Producing a rotor by means of additive manufacturing

A rotor and rotor core technology, applied in the field of short-circuit rings, can solve problems such as the inability to realize the material gradient of short-circuit rings, and achieve the effects of improving efficiency and performance, helping cooling, and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

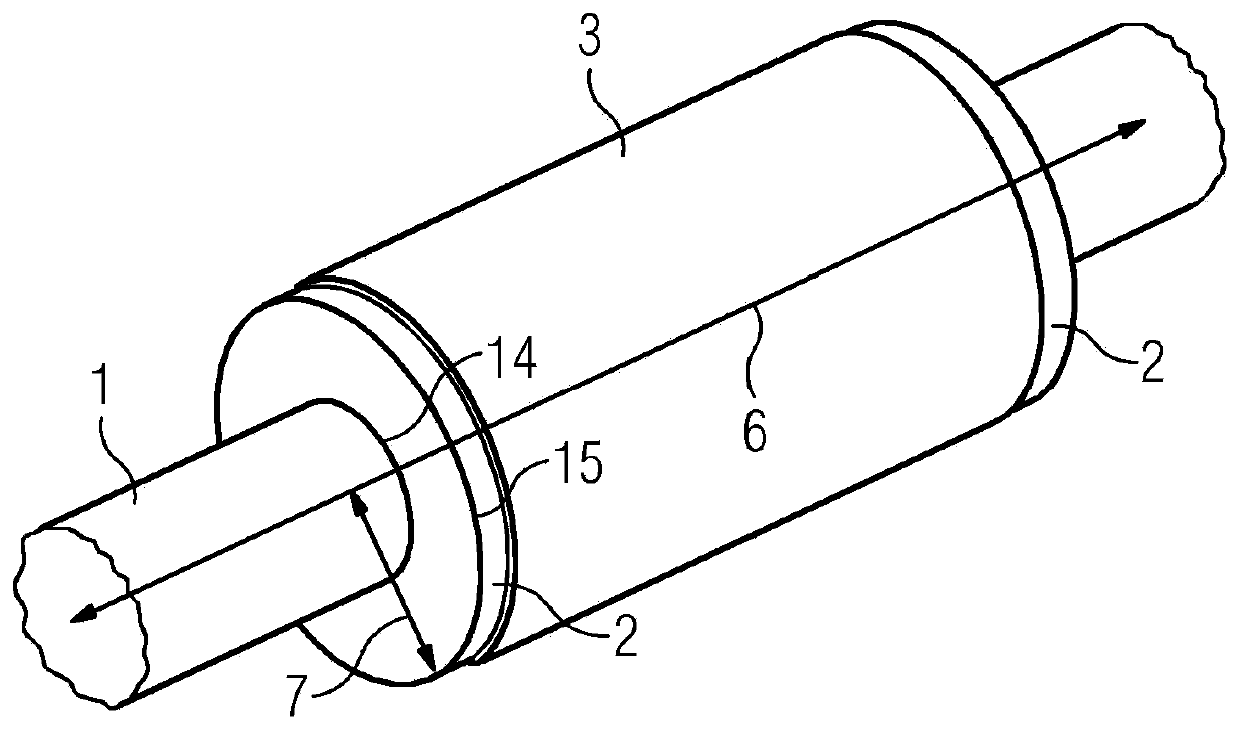

[0039] figure 1 One configuration of a rotor connected to the shaft 1 is shown, the rotor having a rotor core 3 and correspondingly short-circuiting rings 2 at its axial ends. Furthermore, the axial direction 6 and the radial direction 7 are shown, as well as the inner radius 14 and the outer radius 15 of the short-circuit ring. Preferably, the rotor is designed as a squirrel-cage rotor and the rotor comprises squirrel-cage bars extending in the axial direction 6 or substantially obliquely in the axial direction 6 and short circuits at the axial ends of the squirrel-cage bars Ring 2, which shorts the squirrel cage rods. According to the present invention, only the cage rods or the short-circuit rings 2 , or the cage rods and the short-circuit rings 2 can be produced by the MPA method. Advantageously, the squirrel cage bars are prefabricated, preferably from copper or aluminum, and inserted into the rotor core 3, and the short-circuit rings 2 are then added by the MPA method....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com