Rolling disc type working device and slide revolving support thereof

A technology of slewing support and slewing frame, which is applied to the chassis of agricultural machinery, mechanically driven excavators/dredgers, agricultural machinery and machinery, etc., can solve the problem of low frequency adjustment of blade rotation angle, rolling ball and raceway pitting , lubricating oil film is not easy to form and other problems, to avoid abnormal wear, reduce replacement cost, reduce contact stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

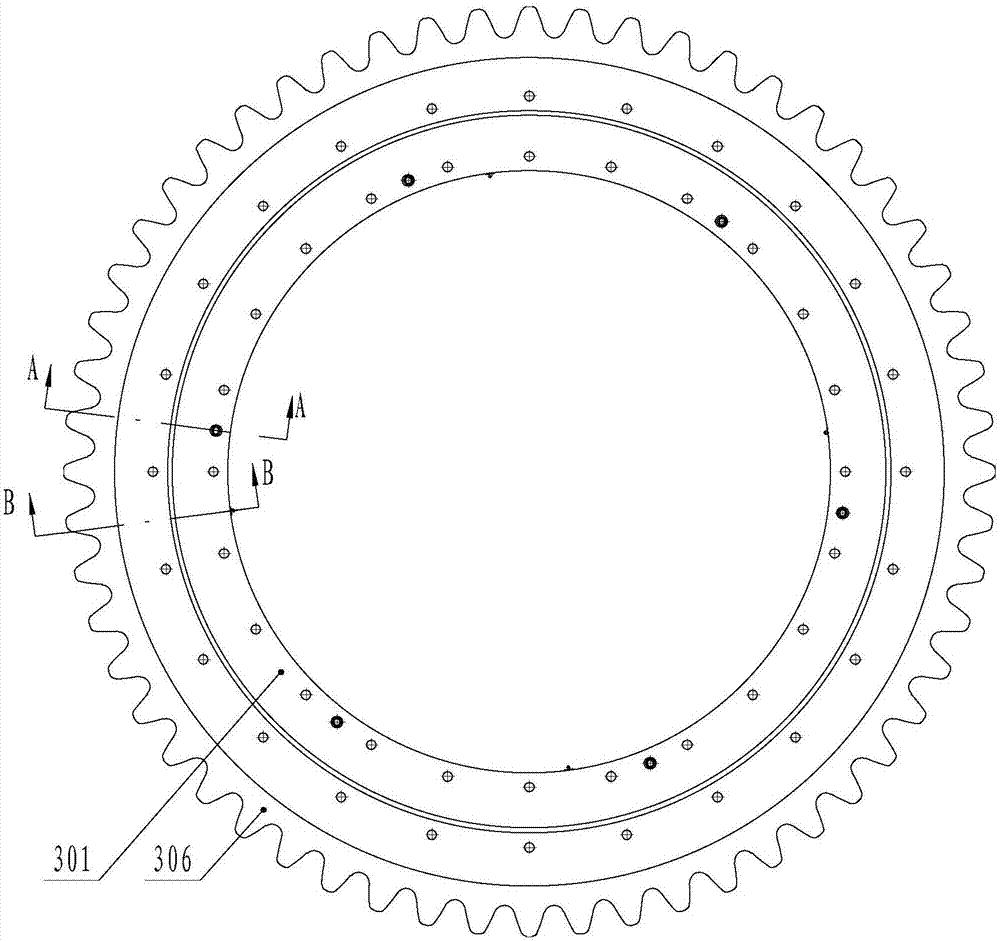

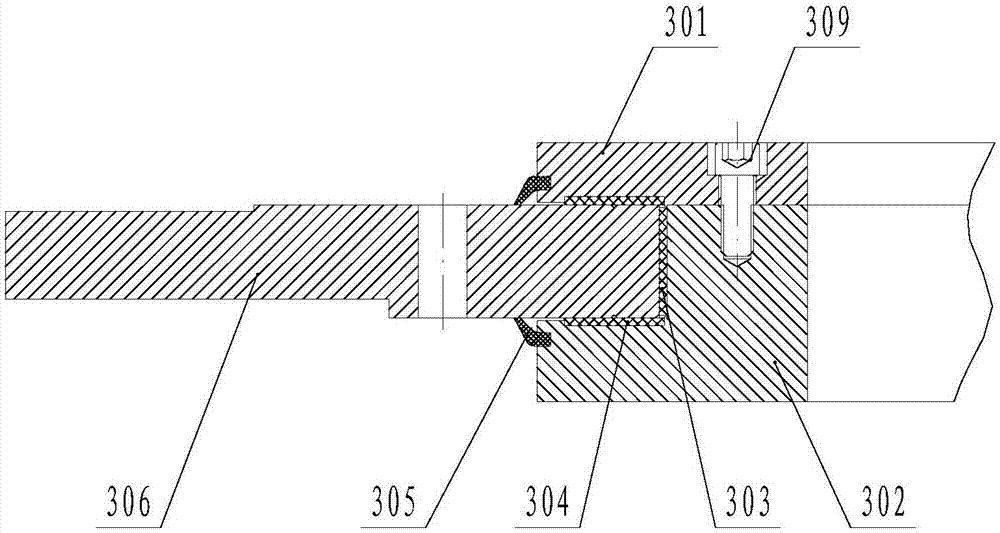

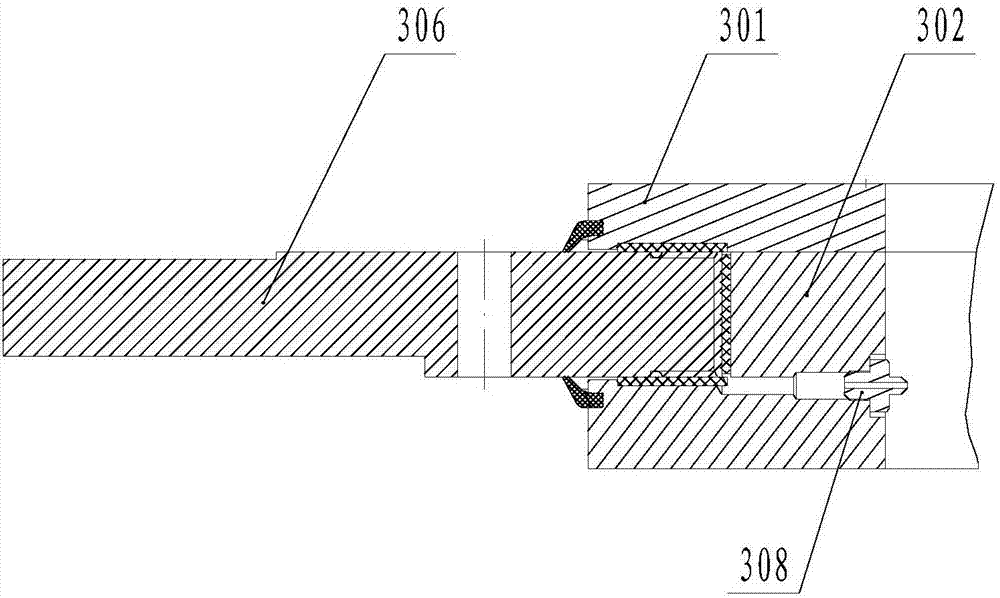

[0030] Embodiment one: if figure 1 and figure 2 As shown, the sliding slewing support 3 includes an upper fixed plate 301 and a lower fixed plate 302, a sliding ring gear is arranged between the upper fixing plate 301 and the lower fixing plate 302, the sliding ring gear is a sliding outer gear ring 306, and the sliding outer gear ring 306 Located on the outer side of the upper fixing plate 301 and the lower fixing plate 302, a composite sliding bearing II 304 and a sealing ring 305 are provided respectively above and below the sliding outer ring gear 306 and between the upper fixing plate 301 and the lower fixing plate 302, and the sealing ring 305 is VR-type sealing ring, a composite sliding bearing I303 is provided between the inner side of the sliding outer gear ring 306 and the lower fixing plate 302; image 3 As shown, the sliding surface of the sliding outer ring gear 306 in contact with the upper fixing plate 301 and the lower fixing plate 302 is respectively provide...

Embodiment 2

[0033] Embodiment two: if Figure 5 As shown, the sliding ring gear is a sliding ring gear 307, and the sliding ring gear 307 is located inside the upper fixing plate 301 and the lower fixing plate 302; the others are the same as the first embodiment.

Embodiment 3

[0034] Embodiment three: as Figure 6 As shown, the rolling disc type working device includes a traction frame 2 of a grader and a revolving frame 4, and the sliding slewing support 3 described in the first embodiment is arranged between the traction frame 2 and the revolving frame 4 of the grader.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com