Rotary tulip contact and contact system for switching device

A plum-blossom contact, rotary technology, applied in the directions of contact meshing, contact heating/cooling, contact surface shape/structure, etc., can solve problems such as contact pieces hanging in the air, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

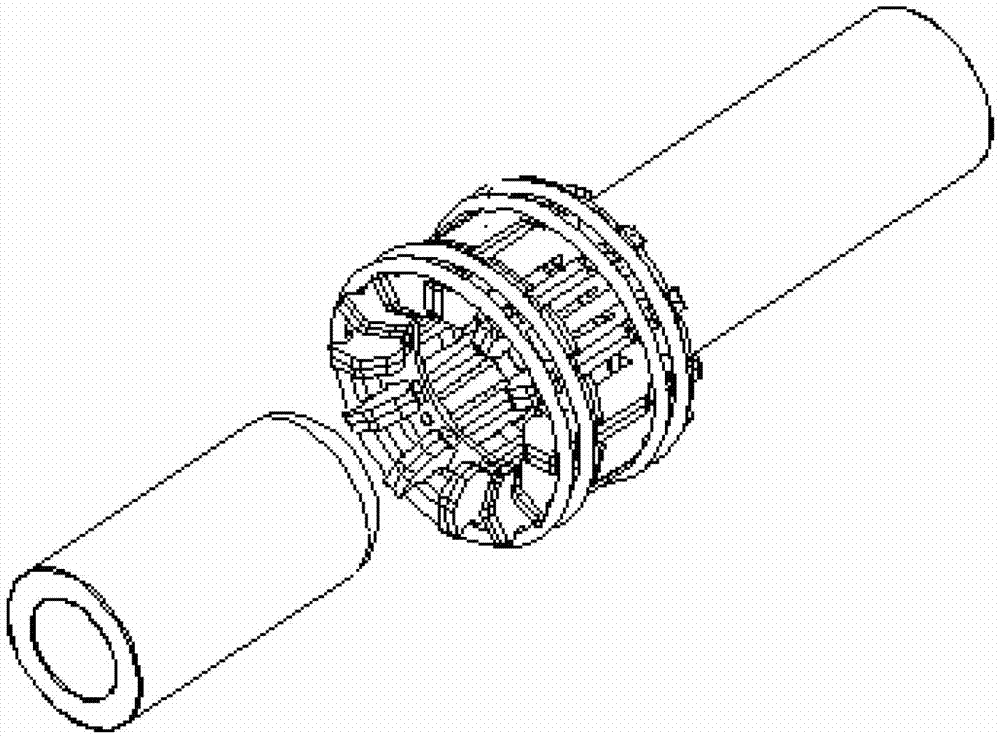

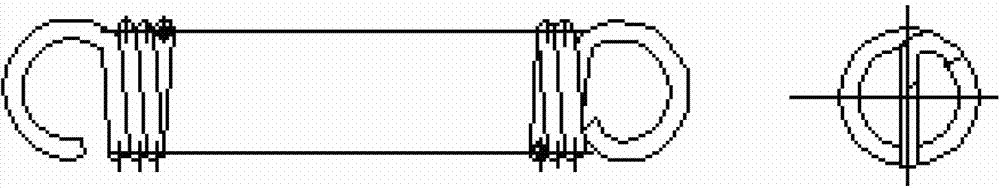

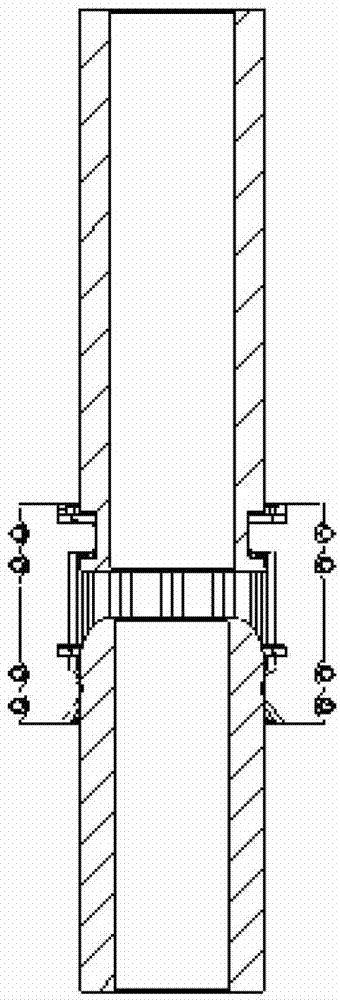

[0041] Such as Figure 4-16As shown, a rotary tulip contact according to the embodiment of the present invention includes a bracket 1 and an annular spring 2. A plurality of contact holes 101; the ring spring 2 is formed by connecting the strip springs end to end through the pull hooks at both ends, and the ring spring 2 is used to fix the contacts in the contact holes, which can increase its mechanical strength. Improve the average bearing force of the spring; also include a plurality of movable contact pieces 3, each movable contact piece 3 has a hemispherical protrusion 301 at the bottom, and the hemispherical protrusion 301 of each movable contact piece 3 is coated There is a solid conductive paste that can increase the overall conductivity of the contact, or a solid conductive paste is coated in the concave groove 401 of each static contact piece 4, and the protrusion 301 of the movable contact piece 3 can be connected to the fixed contact piece 4 at the same time. The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com