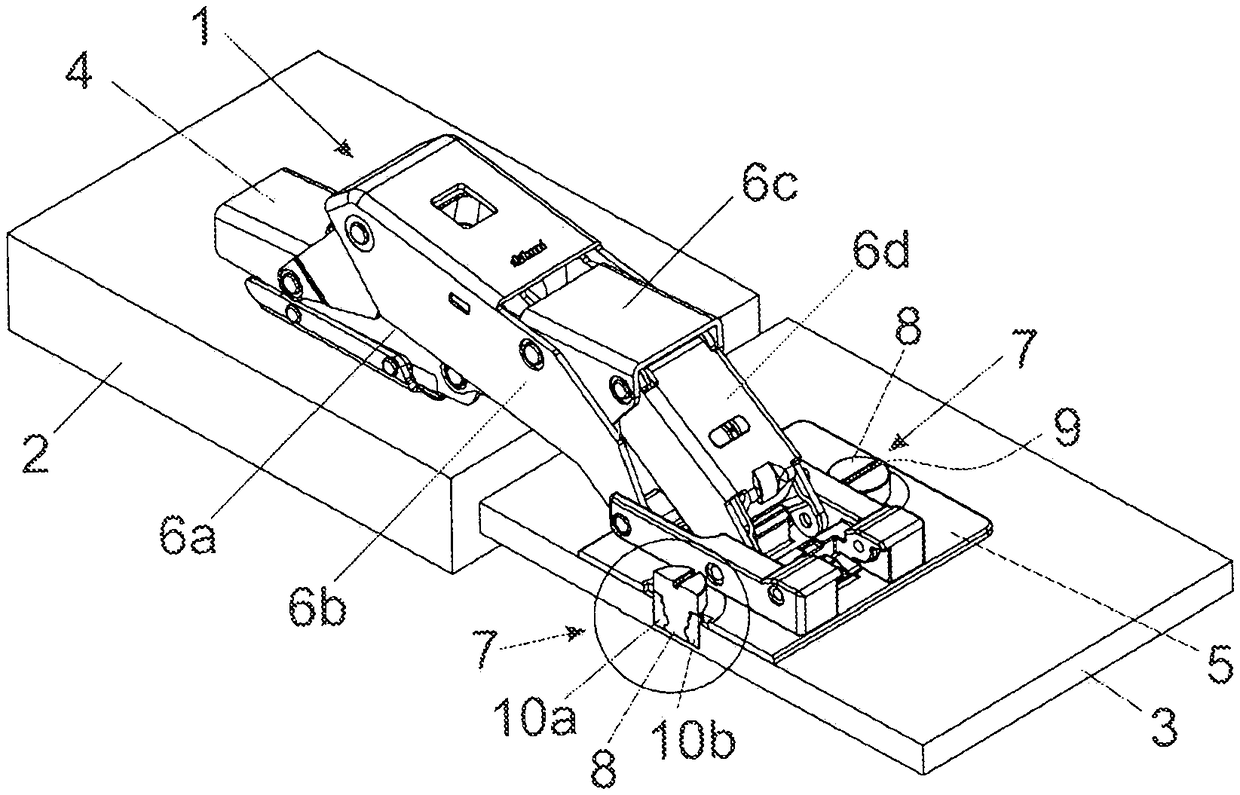

Furniture fitting

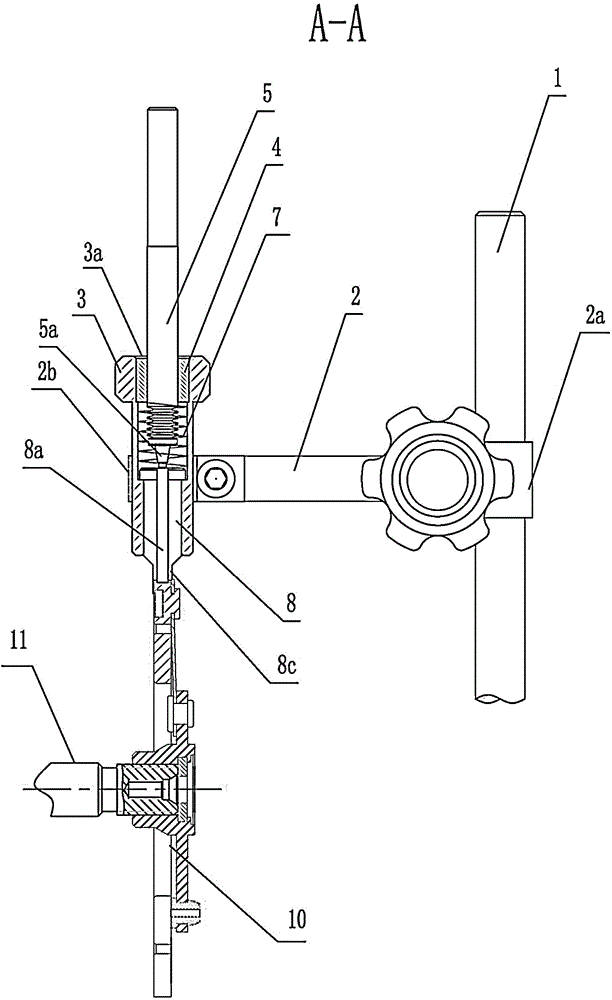

The invention relates to a furniture fitting (1) comprising the following: - a flange (12) for contacting a furniture part (3), and - at least one securing device (7) for securing the furniture fitting (1) to the furniture part (3) by means of the flange (12), wherein - the securing device (7) has at least two securing elements (10a, 10b), which can be inserted into an opening (11), in particulara cylindrical bore, of the furniture part (3), and at least one rotatably mounted locking element (8). The at least two securing elements (10a, 10b) can be moved relative to each other and relative tothe flange (12) by rotating the locking element (8) in a first rotational direction starting from a starting position, and the securing elements can thus be pushed into a spreading position in whichthe at least two securing elements (10a, 10b) can be locked in the opening (11) of the furniture part (3). The at least two securing elements (10a, 10b) can be released from the opening (11) by rotating the locking element (8) in a second rotational direction, wherein the at least two securing elements (10a, 10b) are pretensioned in the direction of the starting position by at least one force accumulator (17) such that the at least two securing elements (10a, 10b) can be retracted out of the spreading position into the starting position by rotating the locking element (8) in the second rotational direction.

Owner:JULIUS BLUM GMBH

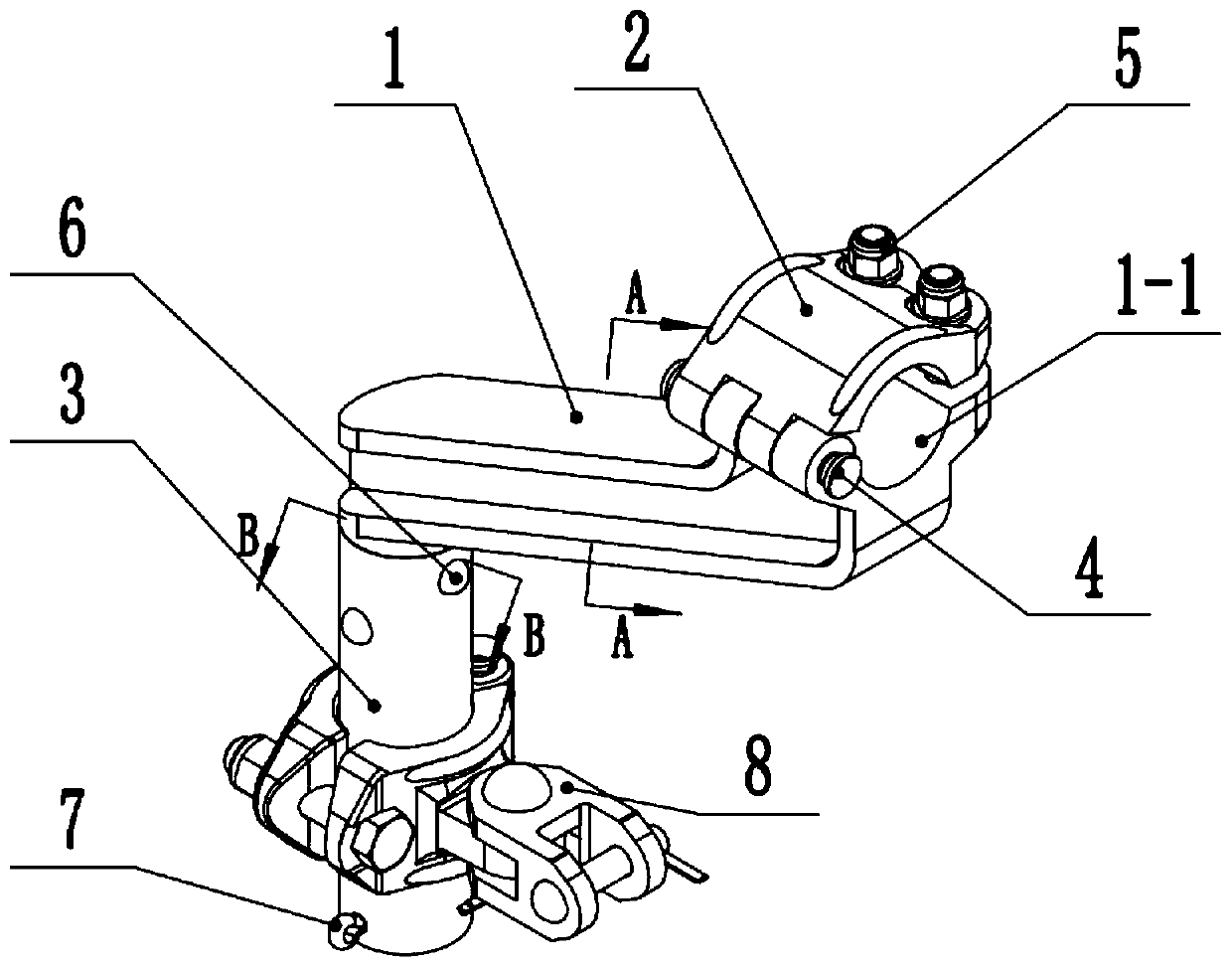

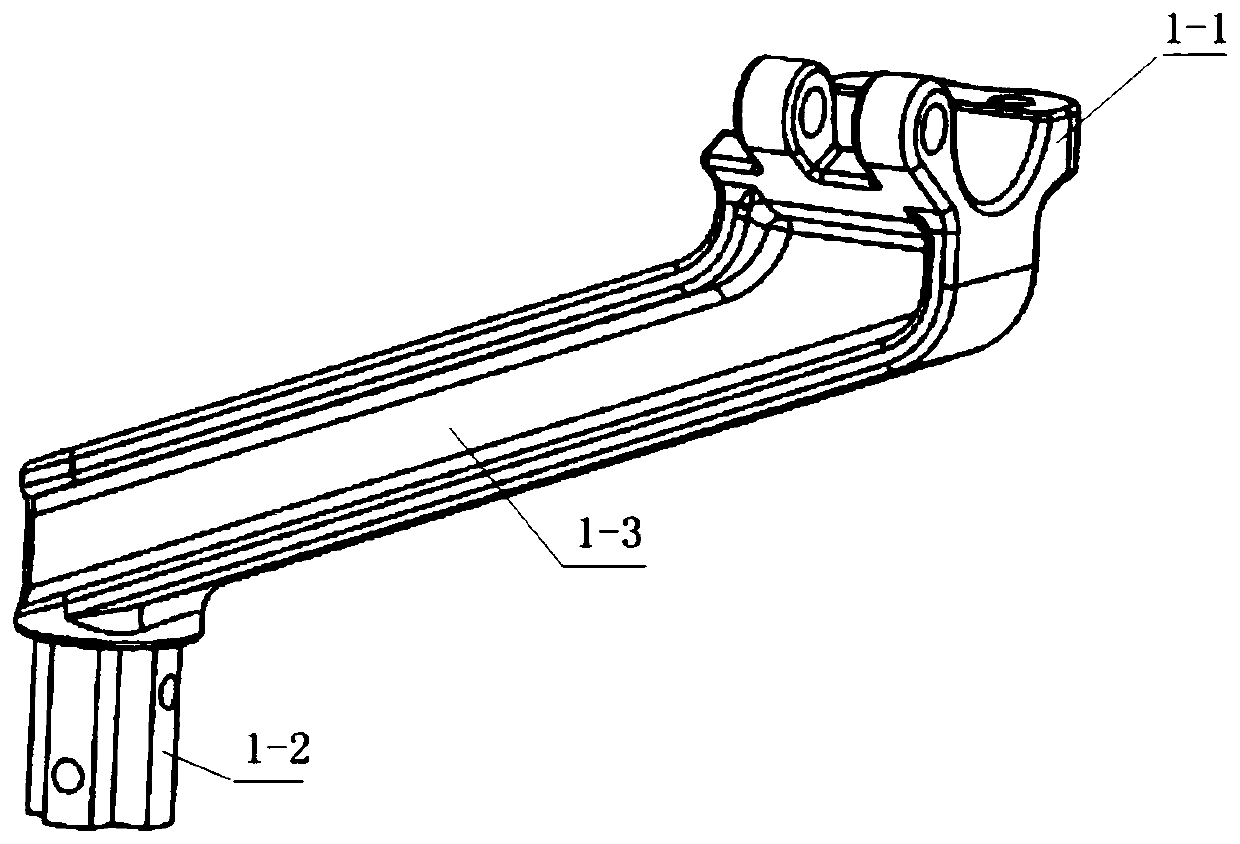

Hinge type bent positioning support

The invention discloses a hinge type bent positioning support. The support consists of a bent connecting seat, an upper hoop, a limiting pipe and a positioner support; and the bent connecting seat iscomposed of a lower hoop, a supporting arm which is connected to the lower portion of the lower hoop and inclines downwards, and a positioning column connected to the lower end of the supporting arm.One side of the upper hoop is hinged to one side of the lower hoop through a pin, and the other side of the upper hoop is connected with the other side of the lower hoop through a bolt pair. The positioning column is inserted into the upper end of the limiting pipe, and the limiting pipe is fixed to the positioning column through rivets in the radial direction in a riveted mode. The positioner support is sleeved on the limiting pipe. The defects in the prior art are overcome.

Owner:宝鸡保德利电气设备有限责任公司

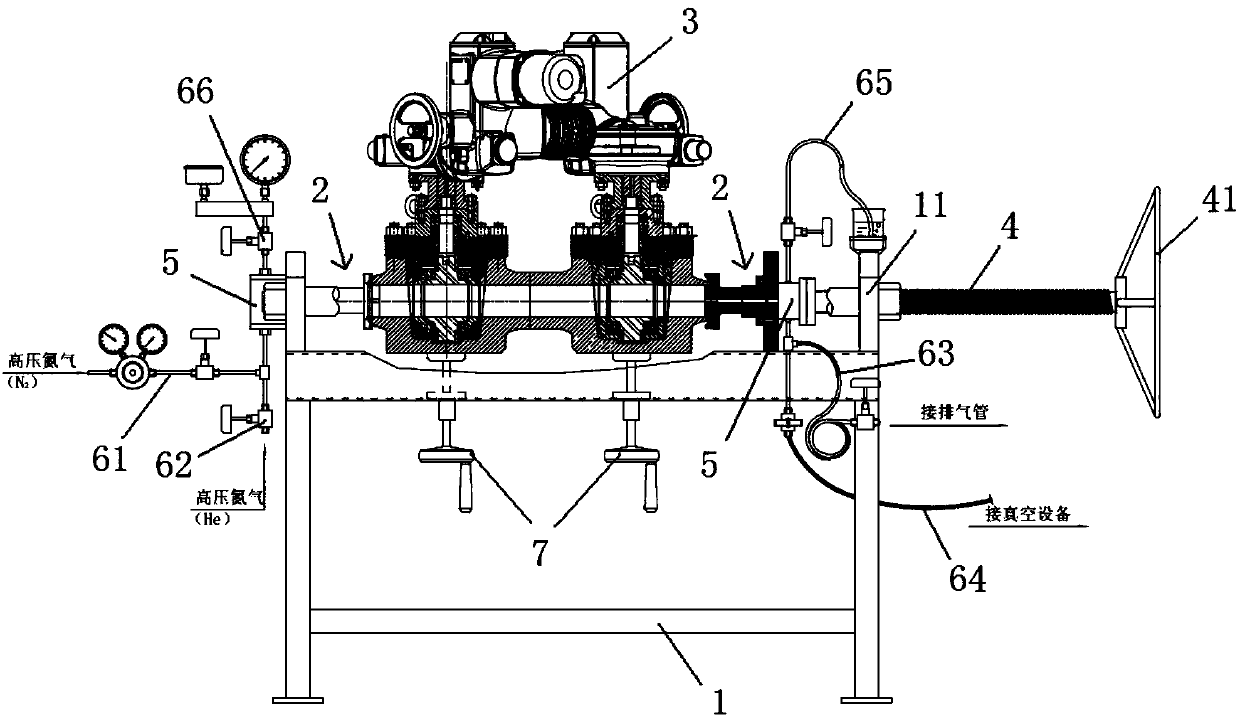

Valve air pressure test device

ActiveCN109253851AAvoid radial forceAvoid harmMeasurement of fluid loss/gain rateEngineeringAtmospheric pressure

The invention belongs to the technical field of valve air pressure test equipment. Aiming at solving the problems that a groove is destroyed and sealing is instable when end face sealing is performedon a welding groove type valve by adopting an existing manner, the invention discloses a valve air pressure test device. The valve air pressure test device comprises a support frame and sealing components; the support frame is provided with two sealing components, and the two sealing components are oppositely arranged at intervals along the same horizontal direction; each sealing component comprises a gland and a support ring; each gland is of a step structure and comprises a first step, a second step and a sealing element, the first step stretches into a port of a valve and performs location,the outer diameter of the second step is larger than the outer diameter of the first step, and the sealing element is located at a position where the first step and the second step are connected; andone end face of each support ring is an inclined plane, an inclination angle is equal to an angle of a groove, each support ring sheathes the corresponding second step, and each inclined plane keepsparallel correspondence with an oblique plane of the groove. The valve air pressure test device disclosed by the invention seals the end face of the valve and can protect the groove and guarantee sealing stability.

Owner:CHINA NUCLEAR IND 23 CONSTR

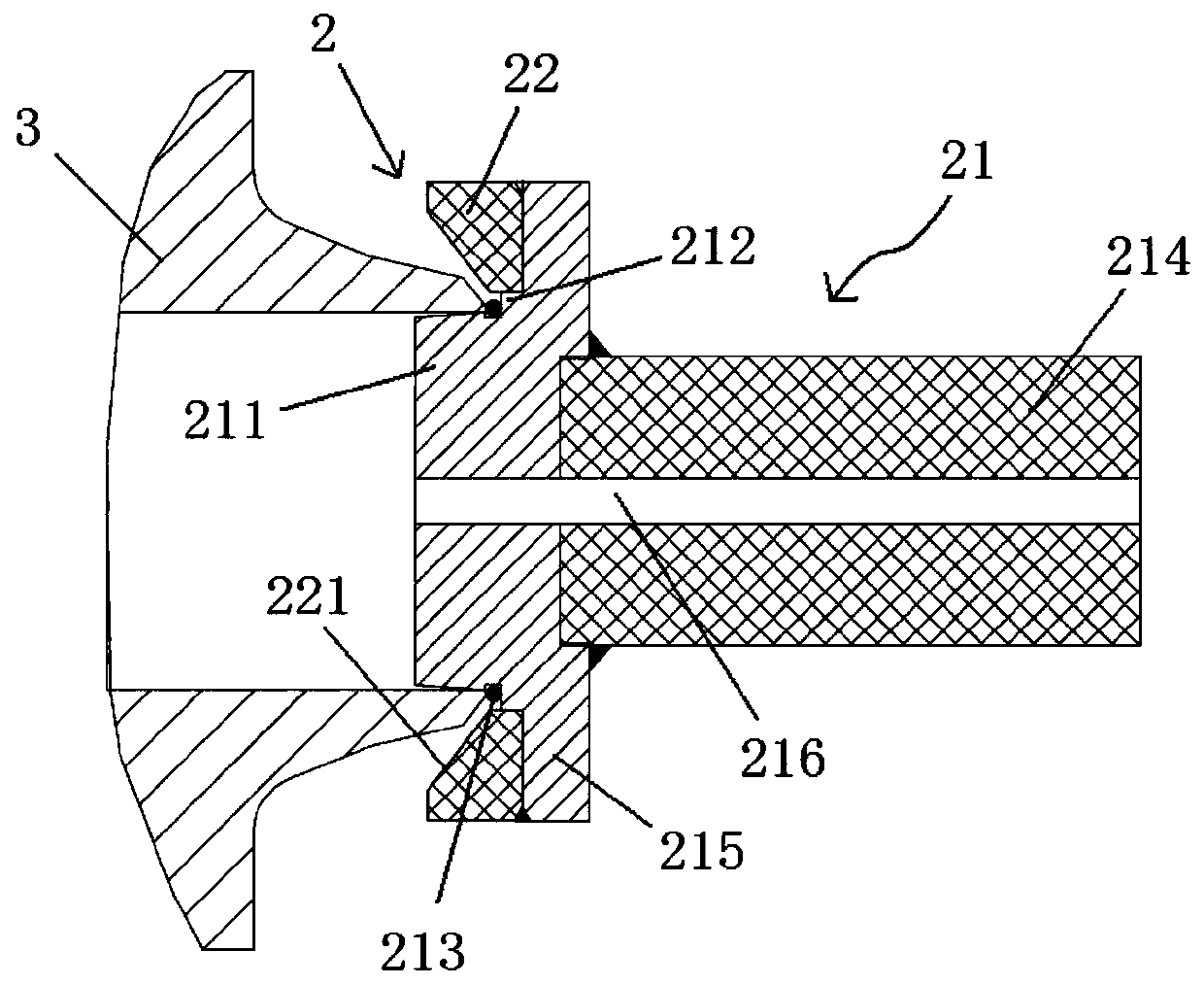

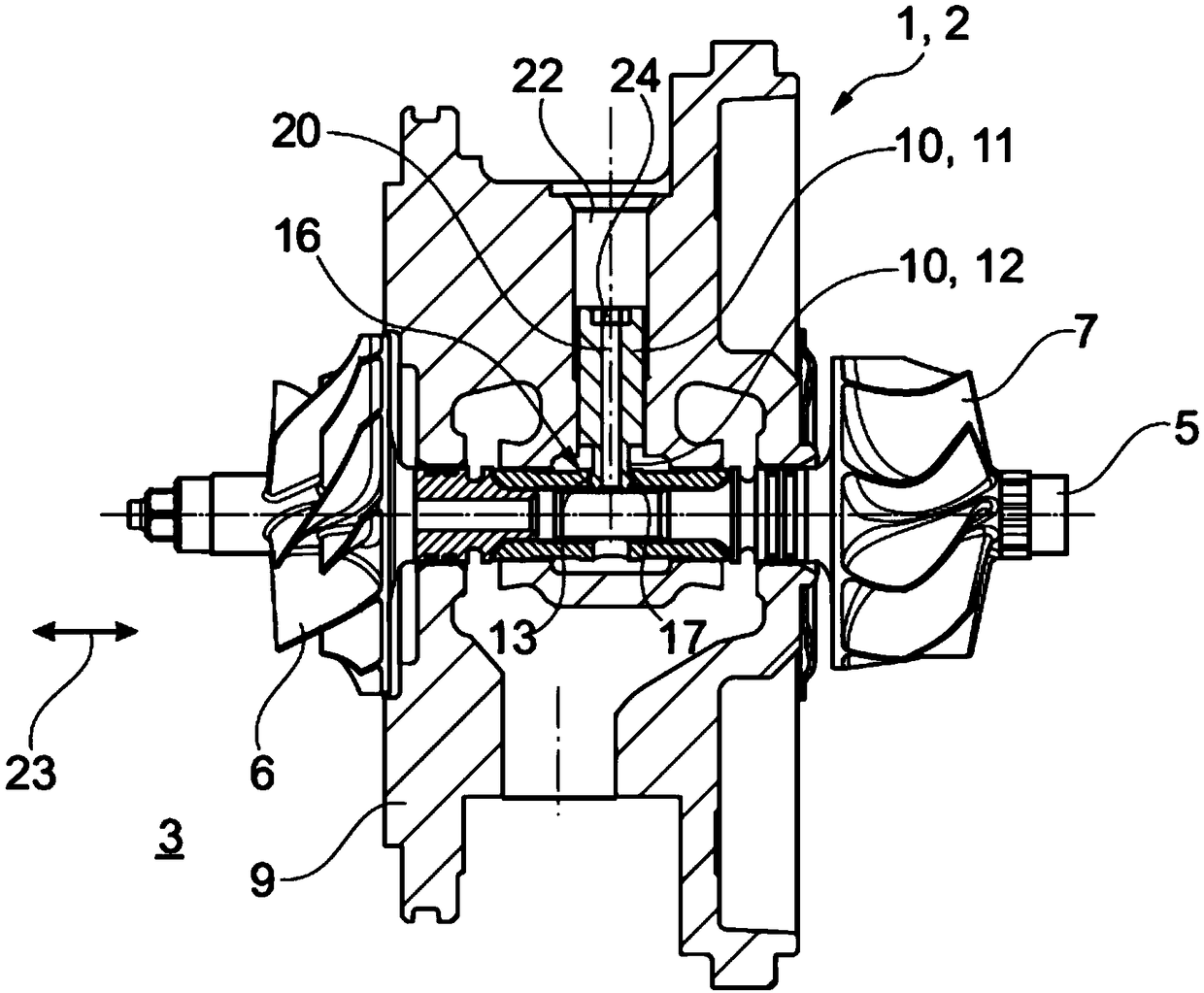

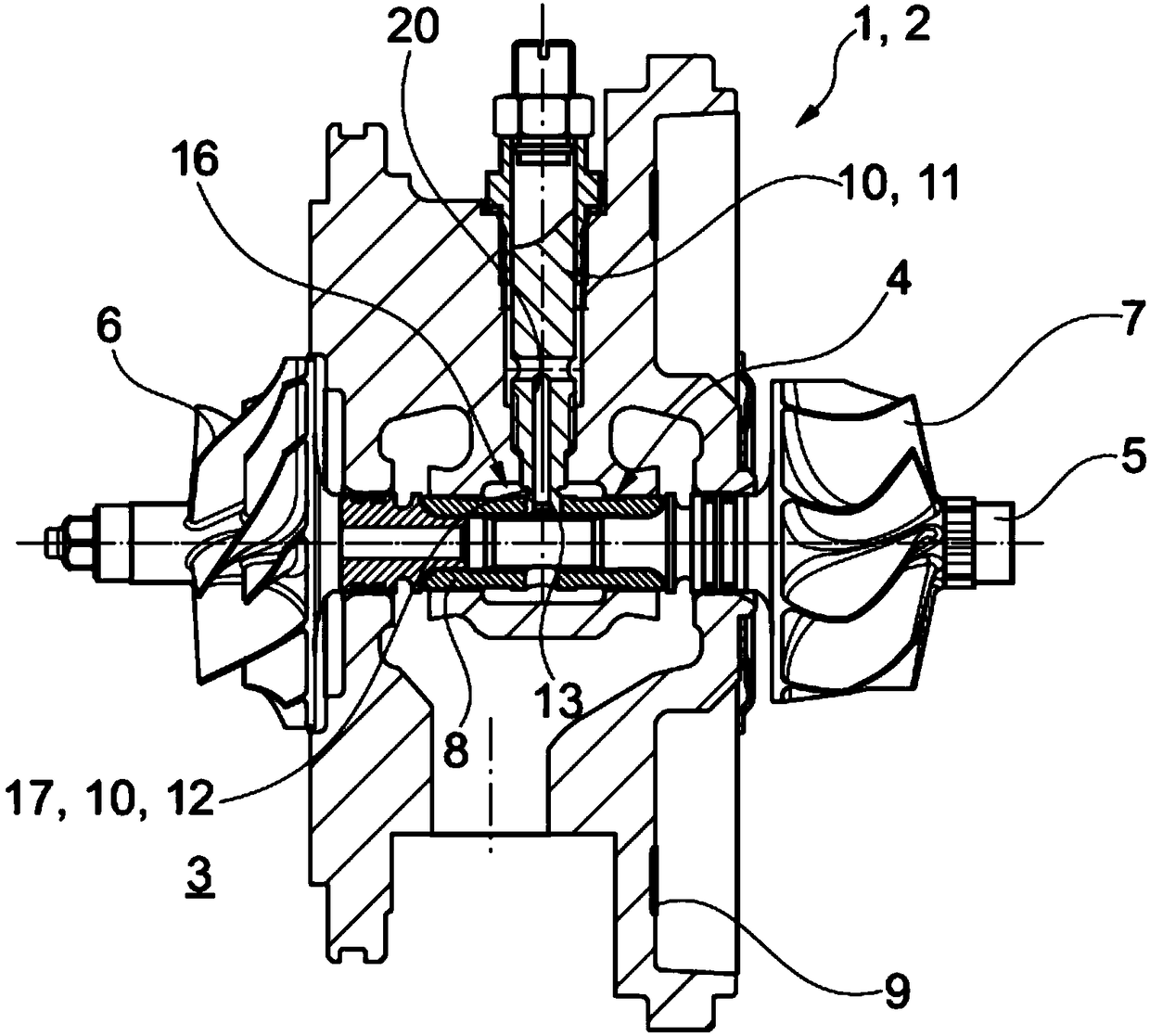

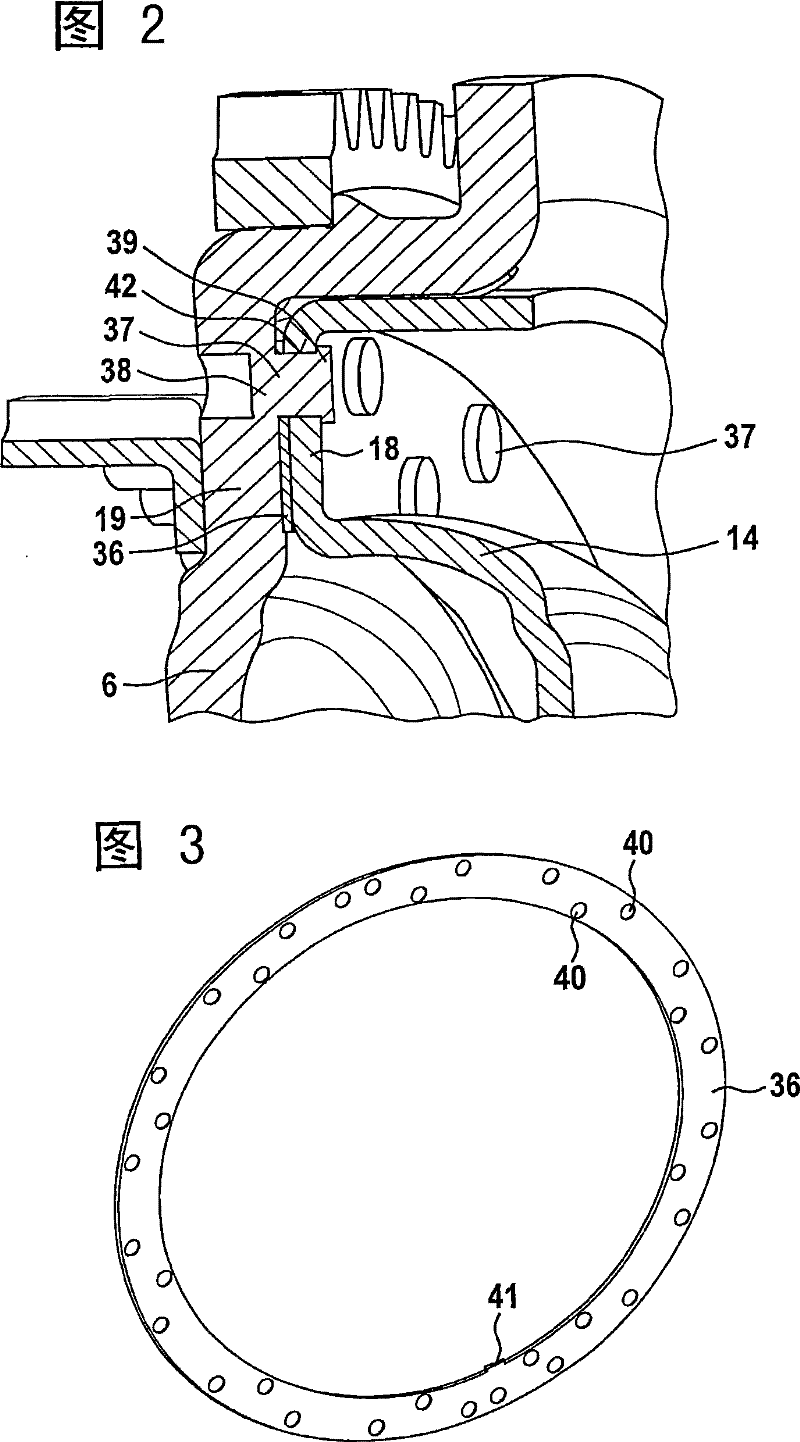

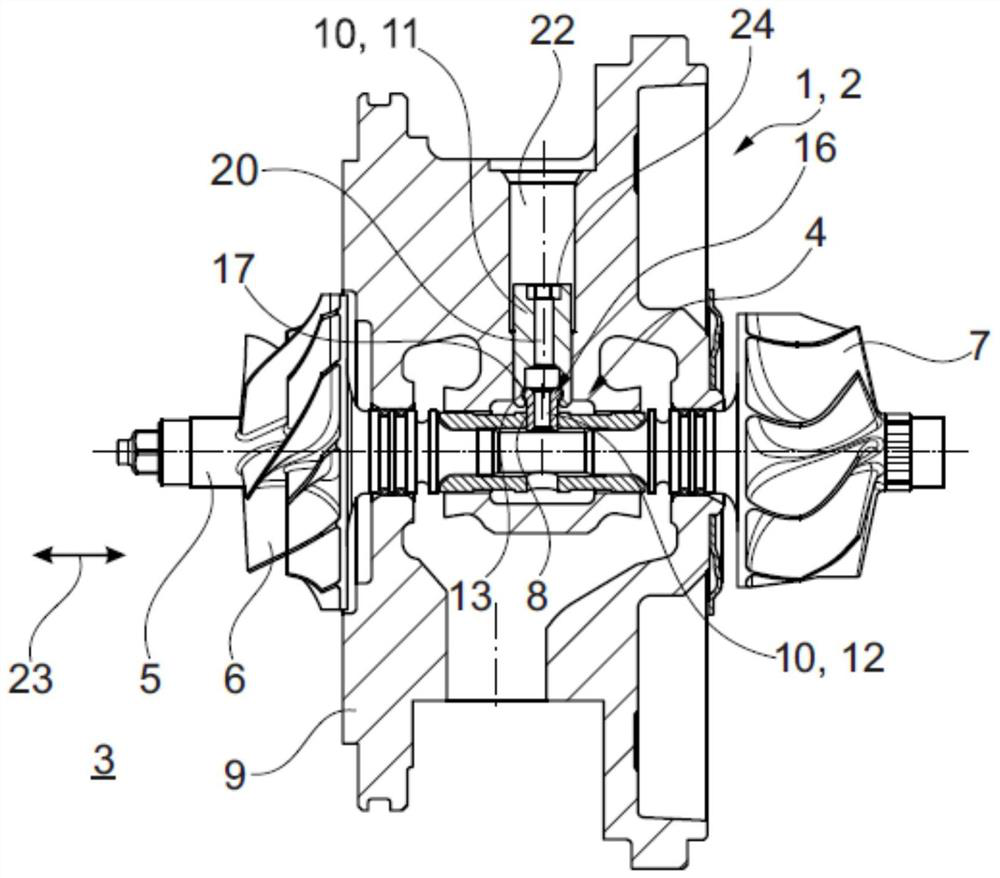

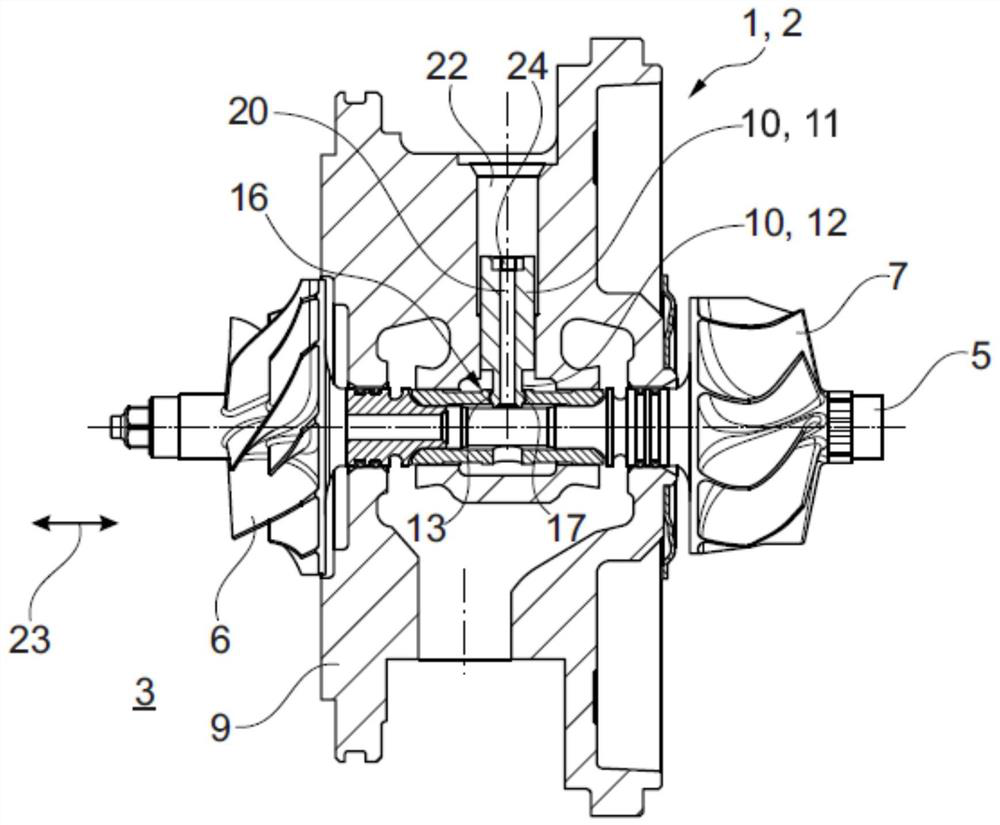

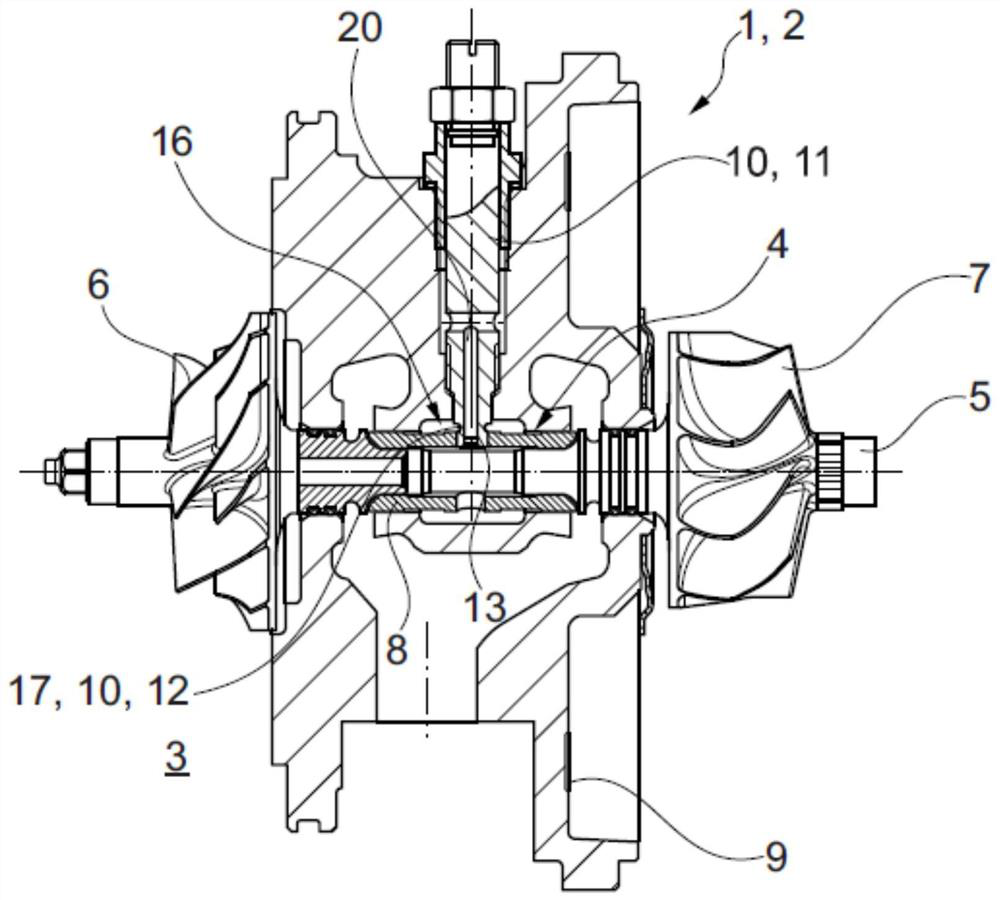

Supercharger

ActiveCN108223136AEnables axial adjustabilityEasy to wearRolling contact bearingsPump componentsEngineeringMechanical engineering

The invention relates to a supercharger (1) equipped with a bearing (4). The bearing (4) allows a shaft (5) to be mounted in the bearing housing (9) via a bearing bush (8), wherein the bearing bush (8) may be securely positioned by a pin (10) that engages into the bearing bush (8) radially from a hub. It is important for the invention that the pin (10) includes a first part (11) rotatably mountedin the bearing housing (9) and a second part (12) engaging in a recess (13) of the bearing bush (8). An axis (14) of the first part (11) and an axis (15) of the second part (12) may run parallel to one another. The bearing bush (8) and the pin (10) may be connected via a ball joint connection (16).

Owner:BOSCH MAHLE TURBO SYST GMBH & CO KG

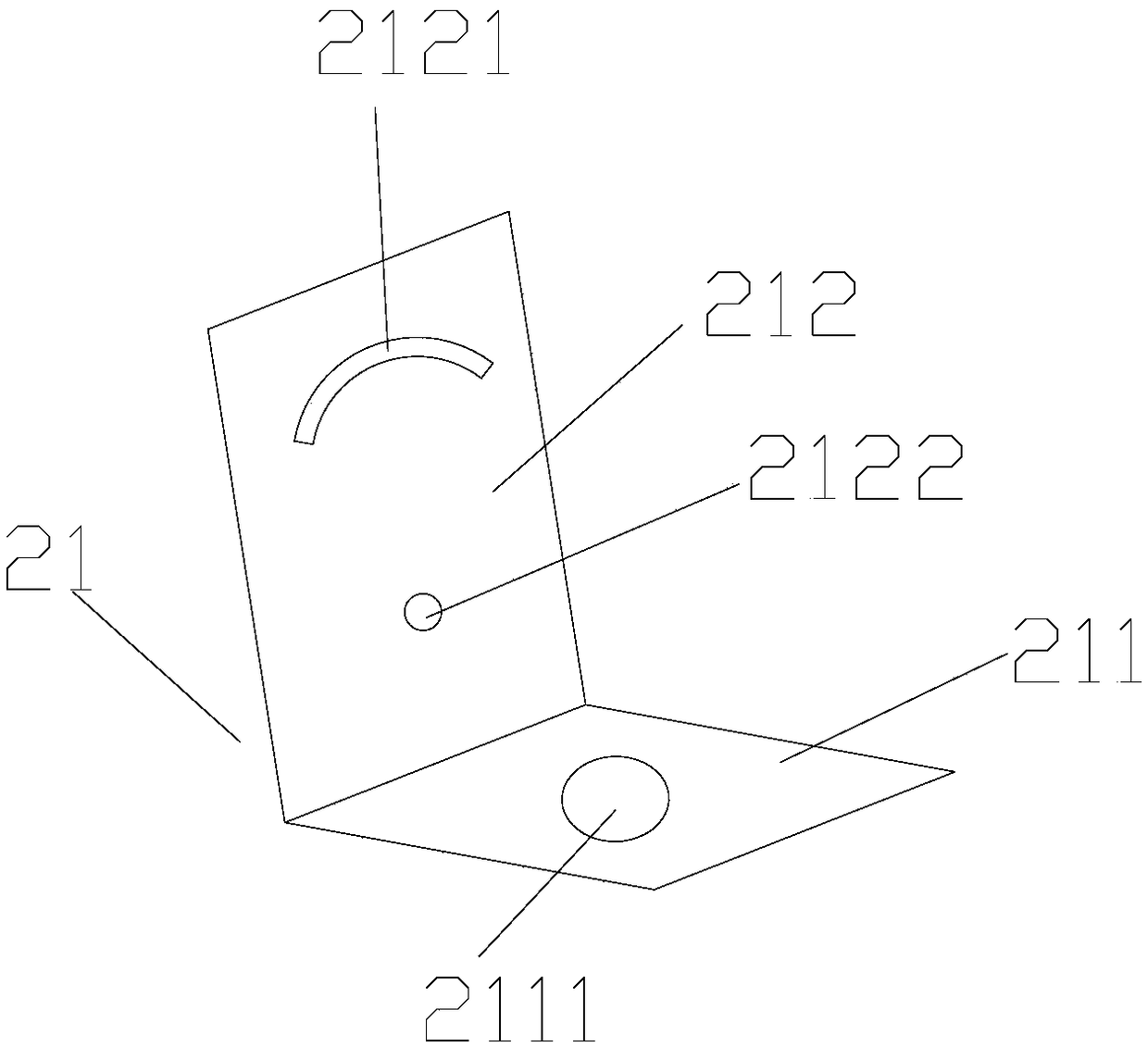

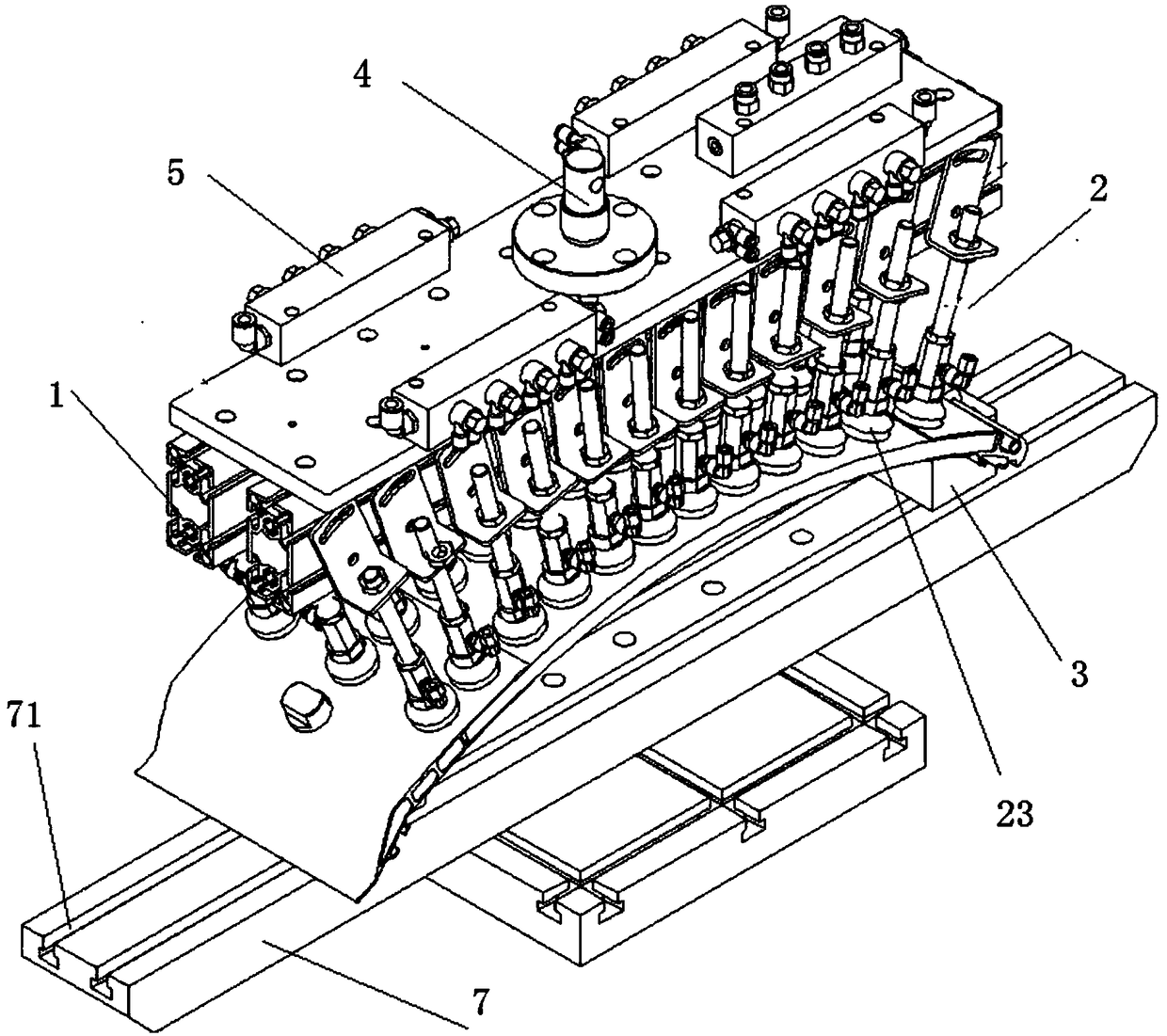

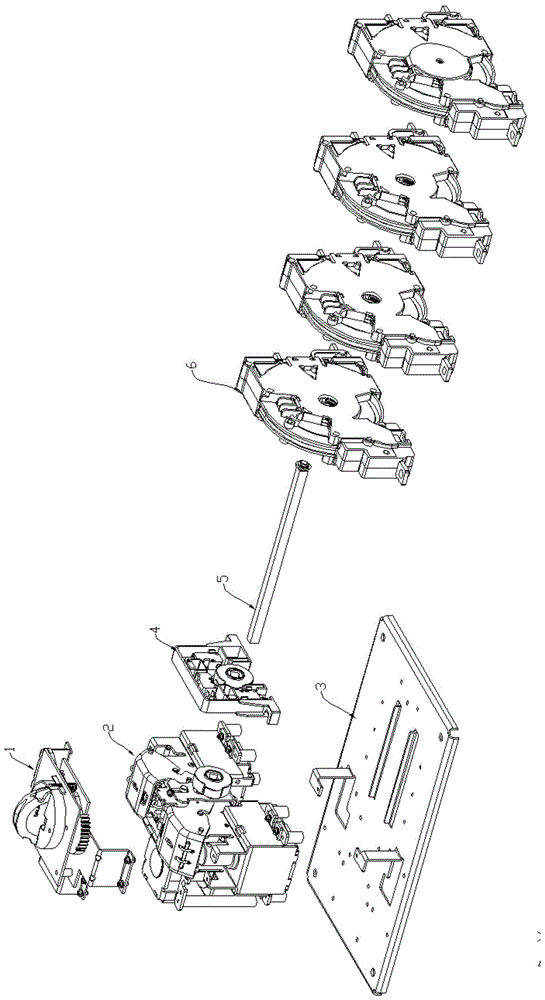

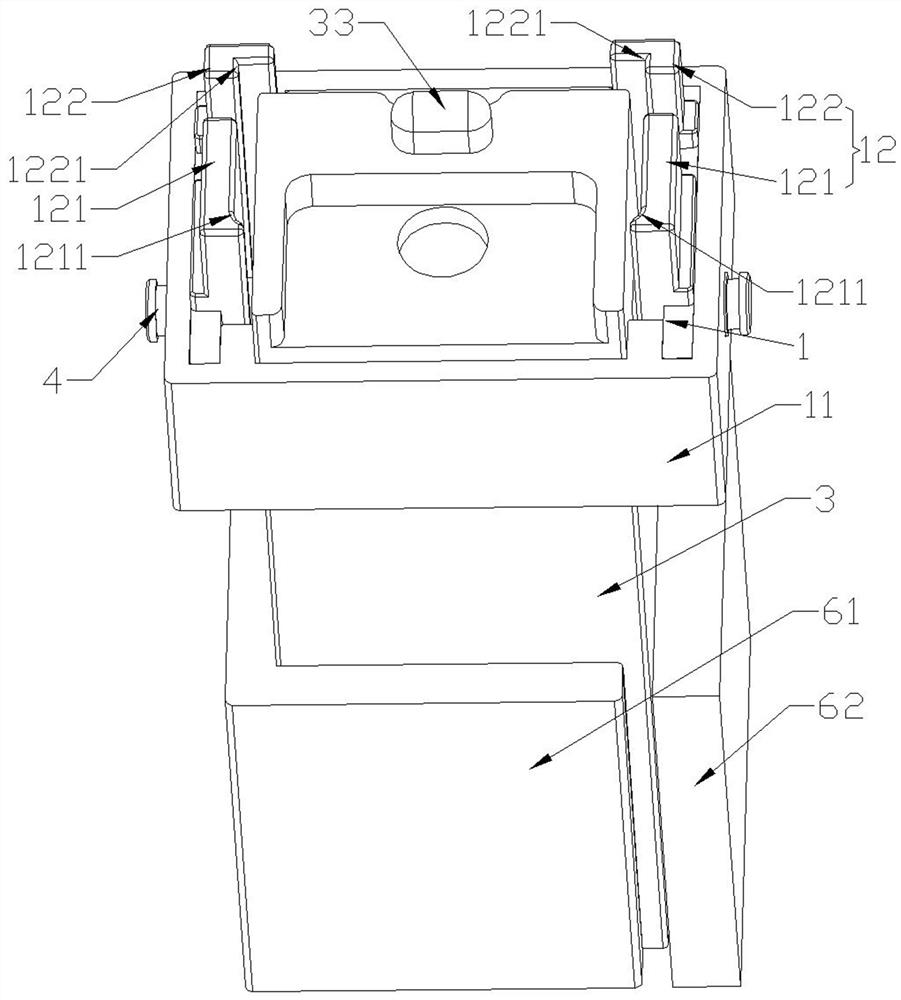

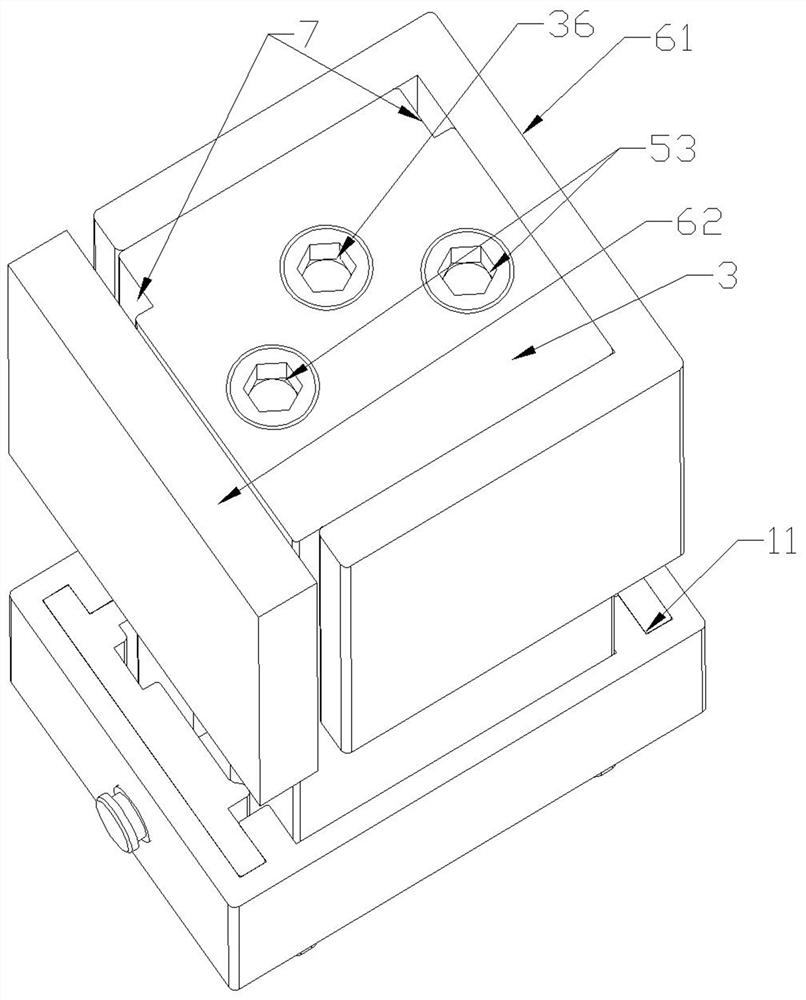

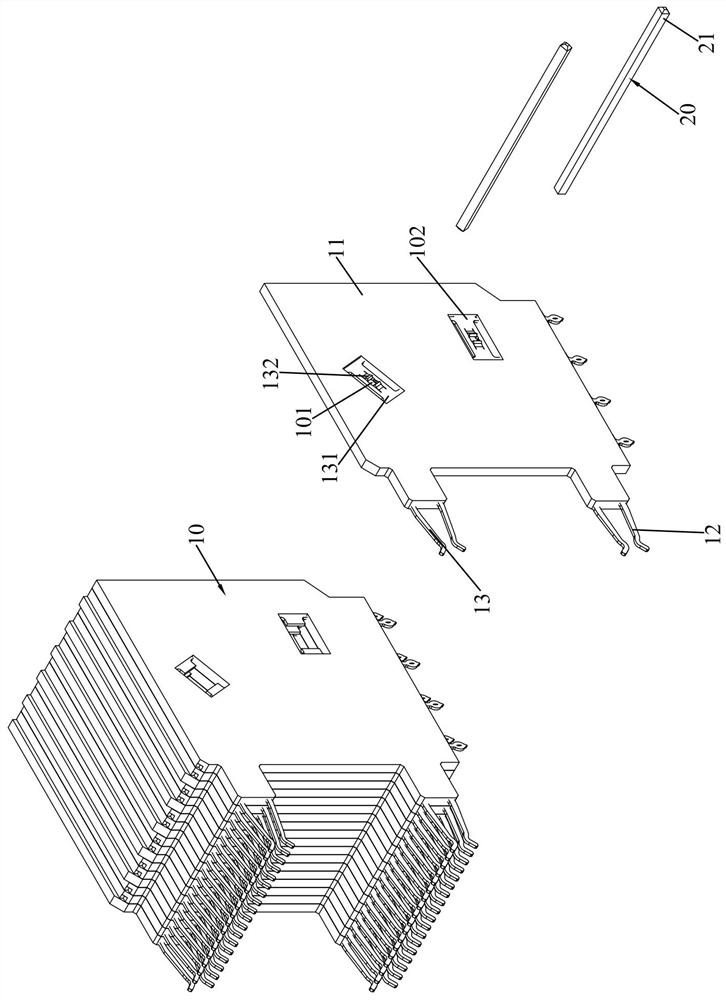

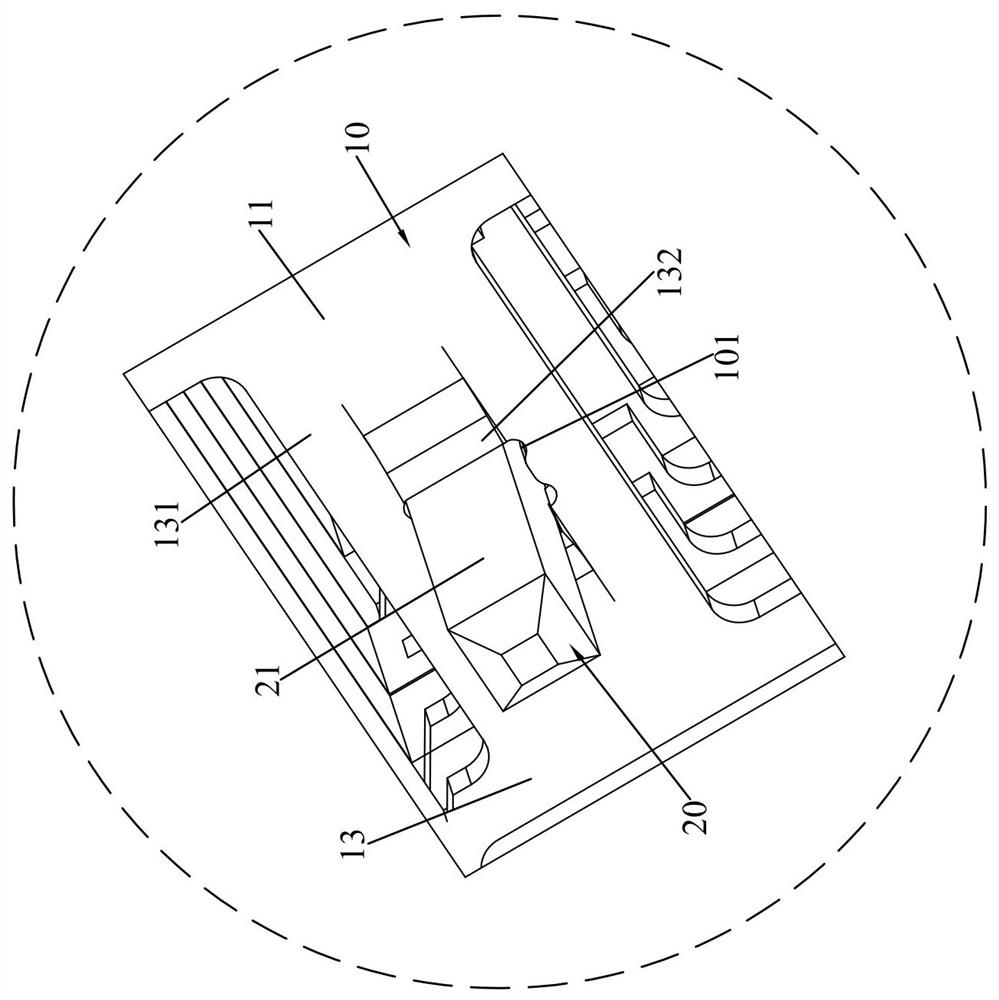

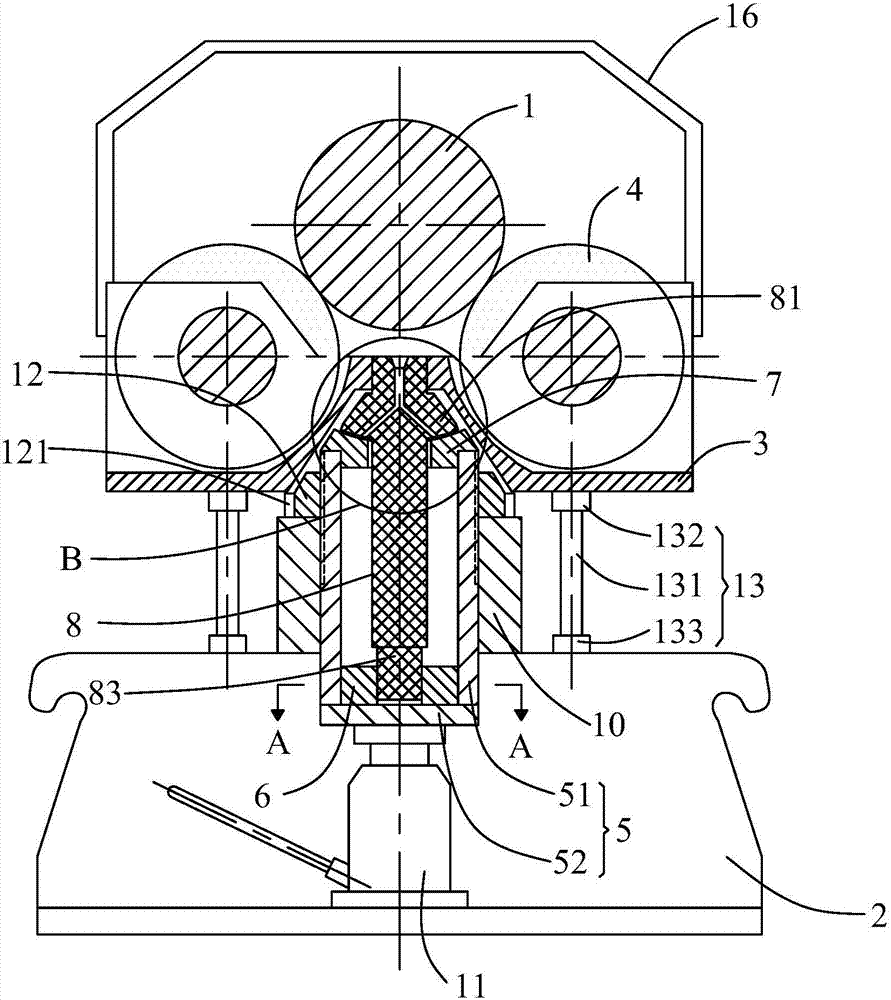

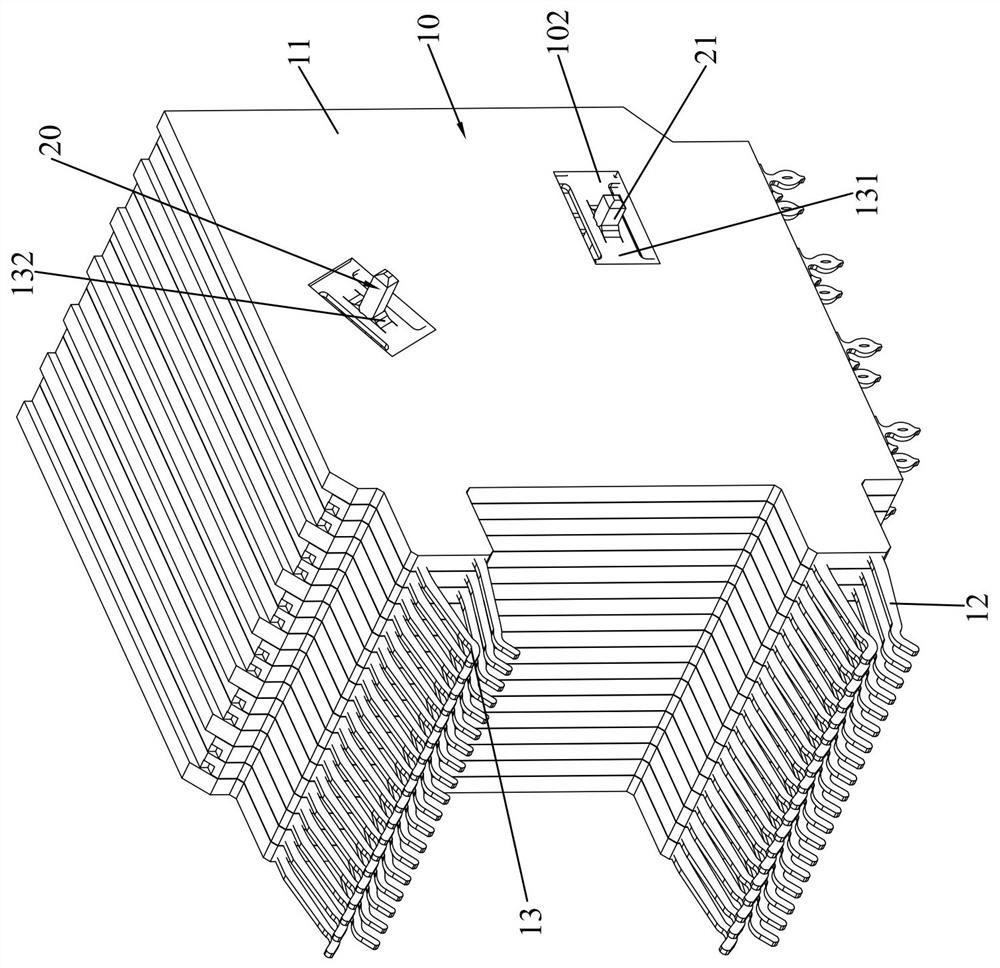

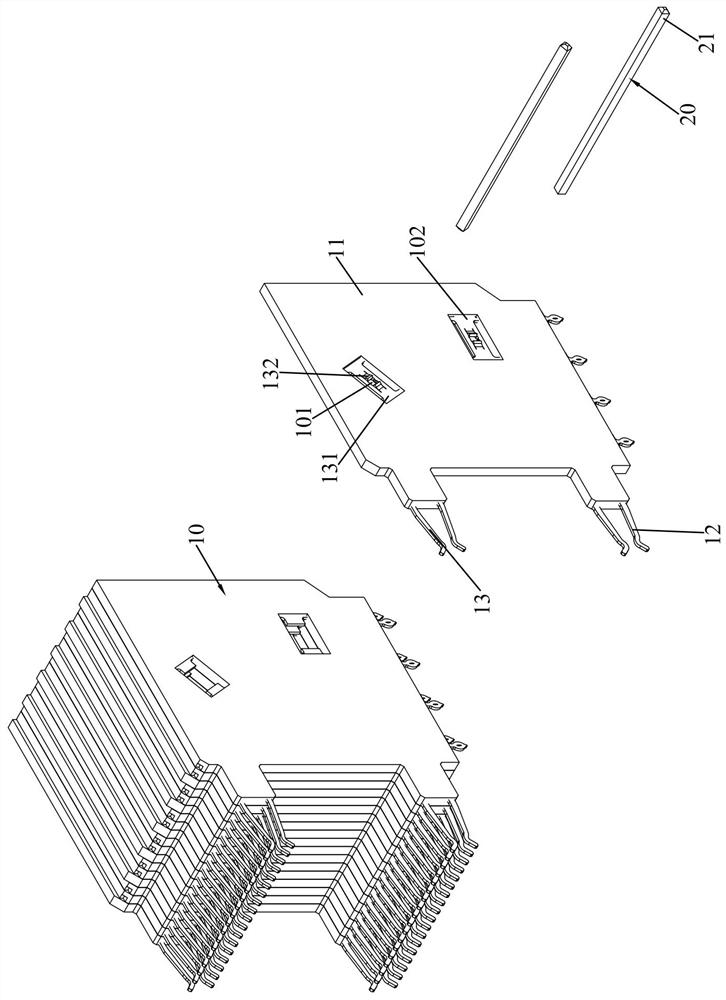

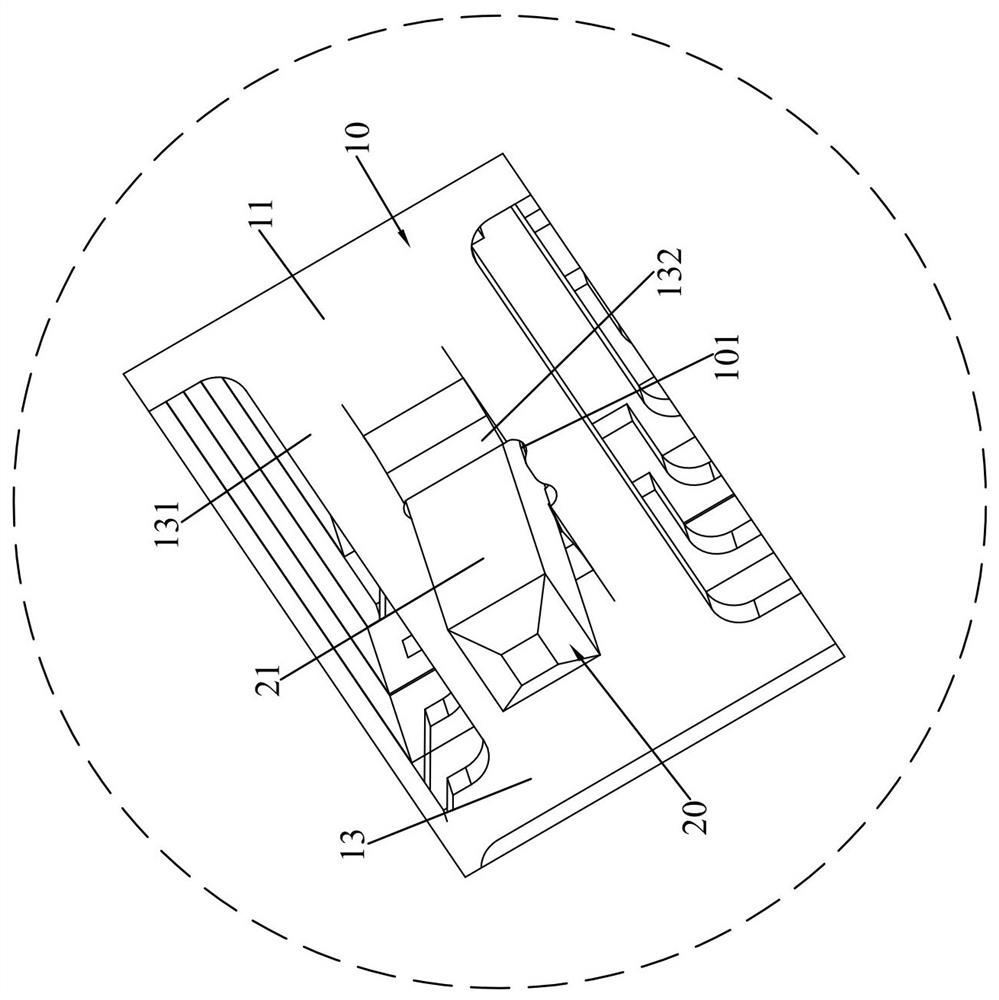

High-speed key material taking and placing device

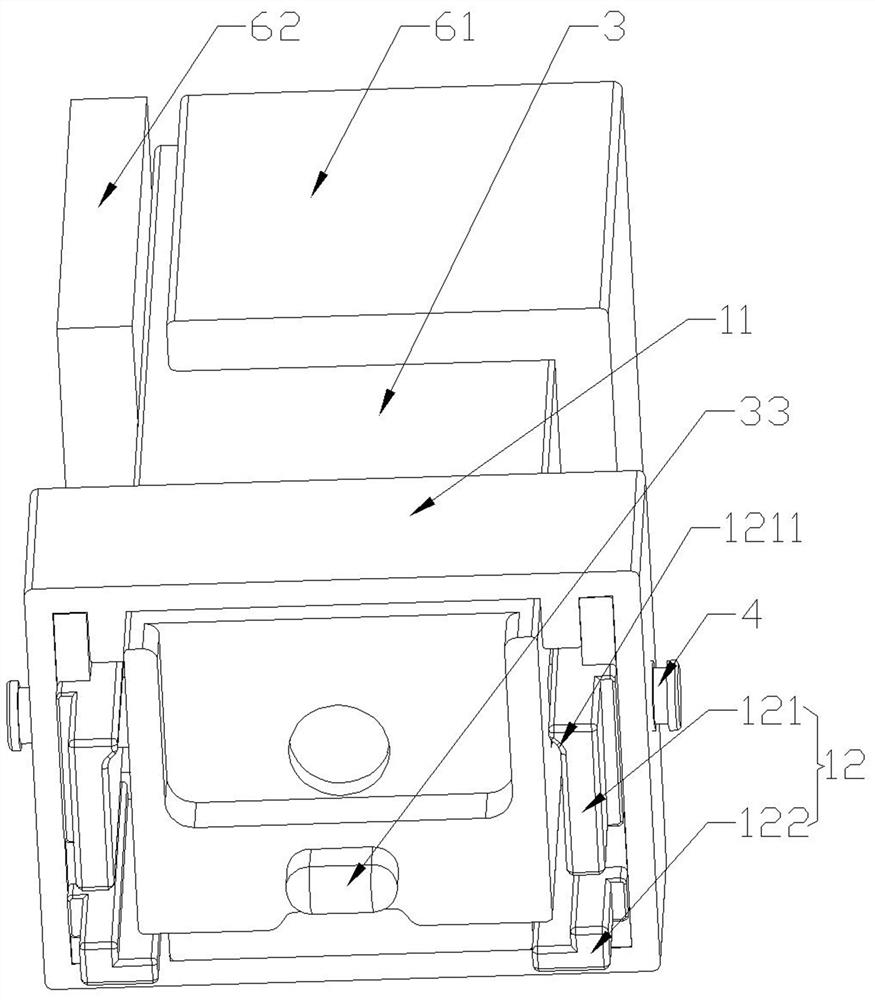

PendingCN113161185AHigh precisionAvoid point contactElectric switchesEngineeringMechanical engineering

The invention aims to provide a high-speed key material taking and placing device. The device is simple in structure, accurate in material taking and placing positioning and capable of ensuring the safety of key materials. The high-speed key material taking and placing device comprises a body and a clamping jaw part (1) which sleeves the body and can move relative to the body, wherein the clamping jaw part (1) comprises a clamping jaw sleeve (11) and at least two clamping fingers (12) arranged at the end of the clamping jaw sleeve (11); X-axis and Y-axis coordinates are established in the longitudinal and transverse directions of the clamping jaw part (1); and the clamping fingers (12) are provided with two opposite curved surfaces in a surrounding shape in the direction of any axis in an XY-axis coordinate system so as to clamp a key material product. The high-speed key material taking and placing device is applied to the processing field of input equipment.

Owner:ZHUHAI HUAYA MACHINERY TECH CO LTD

High-precision sensor protection device

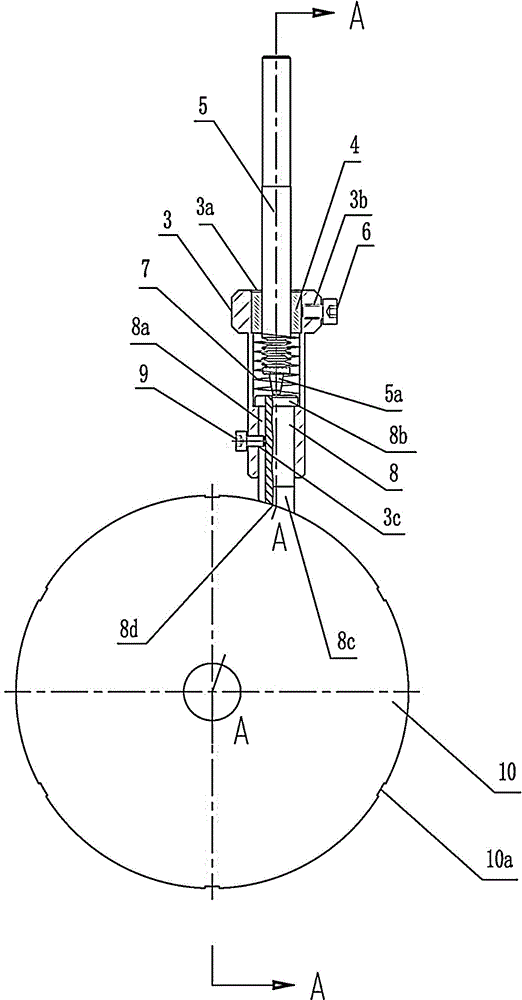

ActiveCN104931001AStable continuous deliveryReduce measurement impactMeasurement devicesEngineeringCircular surface

The invention relates to a high-precision sensor protection device, which is characterized in that a tubular shell (3) is connected to an adjustable bracket, a center hole of the tubular shell (3) is set to be a three-step stepped hole (3a), the upper stepped hole is connected to a hollow clamping sleeve (4), and an inner hole of the clamping sleeve (4) is provided with a sensor (5) in a sleeved mode; the lower stepped hole is connected to a moving sliding head (8), one end of the moving sliding head (8) is provided with a cap (8b) matched with a step surface of the lower stepped hole, the other end of the moving sliding head (8) is provided with a contact sliding head (8c), and the contact sliding head (8c) is provided with a circular arc surface (8d) which is contacted and matched with a cylindrical surface to be detected; a spring (7) is connected between the moving sliding head (8) and the clamping sleeve (4); and a moving measurement probe (5a) of the sensor (5) is contacted with the moving sliding head (8). The high-precision sensor protection device has the significant effects that point contact between the moving measurement probe and a discontinuous circular surface is avoided, influences imposed on circular runout measurement by pits, opened holes, processing slots and the like are effectively reduced, and the sensor is effectively protected.

Owner:ANHUI HAOFANG ELECTROMECHANICS

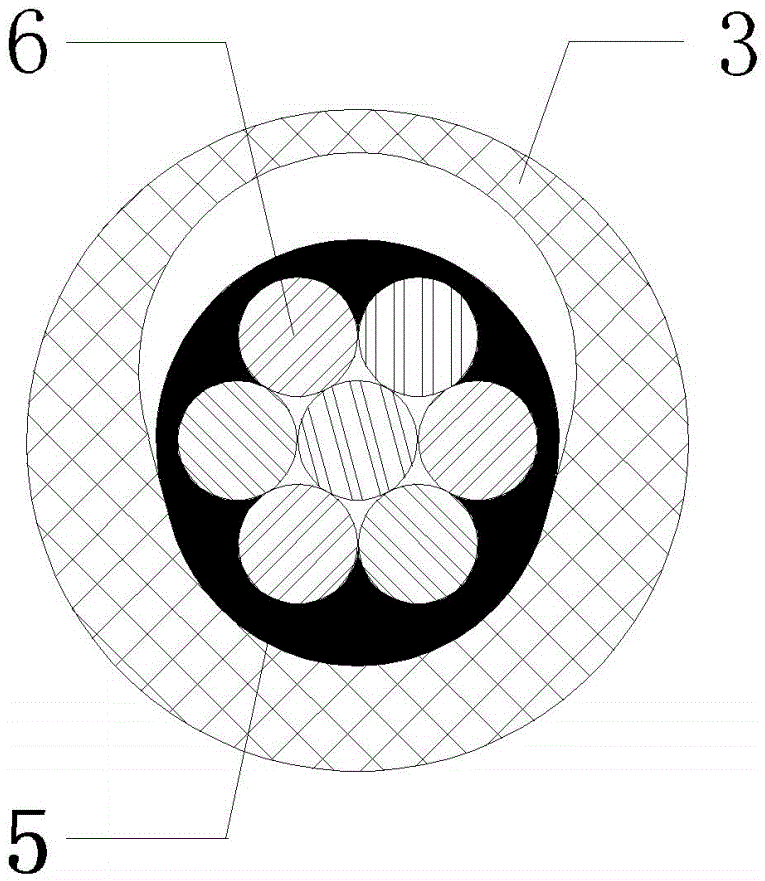

Terminal connection structure of SFF 2*N series optical module

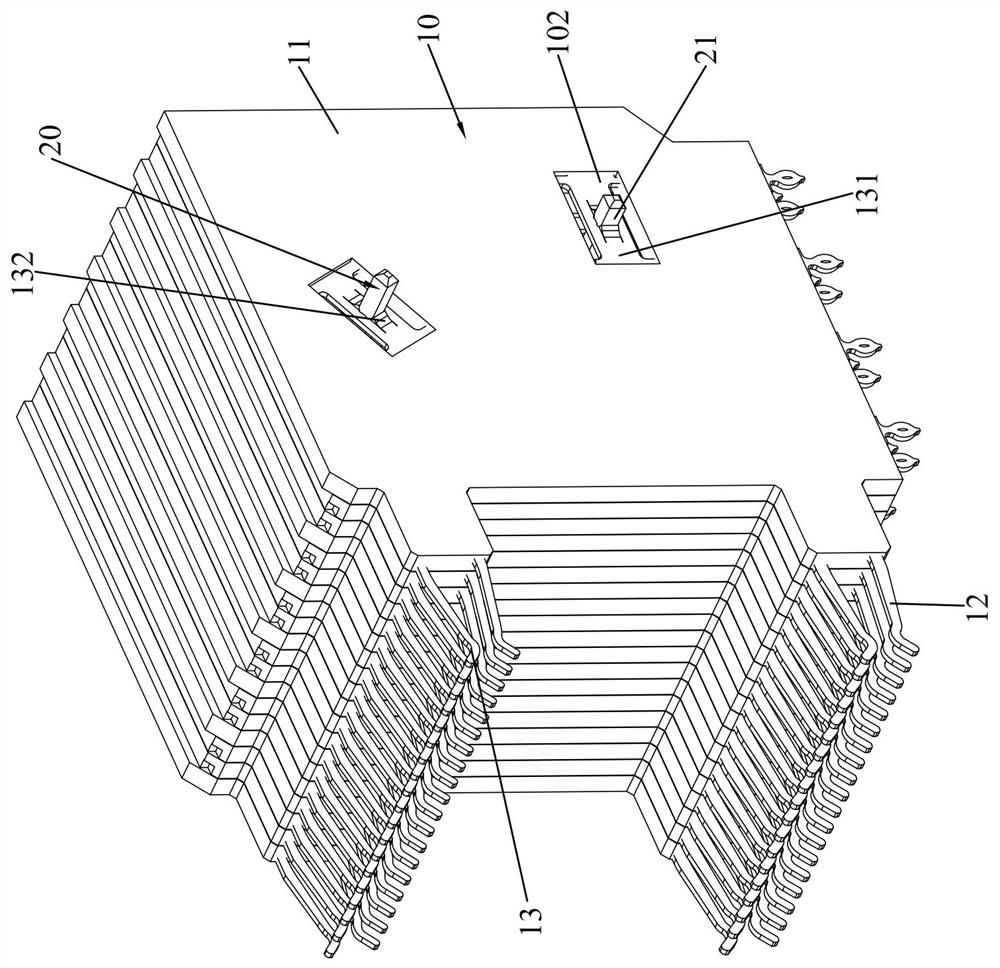

ActiveCN111641082AAvoid point contactReduce processing costsCoupling contact membersCoupling protective earth/shielding arrangementsOptical ModuleEngineering

The invention discloses a terminal connection structure of an SFF 2*N series optical module. The terminal connection structure comprises a plurality of terminal modules and at least one conductive column, wherein the plurality of terminal modules are overlapped together, grounding terminals are embedded, molded and fixed on insulating blocks of part of the terminal modules, through holes are formed in fixing parts of the grounding terminals, and elastic sheets are integrally molded and connected to the edges of the through holes; and the conductive column is provided with a contact plane, theconductive column is separated from a signal terminal and penetrates through the through hole, and the elastic piece elastically abuts against the contact plane to be connected in a conducting mode. The grounding terminal is provided with the through hole, the edge of the through hole is connected with the elastic piece in an integrated manner, and each conductive column is provided with the contact plane, so that the grounding terminals and the conductive columns are conducted and connected on the contact planes through elastic extrusion of the elastic pieces, the dimensional tolerance does not need to be controlled quite accurately, the processing cost can be reduced, the contact stability is improved, and the crosstalk problem can be effectively improved.

Owner:U DDONGGUAN ELECTRONICS TECH CORP +2

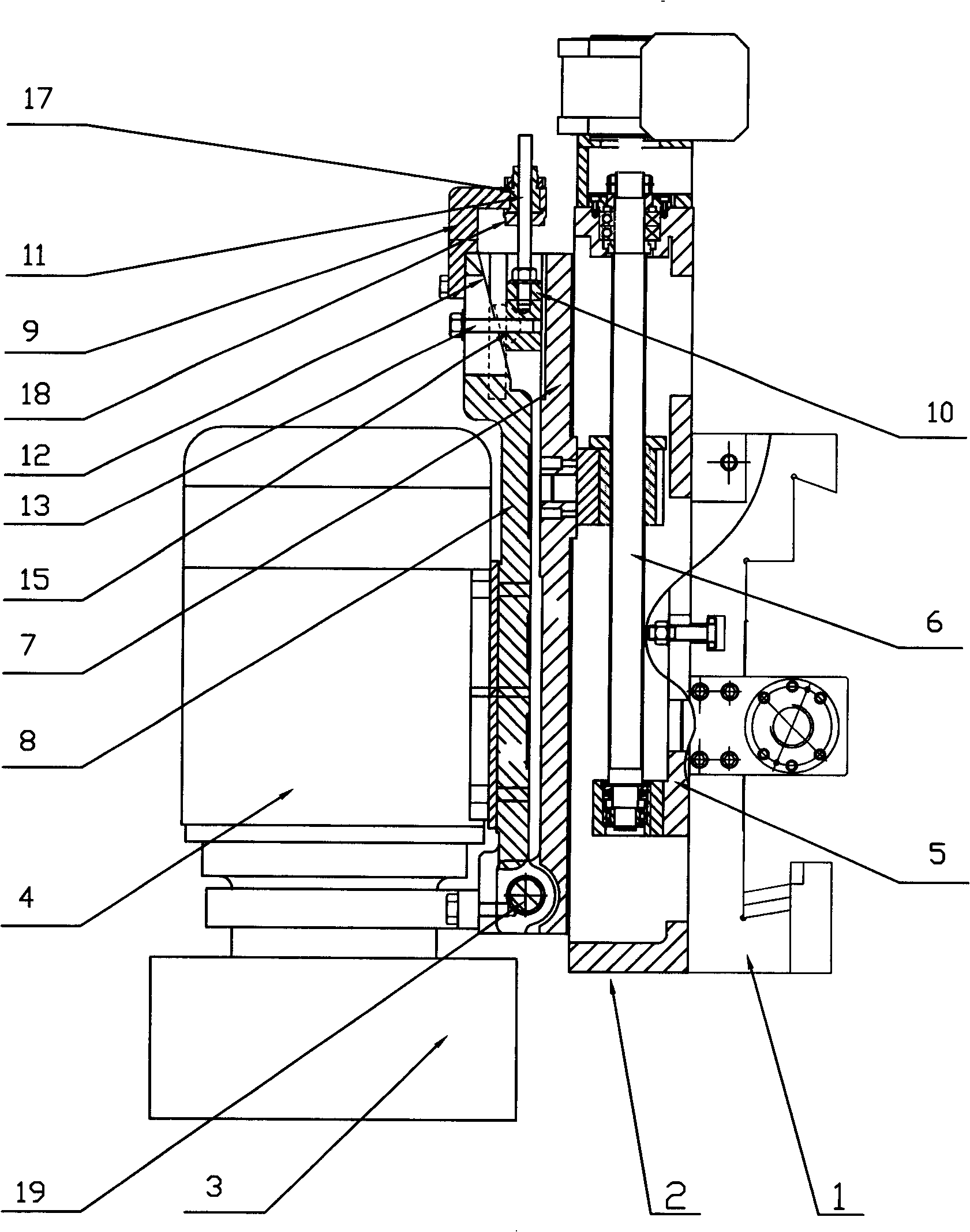

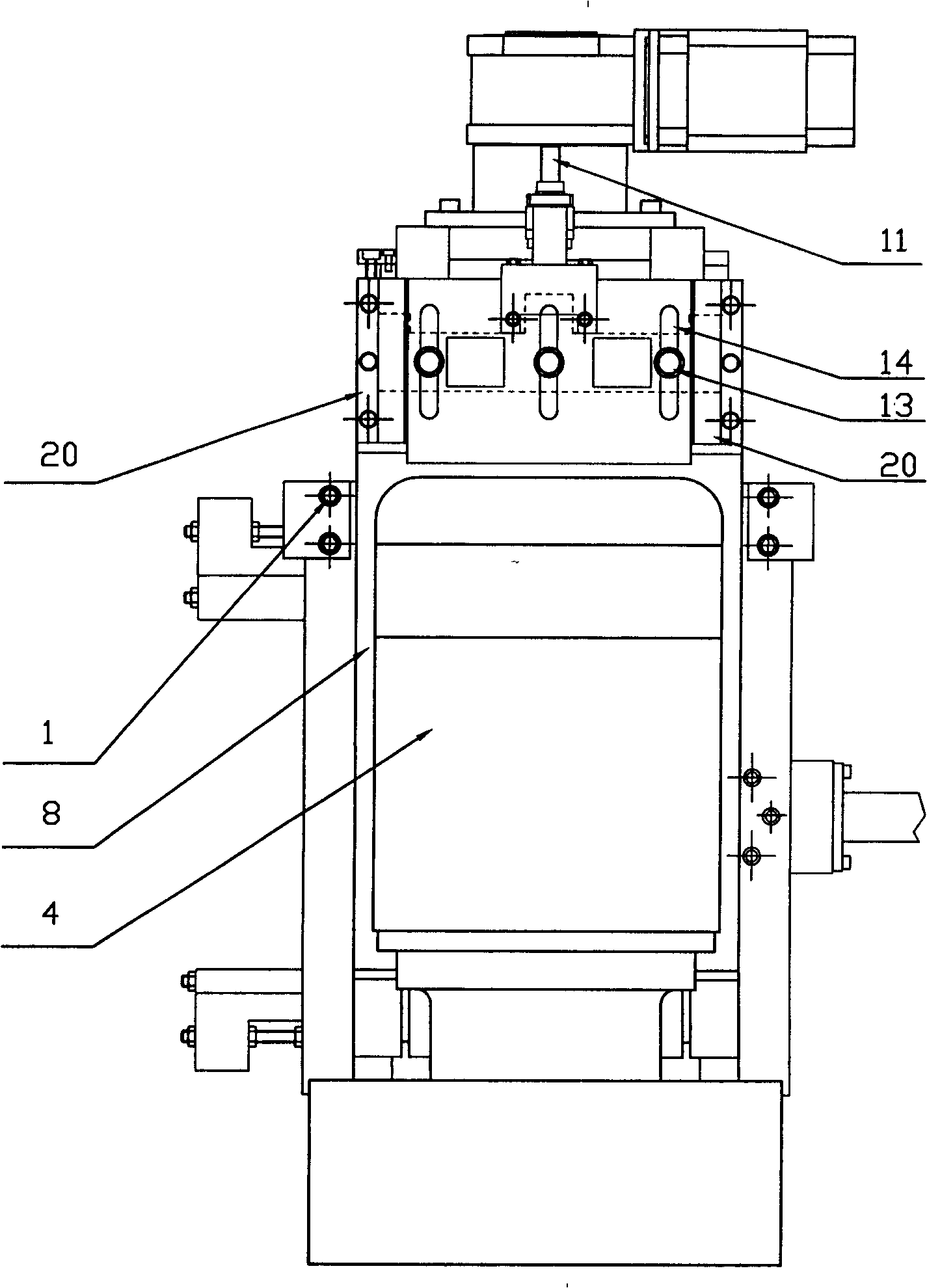

Vertical axis type grinding head

InactiveCN1927542BRealize the adjustment of parallelismAdjust parallelismGrinding machine componentsVertical axisMachining

Owner:GUANGDONG SHENGDU MOLD

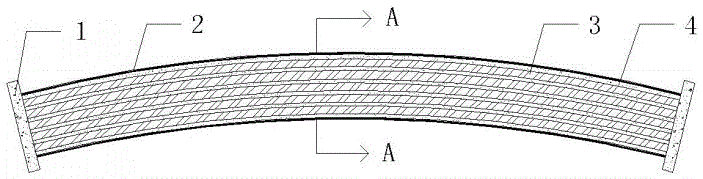

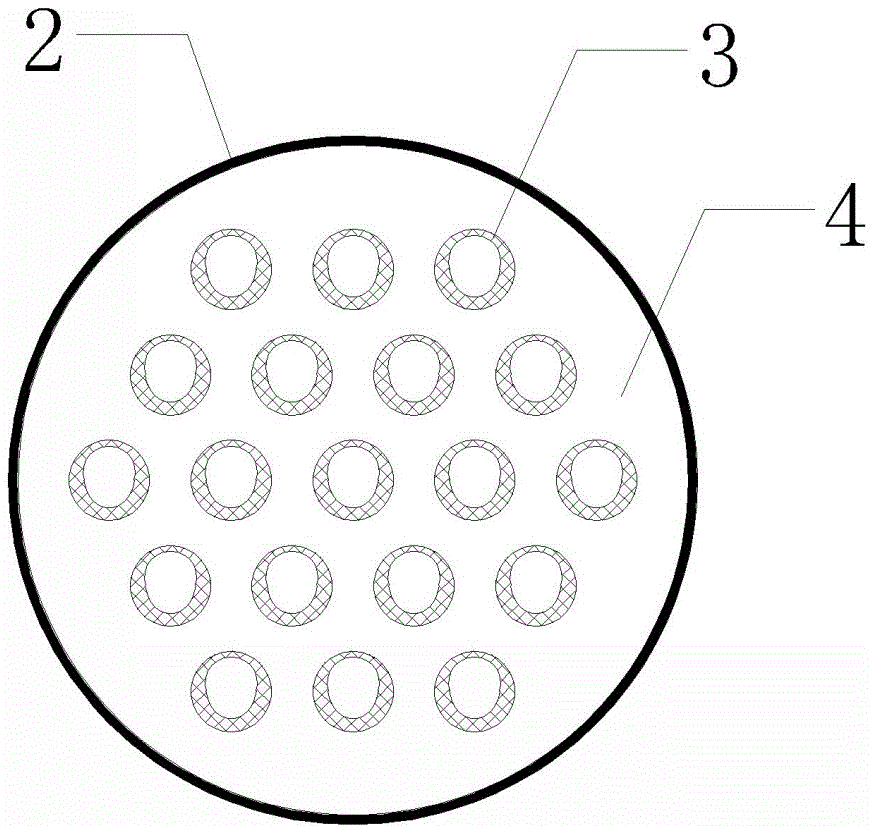

Efficient steel strand wire stay cable saddle

InactiveCN106638310AIncrease contact areaImprove the state of stressBridge structural detailsTowerAbnormal shaped

The invention discloses an efficient steel strand wire stay cable saddle and belongs to the technical field of bridge structures. The stay cable saddle comprises steel strand wires, anchor bearing plates, a sleeve, wire dividing tubes, a filling material and soft metal, wherein the number of the wire dividing tubes is the same as the number of the steel strand wires in the stay cable; the steel strand wires independently pass through the corresponding wire dividing tubes; the periphery of each wire dividing tube is circular; an upper part and a lower part of the inner wall of each wire dividing tube are shaped as arcs with different diameters; the upper part is large, the lower part is small, and a middle part is a special-shaped structure with a diagonal plane; the peripheries of the steel strand wires are coated with a circle of soft metal; the contact area is increased. According to the efficient steel strand wire stay cable saddle, single steel strand wire in the stay cable can be replaced; through a soft metal layer, the stress area of the steel strand wires is increased; meanwhile, the slippage resistance is improved; the slippage of the steel strand wires caused by unbalanced force on two sides of a bridge tower in the operation process of the stay cable can be avoided; the safety of the structure is improved; the efficient steel strand wire stay cable saddle has broad application prospects.

Owner:ZHENGZHOU UNIV

Cast single crystal seed crystal laying method with short bottom red area and few native dislocations

ActiveCN112458530AShorten the lengthReduce lattice distortionPolycrystalline material growthFrom frozen solutionsSeed crystalMonocrystalline silicon

The invention discloses a cast single crystal seed crystal laying method with a short bottom red area and few native dislocations, which comprises the following steps: removing the head, tail and edgeskins of a Czochralski silicon rod, carrying out linear cutting to obtain cast single crystal seed crystals, and carrying out sand blasting treatment on the surfaces of the cast single crystal seed crystals to increase the surface roughness of the cast single crystal seed crystals; cutting the polycrystalline silicon block or the monocrystalline silicon block to obtain a thick sheet, and carryingout sand blasting on the surface of the thick sheet to increase the surface roughness of the thick sheet; laying a first thick sheet layer at the bottom of the crucible; spreading casting single crystal seed crystals on the first thick sheet layer, and reserving a gap between the side faces of every two adjacent casting single crystal seed crystals; spreading a second thick sheet layer in the center of the upper surface of each cast single crystal seed crystal; paving a thick sheet on the second thick sheet layer, tightly attaching the side wall of the thick sheet to form a third thick sheetlayer, placing a raw silicon material, a recycled silicon material and the like on the third thick sheet layer, manufacturing a temperature gradient in the vertical direction when the silicon materialis melted to 1 / 2 position of the cast single crystal seed crystal layer, and gradually solidifying from bottom to top to obtain a cast single crystal silicon ingot.

Owner:NANCHANG UNIV

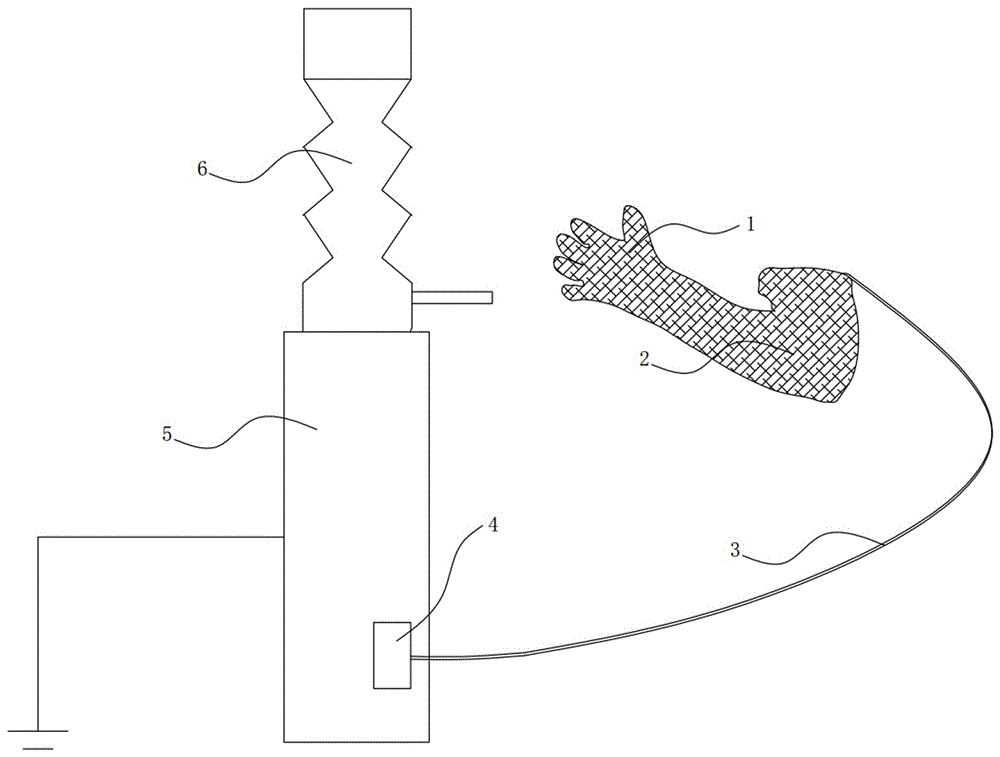

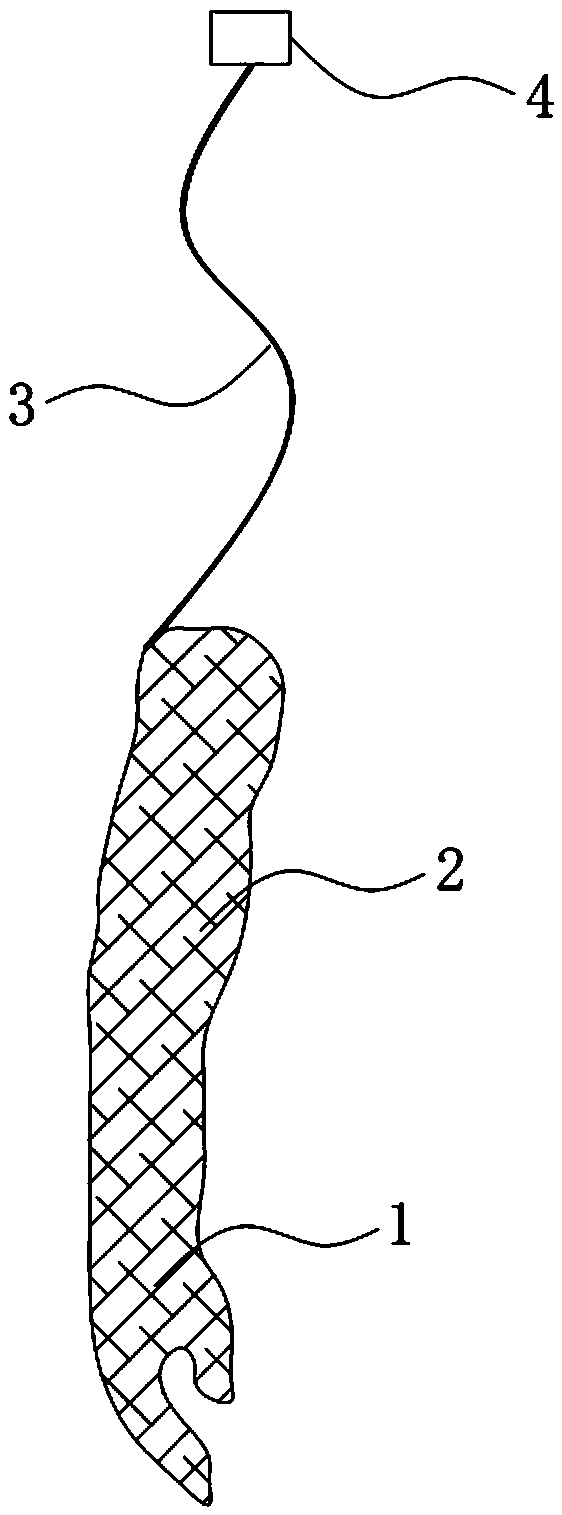

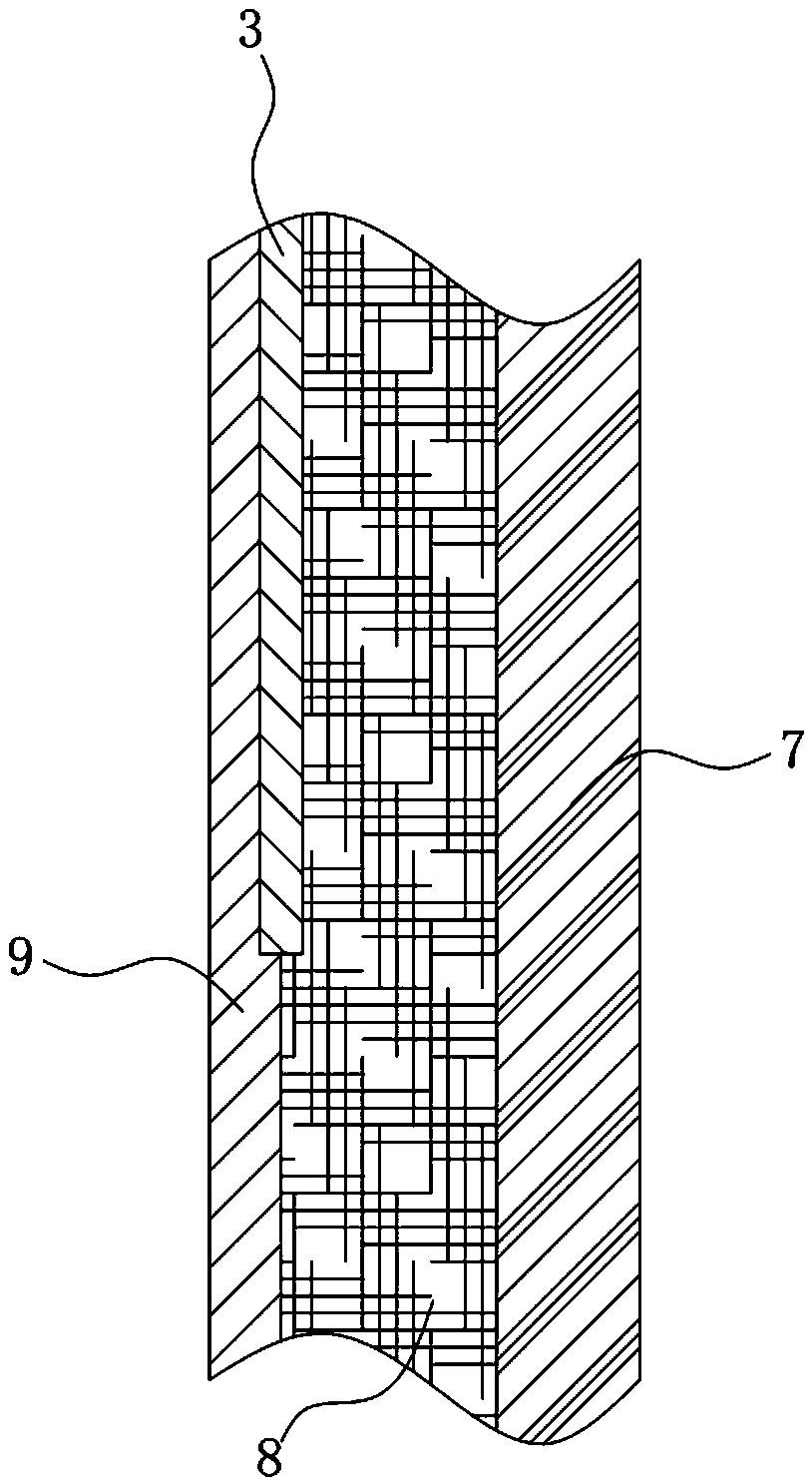

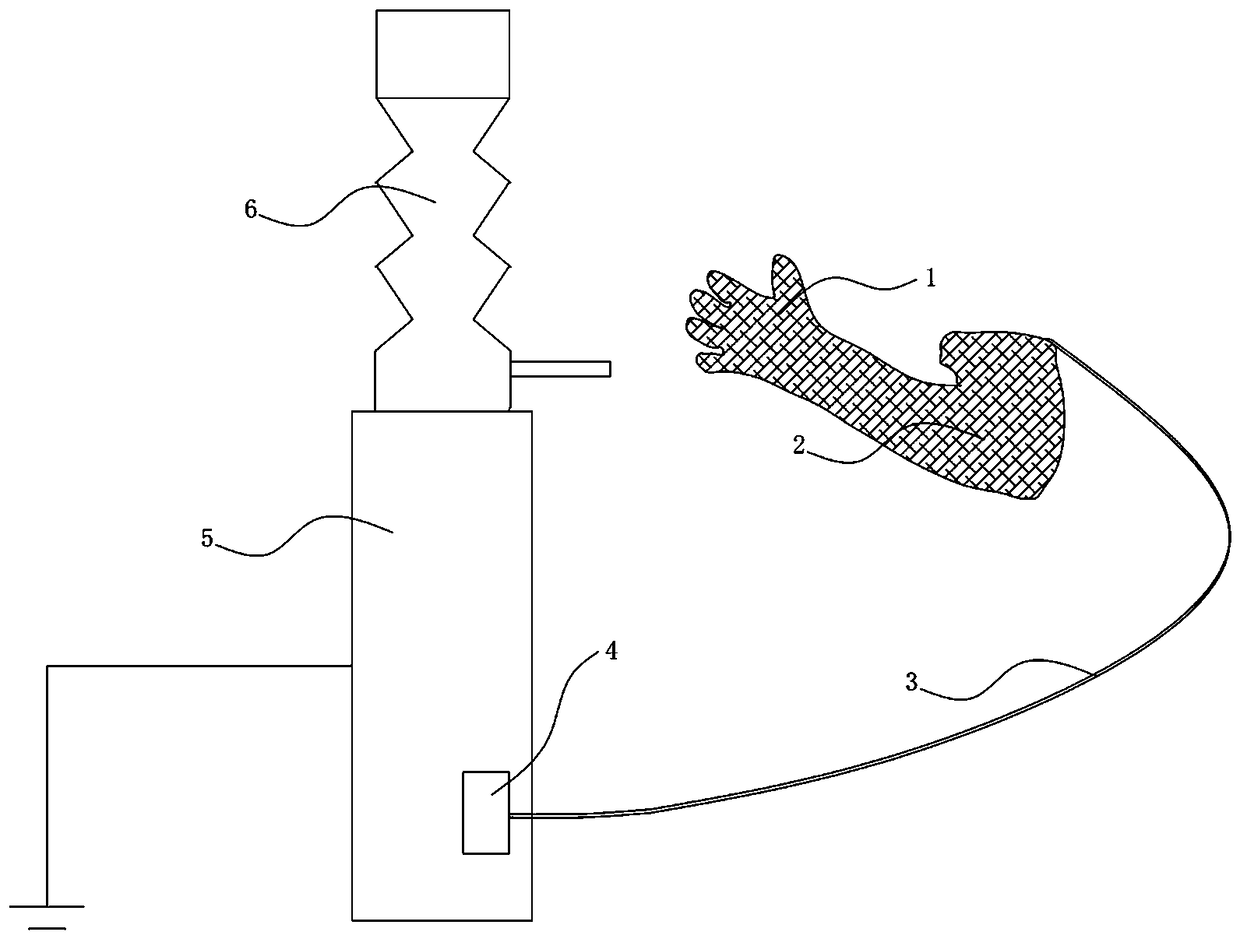

Anti-static insulating glove and application thereof

InactiveCN105876941AImprove work efficiencyPrevent static electric shockSynthetic resin layered productsGlovesElectricityEngineering

The invention relates to the technical field of electric power protective equipment and relates to a protective glove, in particular to an anti-static insulating glove and application thereof. The anti-static insulating glove comprises a glove body and a lead-out portion. The glove body is made of a layered flexible material consisting of an insulating layer, a base layer and an electric conduction layer, the insulating layer is positioned on the outer side of the glove body, and the electric conduction layer is positioned on the inner side of the glove body. The lead-out portion comprises a magnetic iron part which is electrically connected with the electric conduction layer through a wire. The anti-static insulating glove is capable of preventing static shock effectively to reduce safety risks of operation personnel.

Owner:STATE GRID CORP OF CHINA +2

Vibration damping unit

InactiveCN101223381BEasy to set upReduce torsional resistanceRotating vibration suppressionEngineeringFlywheel

The present invention relates to a dual-mass flywheel comprised of a primary mass which can be connected to the output shaft of an engine, and of a secondary mass which can be connected to the input shaft of a transmission, these masses being positioned concentric and axial to one another by means of at least one bearing and being able to rotate relative to one another in a limited manner againstthe action of a damping device with energy storage mechanisms. The energy storage mechanisms are accommodated in an annular ring-like chamber, which is formed by the components of the primary mass and which contains a viscous medium.

Owner:SCHAEFFLER TECH AG & CO KG

A kind of antistatic insulating glove and application thereof

InactiveCN105876941BImprove work efficiencyPrevent static electric shockSynthetic resin layered productsGlovesElectricityStatics

The invention relates to the technical field of electric power protective equipment and relates to a protective glove, in particular to an anti-static insulating glove and application thereof. The anti-static insulating glove comprises a glove body and a lead-out portion. The glove body is made of a layered flexible material consisting of an insulating layer, a base layer and an electric conduction layer, the insulating layer is positioned on the outer side of the glove body, and the electric conduction layer is positioned on the inner side of the glove body. The lead-out portion comprises a magnetic iron part which is electrically connected with the electric conduction layer through a wire. The anti-static insulating glove is capable of preventing static shock effectively to reduce safety risks of operation personnel.

Owner:STATE GRID CORP OF CHINA +2

Turbine rotor roller bracket

The invention provides a novel roller bracket for a steam turbine rotor. The novel roller bracket comprises a base, a roller bracket body located above the base, and two supporting rollers arranged in a left-right symmetry mode. The two supporting rollers are both mounted in the roller bracket body in a rotatable mode. After the rotor is placed on the novel roller bracket for the steam turbine rotor, the two supporting rollers are located on the left side and the right side of a rotor journal respectively, and the outer circumferential faces of the supporting rollers make contact with the outer circumferential face of the rotor journal. The supporting rollers can rotate along the vertical radial line of the rotor journal, and swing front and back along the transverse radial line of the rotor journal. After the rotor is placed on two novel roller brackets, oppositely arranged front and back, for the steam turbine rotor, the supporting rollers can rotate and swing front and back automatically through pressure of the rotor on the supporting rollers, so that the outer circumferential faces of the supporting rollers are always in line contact with the outer circumferential face of the rotor journal, point contact between the supporting rollers and the rotor journal is avoided, and therefore the phenomenon of stress concentration is avoided, and burring of the outer circumferential face of the rotor journal and damage to the rotor are prevented.

Owner:SHANGHAI HAIYE ELECTROMECHANICAL EQUIP CO LTD

Terminal connection structure of sff 2×N series optical modules

ActiveCN111641082BAvoid point contactReduce processing costsCoupling contact membersCoupling protective earth/shielding arrangementsOptical ModuleEngineering

The invention discloses a terminal connection structure of an SFF 2×N series optical module, which includes a plurality of terminal modules and at least one conductive column; the plurality of terminal modules are stacked together, and some of the terminal modules are inlaid and molded on insulating blocks A ground terminal is fixed, and a through hole is opened on the fixed part of the ground terminal, and the edge of the through hole is integrally formed and connected with a shrapnel; the conductive post has a contact plane, and the conductive post is separated from the signal terminal and passes through the aforementioned through hole. The resilient pressure makes the conductive connection on the contact plane. A through hole is opened on the grounding terminal, and the edge of the through hole is integrally formed with a shrapnel, and there is a contact plane on the conductive post, so that the ground terminal and the conductive post are elastically pressed on the contact plane by the shrapnel for conduction connection. , so there is no need to control the dimensional tolerance quite accurately, which can reduce the processing cost, improve the stability of the contact, and effectively improve the crosstalk problem.

Owner:U D (DONGGUAN) ELECTRONICS TECH CORP +2

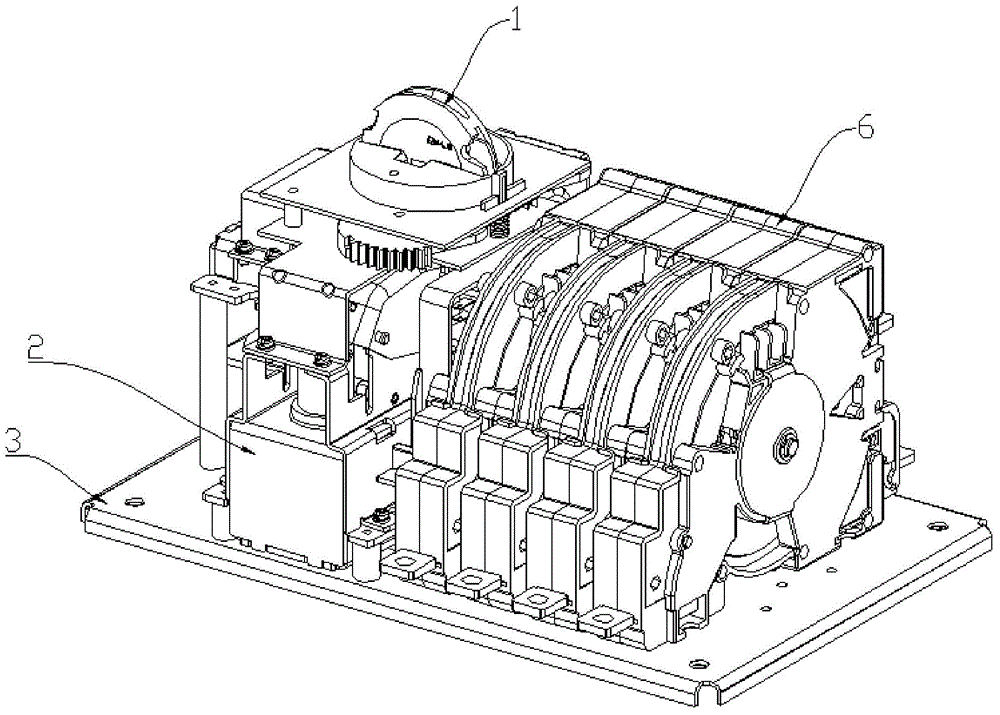

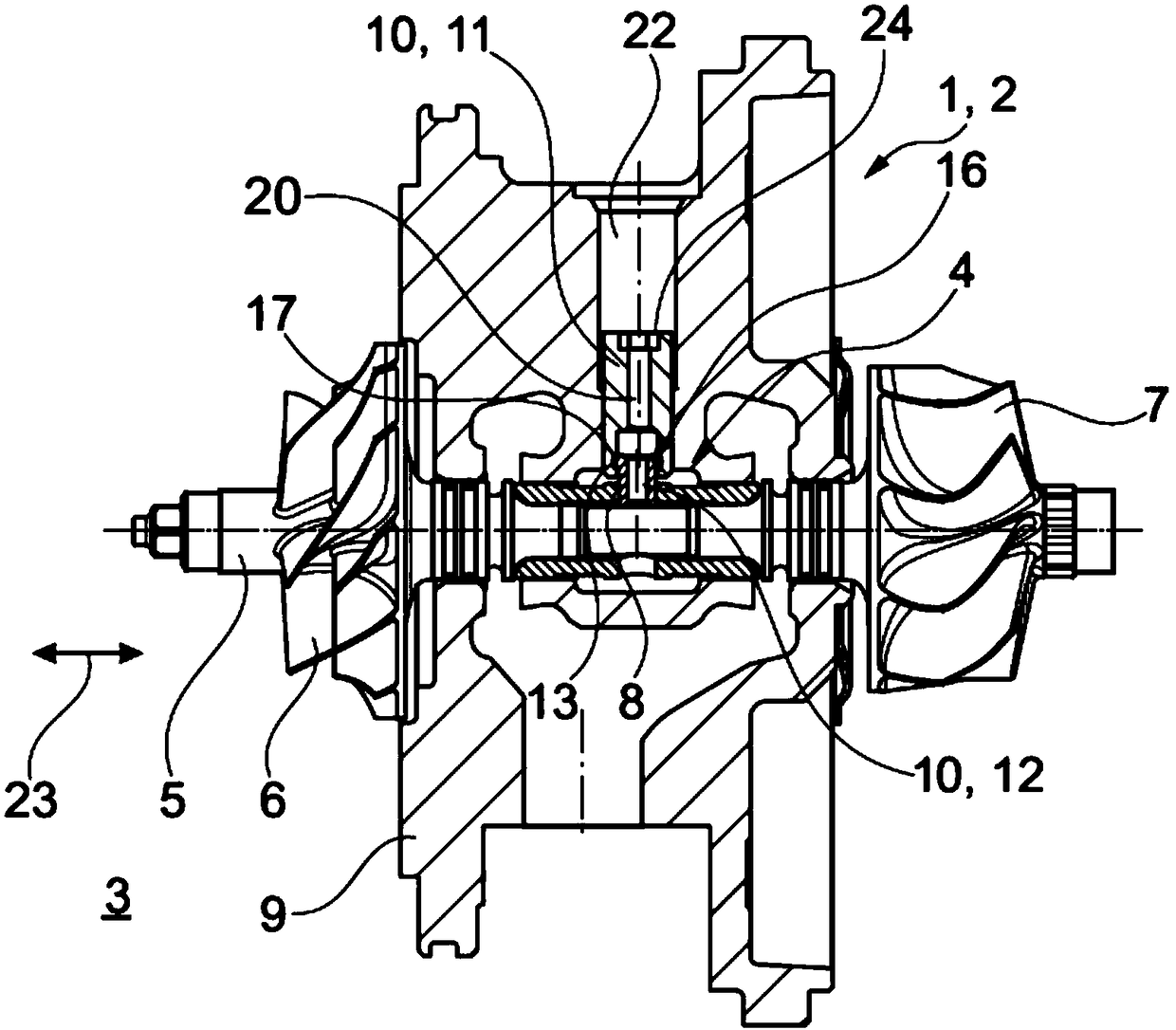

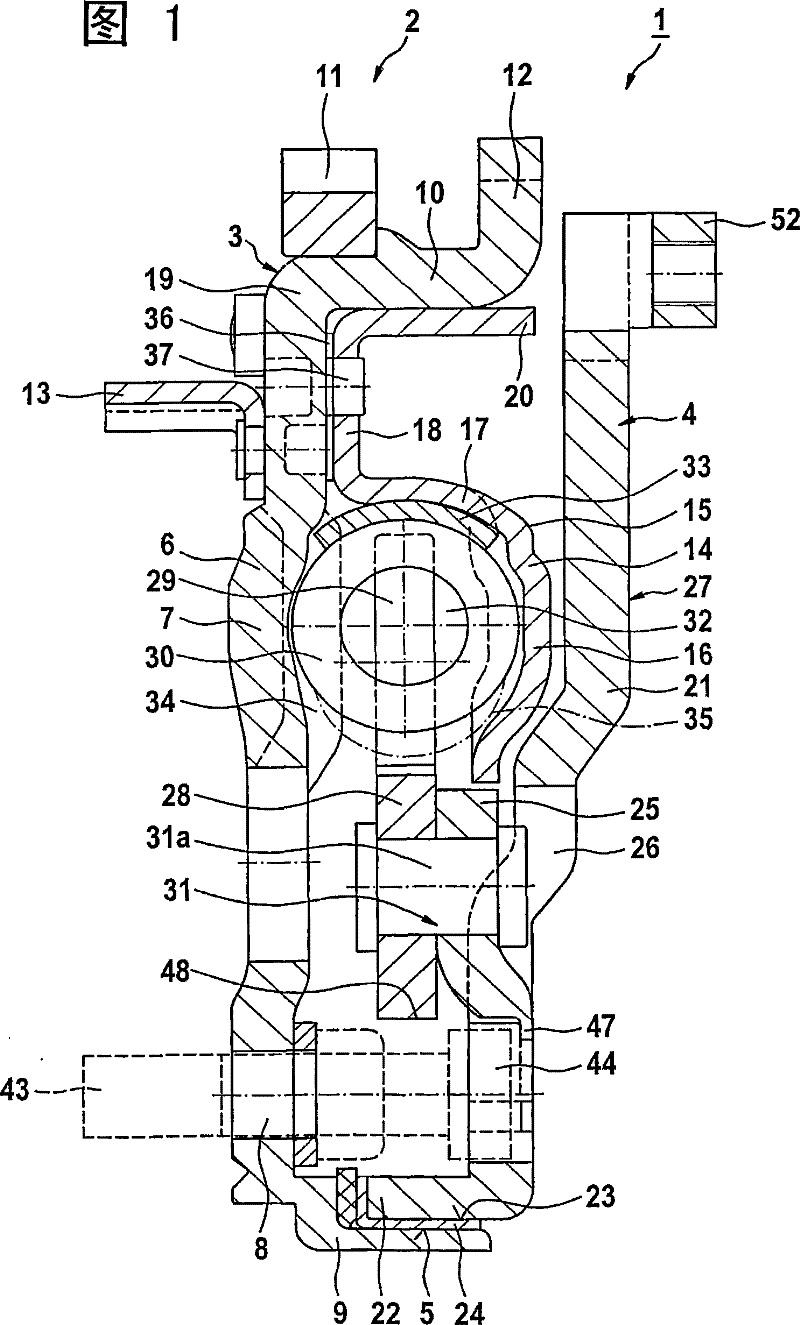

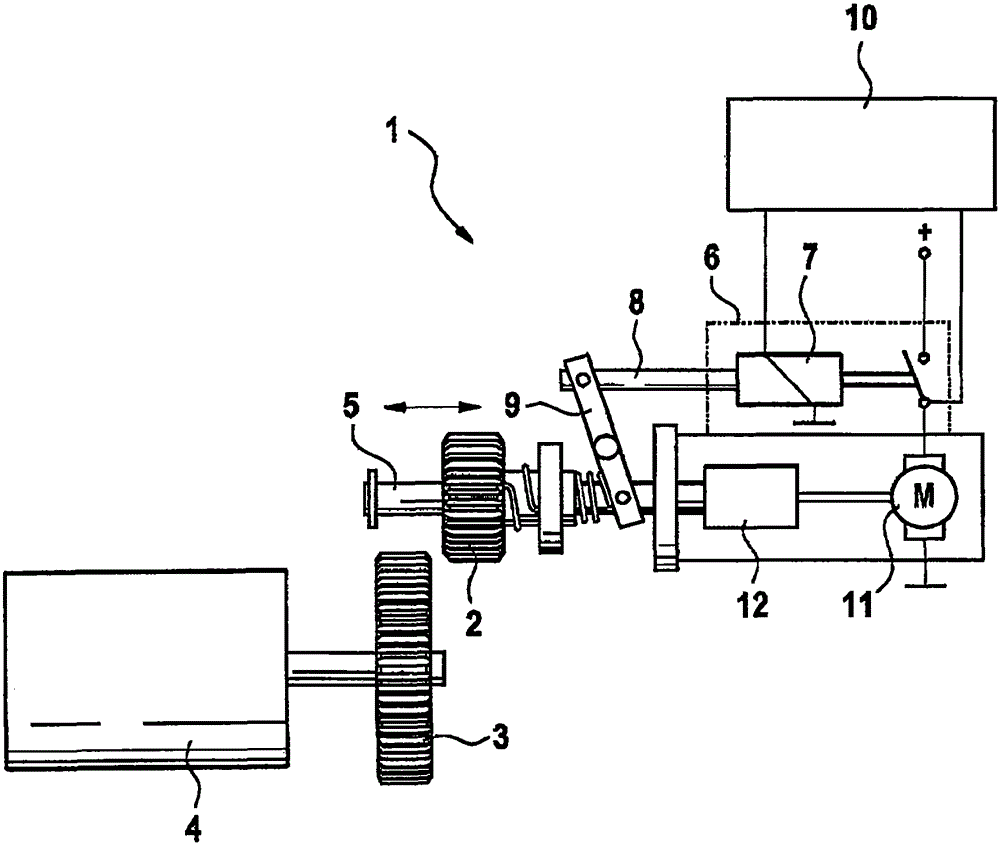

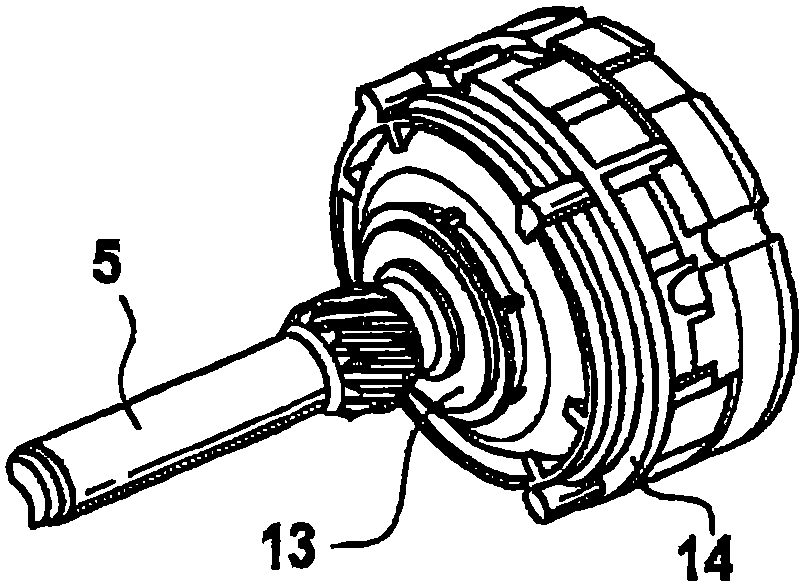

starters for internal combustion engines

InactiveCN102926907BSave installation spaceAvoid point contactPower operated startersElectric motor startersCurve shapeDrive shaft

The starter (1) is provided with an electric drive motor, which drives a drive shaft (5), where a lock washer (13) is held positively on the shaft of the starter. The lock washer is formed annular. The lock washer is adjusted between two cross-sectional geometries. The inner diameter of the lock washer changes during the adjustment. The locking washer has a curved shape in the former cross-sectional geometry. The lock washer is executed as sticking washer.

Owner:ROBERT BOSCH GMBH

supercharger

ActiveCN108223136BEnables axial adjustabilityEasy to wearRolling contact bearingsPump componentsPhysicsElectrical and Electronics engineering

The invention relates to a supercharger (1) having a bearing arrangement (4) which mounts a shaft (5) in a bearing housing (9) via a bearing bush (8), wherein the bearing bush Stable positioning of (8) is provided by pins (10) engaged in bearing bushes (8) radially from the hub. It is important for the invention that the pin (10) comprises a first part (11) mounted rotatably in the bearing housing (9) and a second part engaging in a recess (13) of the bearing bush (8) Two parts (12) in which the axis (14) of the first part (11) and the axis (15) of the second part (12) extend parallel to each other; the bearing bush (8) and the pin (10) are connected via a ball joint The pieces (16) are interconnected.

Owner:BOSCH MAHLE TURBO SYST GMBH & CO KG

A casting single crystal seed crystal laying method with short bottom red zone and few primary dislocations

ActiveCN112458530BShorten the lengthReduce lattice distortionPolycrystalline material growthFrom frozen solutionsCrucibleSurface roughness

The invention discloses a casting single crystal seed crystal laying method with short bottom red area and few primary dislocations, which comprises the following steps: removing the head and tail, edge skin and wire cutting of a Czochralski single crystal silicon rod to obtain a cast single crystal seed crystal , to sandblast its surface to increase its surface roughness; to cut a thick slice from a polycrystalline silicon block or a monocrystalline silicon block, to sandblast the surface of the thick slice to increase its surface roughness; to lay the first thick slice on the bottom of the crucible Sheets; cast single-crystal seeds are laid on the first thick sheet, with gaps on the sides between adjacent cast single-crystal seeds; a second thick sheet is laid at the center of the upper surface of each cast single-crystal seed Lay thick sheets on the second thick sheet, and the side walls of the thick sheets are closely bonded to form the third thick sheet. Place primary silicon materials, recycled silicon materials, etc. on the third thick sheet layer. When the silicon material is melted to the casting unit At the 1 / 2 position of the seed crystal layer, a temperature gradient in the vertical direction is created to gradually solidify from the bottom up to obtain a cast monocrystalline silicon ingot.

Owner:NANCHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com