Movable grain unloading opening mechanism of combine harvester, grain unloading device and harvester

A technology of combine harvester and grain unloading device, applied in the direction of harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of hidden dangers, low efficiency, and the inability of grain to be quickly and effectively filled with trailers, etc., to save operating costs. , The principle is simple, the effect of eliminating the hidden danger of unloading grain safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

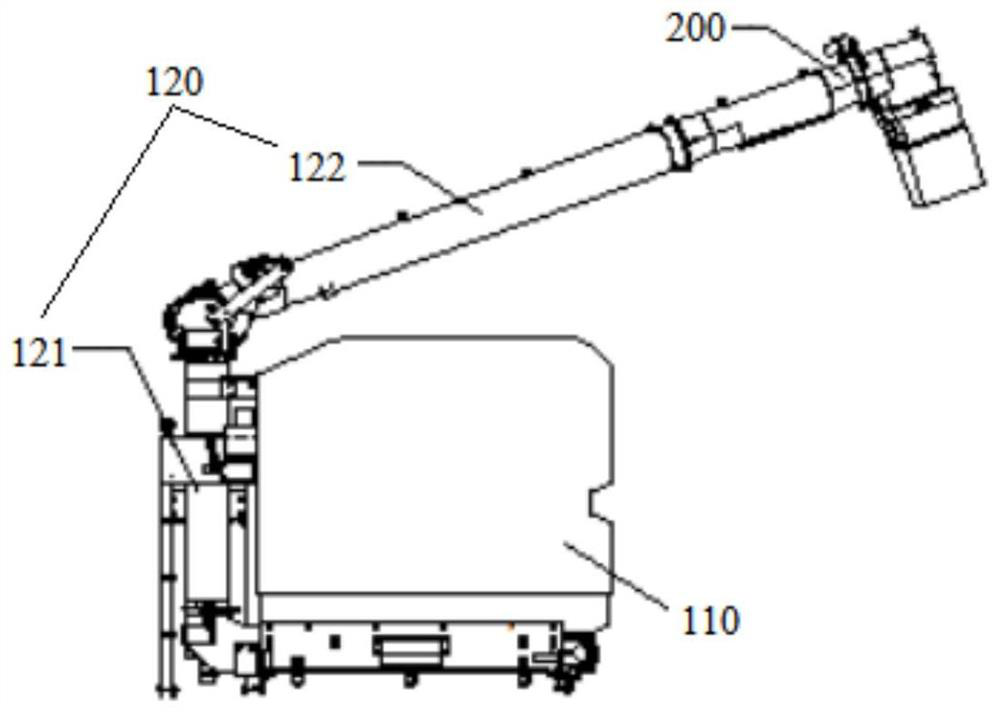

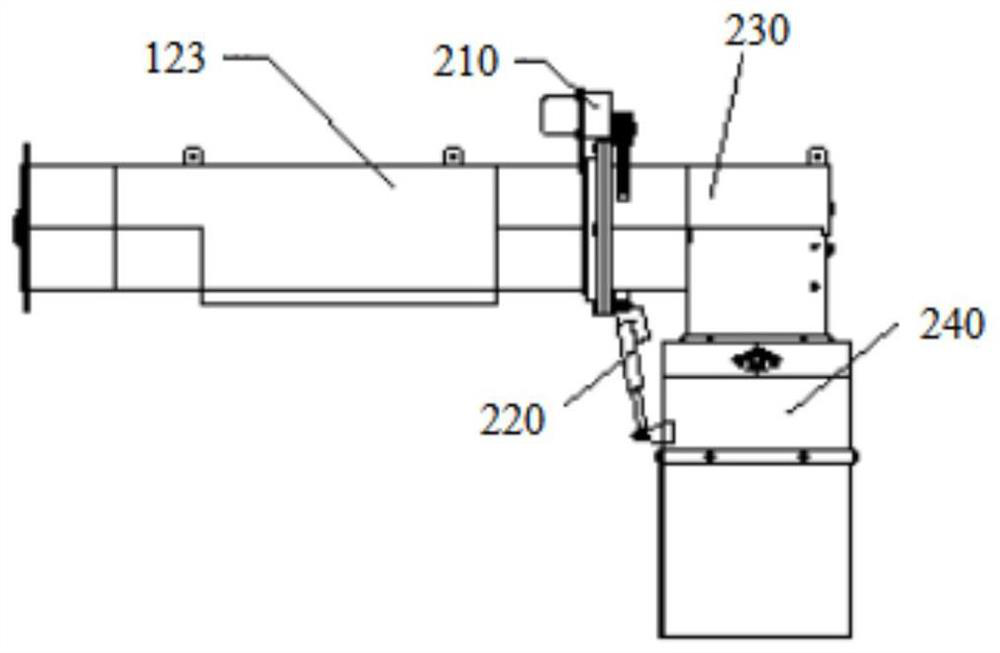

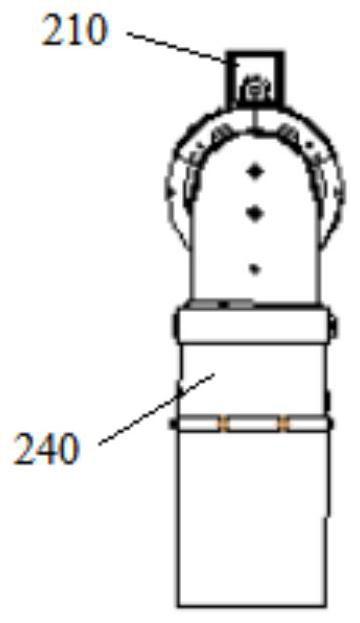

[0080] combine figure 1 , a kind of combined harvester movable unloading opening mechanism of the present embodiment is arranged at the end of the auger assembly 120, specifically, the auger assembly 120 includes a vertical auger assembly 121 and a horizontal auger assembly 122 for unloading grain. The movable grain unloading mechanism 200 includes two parts, one part is a radial rotation assembly 230 that can rotate around the axis of the grain unloading horizontal auger assembly 122; Swing assembly 240 .

[0081] See Figure 6a and Figure 6b , the radial rotation assembly 230 includes a radial rotation assembly housing 231, one end of the radial rotation assembly housing 231 is a circular opening, and a flange 234 is arranged on the circumference of the circular opening, see Figure 3a and Figure 3b , the flange 234 is connected with the grain unloading horizontal auger assembly 122 by rotating the flange seat 127, the flange 234 can rotate in the rotating flange seat ...

Embodiment 2

[0096] See figure 1 , a grain unloading device of the present embodiment, including a movable grain unloading mechanism of a combine harvester in Embodiment 1, and also includes a grain collection box 110 and an auger assembly 120 .

[0097] The grain collection box 110 is used for temporarily storing the clean grain after threshing and cleaning by the harvester; the auger assembly 110 includes a vertical auger assembly 121 and a horizontal auger assembly 122 for unloading grain. The lower end of the vertical auger assembly 121 is connected with the horizontal auger assembly in the grain collection box 110, the upper end of the vertical auger assembly 121 is connected with one end of the grain unloading horizontal auger assembly 122, and the grain unloading horizontal auger assembly 122 is away from the vertical auger assembly One end of 121 is connected with movable grain unloading mouth mechanism 200. During the working process, the grain passes through the vertical auger a...

Embodiment 3

[0102] A harvester in this embodiment includes a grain unloading device in Embodiment 2, and also includes a harvester body 300 .

[0103] See Figure 10 , the harvester body 300 can be an existing combine harvester, and the general operation process of the combine harvester is cutting→transporting→threshing→cleaning→collecting grain→unloading grain. After the harvester body 300 completes the process of cutting, conveying, threshing, and cleaning, the grain is stored in the grain collection box 110 of the grain unloading device 100 arranged on the harvester body 300, and then through the auger assembly 120 and the movable grain unloading port. The mechanism 200 unloads the food onto the transport vehicle 400 .

[0104] Because the auger assembly 120 and its vertical auger assembly 121 in the grain unloading device 100 of the embodiment are all movably connected with the horizontal auger assembly 122 for unloading grain, the horizontal auger assembly 122 for unloading grain ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com