Patents

Literature

64 results about "Asynchronous machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

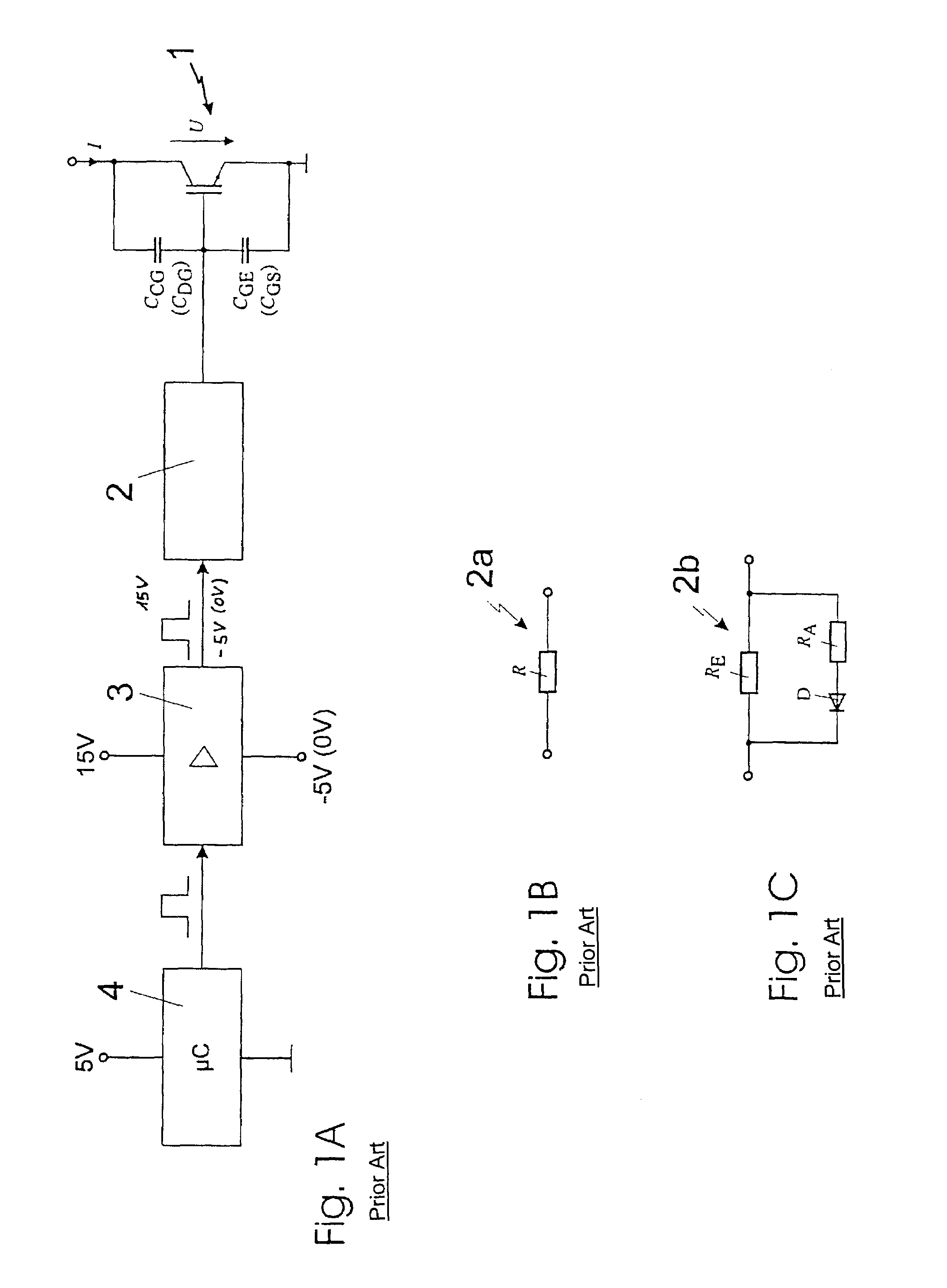

The Asynchronous Machine block implements a three-phase asynchronous machine (wound rotor, single squirrel-cage, or double squirrel-cage). It operates in either generator or motor mode. The mode of operation is dictated by the sign of the mechanical torque: If Tm is positive, the machine acts as a motor.

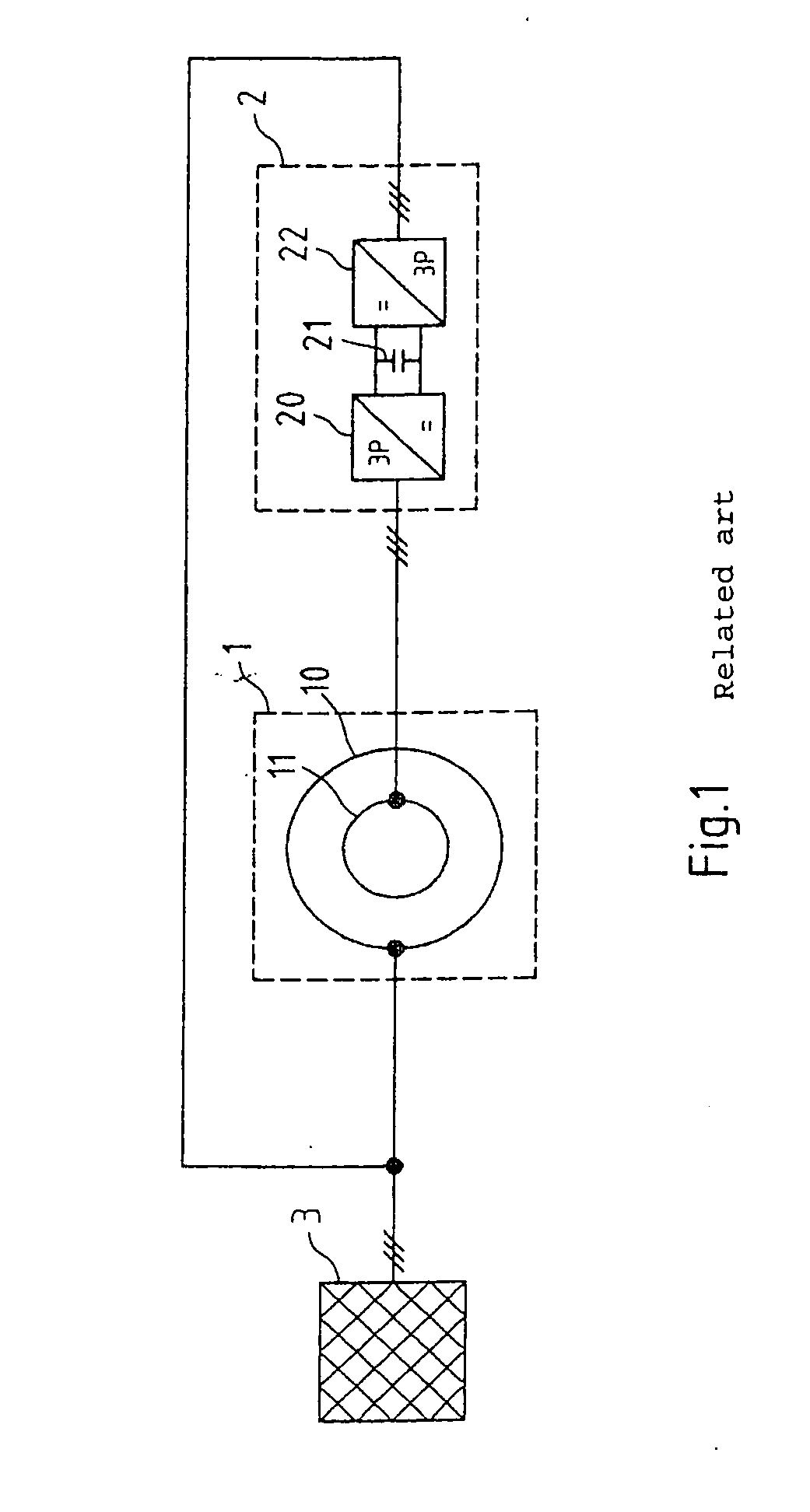

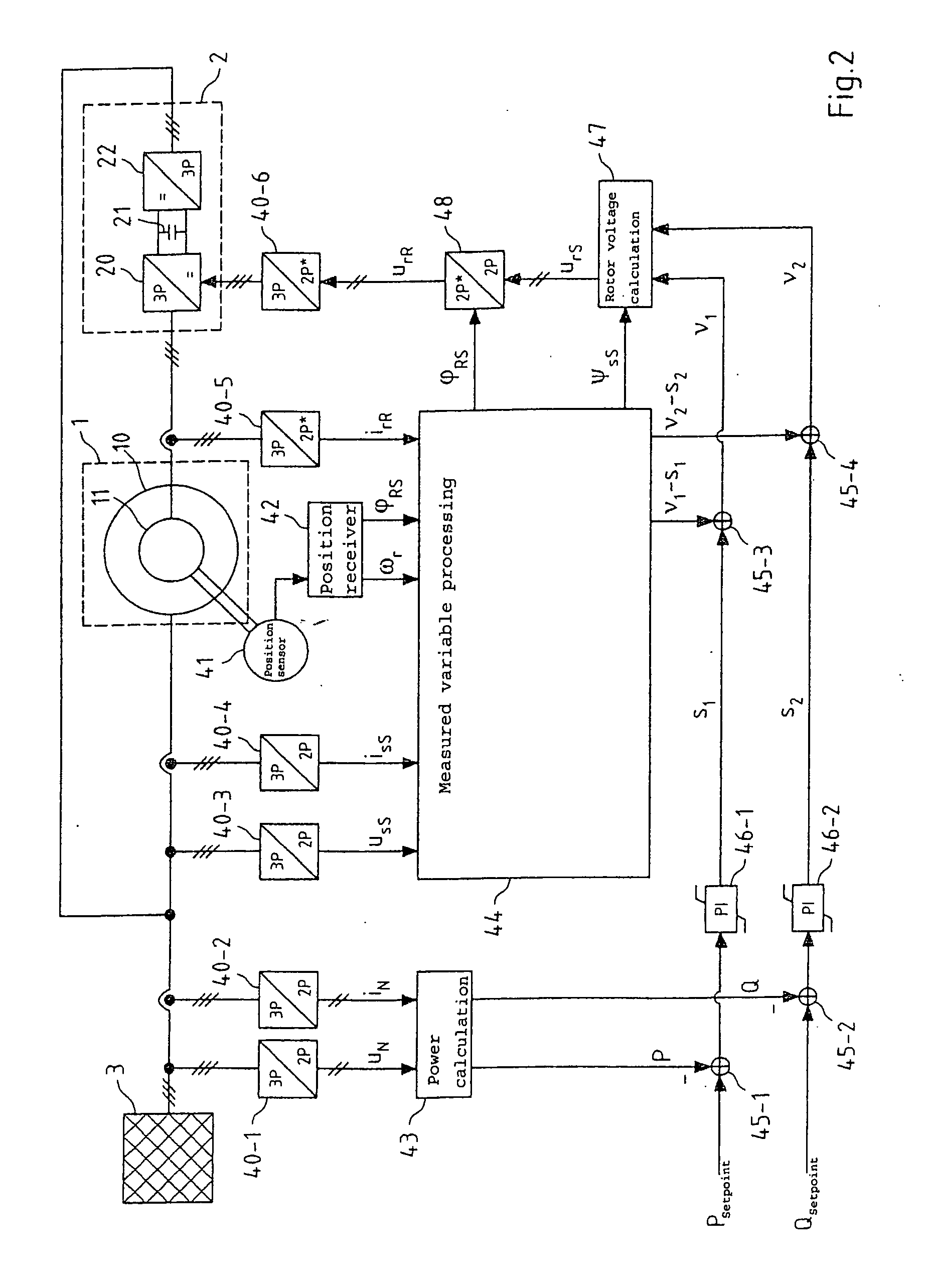

Power control of an induction machine

ActiveUS7423406B2Simple simultaneously stable regulationSimple processGenerator control circuitsIgnition automatic controlElectric machineConductor Coil

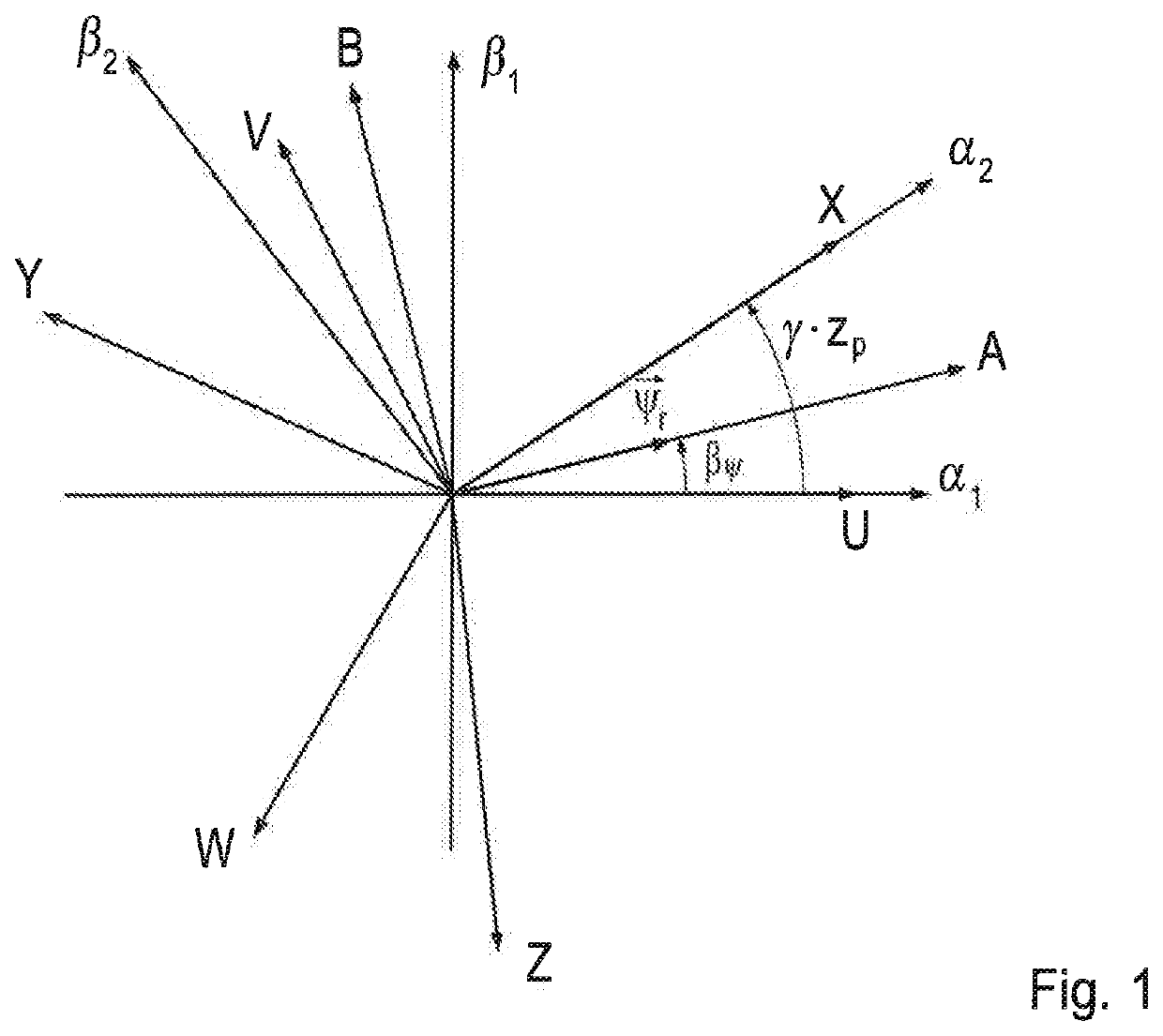

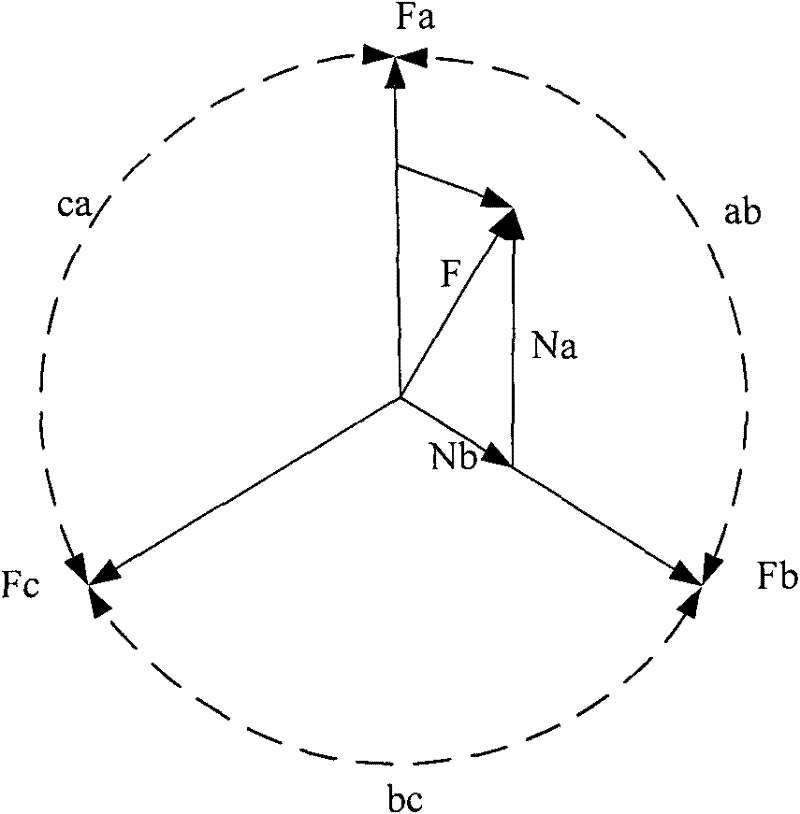

Regulation of the active and reactive power of an induction machine in a coordinate system fixed on the winding, wherein a first regulator output variable is generated using a first regulator as a function of a setpoint variable deviation of the active power and a second regulator output variable is generated using a second regulator as a function of a setpoint variable deviation of the reactive power, feedback variables are added to each of the first and second regulator output variables, which are functions of at least one chronologically changing system variable of the induction machine, and a voltage or a current of the induction machine is determined as a manipulated variable without further regulation at least from the first and second regulator output variables added to the feedback variables. The feedback variables may linearize the regulation path and then allow restriction to only two simple regulators, e.g., two PI regulators. The regulation may be used in double-fed asynchronous machines.

Owner:K B ELECTRONICS INC

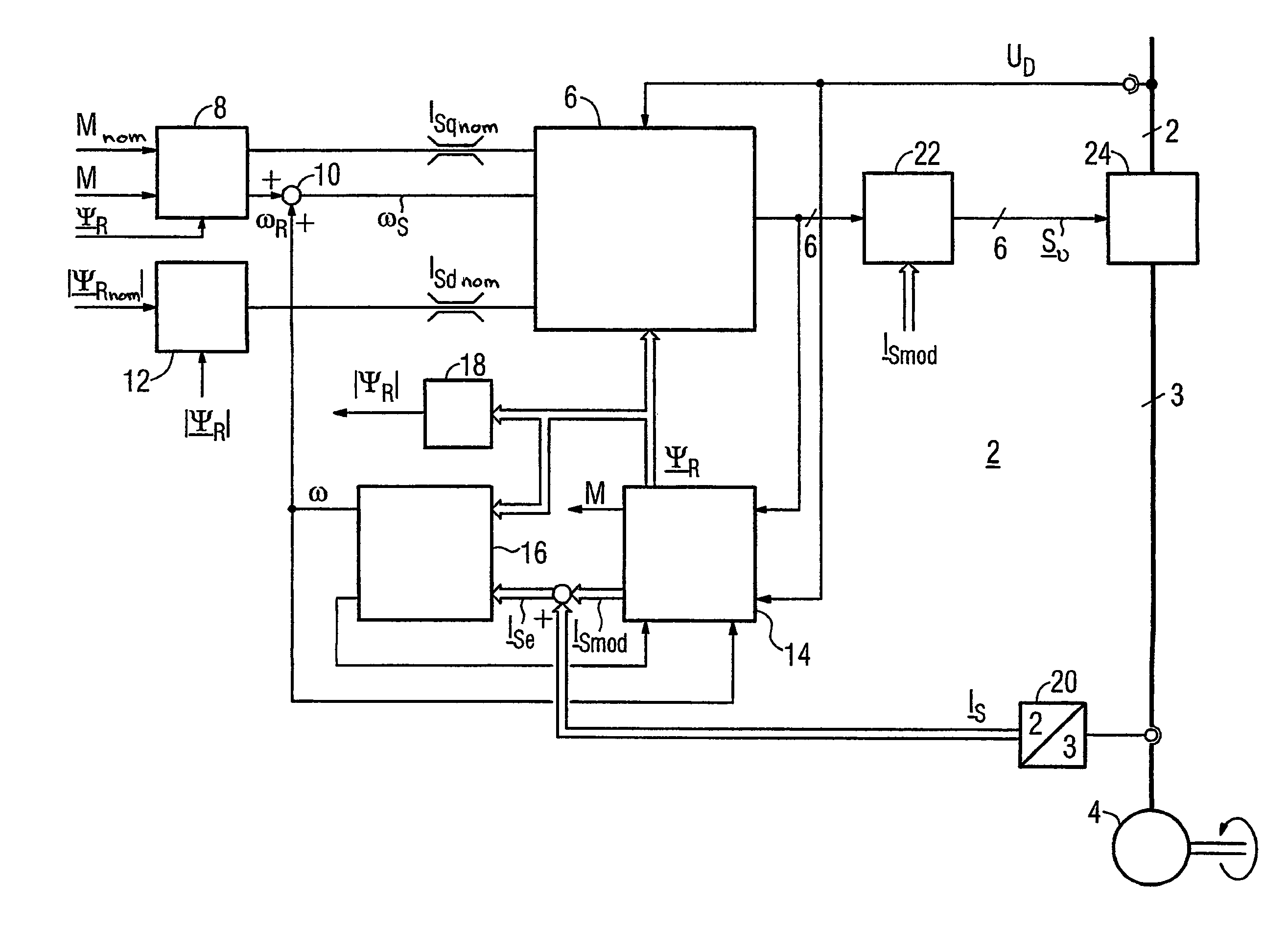

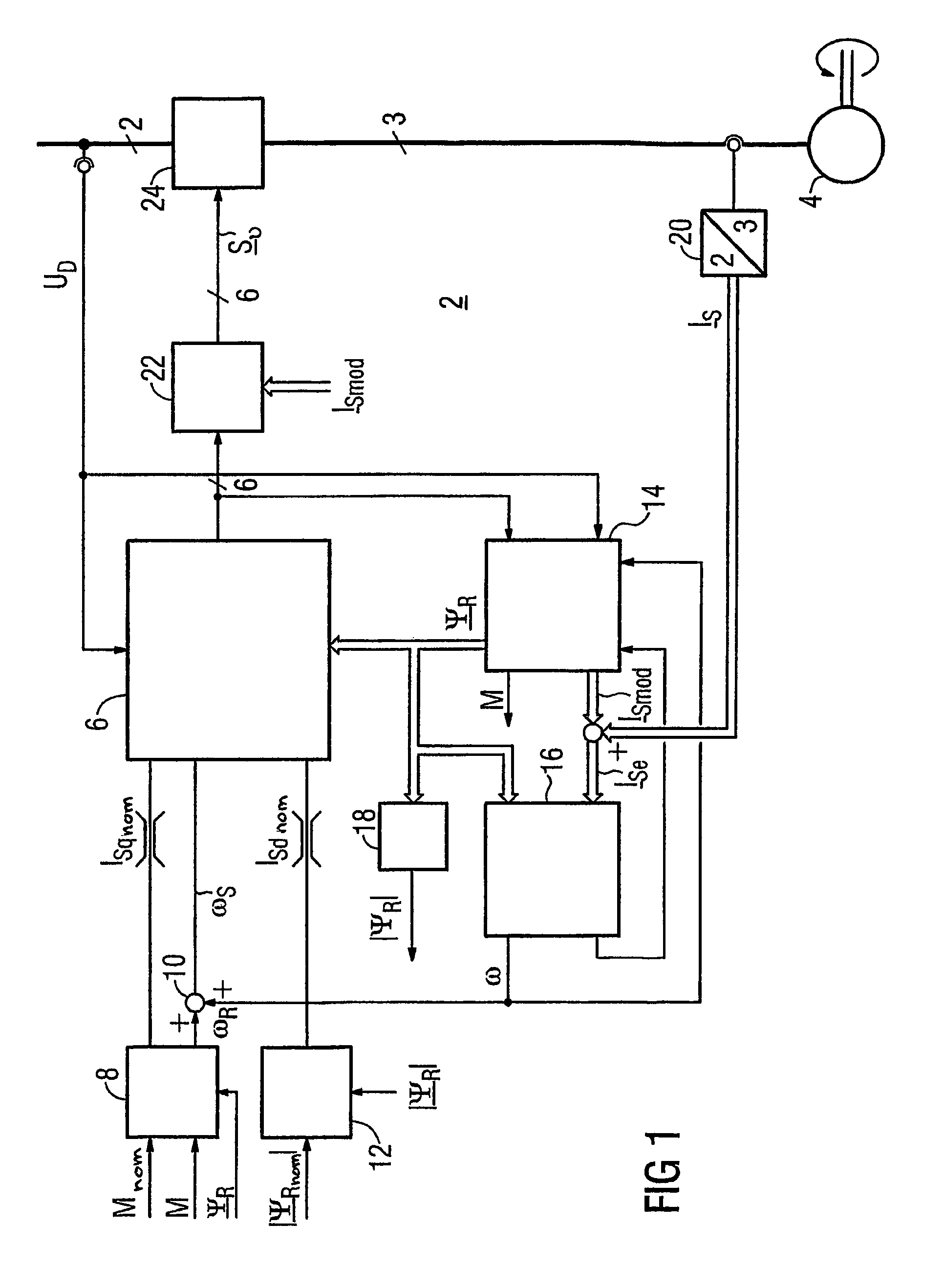

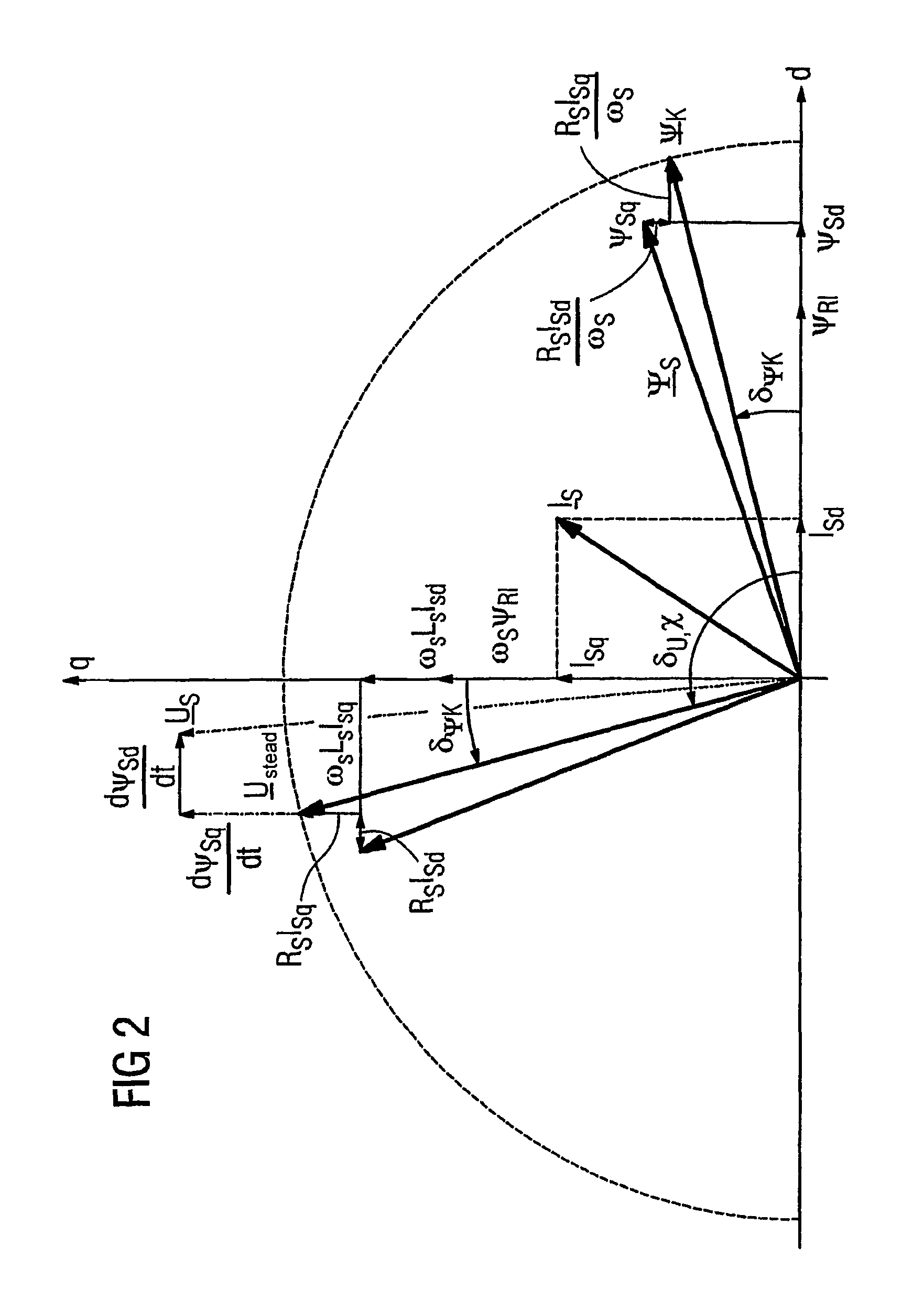

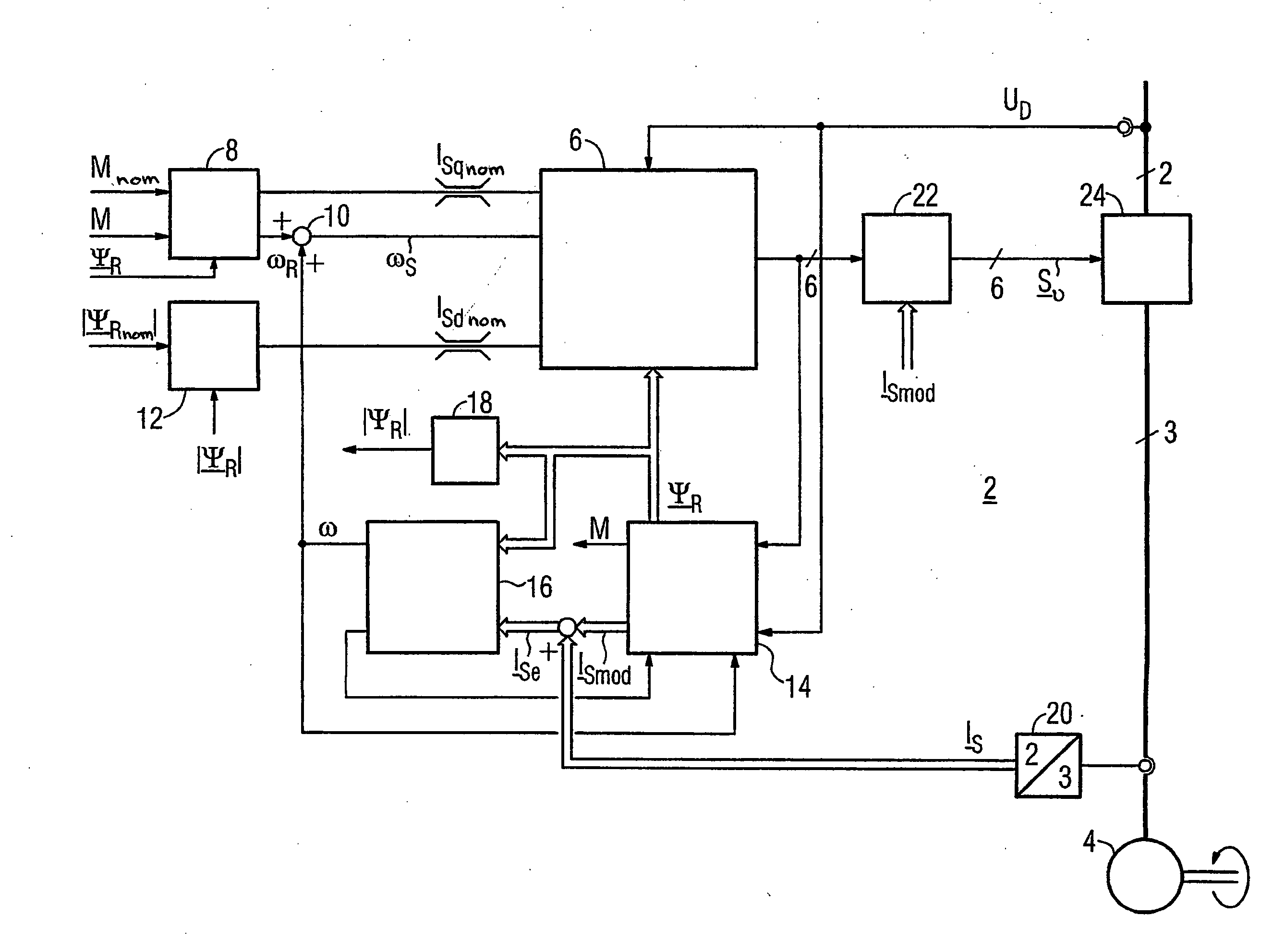

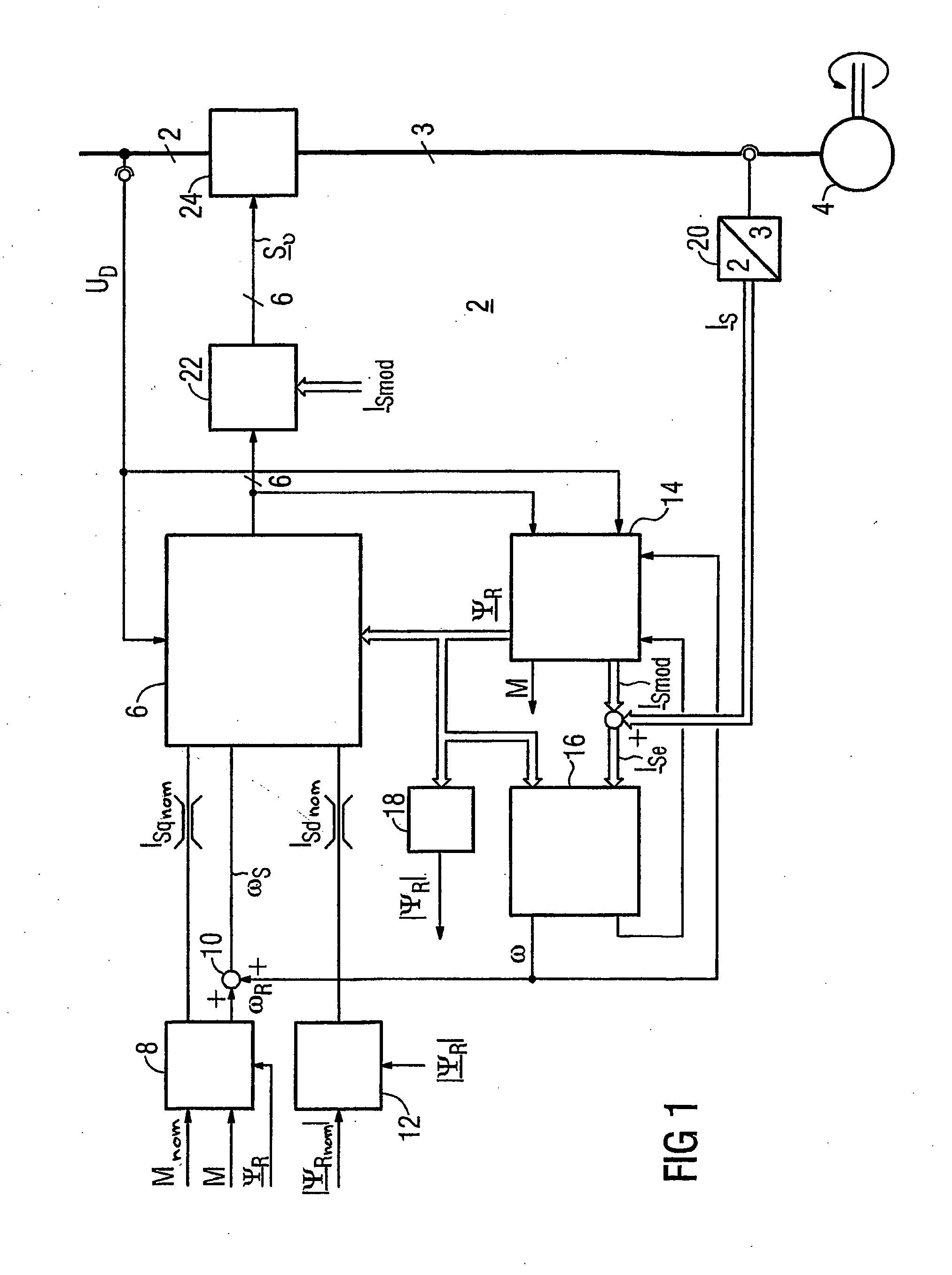

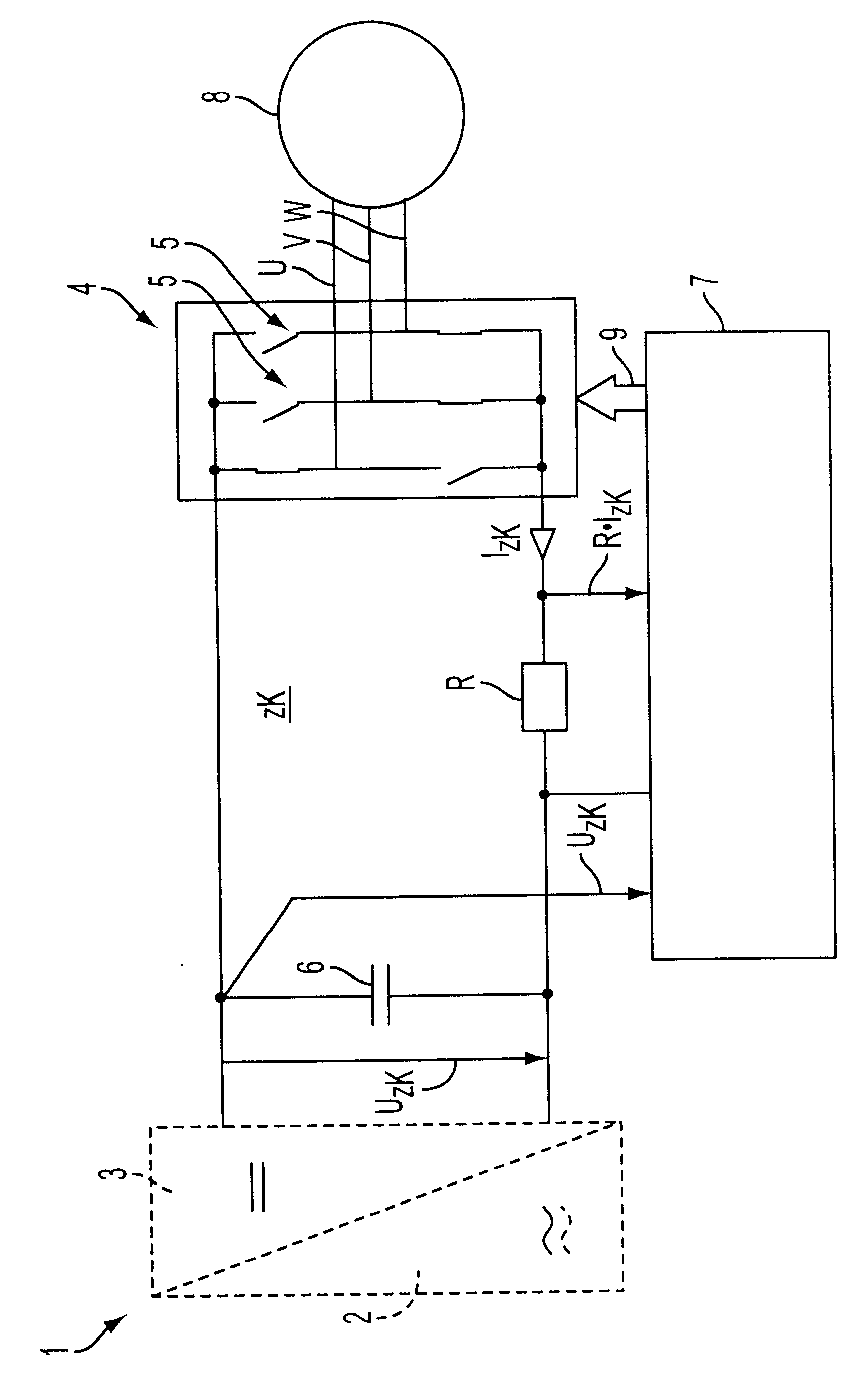

Method for controlled application of a stator current set point value and of a torque set point value for a converter-fed rotating-field machine

InactiveUS7746039B2Avoid disadvantagesBroaden the fieldElectronic commutation motor controlVector control systemsElectric machineMagnetic poles

Owner:SIEMENS AG

Method for Controlled Application of a Stator Current Set Point Value and of a Torque Set Point Value for a Converter-Fed Rotating-Field Machine

InactiveUS20080136380A1Avoid disadvantagesBroaden the fieldElectronic commutation motor controlVector control systemsElectric machineMagnetic poles

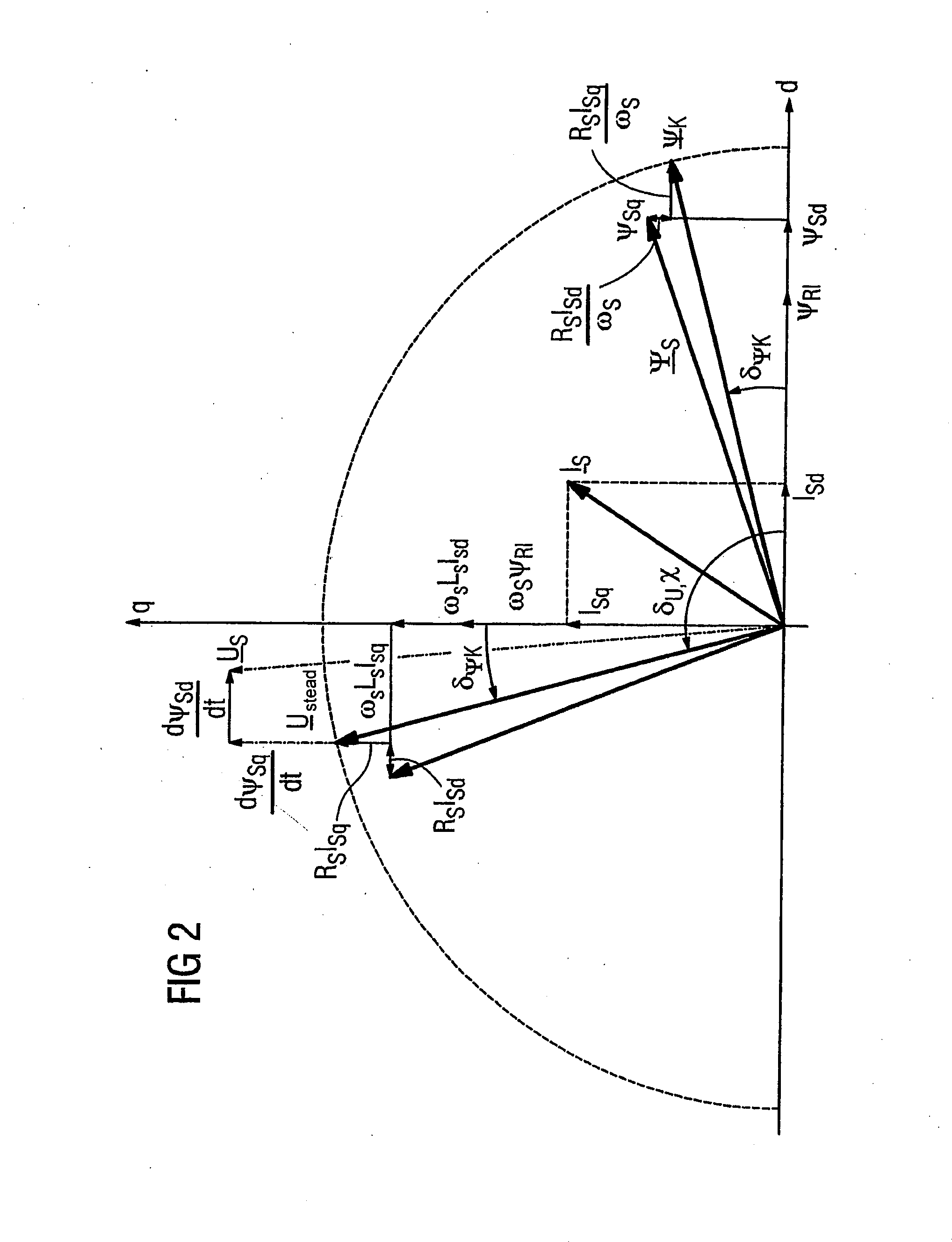

The invention relates to a method for the controlled application of a stator-current target value (ISnom) and a torque target value (Mnom) for a polyphase machine (4) that is supplied by an electronic power converter. According to the invention: current components (ISdnom, ISqnom) in a co-ordinate system (d, q) with a fixed rotor flux or rotating magnetic pole are calculated in accordance with a torque target value and in asynchronous machines in accordance with a rotor-flux target value (ΨRnom), a calculated rotor-flux actual value (Ψ<SB>R< / SB>) or a rotating magnetic-pole flux; a stator-circuit frequency (ω<SB>S< / SB>) is determined; a terminal-flux target value (ΨKnom) is calculated in accordance with the values (ISnom, ISqnom, Ψ<SB>R< / SB>, ω<SB>S< / SB>) by means of the machine parameters (L, R<SB>S< / SB>), said terminal-flux target value being subsequently projected onto a flux-course curve, selected from stored, off-line optimised flux-course curves. This permits the state of the stator current (I<SB>S< / SB>) to be regulated in relation to the rotor flux (Ψ<SB>R< / SB>) or rotating magnetic-pole flux by means of momentary values, facilitating a stationary and dynamic precise control of motor currents (I1,I2,I3) and thus the torques (M) of a polyphase machine (4).

Owner:SIEMENS AG

Position-sensor-free permasyn motor direct driving device and driving method

InactiveCN101814882ARealize vector control modeGood handlingAC motor controlVector control systemsPermanent magnet synchronous motorPower grid

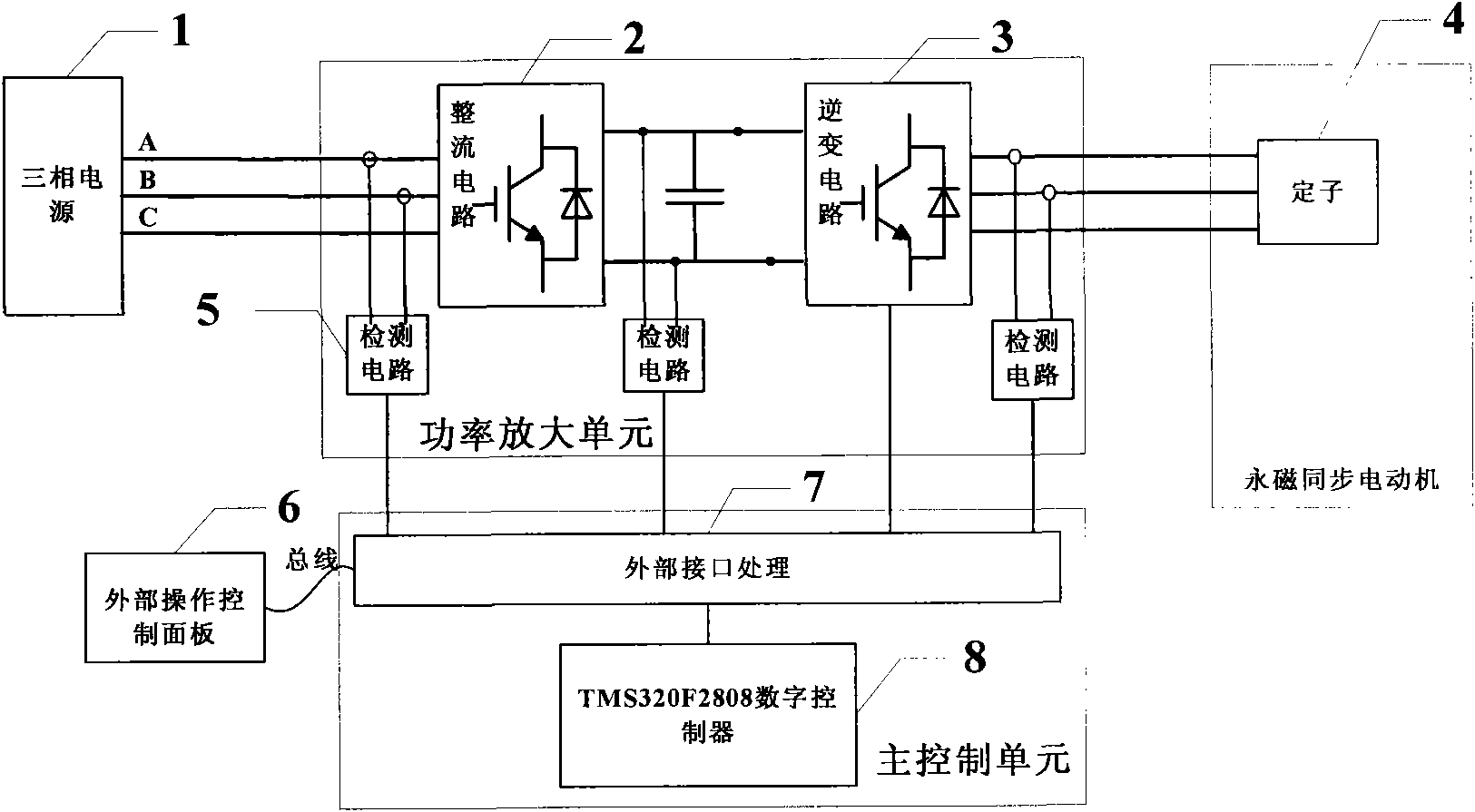

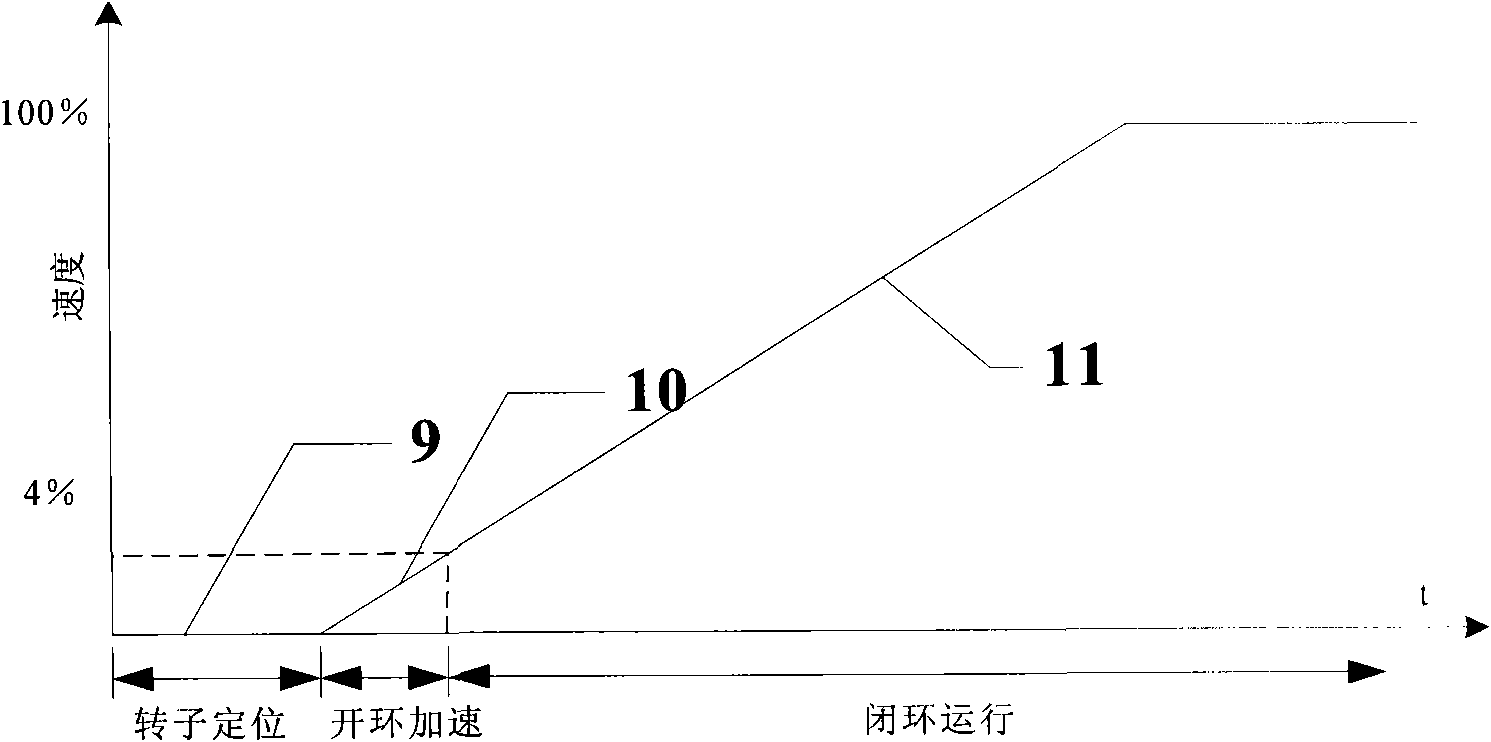

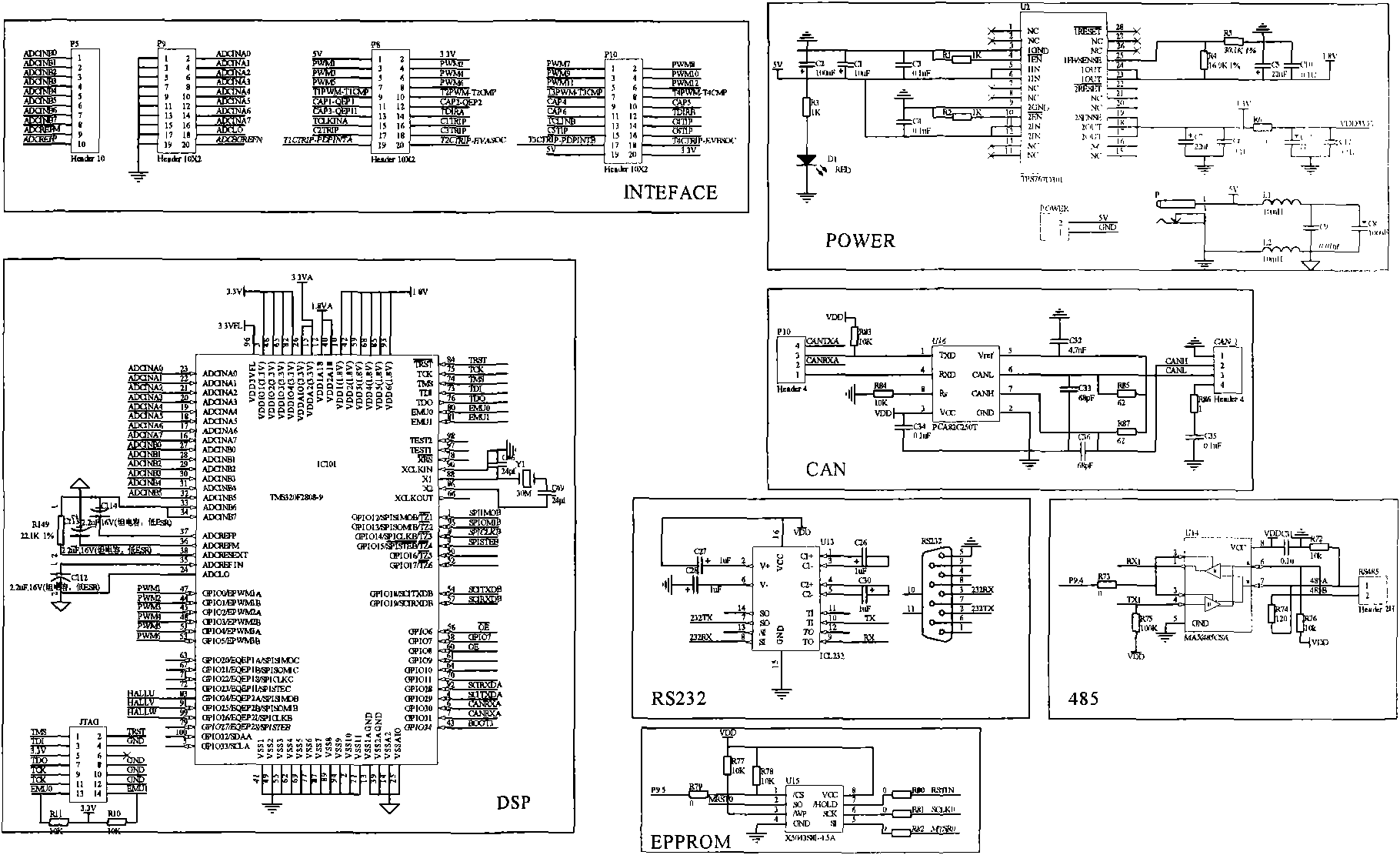

The invention provides a position-sensor-free permasyn motor direct driving device and a driving method. The position-sensor-free permasyn motor direct driving device mainly consists of a power amplification unit, a main control unit, an operation control unit and a permasyn motor, wherein the power amplification unit consists of a controllable rectifier circuit, an inverter circuit and a detection circuit, the main control unit consists of an interface processing circuit and a digital controller, the operation control unit is mainly realized through an external operation control panel, and the permasyn motor comprises a motor stator and a rotor. The invention replaces the technical scheme of an asynchronous motor and a speed reducer, adopts the permasyn motor, and can improve the device efficiency. Through the adoption of the technical scheme without a position sensor, the invention can improve the operation stability and the environment adaptability, add the input power factor correction and wave filtering links, reduce the interference on the electric network and the wire inlet loss, and reach the goal of green and energy saving effect of the device.

Owner:HARBIN ENG UNIV

Printed alternating-current motor

ActiveCN106374643AReduce volumeLight in massMagnetic circuit rotating partsSynchronous machine detailsPermanent magnet synchronous machineEngineering

Owner:CHINA UNIV OF MINING & TECH

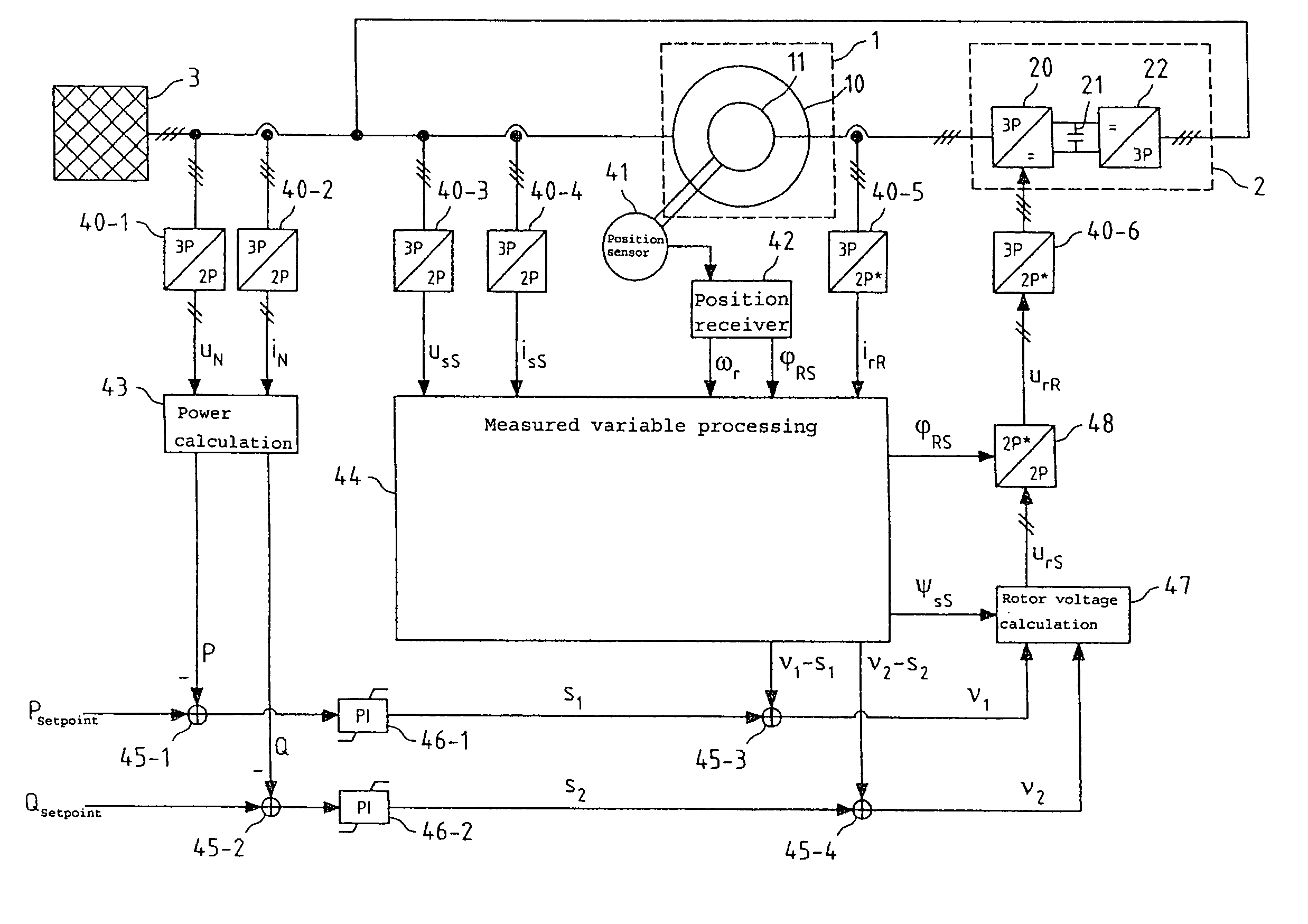

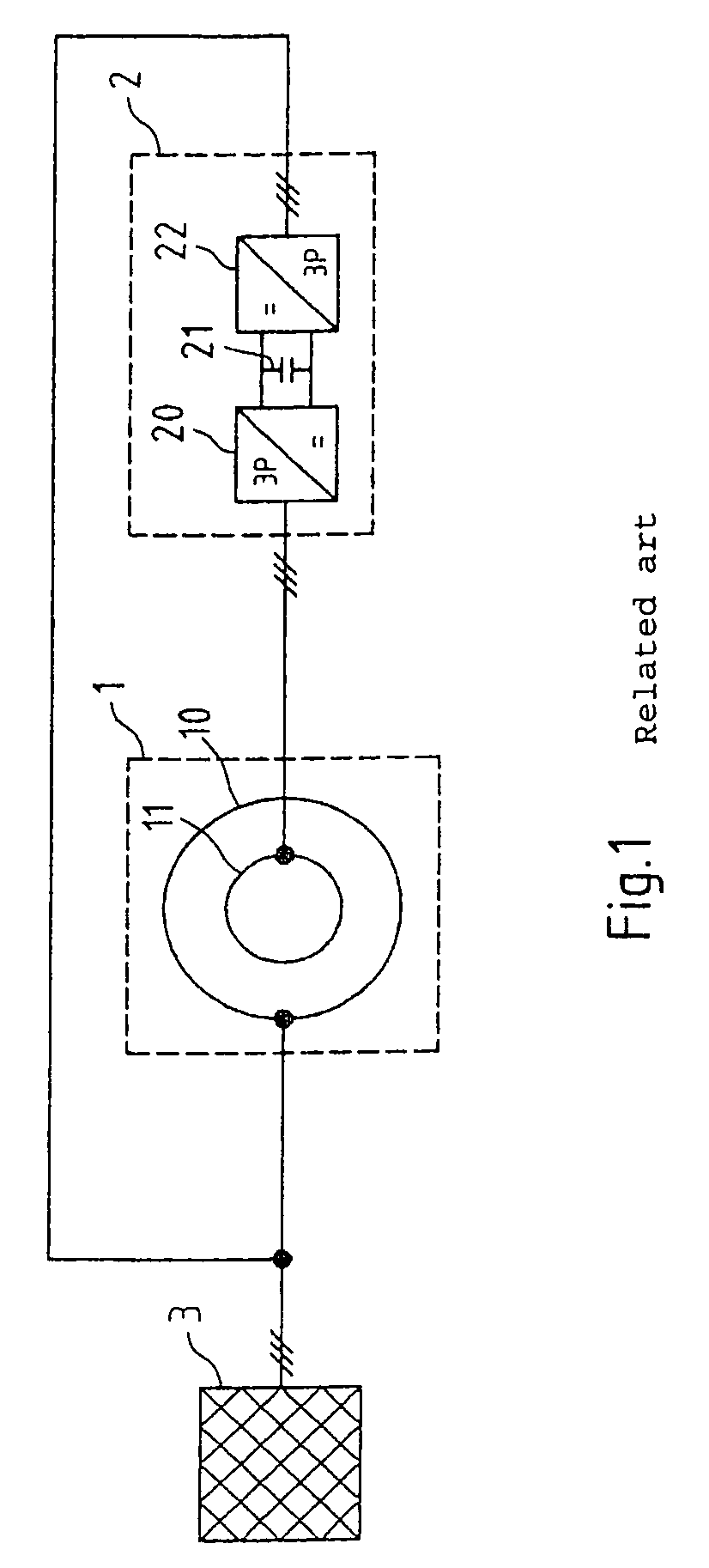

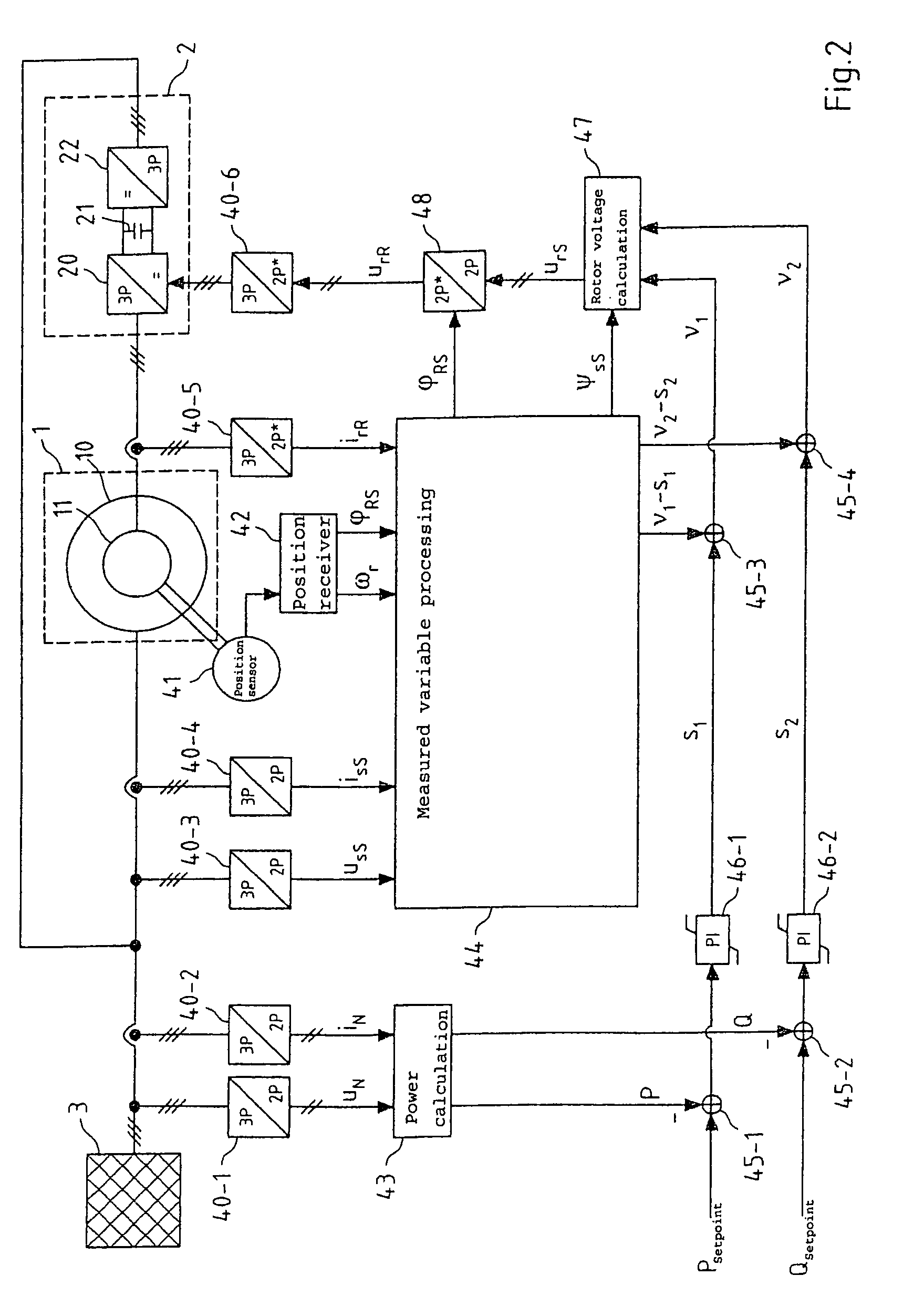

Power control of an induction machine

ActiveUS20070052394A1Stable of active powerSimple simultaneously stable regulationGenerator control circuitsIgnition automatic controlTemporal changeElectric machine

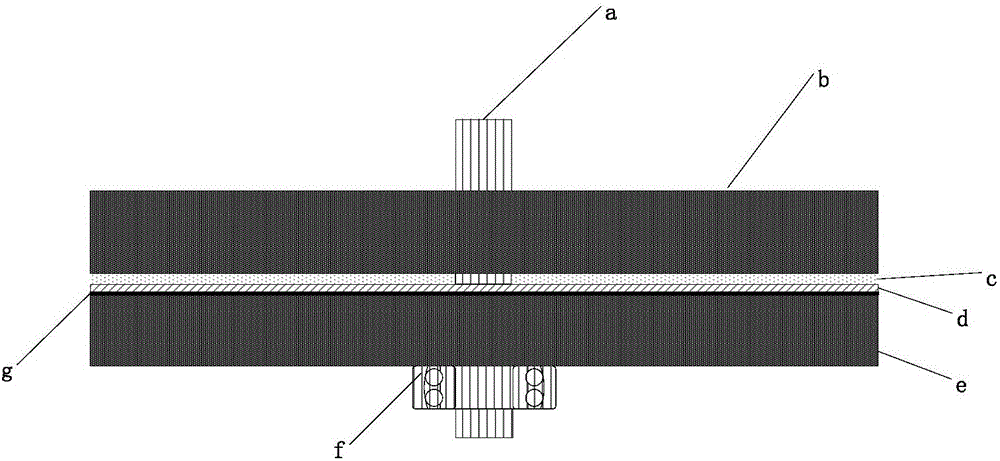

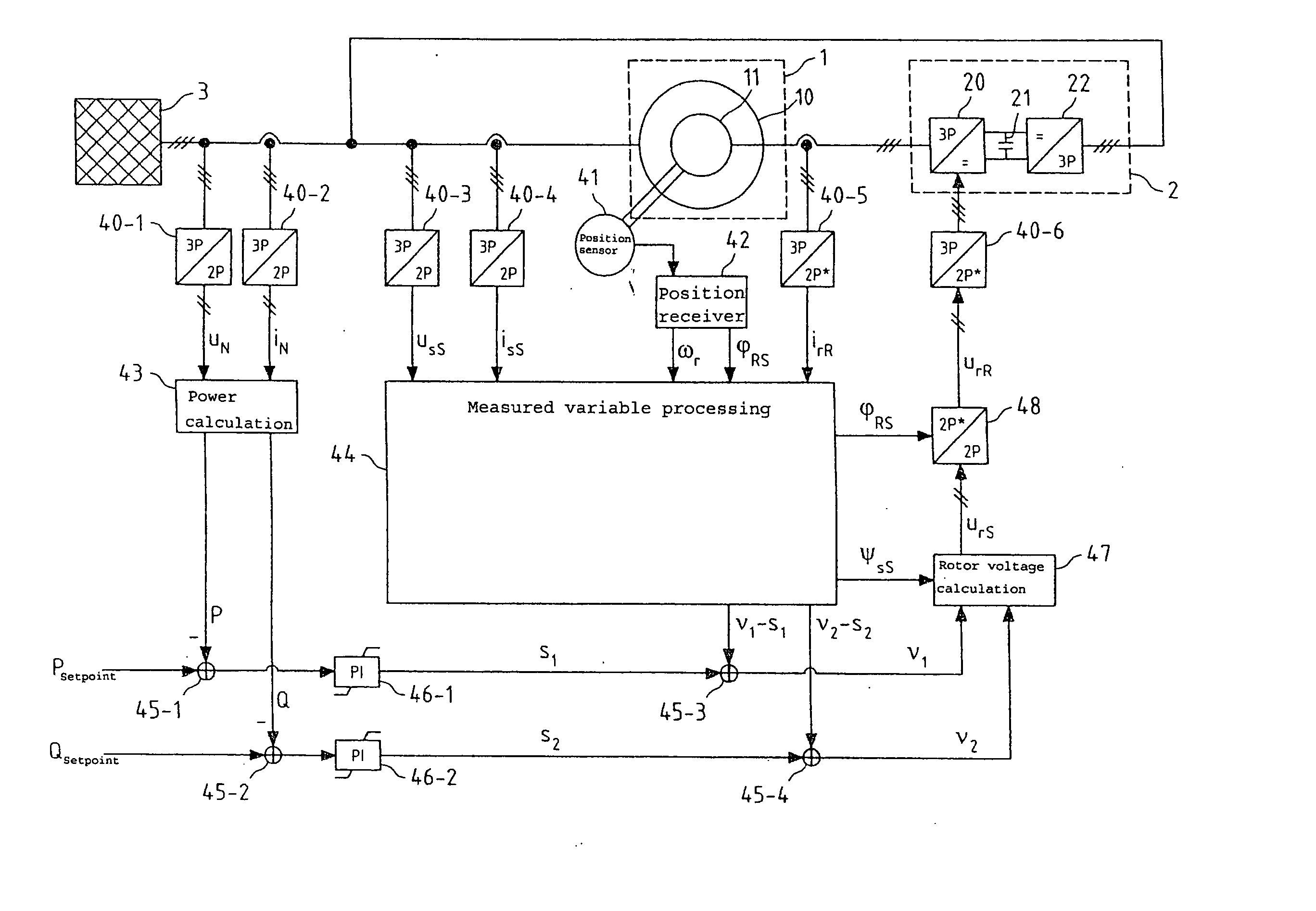

Regulation of the active and reactive power output or received by a induction machine (1) in a coordinate system fixed on the winding, wherein a first regulator output variable is generated using a first regulator (46-1) as a function of a setpoint variable deviation of the active power and a second regulator output variable is generated using a second regulator (46-2) as a function of a setpoint variable deviation of the reactive power, feedback variables are charged on each of the first and second regulator output variables, which are functions of at least one chronologically changing system variable of the induction machine, and a voltage or a current of the induction machine is determined as a manipulated variable without further regulation at least from the first and second regulator output variables charged with the feedback variables. The feedback variables may linearize the regulation path and then allow restriction to only two simple regulators, e.g., two PI regulators. The regulation may be used in double-fed asynchronous machines.

Owner:CONVERTERTEC DEUT GMBH

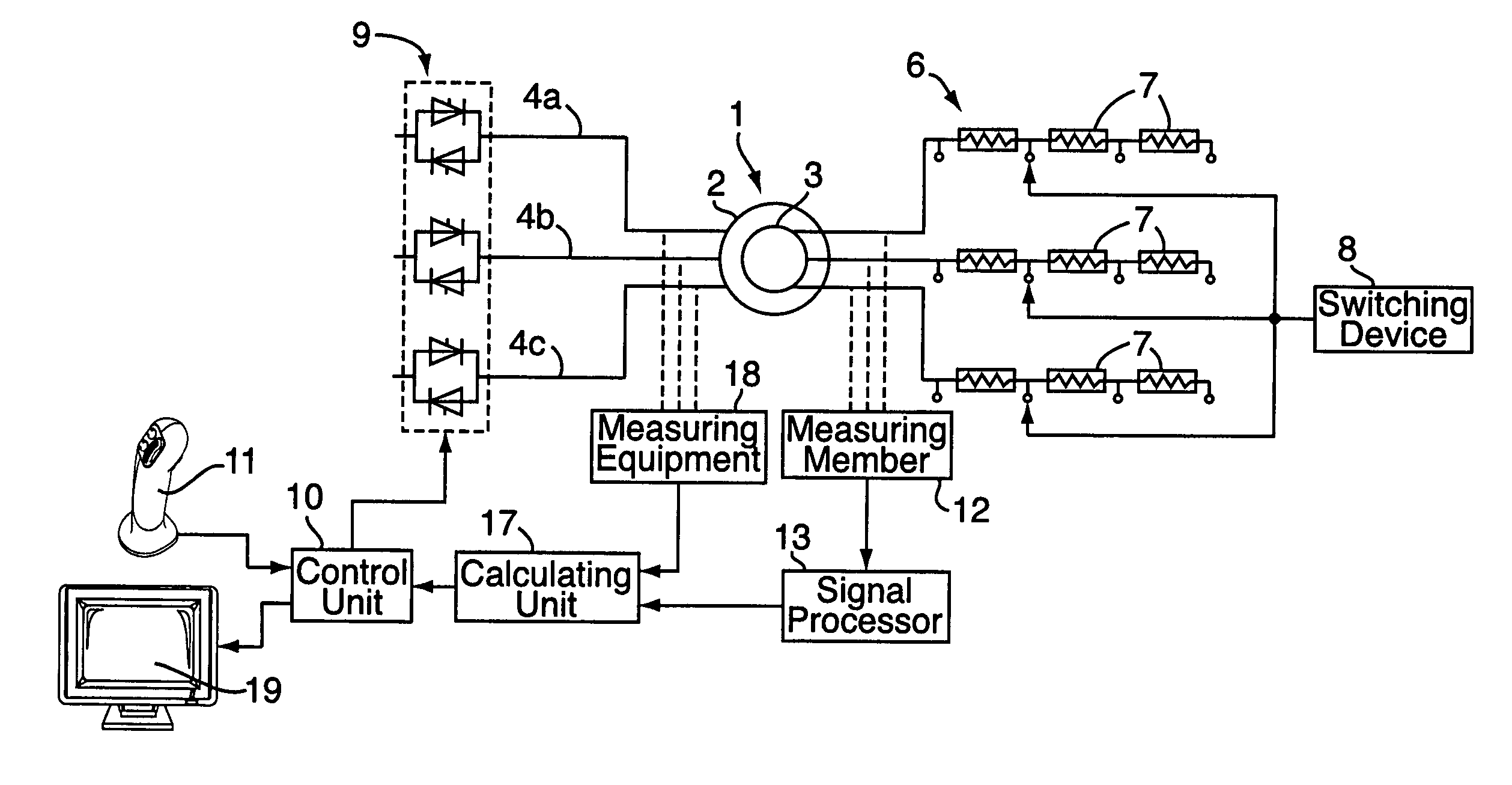

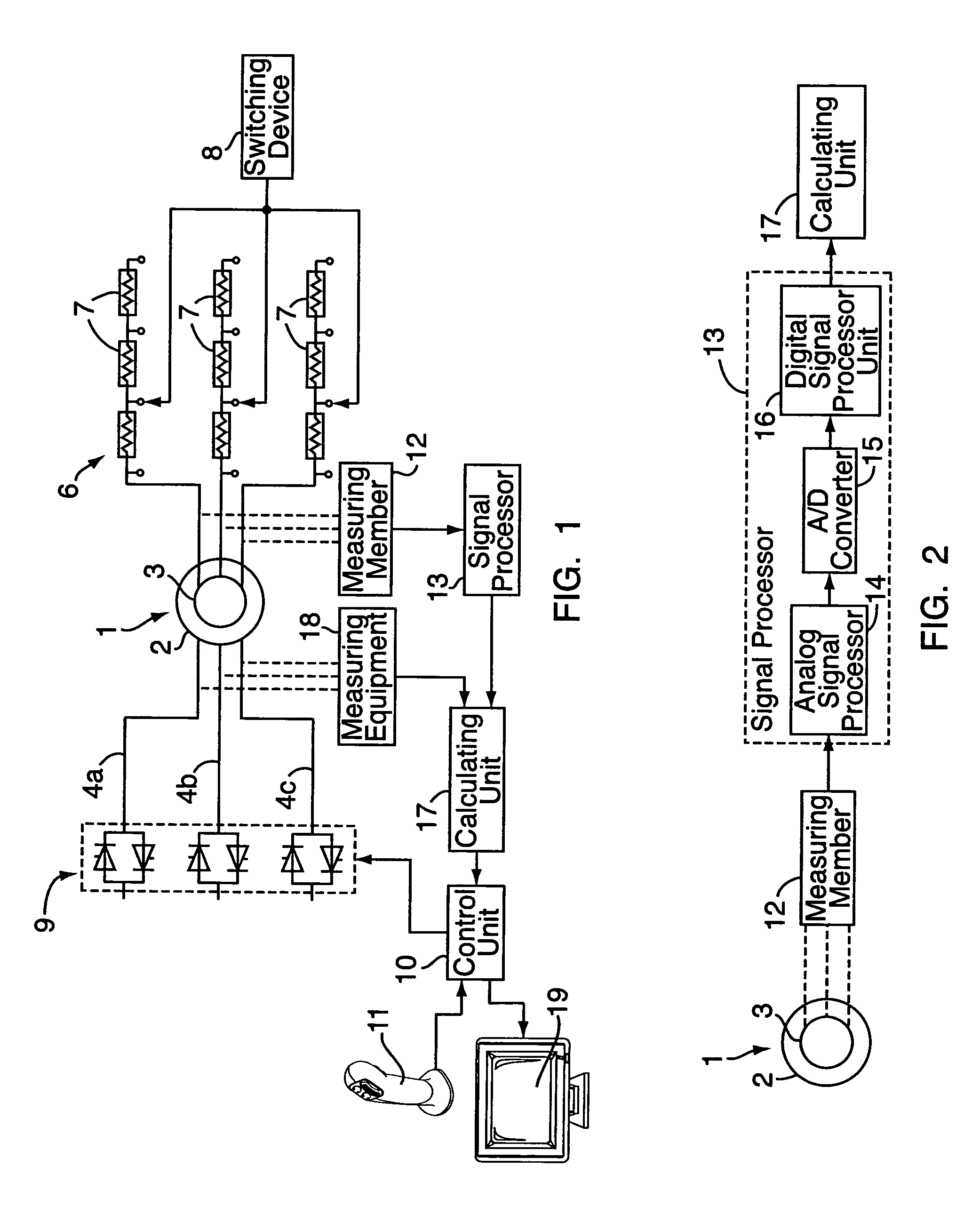

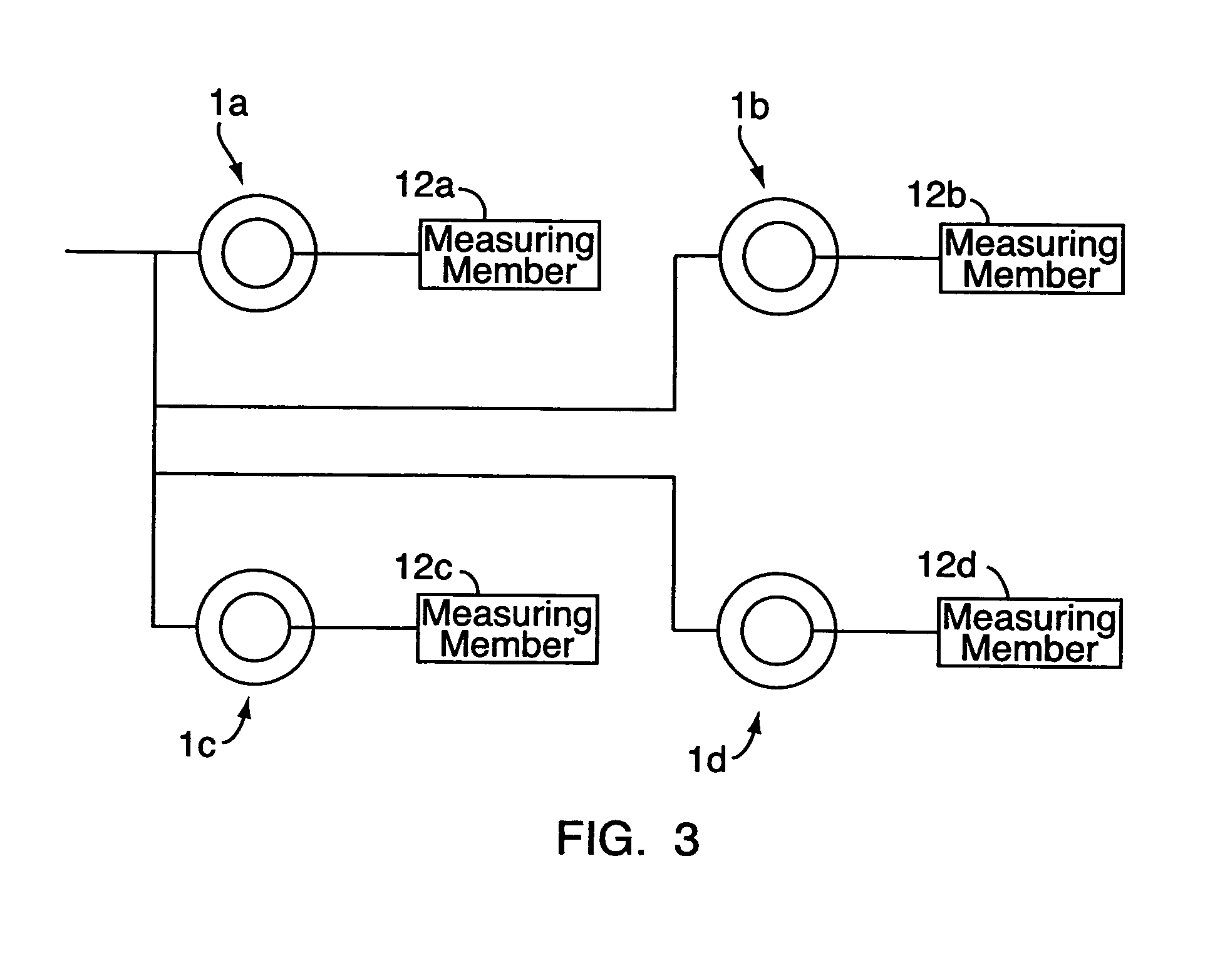

Device and a method for estimating the speed of a slip ring asynchronous machine

InactiveUS6995539B1Efficient fault detectionImprove accuracySingle-phase induction motor startersElectronic commutation motor controlEngineeringThree-phase

The invention relates to a device and a method for estimating the speed of a slip ring asynchronous machine. The asynchronous machine includes a stator having a stator winding, arranged to be fed with three-phase voltage and current in order to generate a varying magnetic flux, and a rotor having a rotor winding in which the magnetic flux is arranged to induce a voltage to create an electromagnetic torque. The device includes a measuring member arranged to measure the value of the voltage in the rotor winding during at least one time period and a calculating unit, which is arranged, using the above measured voltage, to calculate a value of the rotor speed.

Owner:ABB (SCHWEIZ) AG

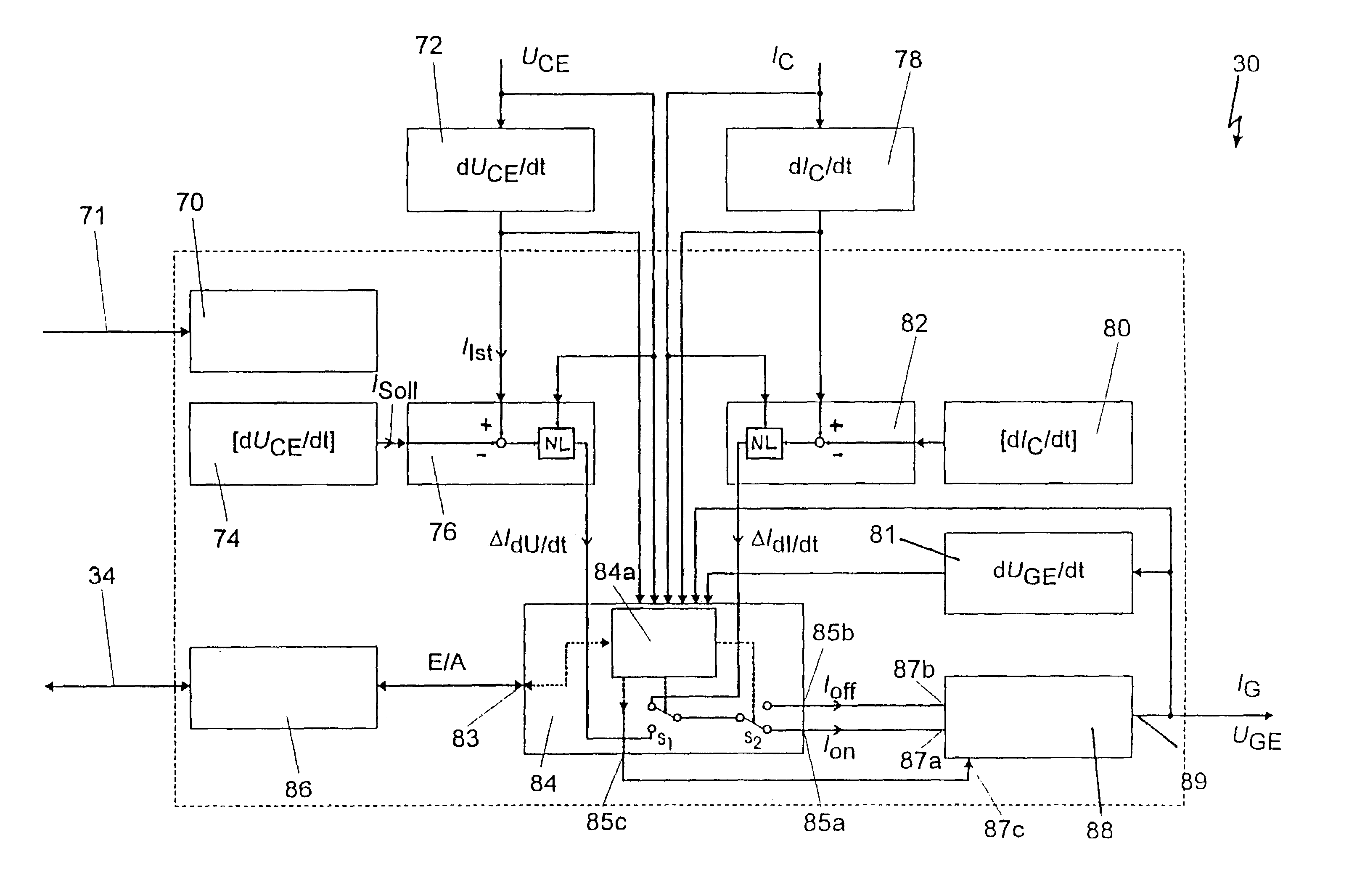

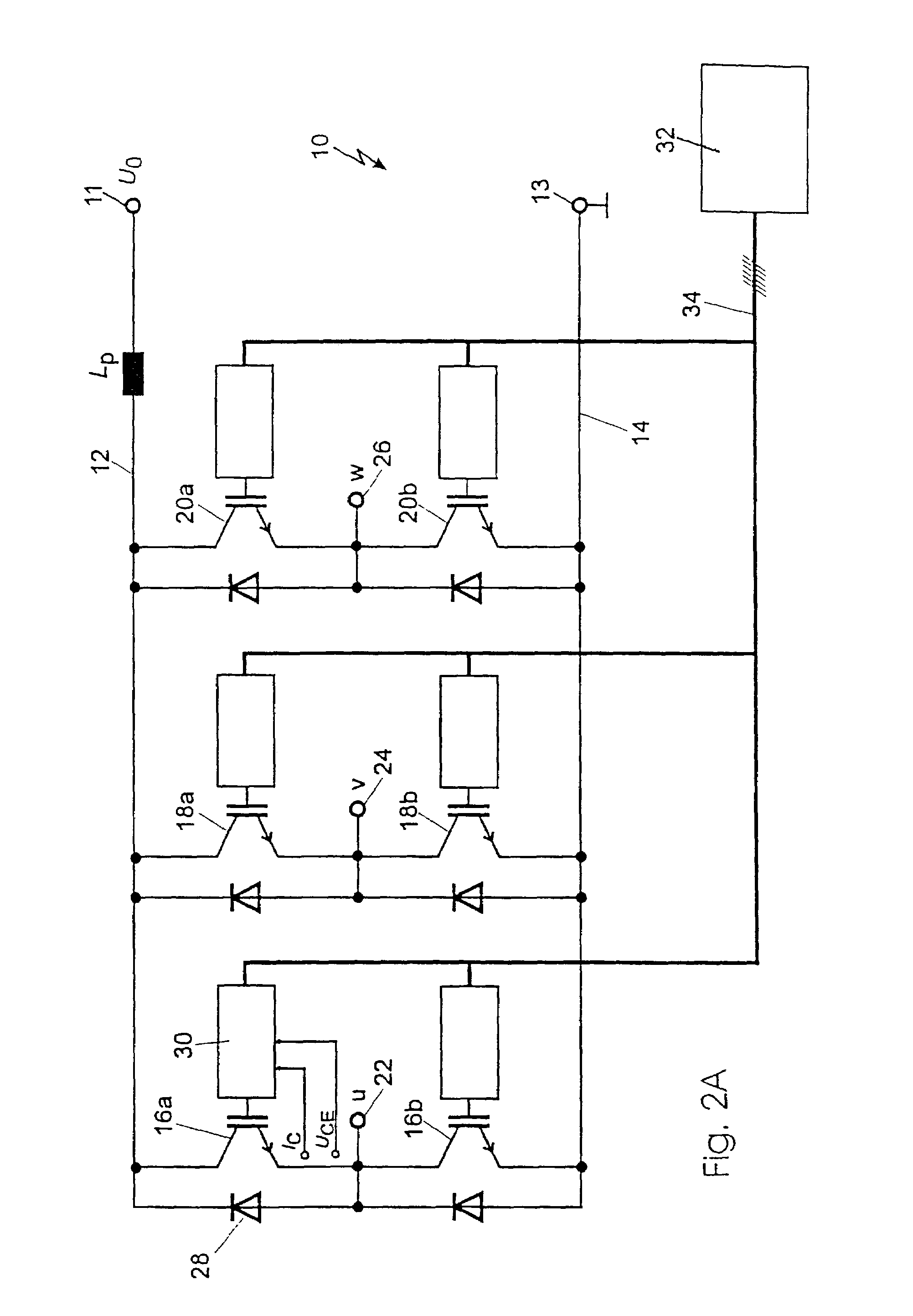

Method and device for switching on and off power semiconductors, especially for the torque-variable operation of an asynchronous machine, for operating an ignition system for spark ignition engines, and switched-mode power supply

InactiveUS7046051B2Improve interferenceTransistorElectronic switchingTime functionPower factor control

A method and device for switching power semi-conductors on and off, especially for IGBTs and MOS-FETs with inductive loads, and how they would be employed with torque-variable asynchronous machines, in ignition systems for spark ignition engines, in switch mode power supplies and power factor controllers. During a switching operation of the power semiconductor, a voltage across the semiconductor and the current through the semiconductor are measured, a time function of the voltage as well as a time function of the current are controlled, and the control of the voltage time function and the control of the current time function are effected essentially one after the other.

Owner:RUBITEC GES FUR INNOVATION & TECH DER RUHR UNIV BOCHUM

Permanent magnet synchronous motor

ActiveCN101005219AImproved axial ventilationIncrease the lengthMagnetic circuit rotating partsManufacturing stator/rotor bodiesPermanent magnet synchronous motorRare earth

Following structures are adopted in the electromotor of rare earth permanent magnet: slotted solid pole, extension duplex start-up cage, pole core with large polar arc, large even air gap or heteropic air gap, small rectangle block of permanent magnet embedded to slot. Comparing with conventional permanent magnet motor of laminated pole, the basic series of permanent magnet synchronous motor possesses advantages: obviously raised starting torque 2.2-3.7, and asynchronous motor as 1.8-2.0; raised capability rank, for example it is possible to use 22kW permanent magnet motor to replace asynchronous motor in 30kWY series so as to obtain energy saving effect; start up current 5-7 times of the disclosed motor is smaller than start up current of asynchronous motor; moreover, shorter start up current, and no severe oscillation phenomenon. The basic series also overcomes difficult problem of demagnetization of neodymium - iron - boron permanent magnet electromotor.

Owner:北京佐腾达制冷空调设备有限公司 +1

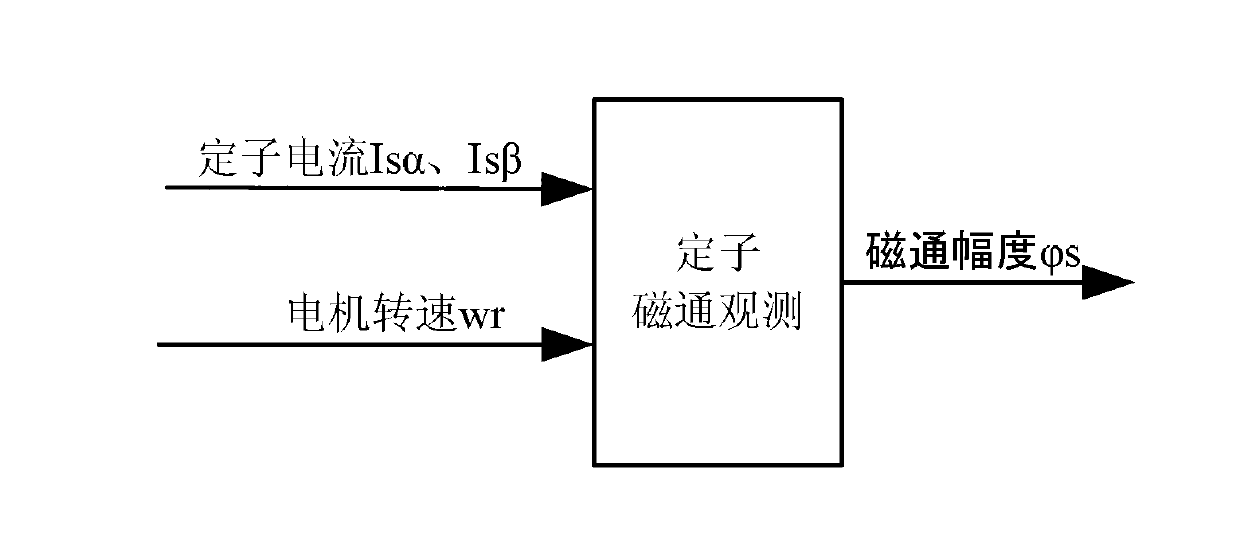

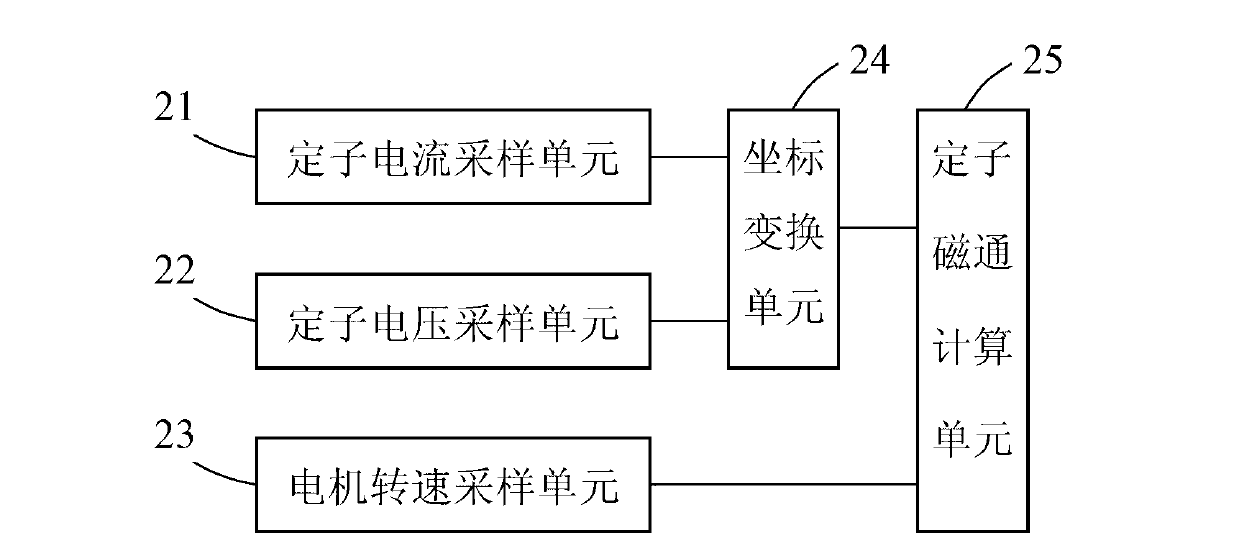

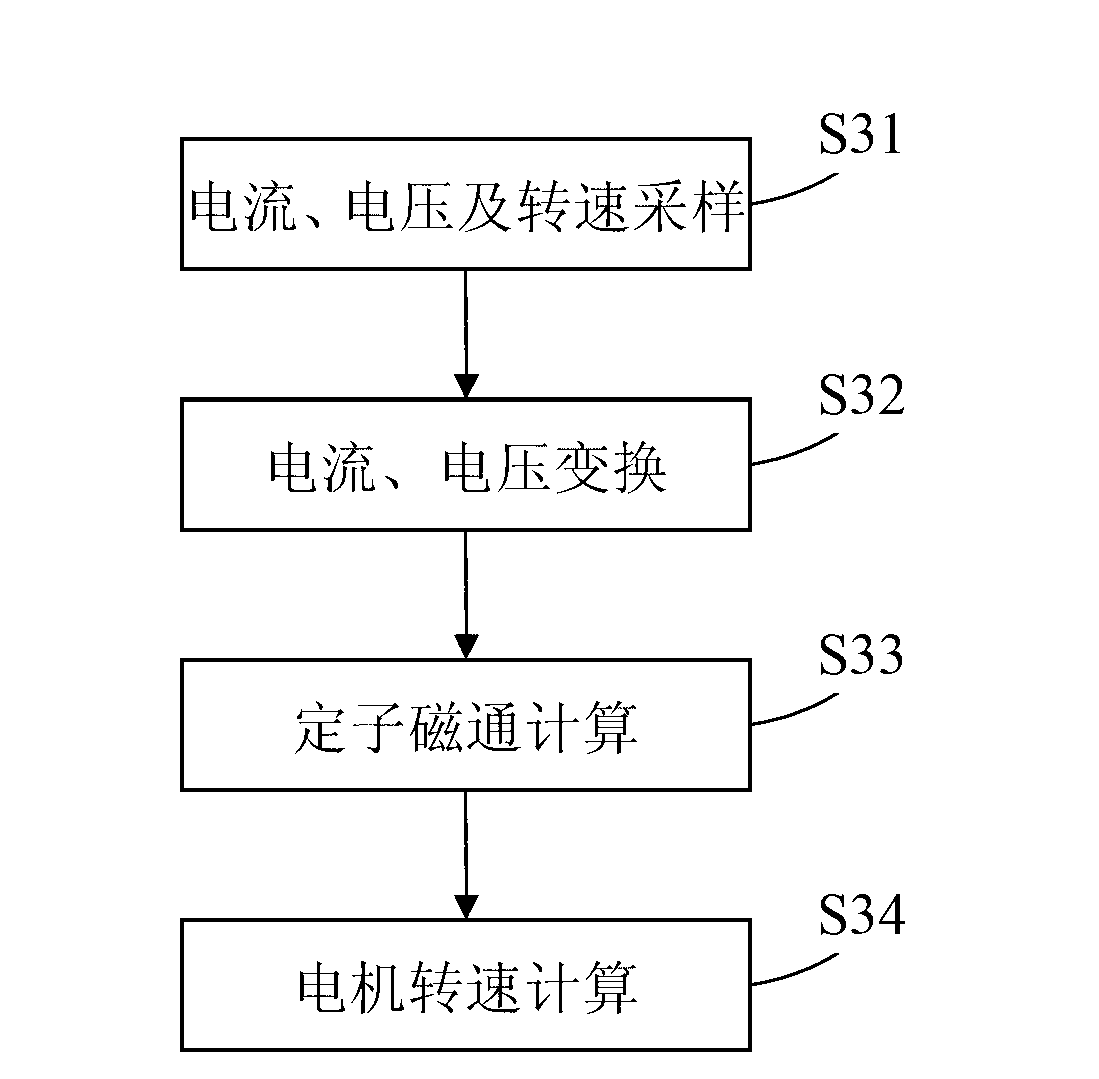

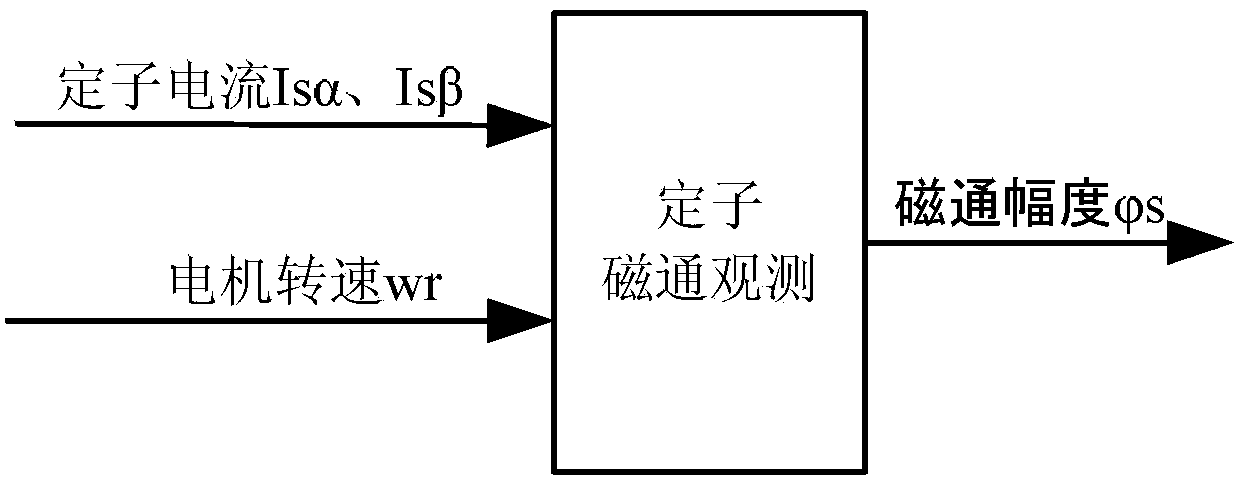

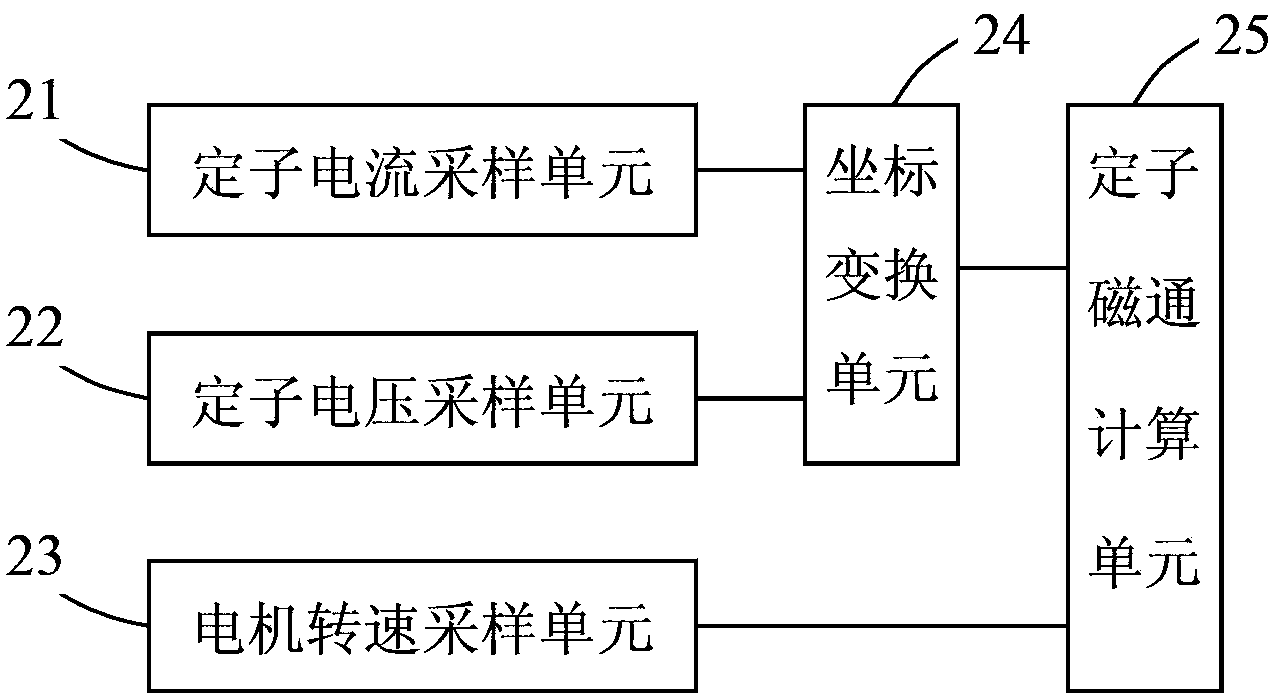

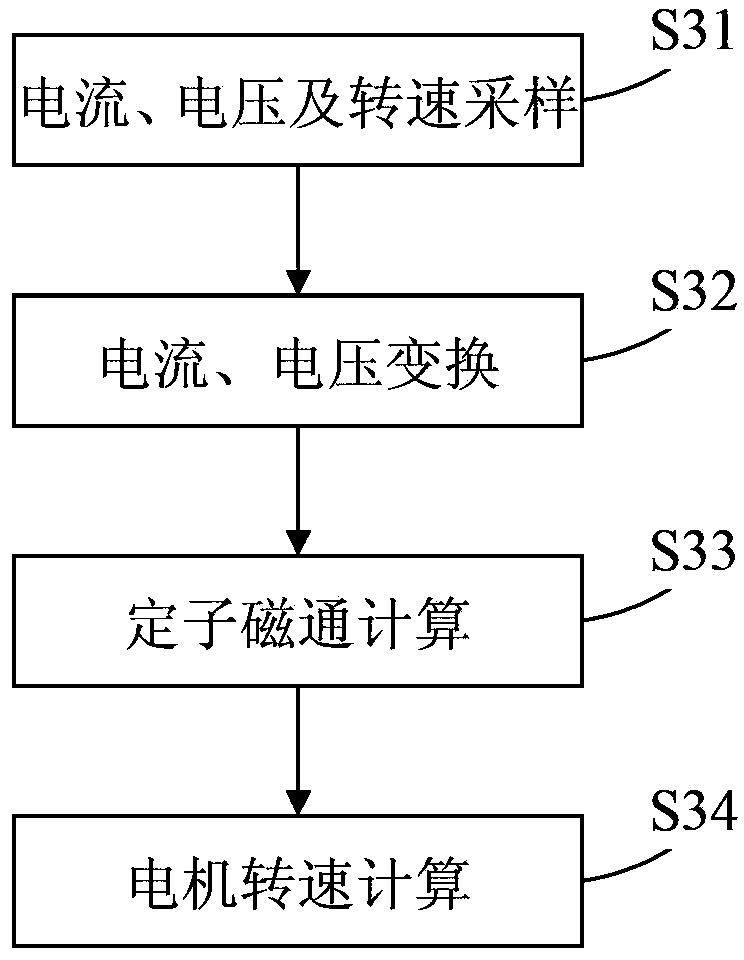

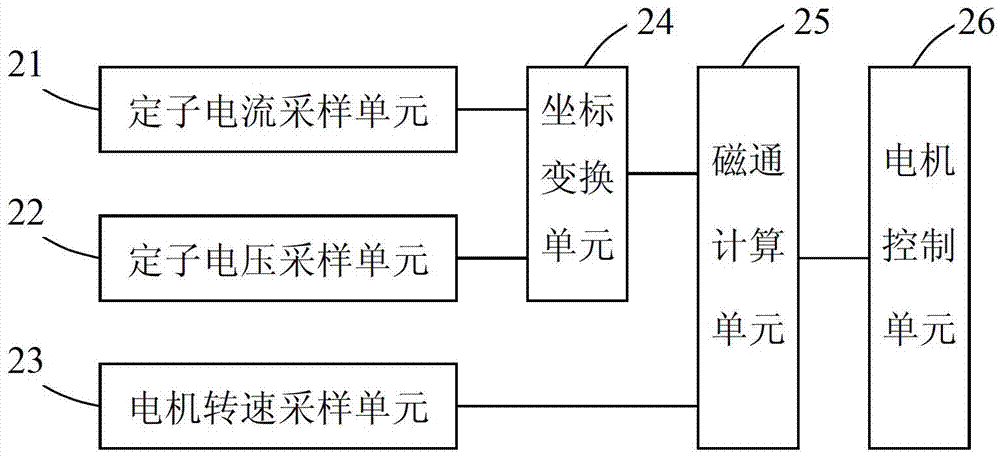

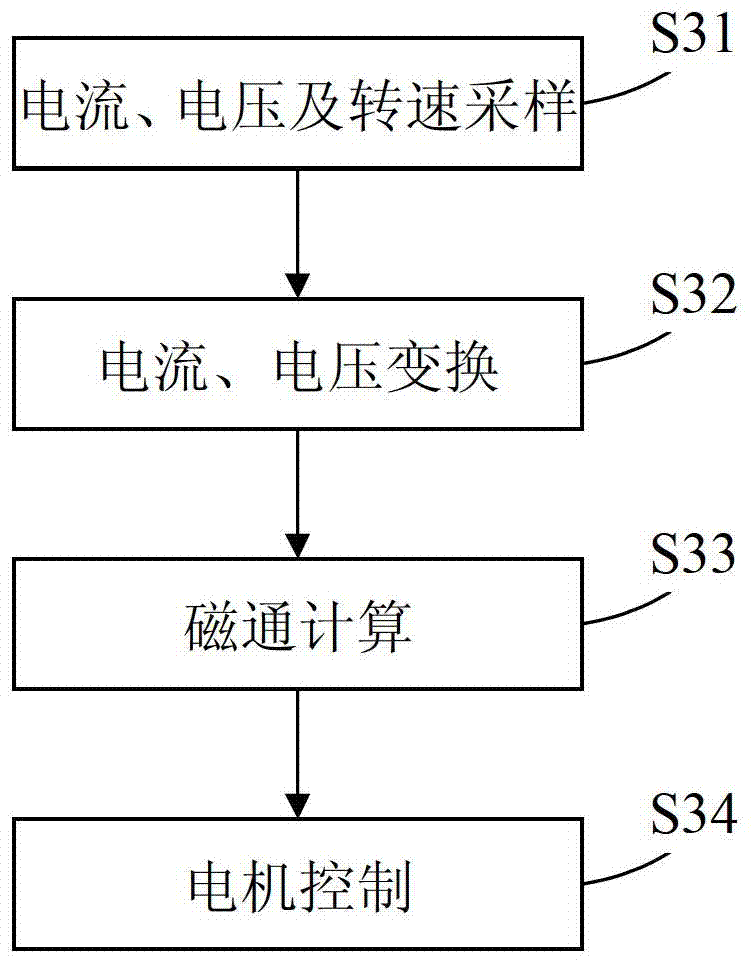

Asynchronous machine stator flux estimation system based on current model and method

ActiveCN102983806ASolve inaccurateGood flux estimation effectElectronic commutation motor controlAC motor controlStator voltageMotor speed

The invention provides an asynchronous machine stator flux estimation system based on a current model and a method. The system comprises a stator current sampling unit, a stator voltage sampling unit, a motor speed sampling unit, a coordinate conversion unit and a stator flux calculating unit, wherein the stator current sampling unit, the stator voltage sampling unit and the motor speed sampling unit are respectively used for sampling stator three-phase current, voltage and motor rotor speed of a three-phase motor; the coordinate conversion unit is used for converting the stator three-phase current and the stator three-phase voltage obtained through sampling into stator current and stator voltage of an axis alpha and an axis beta; and the stator flux calculating unit is used for calculating stator flux amplitude of the motor according to the stator current and the stator voltage of the axis alpha and the axis beta and the motor rotor speed. The invention also provides a corresponding method. The system obtains good stator flux estimation effect by decoupling cross coupling items estimated through stator flux of the axis alpha and the axis beta in a static coordinate system.

Owner:SUZHOU INOVANCE TECH CO LTD

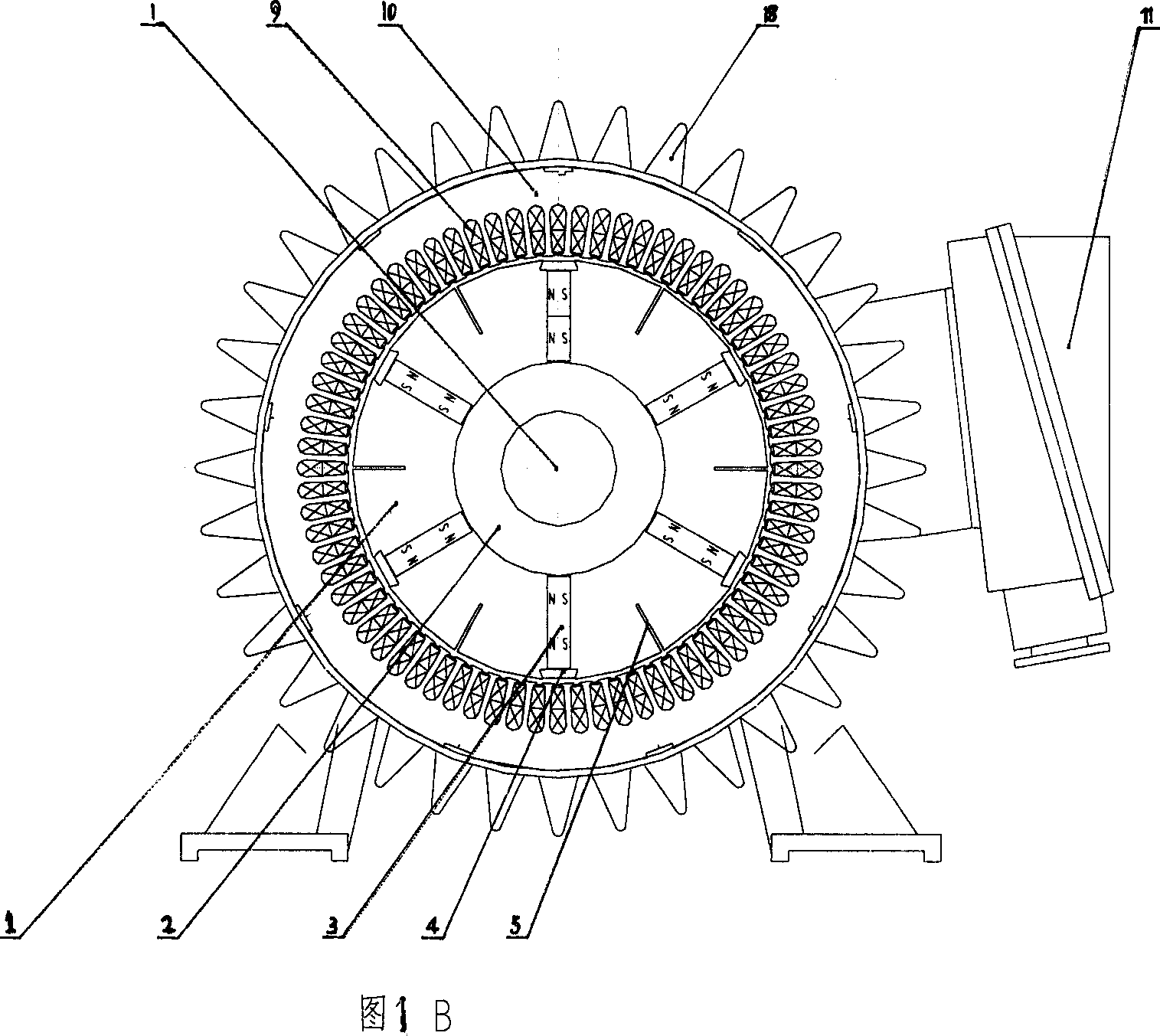

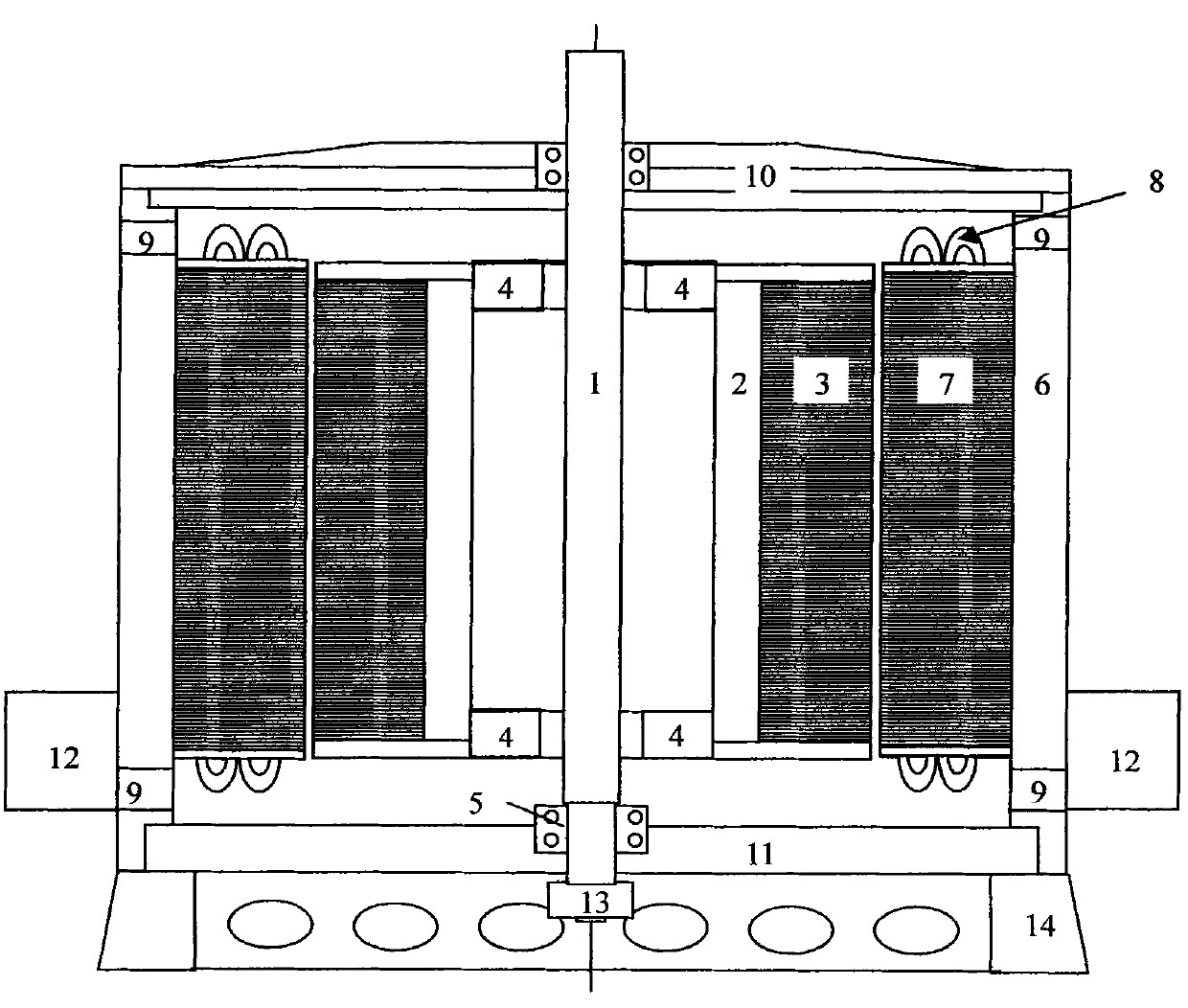

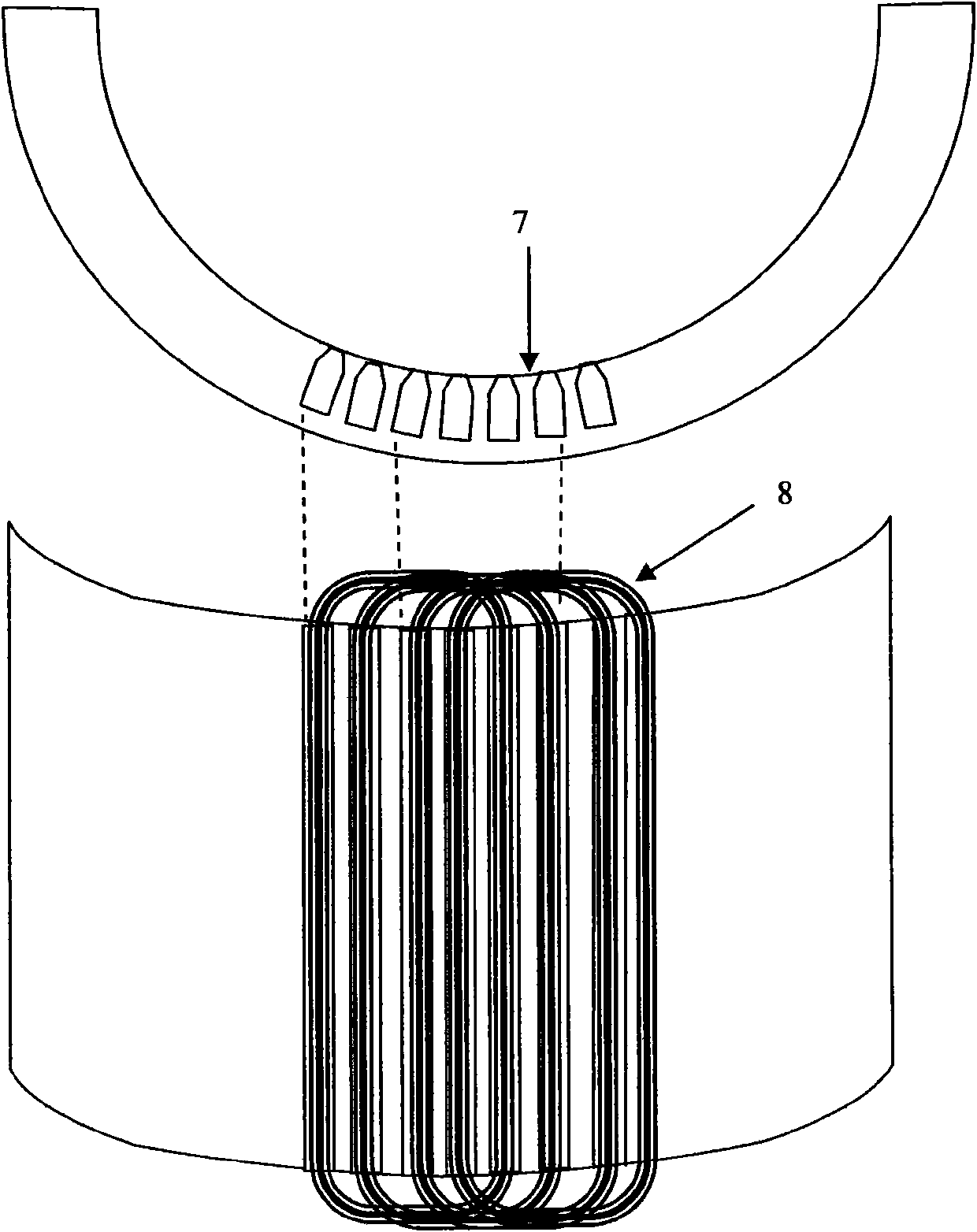

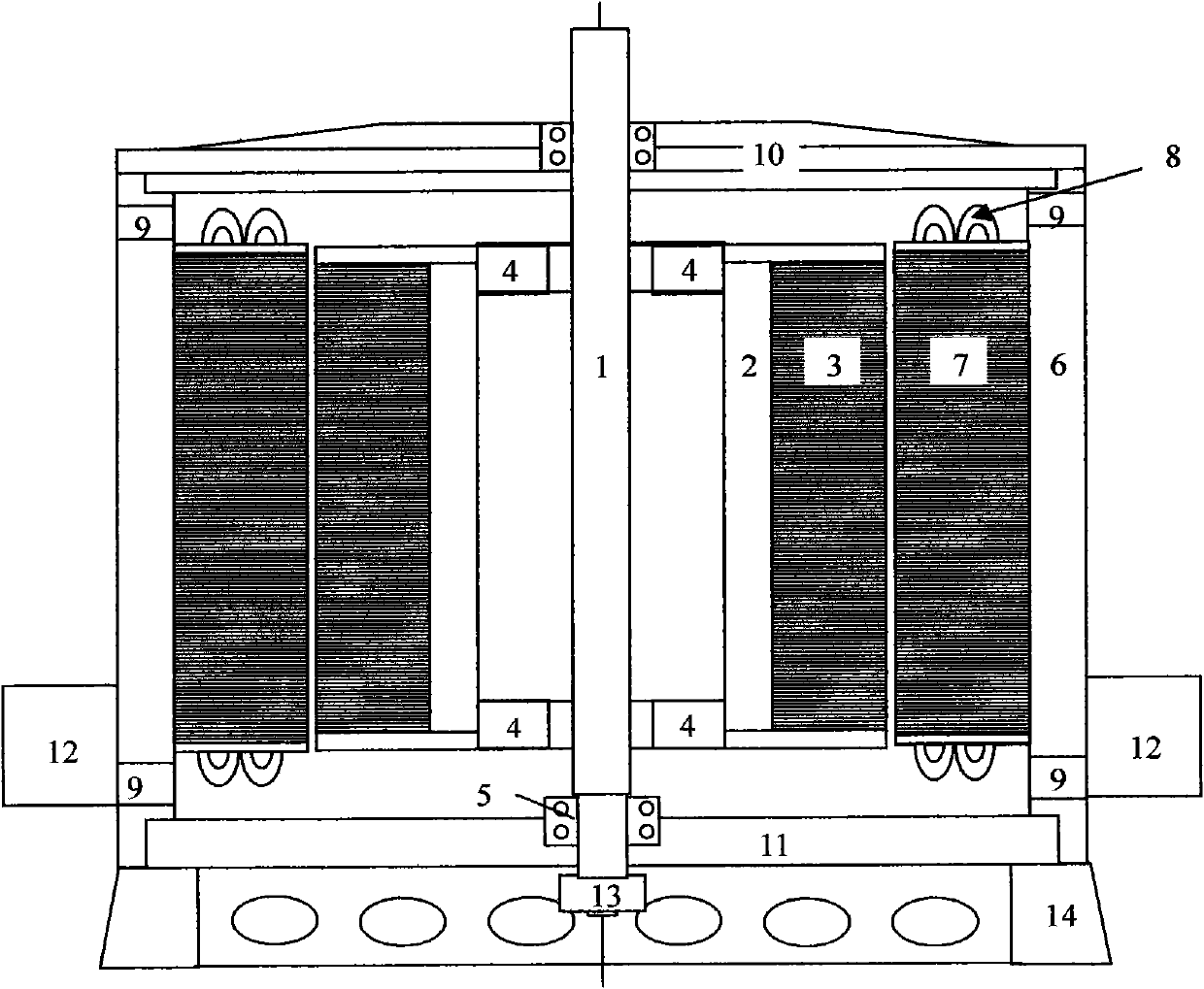

Multi-winding asynchronous change-pole generator

InactiveCN101908807APrevent invasionAvoid corrosionMagnetic circuit rotating partsAsynchronous induction motorsMagnetic polesConductor Coil

The invention discloses a multi-winding asynchronous change-pole generator comprising a rotor, a stator and a radiation cooling device. The energy generated by the rotor is transmitted to the stator through magnetism and is converted into voltage and current by the stator to be transmitted to a grid; an electric brush of the rotor and a slip ring of the generator as well as a rotor inverter of a double-feed generator are not needed, wherein the rotor adopts a mouse cage type structure; a rotor shaft comprises two parts of a crankshaft and a shaft drum which are fixed together; the shaft drum adopts a hollow manner; air holes are arranged at both ends of the shaft drum; the magnetic pole of the rotor is fixed on the shaft drum; the stator is a multi-winding change-pole type stator structure; the mode of connection is a two-winding asynchronous change-pole mode and a multi-winding asynchronous change-pole model containing more than two windings; the number of the pole pairs of the stator is changed by changing the mode of connection of the winding coil; and the radiation cooling device adopts a shaft drummer type rotor cooling radiation mode. The invention is suitable for the characteristic of wind power natural environment and meets the grid requirement.

Owner:李树广

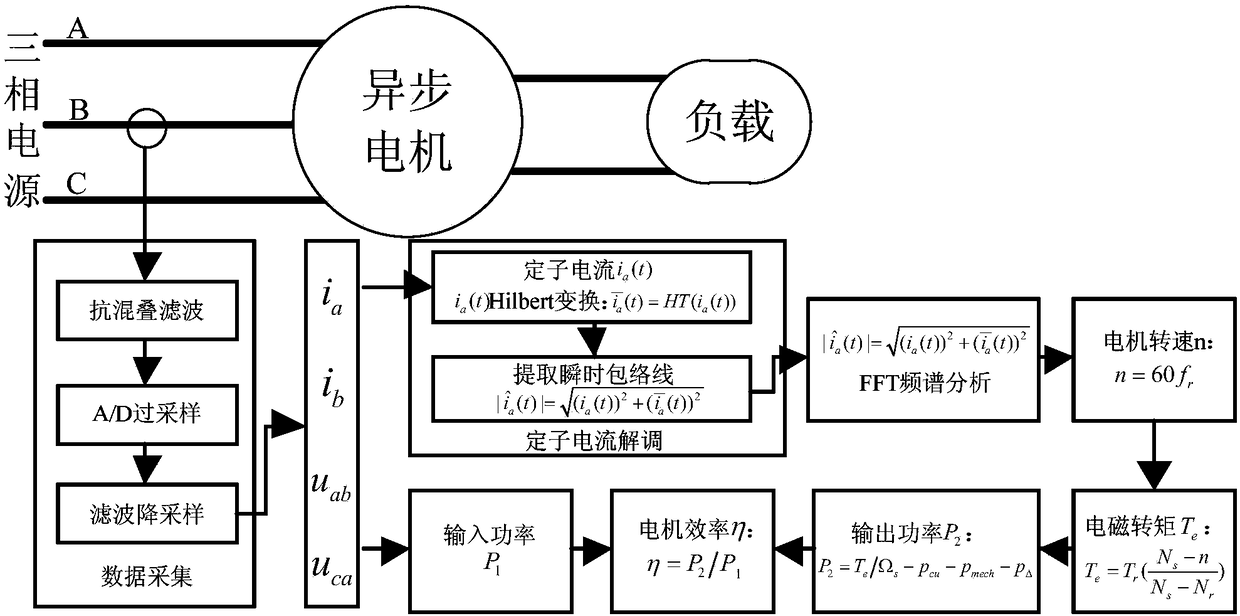

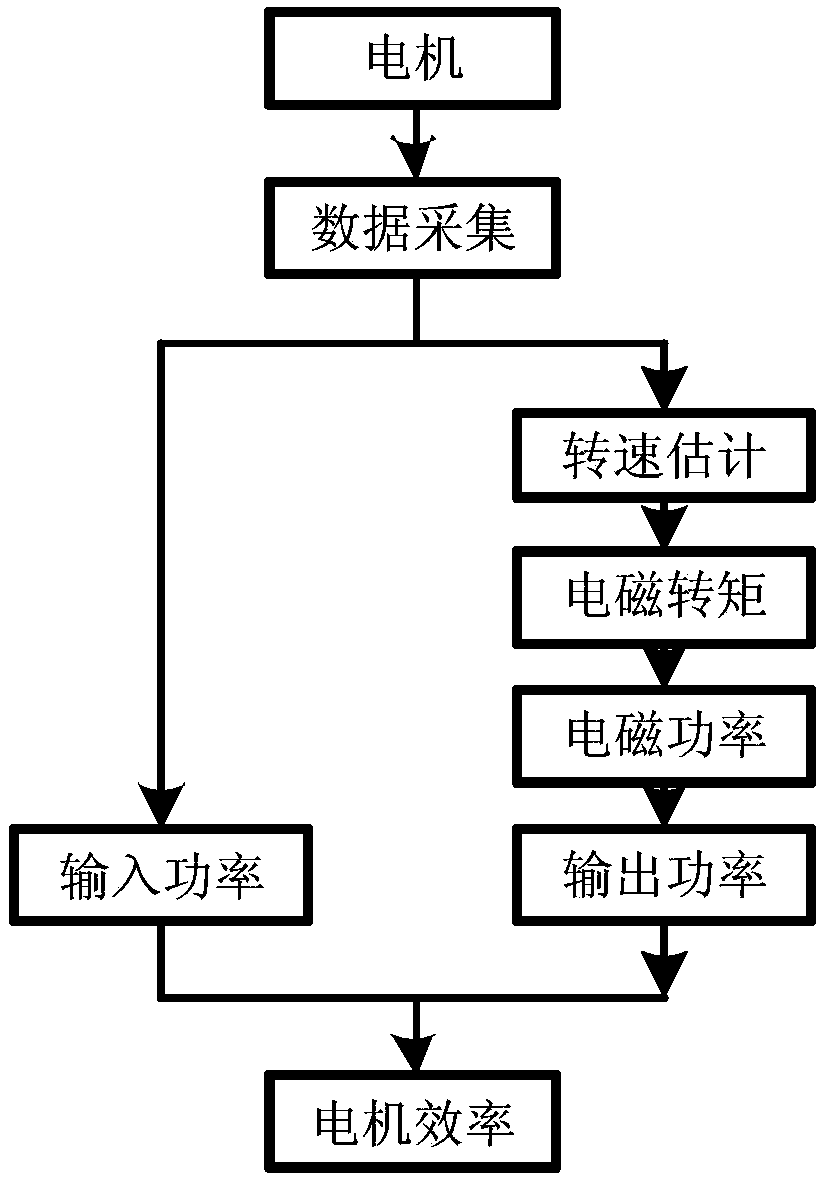

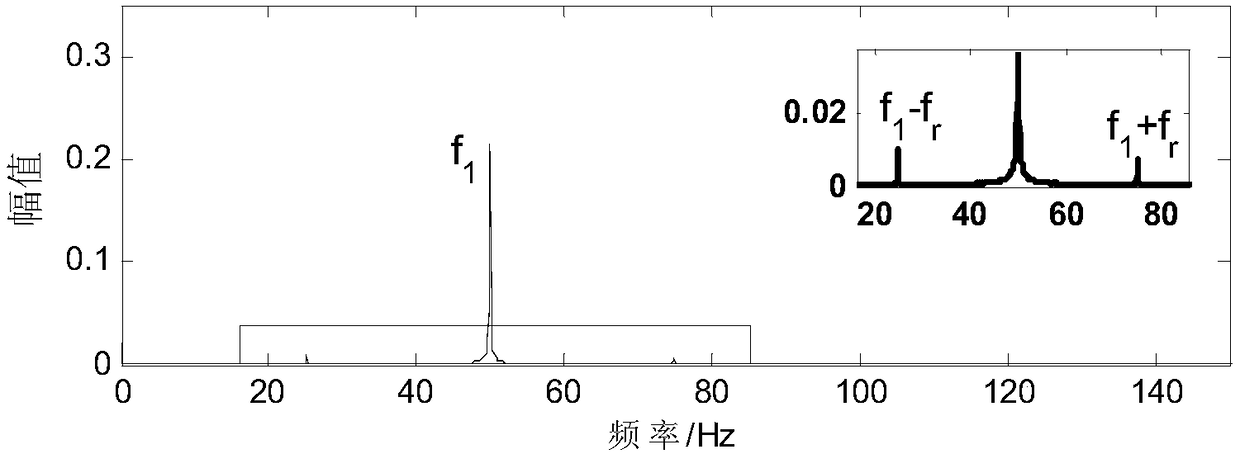

Asynchronous motor energy efficiency estimation method based on online monitoring

InactiveCN108089125AEnables non-intrusive monitoringLow costDynamo-electric machine testingEstimation methodsElectric machine

The invention relates to the asynchronous motor energy efficiency estimation method based on online monitoring; the method comprises the following steps: analyzing fixed eccentric harmonic wave signals gathered from the asynchronous motor stator current and identifying the signals to obtain the rotor rotating speed; secondarily, using the linear portion of the asynchronous motor machinery featuresand the rotating speed to obtain the motor rotor shaft electromagnetic torque; finally, using the electromagnetic torque and a motor synchronization angular velocity to solve the motor output power,thus identifying the motor operation energy efficiency. The method analyzes the fixed eccentric harmonic waves in the stator current so as to estimate the motor rotating speed, thus preventing photoelectric encoder installation, and realizing speedtransmitter-free rotating speed estimation; the method obtains the motor rotor shaft electromagnetic torque according to the linear portion of the asynchronous motor machinery features and the rotating speed, and solves the problems that the motor rotor shaft electromagnetic torque cannot be directly measured; the method is simple in operation, can reduce the system cost, and can fast obtain the motor operation energy efficiency.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

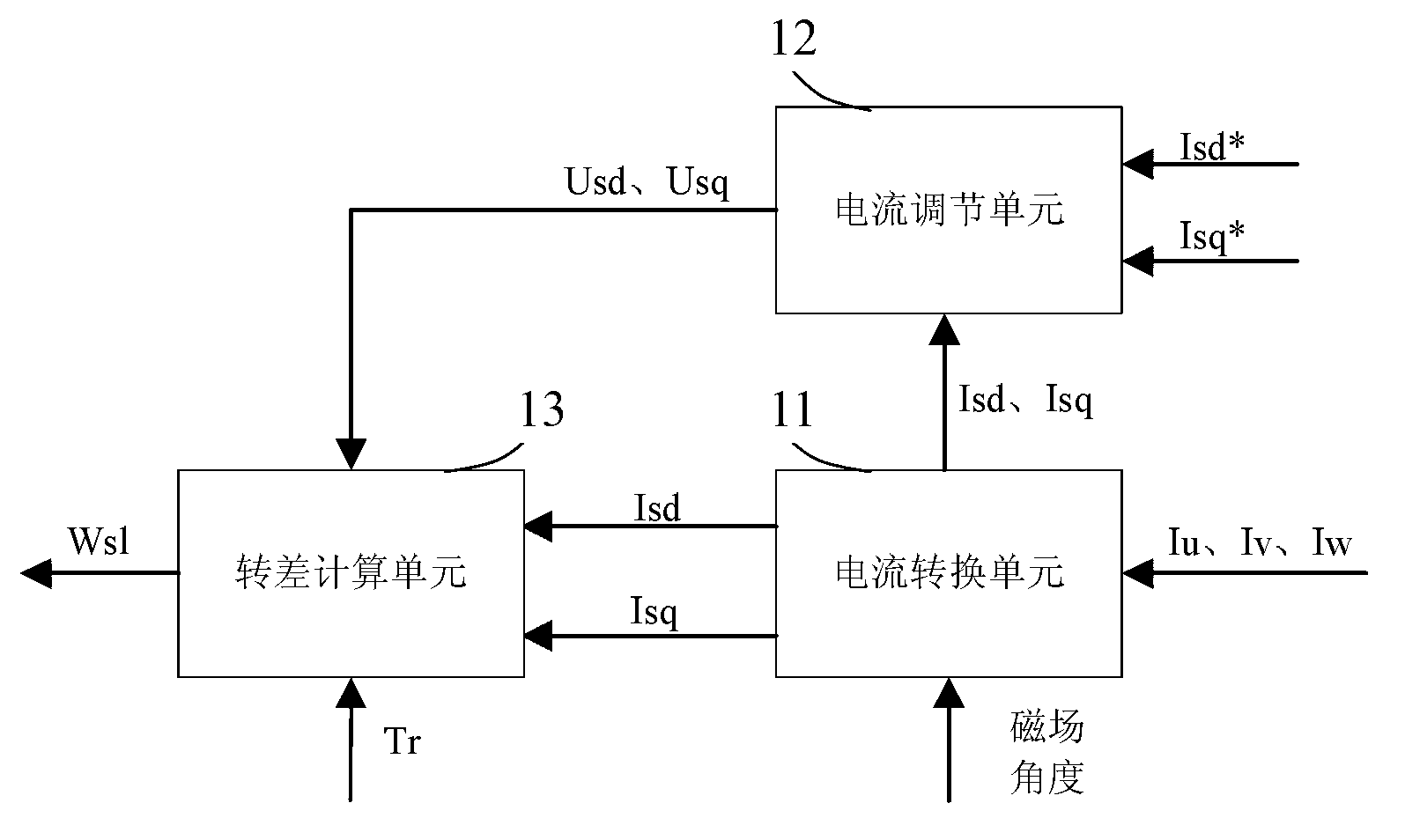

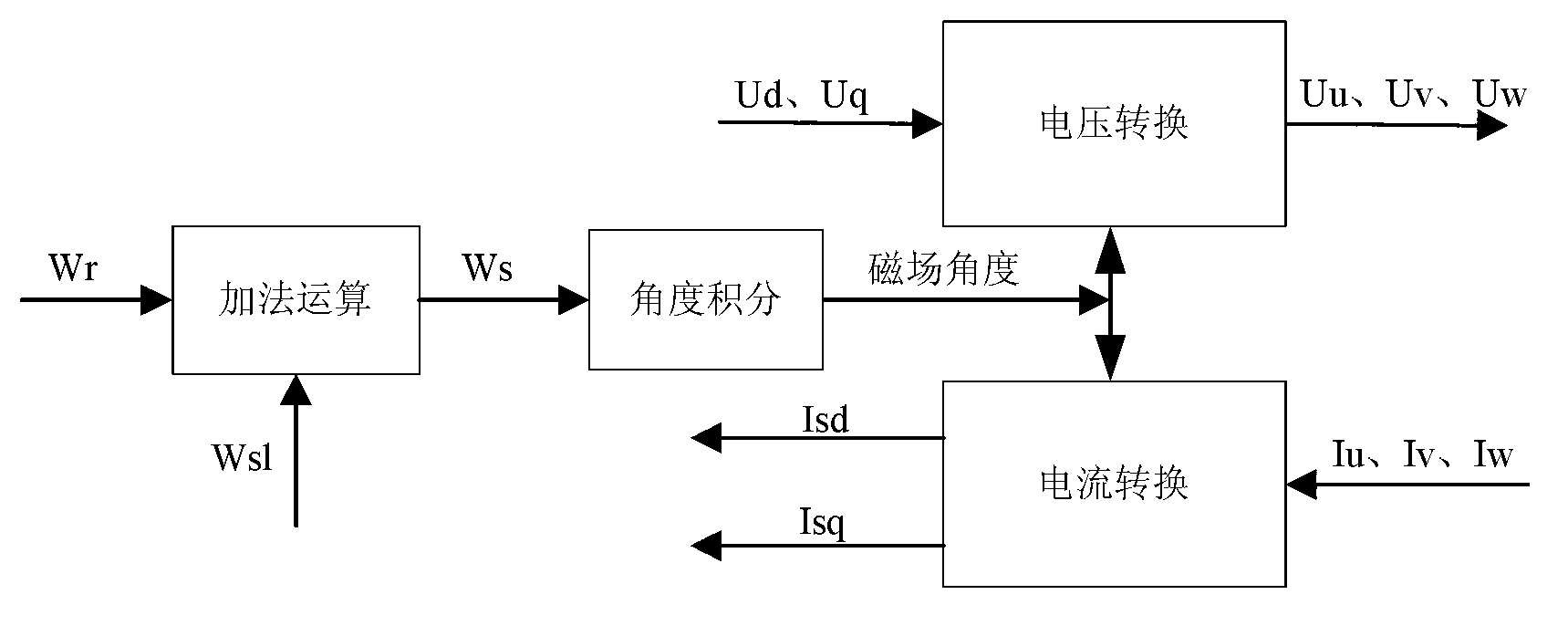

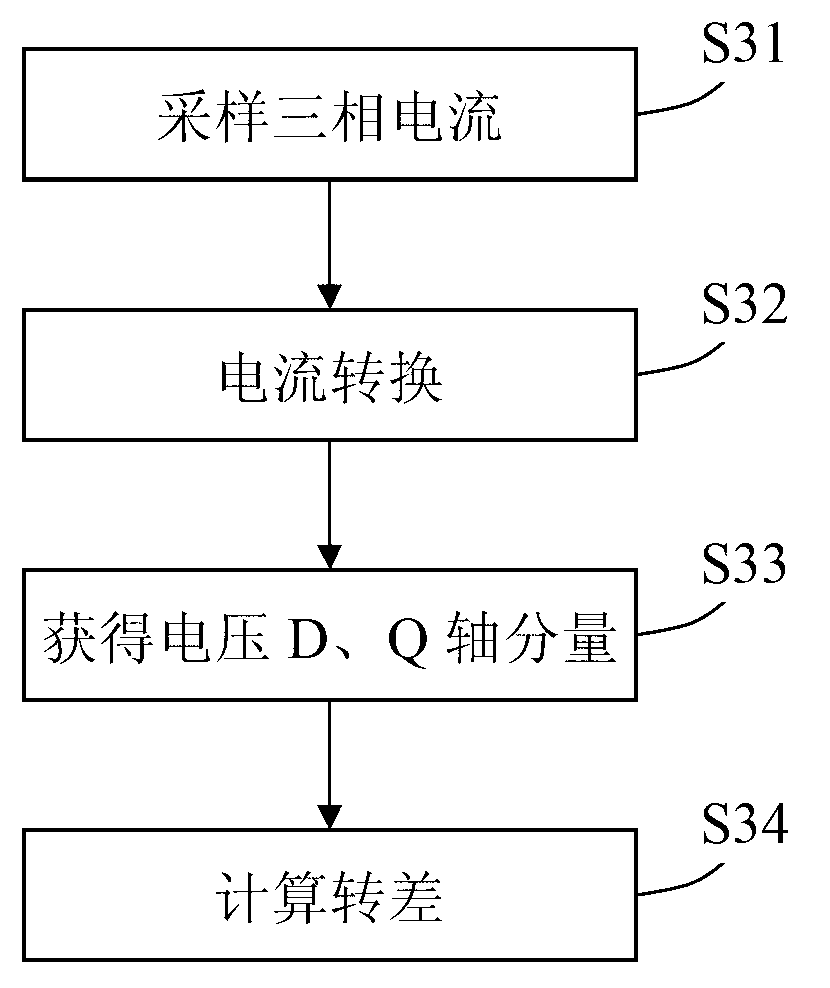

Power calculation based slip estimation system and power calculation based slip estimation method

ActiveCN103023421AHigh control precisionSmall magnetic field orientation errorElectronic commutation motor controlVector control systemsStator voltageRC time constant

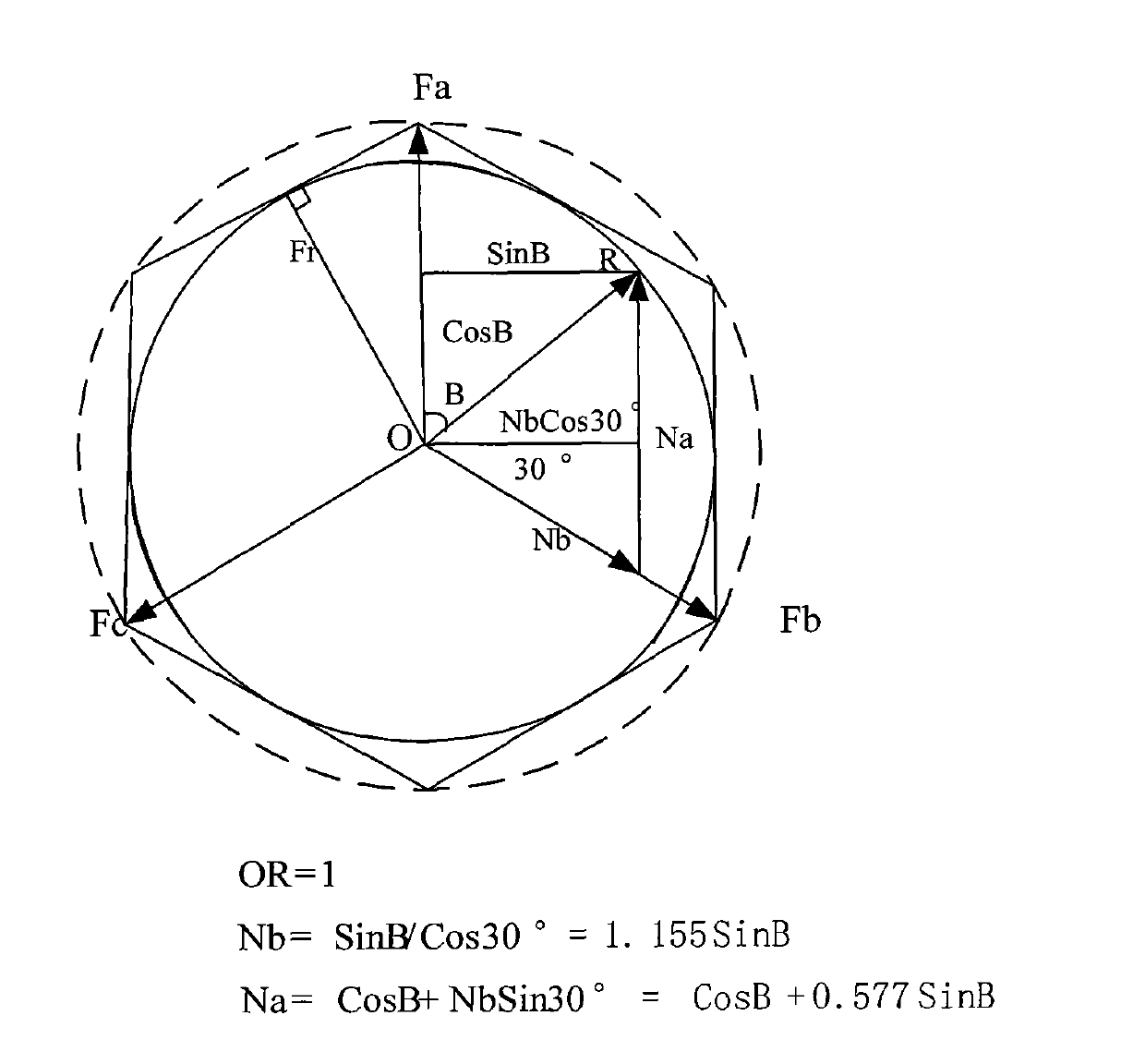

The invention provides a power calculation based slip estimation system. The power calculation based slip estimation system comprises a current sampling unit, a current conversion unit, a current regulation unit and a slip calculation unit, wherein the current sampling unit is used for sampling three-phase current of an asynchronous motor, the current conversion unit is used for obtaining feedback current D-axis component and Q-axis component, the current regulation unit is used for obtaining D-axis stator voltage and Q-axis stator voltage, and the slip calculation unit is used for obtaining slip according to the D-axis stator voltage, the Q-axis stator voltage, the feedback current D-axis component, the Q-axis component and a rotor time constant. The invention further provides a corresponding method. The system and the method have the advantages that the slip is estimated according to the ratio of active power to reactive power to enable rotor field orientation error caused by the rotor time constant Tr during speed regulation to become smaller, so that rotor field orientation effect of the asynchronous motor is improved effectively, and torque control precision is improved.

Owner:SUZHOU INOVANCE TECH CO LTD

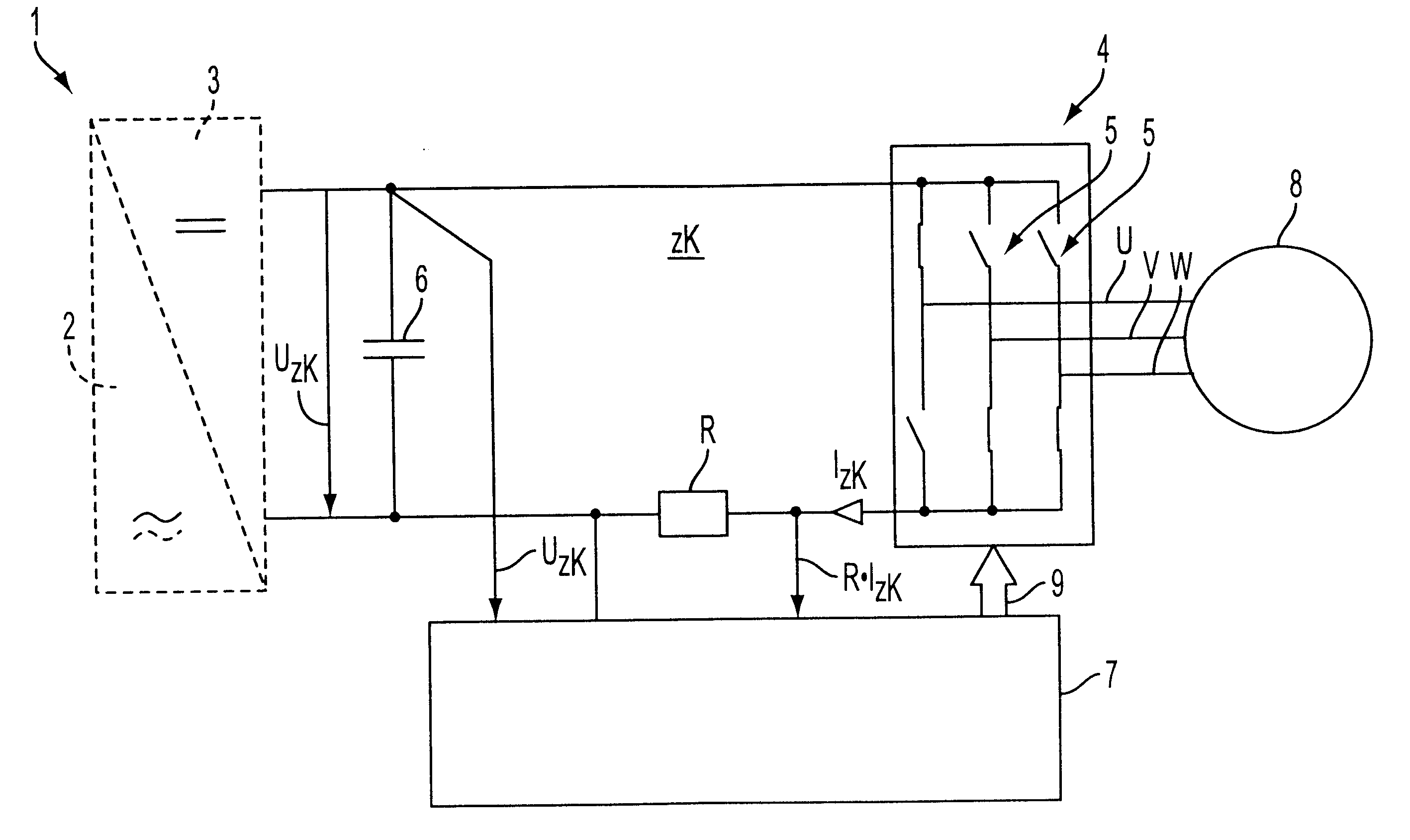

Method for regulating a three-phase machine without a mechanical rotary transducer

InactiveUS6479971B1Electronic commutation motor controlVector control systemsElectric machineryEngineering

A method is provided for regulating a three-phase machine functioning under any operational conditions without a mechanical rotary transducer. The machine is supplied with D.C. power by an inverter, where parameters of a D.C. link using an actual switching state of the inverter are detected for regulation. The method includes measuring (1) flow direction required for field-oriented control in asynchronous machines, and (2) rotor position for rotor-oriented control in synchronous machines. The measuring is performed by using spatial magnetic conductivity fluctuations in the machine. The conductivity fluctuations are detected using parameters for a D.C. link. An actual switching state of an inverter is used in the measuring process. Mathematical evaluation to calculate flow direction or rotor direction is then performed.

Owner:SCHRODL MANFRED

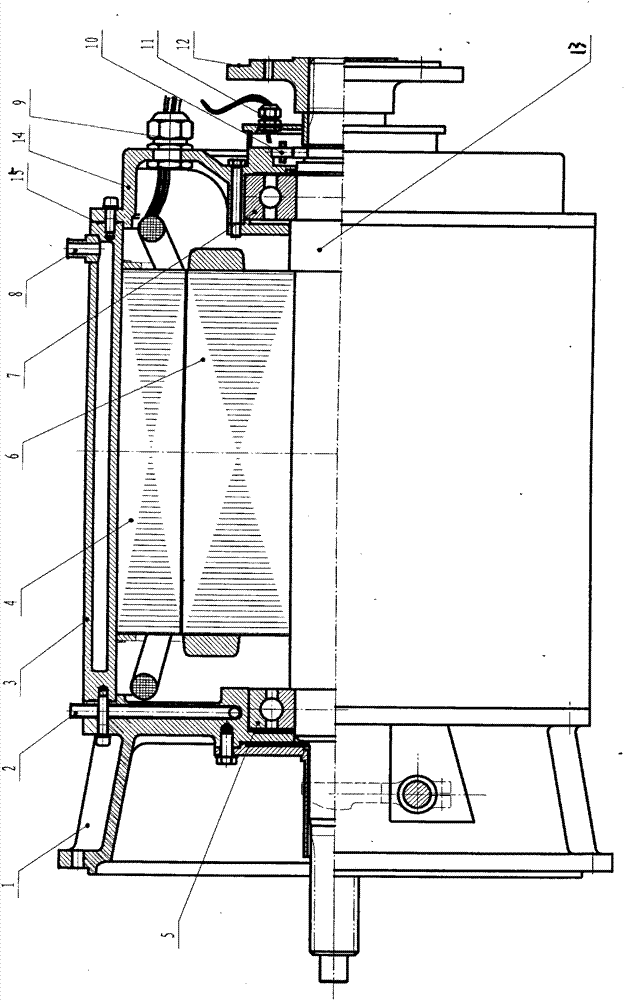

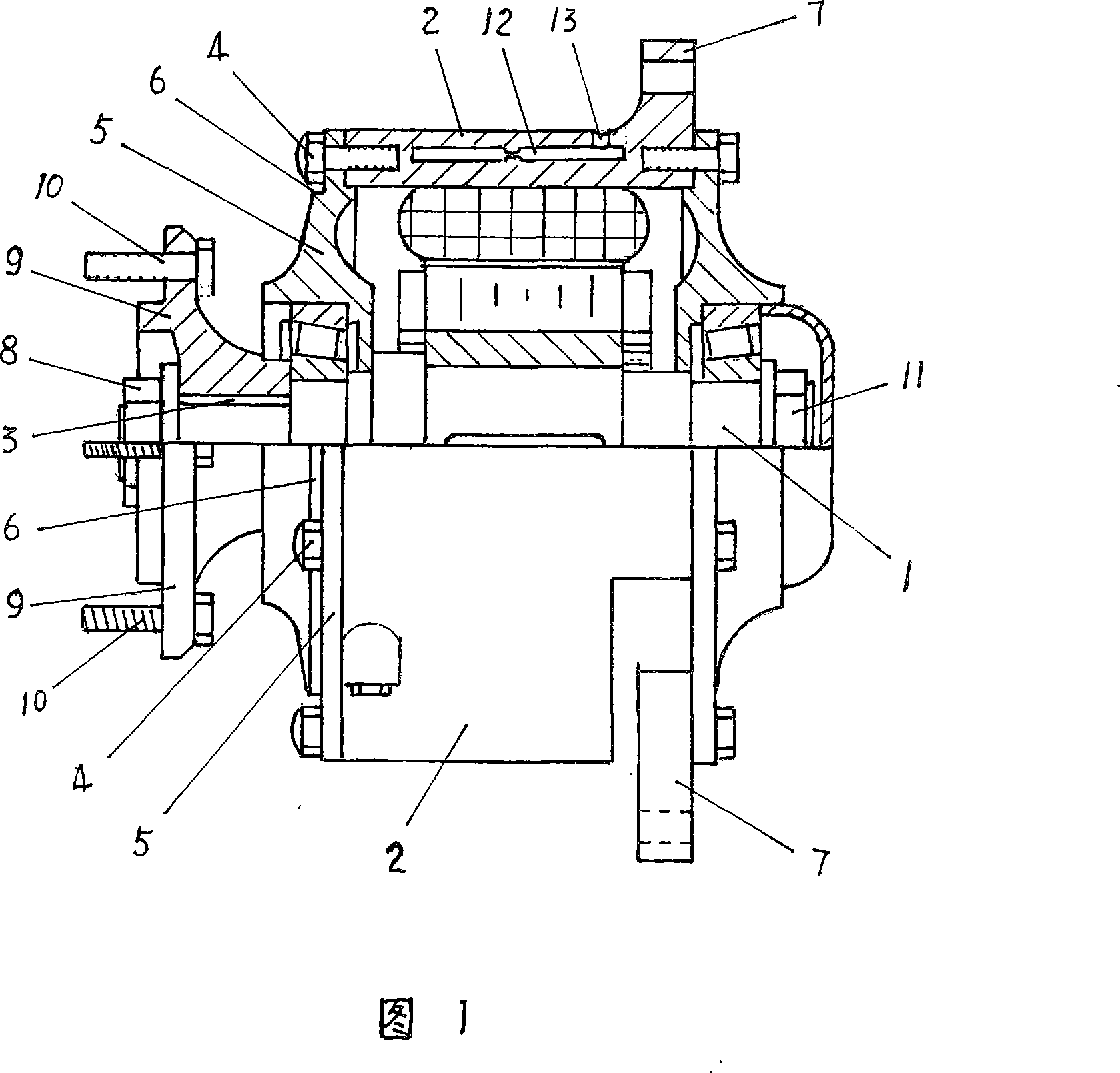

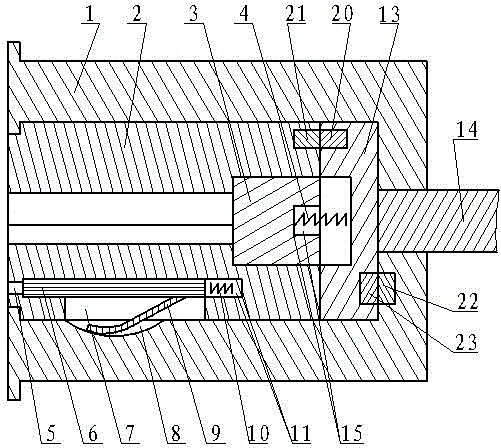

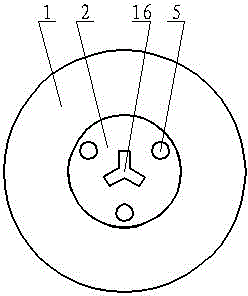

Water-cooled asynchronous motor for hybrid vehicle

ActiveCN102820752AEven heat dissipationGuaranteed concentric outer diameterAsynchronous induction motorsCooling/ventillation arrangementDrive motorAlloy

The invention discloses a water-cooled asynchronous motor for a hybrid vehicle and belongs to the structure of an asynchronous machine. A motor which is used in a coach is designed to the water-cooled asynchronous motor, a novel cooling mode is used in aspects such as a casing of the motor, a water cavity inside the motor and a bearing, a casing water-cooled waterway is designed to an even water channel, the flow is smooth, the resistance is low and the radiation is quick. Simultaneously, gasket positions are arranged on an upper end face and a lower end face of the casing axially, a water-stop structure of annular gaskets are used in a connection portion of a base and the water channel, by the aid of gaskets, a process that an aluminum alloy plate is welded and sealed is omitted, materials, working hours and cost are saved, the defect of poor welded sealing caused by argon arc welding is avoided, the reliability of water-cooled casing usage and motor operation is improved, and the water sealing effect is good. The water-cooled asynchronous motor is mainly used in the coach using hybrid power and serves as a main drive motor.

Owner:宁德时代电机科技有限公司

Applying a control unit to an asynchronous machine which is operated without a rotary encoder

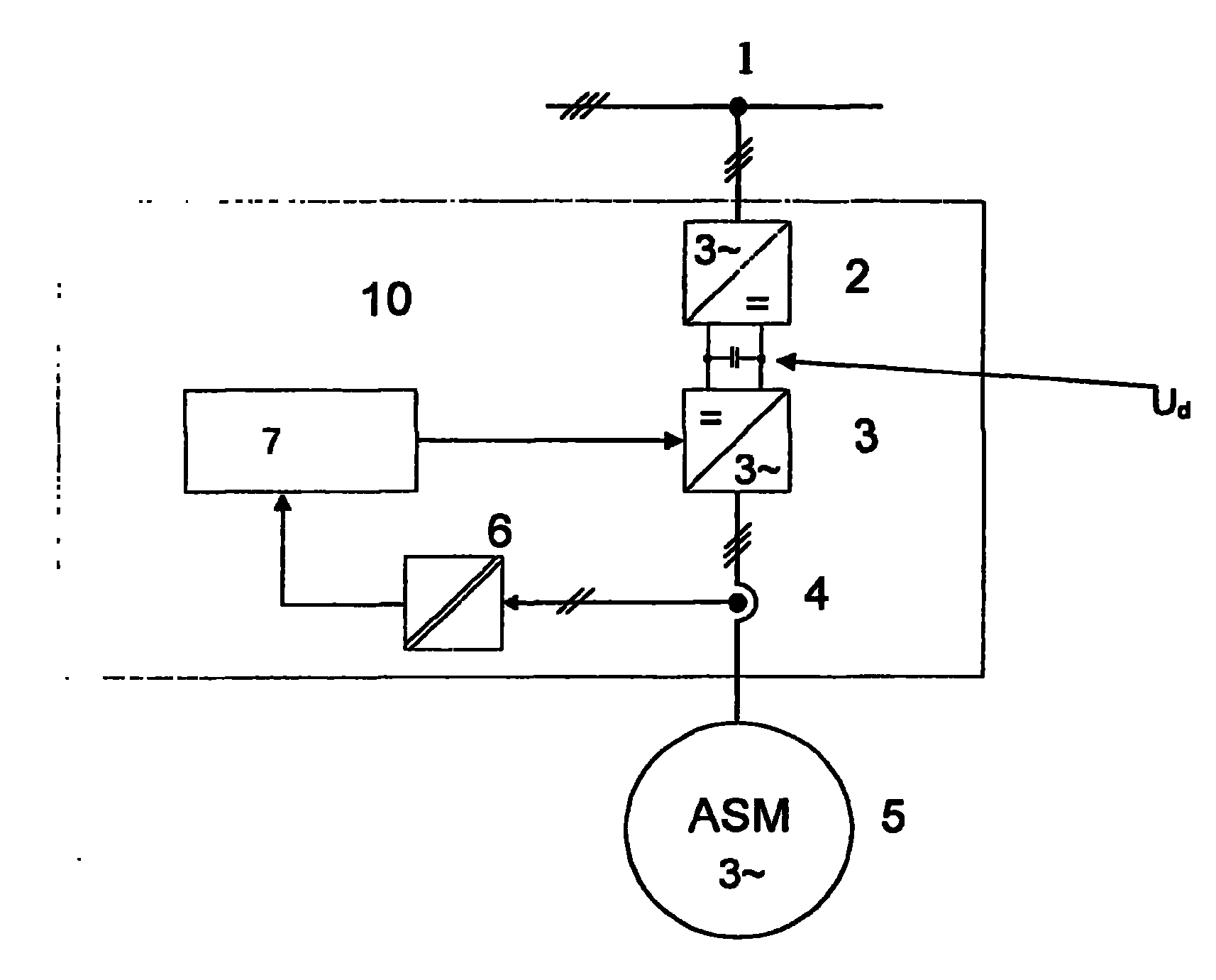

ActiveCN101971482AAvoid current peaksReduce mechanical speedElectronic commutation motor controlVector control systemsFrequency changerVoltage vector

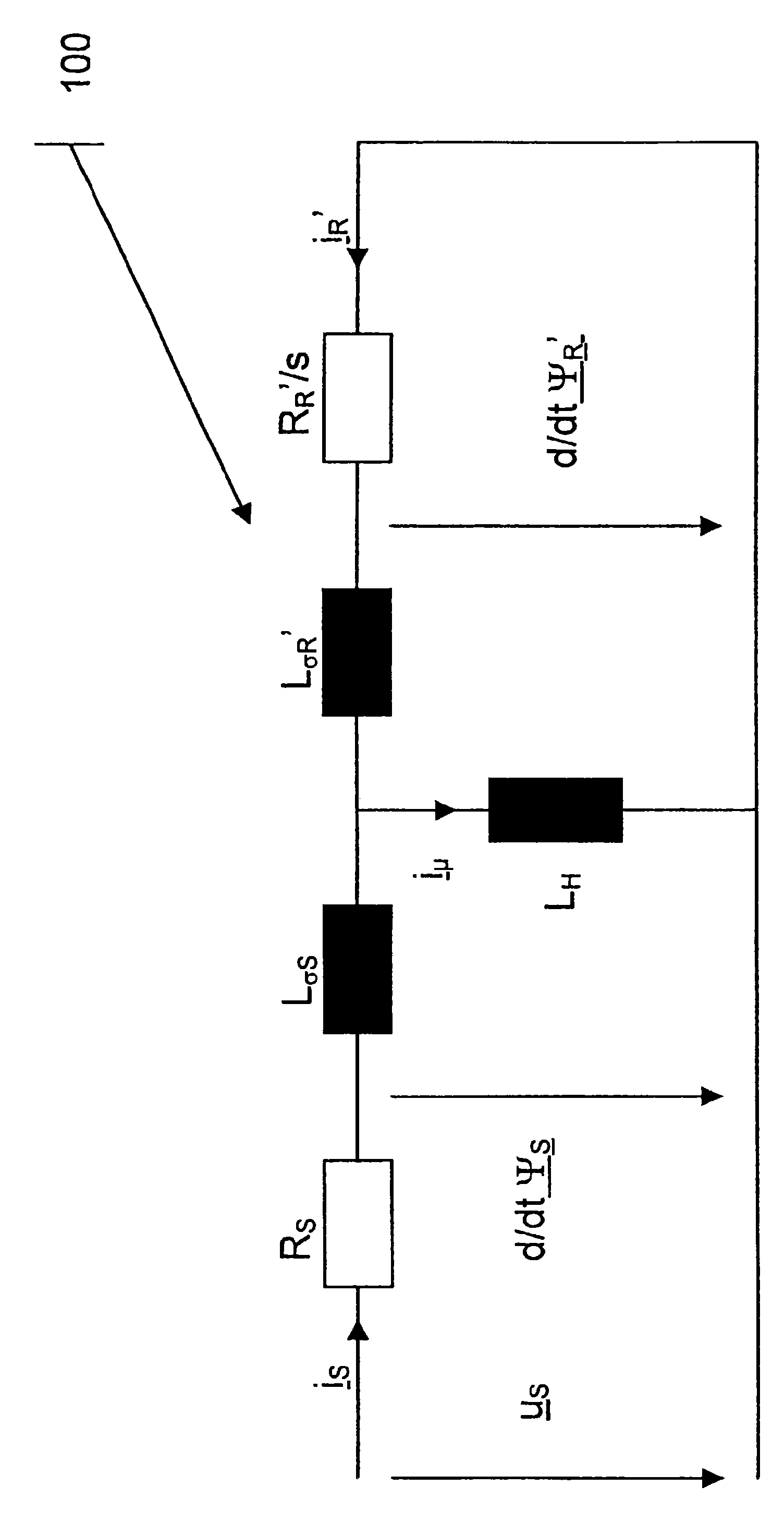

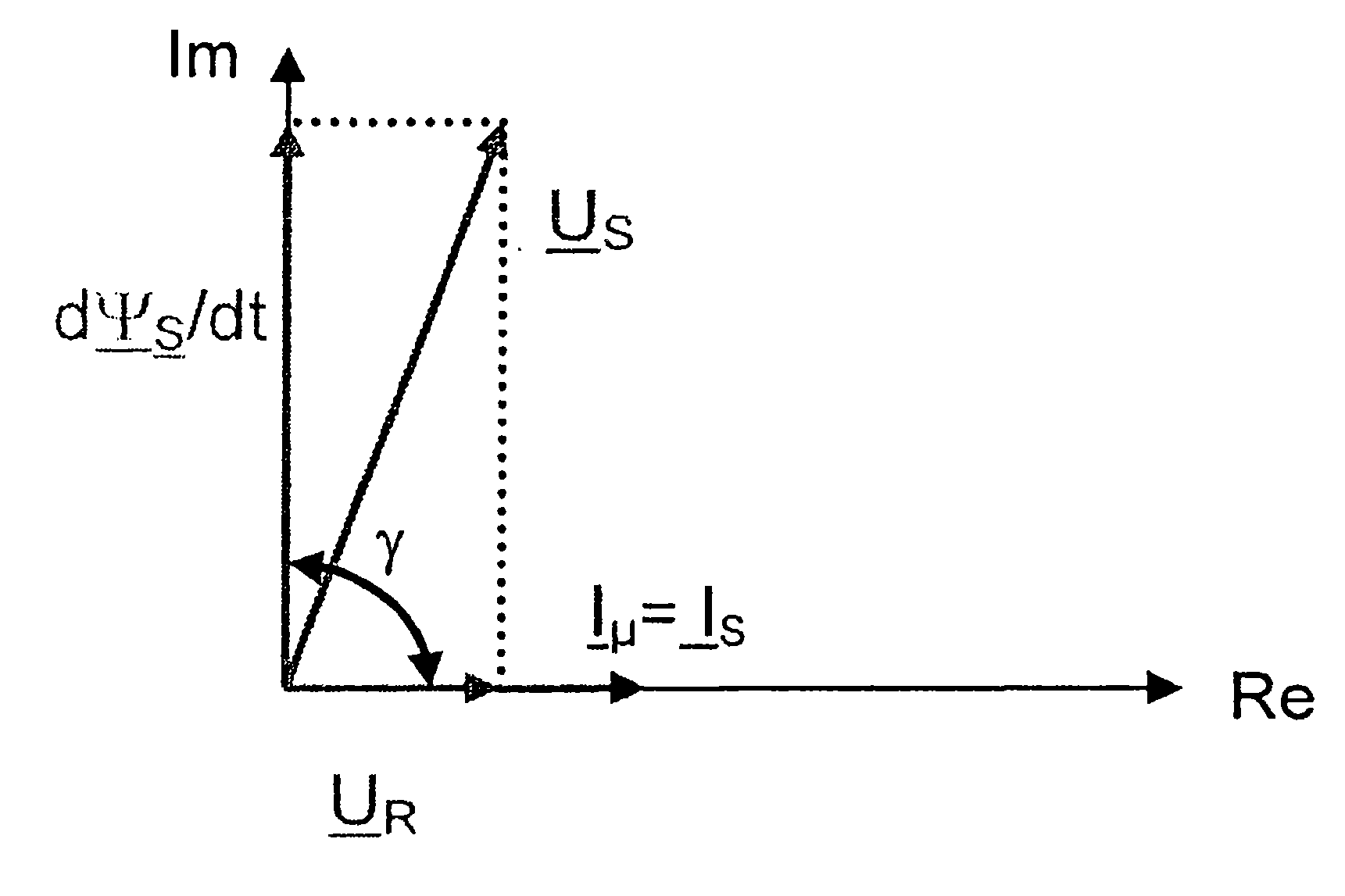

The problem of the invention is to achieve a connection or application of a converter to a rotating asynchronous machine, which is operated without an encoder, without a high current and without a torque surge. The mechanical system and the controlling system are not to be overloaded. The method is also to be capable of functioning independently of the residual magnetism. A method is proposed as a control unit, which employs an inverter or converter, in order to power the asynchronous machine (5), which rotates at a mechanical speed. The asynchronous machine is regulated by the control unit. A stator current vector (i s) is ascertained from measured currents of the stator windings of the asynchronous machine (5) and a rotating stator voltage vector (u s). A calculation of a stator flux change vector is performed from the stator current vector (i s), the stator voltage vector (u s), and a stator resistance (RS) according to a motor model (100). An angle difference (gamma) between the stator current vector (i S) and the stator change vector is calculated. This angle difference (gamma) is regulated to a target value of 90 DEG or -90 DEG , wherein an output signal of said controller corresponds to a rotating field frequency (omega) of the voltage vector of said stator which is to be applied. A regulation of an amplitude of the stator voltage vector is performed via a current controller (51), to which the difference of a current target value and a variable which corresponds to the amplitude of the stator current is provided at the input as the control difference (51a).

Owner:LENZE DRIVES

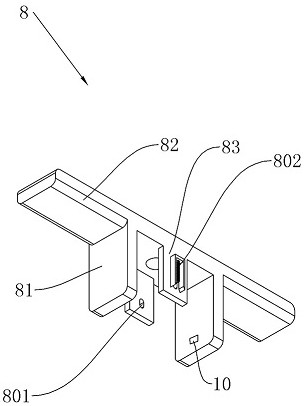

Double-motor driving device of parking device and control method thereof

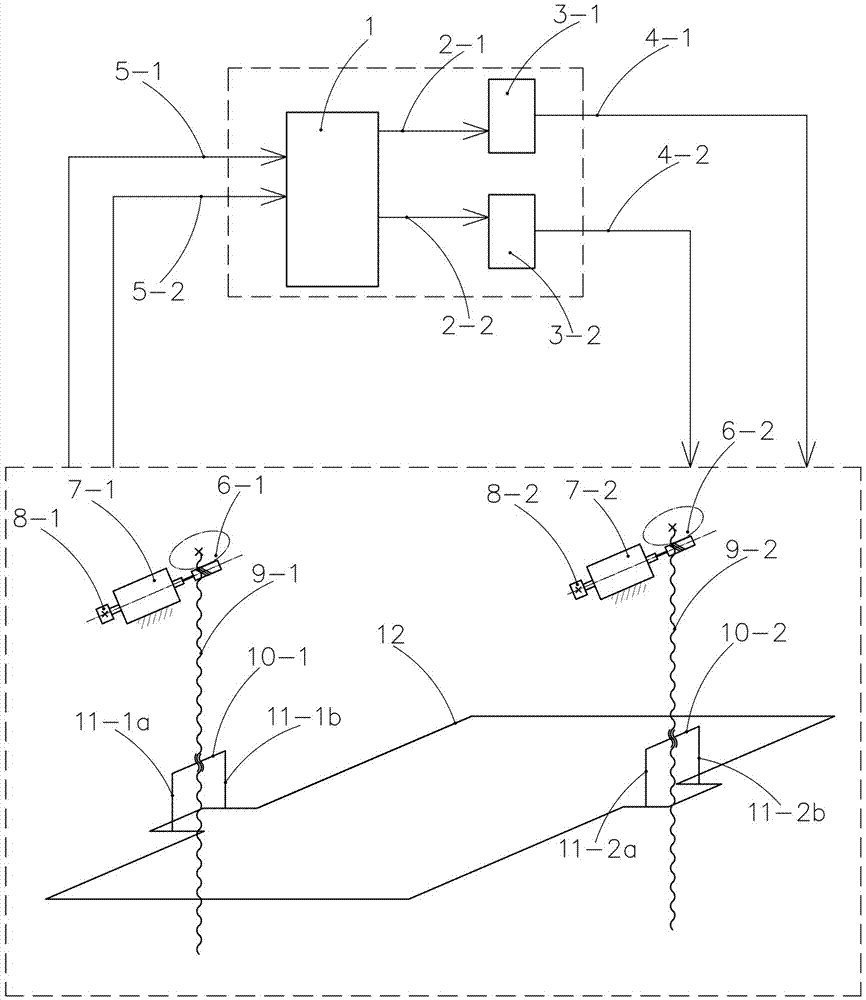

PendingCN107204682AAvoid safety accidentsAC motor controlMultiple dynamo-electric motors speed regulationFrequency changerConverters

The invention provides a double-motor driving device of a parking device and a control method thereof. The double-motor driving device of the parking device and the control method thereof solve a deficiency of safety hazard which is caused by a current parking device adopting a single motor to drive a chain or a steel wire to perform cycle traction and installation size limitation of single motor which drives two sets of screw-nut mechanisms. The double-motor driving device is constituted by two sets of power driving mechanisms consisting two sets of motors having identical parameters and a reduction gearbox and respectively drives two sets of screw and screw units; two nut seats performs traction on two sides of a vehicle-loading plate to achieve elevation driving through pulling by the steel wire or traction through the screws; the driving device control method adopts two frequency converters with identical parameters and matched measures to realize synchronous control on two three-phase asynchronous machines and provides multiple schemes to choose.

Owner:梁崇彦

External spline shaft hub motor

InactiveCN101212161ASimple structureEasy to install and connectElectric propulsion mountingMotor depositionEngineeringElectric vehicle

The invention provides a hub motor with external spline shaft. Based on a traditional motor with three asynchronous machines and through the design change of shape and structure, the invention is allowed to be a hub motor with reliable performance, simple structure and strong practicality. Two sides of a motor shell are provided with motor pedestals perpendicular to motor shafts so as to continent for connecting with a suspension of an electric vehicle; the external end of the motor shafts are provided with the external spline and a wheel connector; a wheel and a brake drum or a brake disk are arranged on the wheel connector on the external end of the motor shaft by a wheel bolt. A brake floor and a brake clamp support are arranged on an external side end cover of the hub motor. The internal end of the motor shaft is provided with a gap-adjusting nun used for adjusting the gaps of the bearing, namely, used for adjusting the gaps of the wheels in real usage. The invention is applicable to the manufacture of small-sized electric vehicle.

Owner:鲁泊凡

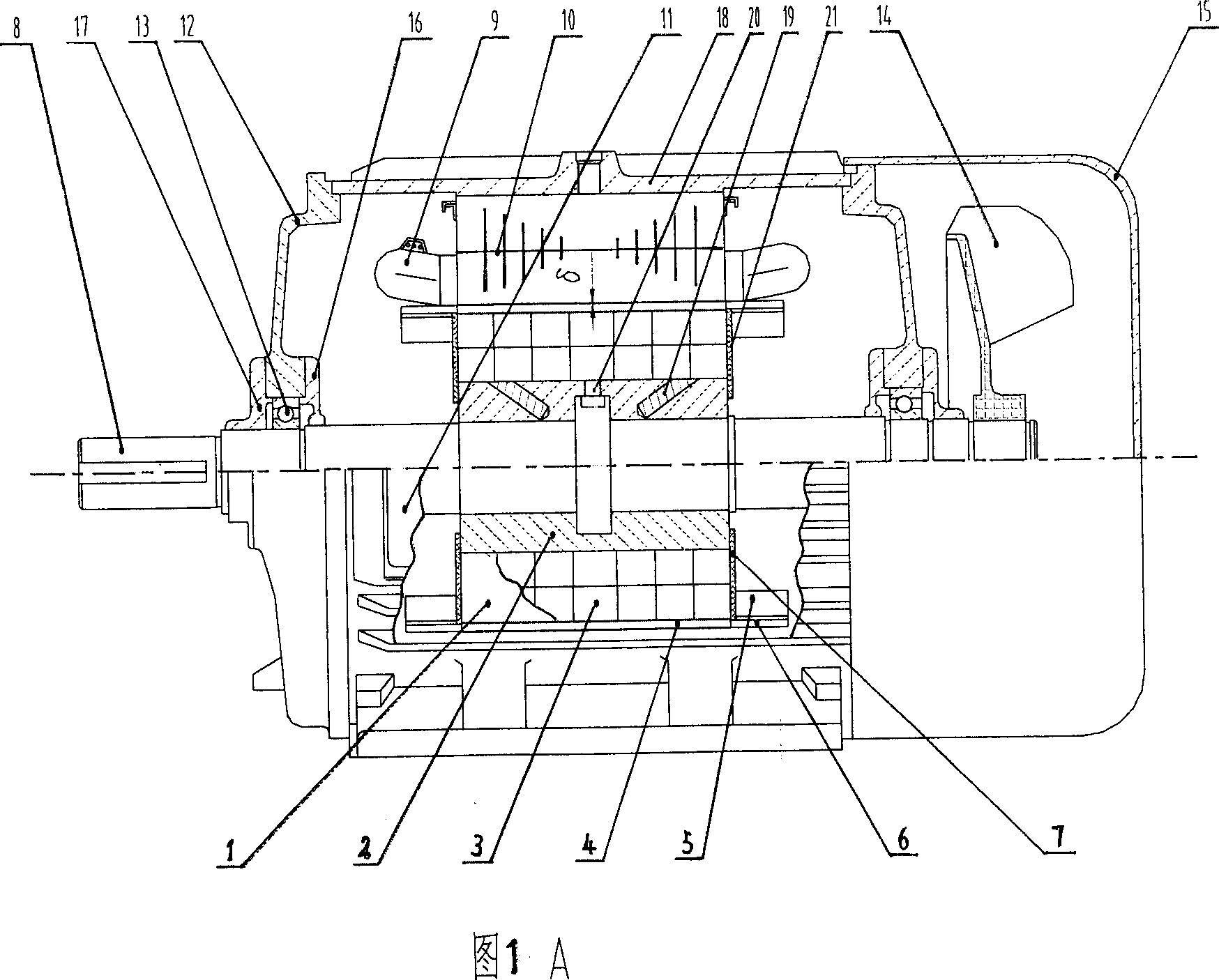

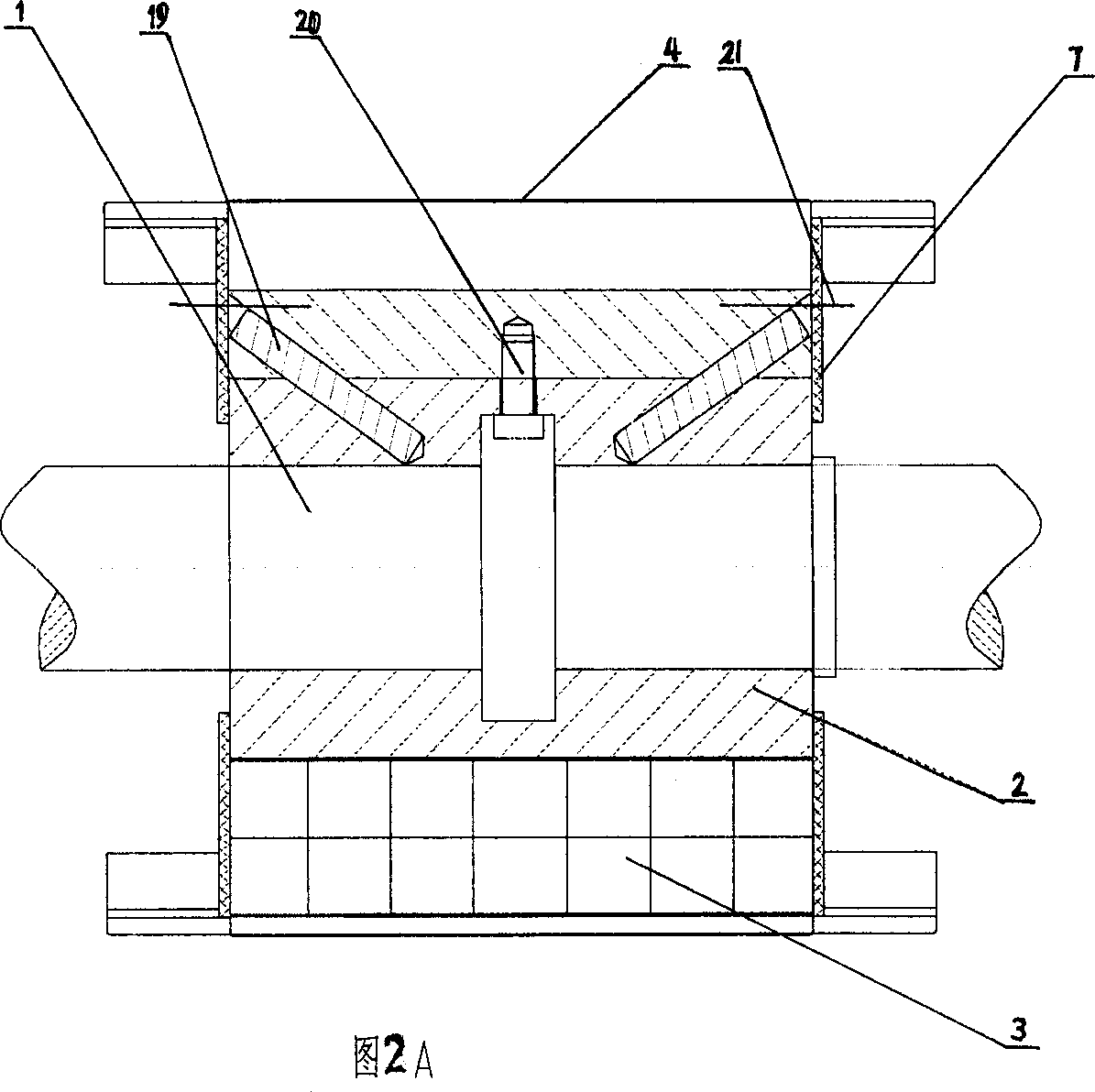

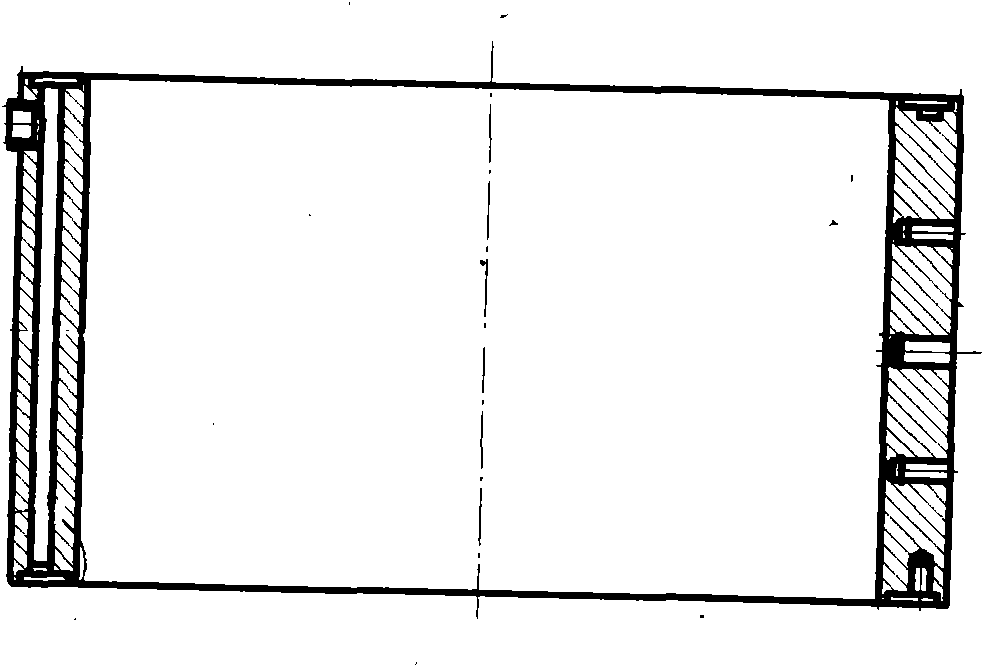

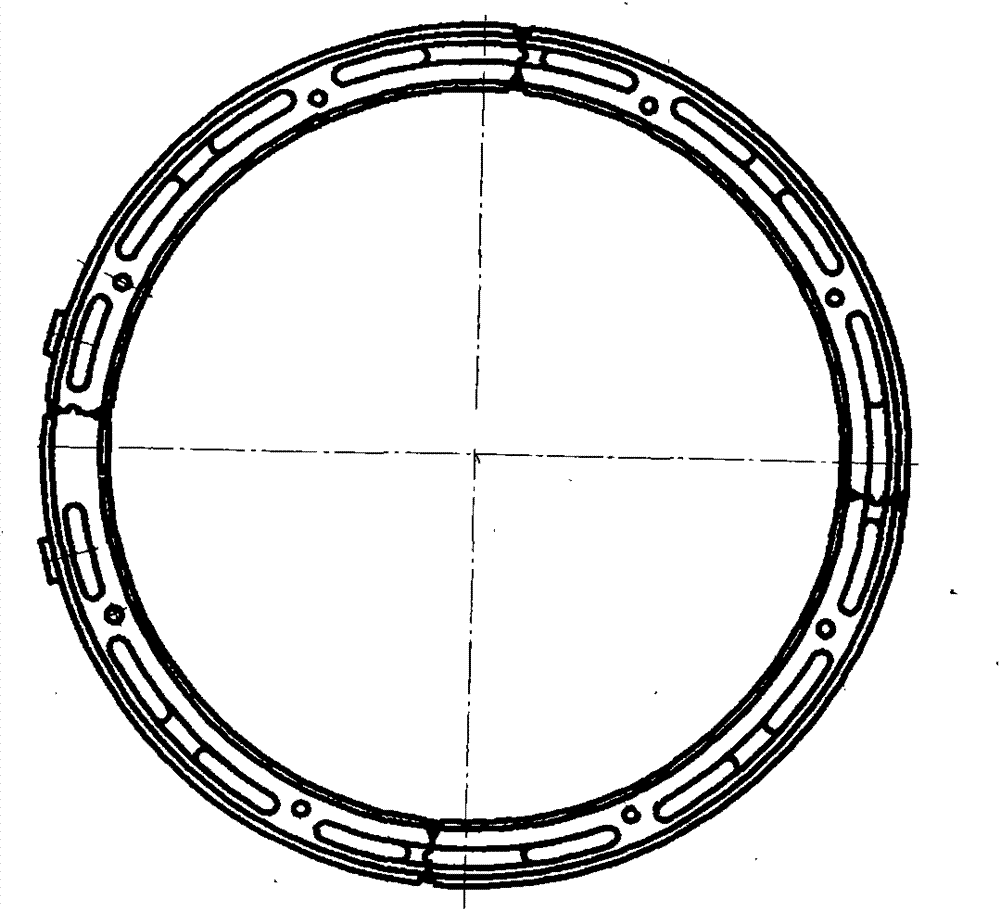

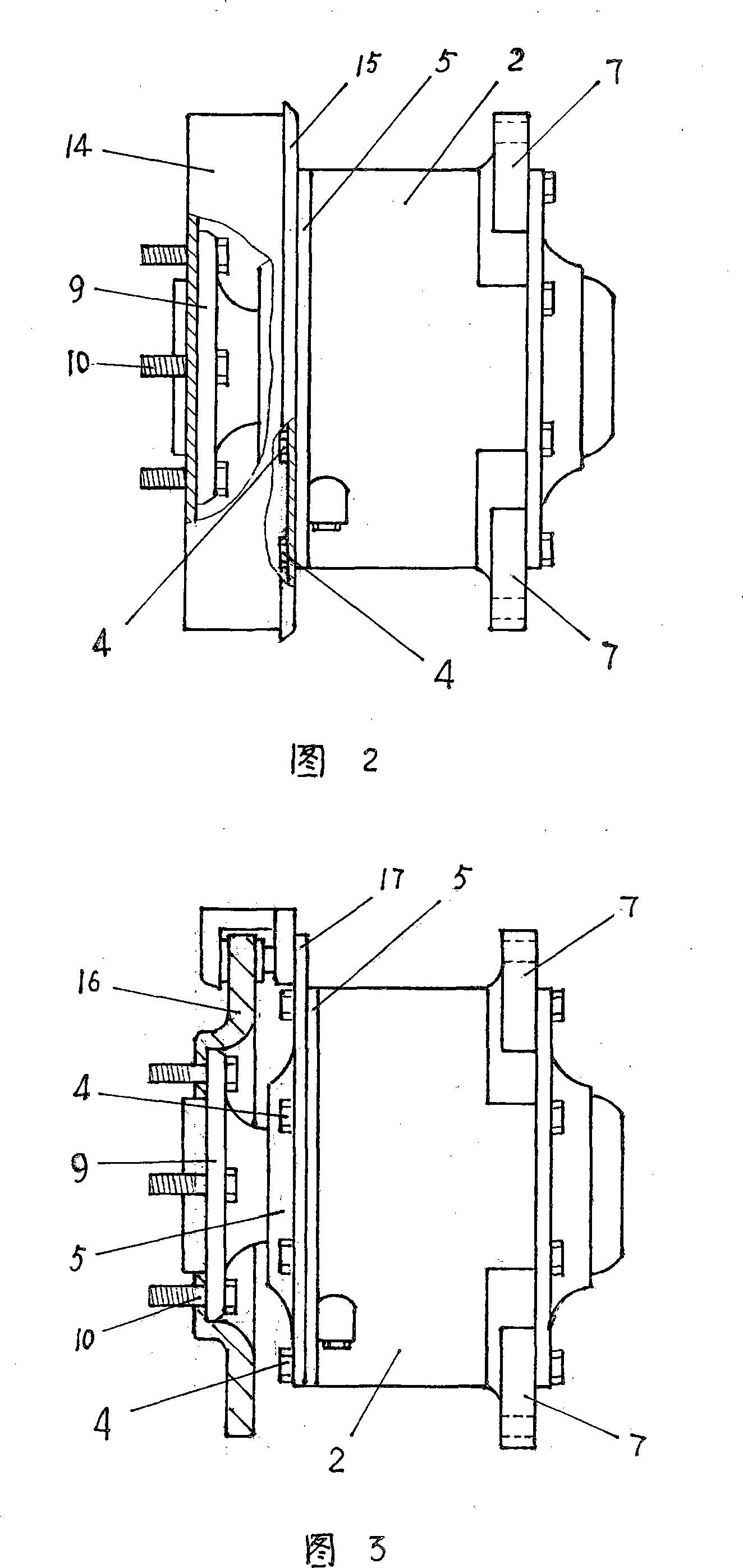

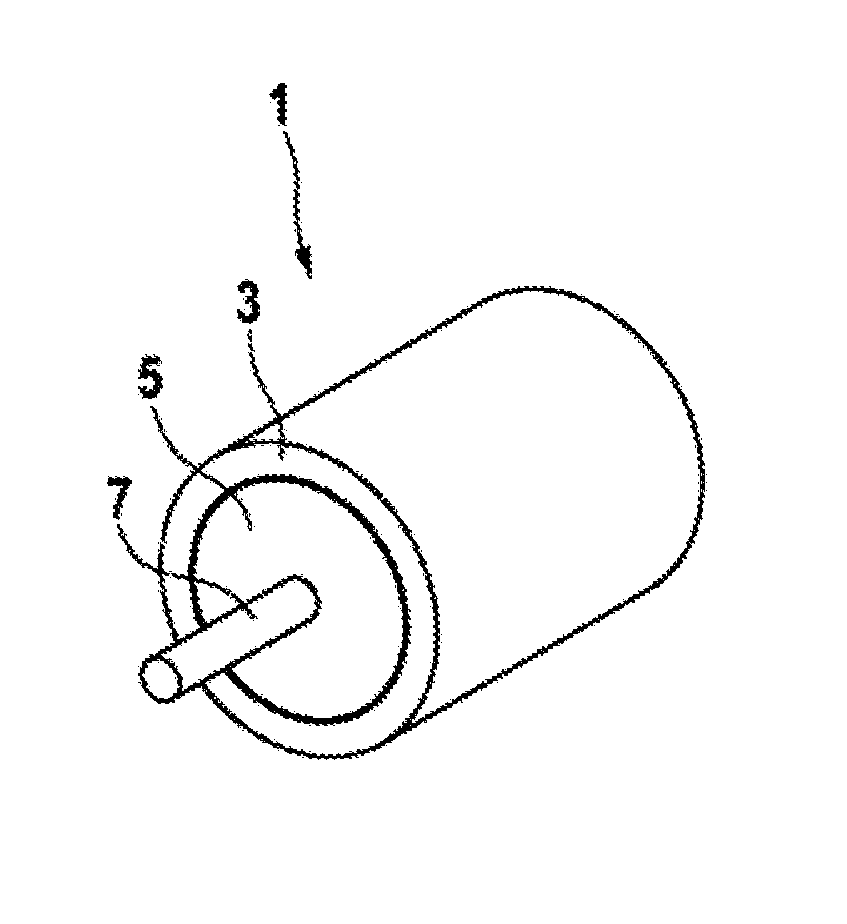

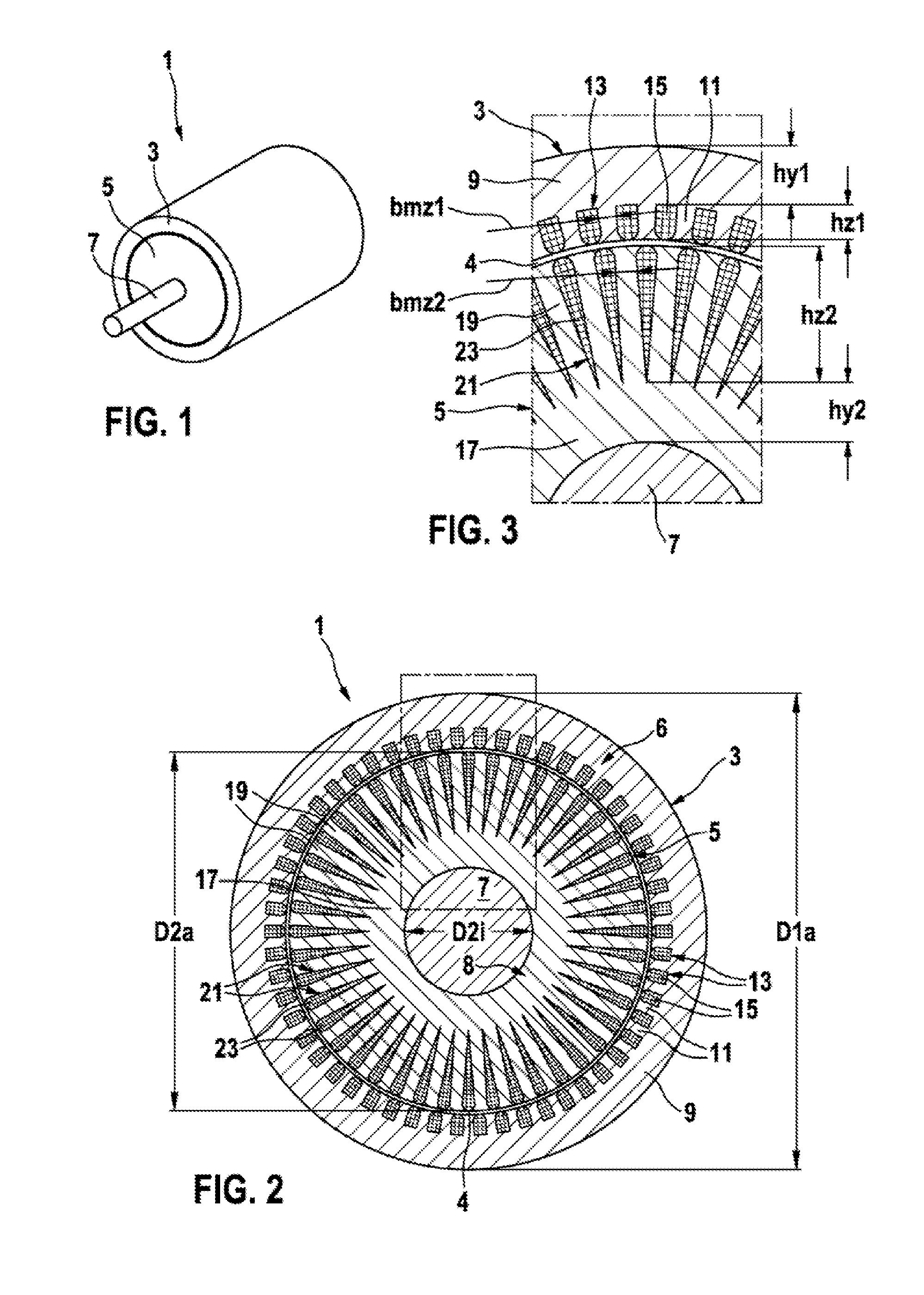

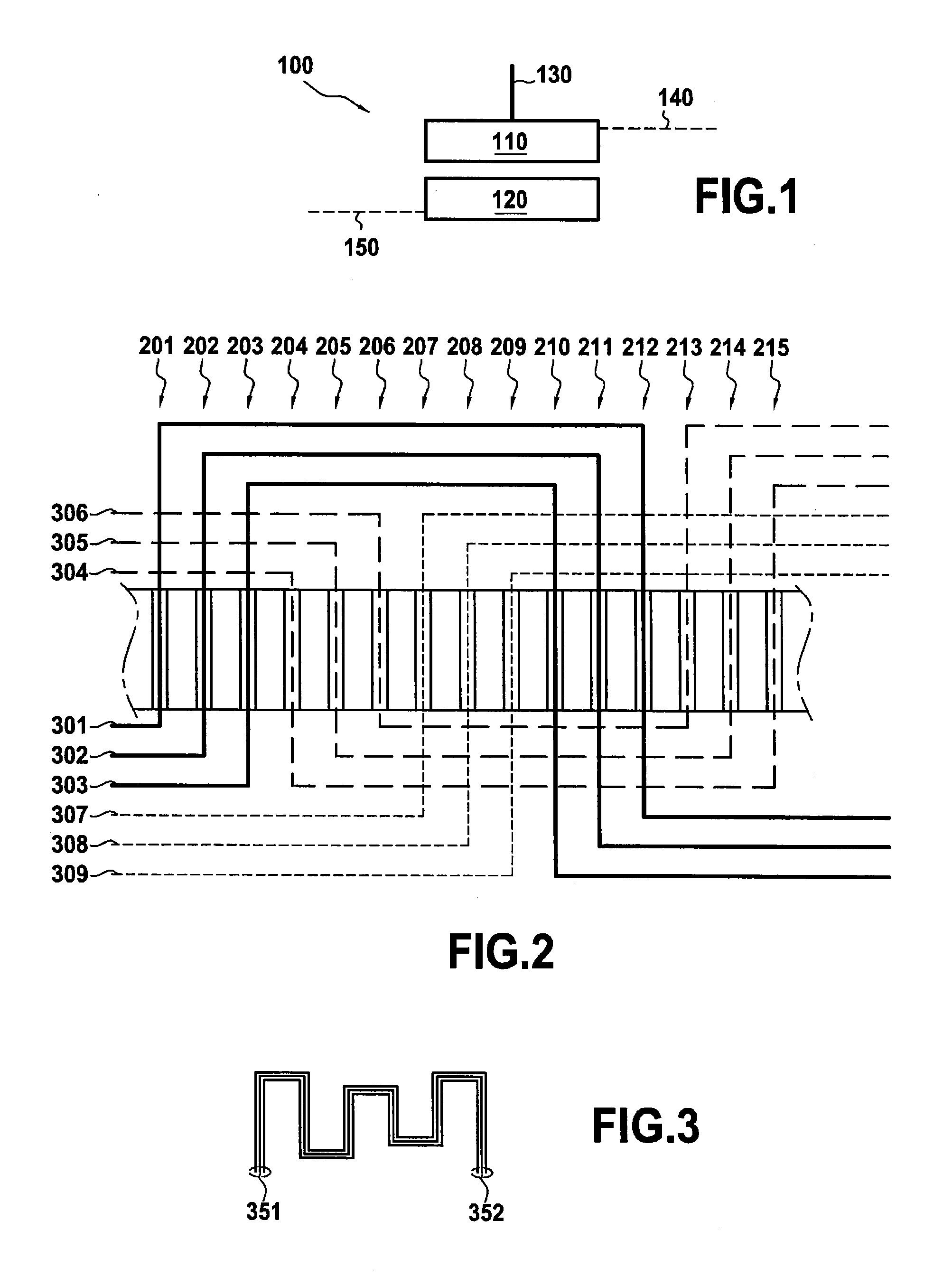

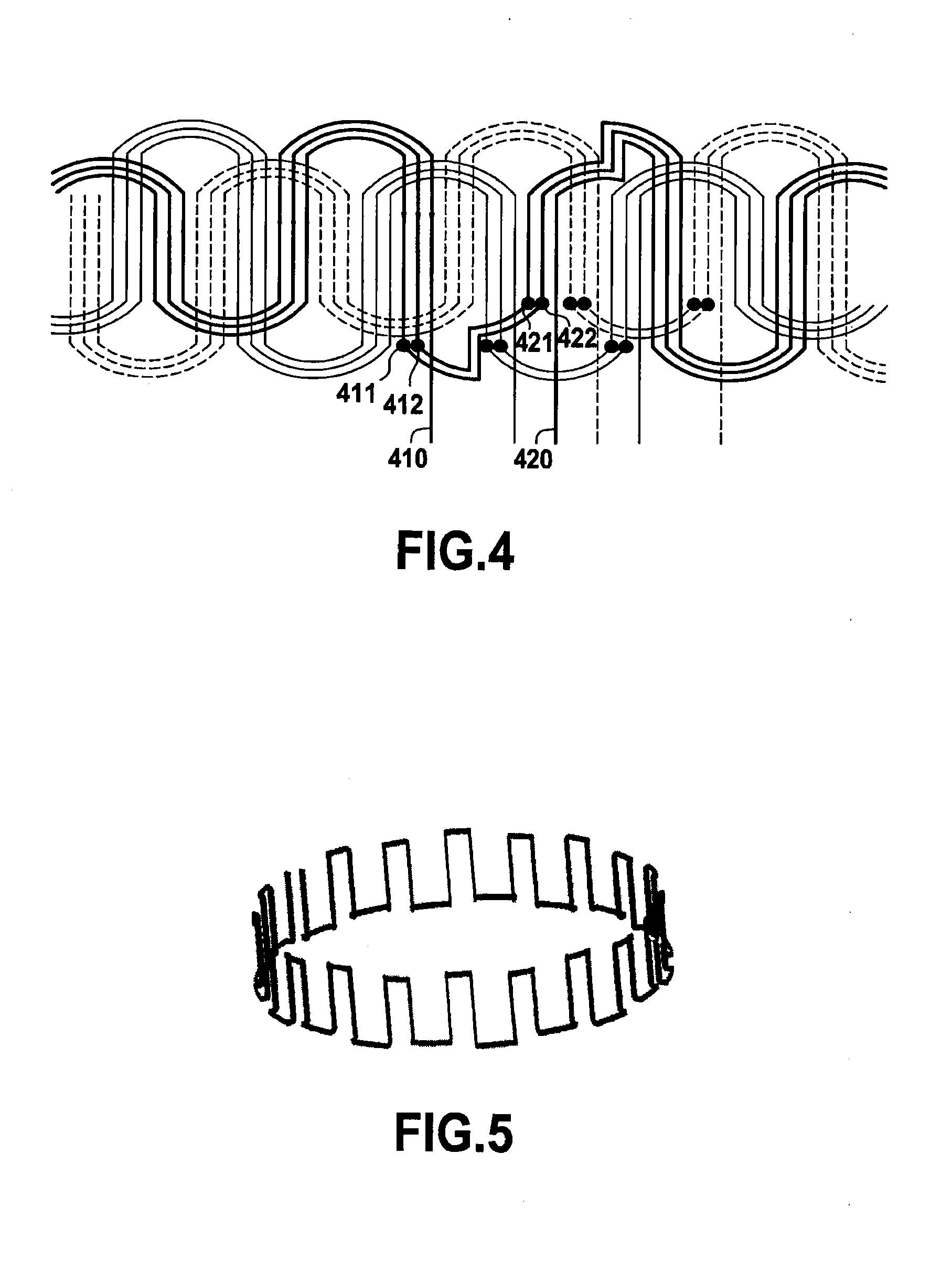

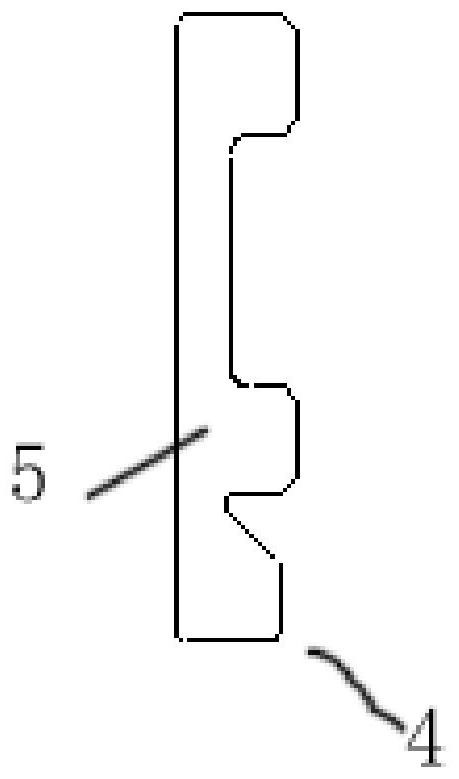

Asynchronous machine with optimized distribution of electrical losses between stator and rotor

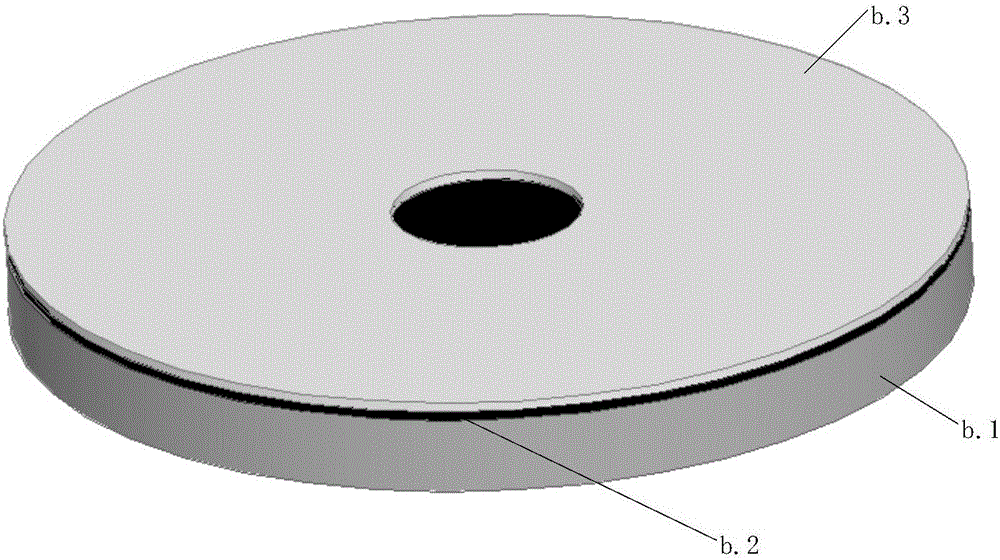

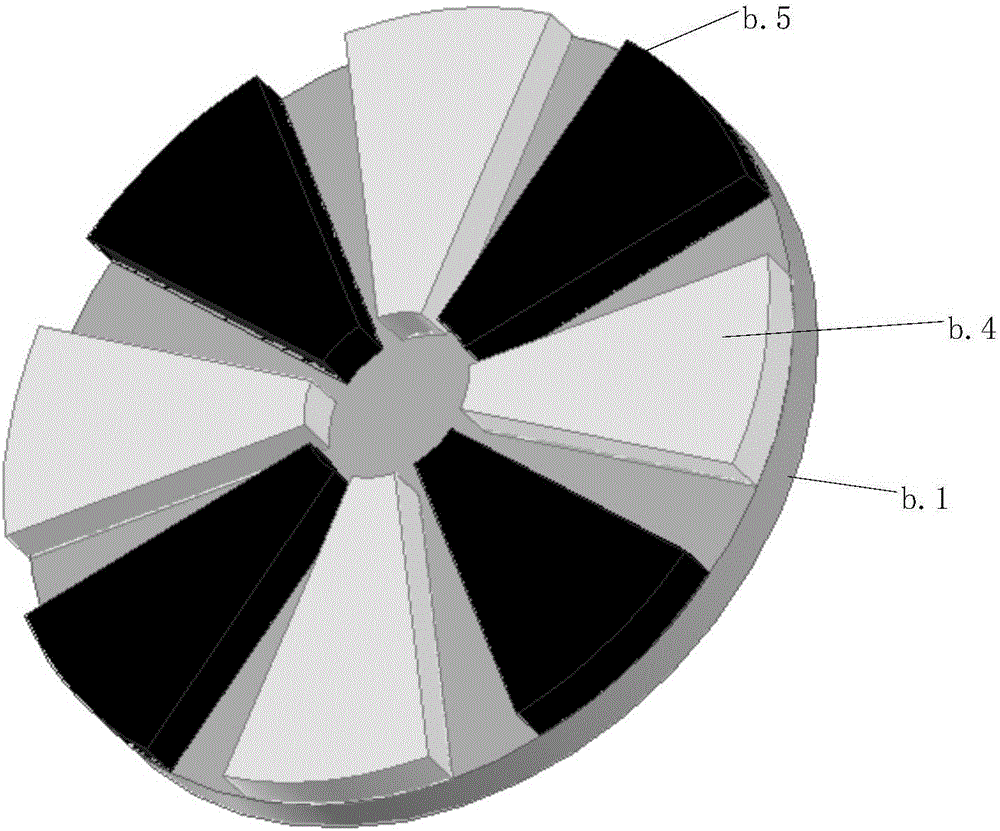

ActiveUS20150311759A1Improve adaptabilityHigher continuous torqueMagnetic circuitElectric machinesElectric machineEngineering

The invention relates to an asynchronous machine (1) as can be used particularly in electric vehicles or hybrid vehicles. The asynchronous machine (1) has a rotor (5) and a stator (3). The asynchronous machine is designed and controlled in such a manner that it has a pole pair number p of p=3. Because of the reduced yoke saturation that can consequently be achieved, the stator yoke (9) can be designed with a lesser height hy1, such that a ratio of the outer rotor diameter D2a to the outer stator diameter D1a can assume values between 0.7 and 0.8. As a result, enlarged rotor teeth (19) and correspondingly enlarged rotor grooves (21) can be formed in the rotor (5), such that electrical losses in the material in the rotor grooves (21) acting as the rotor coil element (23) are smaller in comparison to conventional asynchronous machines. The electrical losses occurring to a greater extent in the stator (3) compensating for this lead to a lesser warming of the stator (3) than would be the case with the rotor (5) as the stator (3) can be cooled by simple means. Overall, a higher continuous torque can thus be achieved with the asynchronous machine (1) according to the invention.

Owner:ROBERT BOSCH GMBH

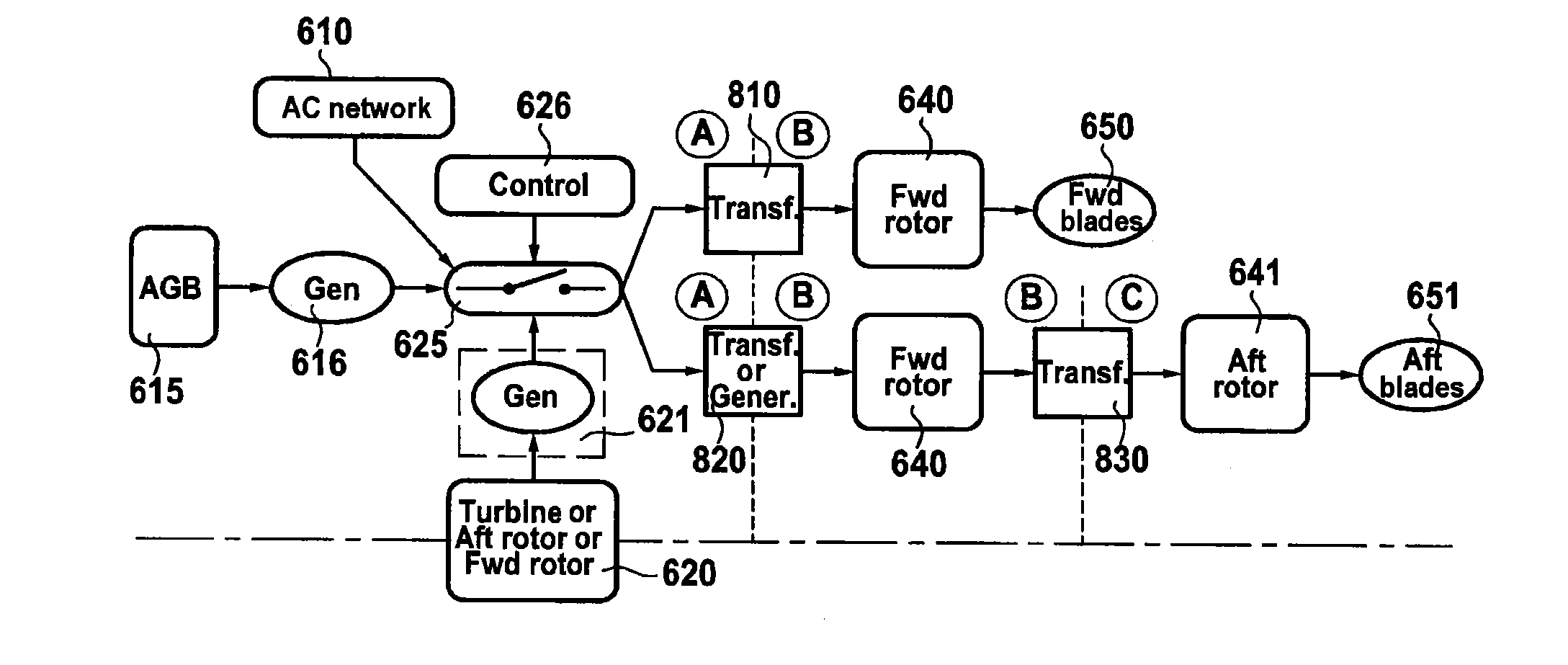

Electrical power supply system comprising an asynchronous machine, and an engine fitted with such an electrical power supply system

ActiveUS20150108760A1Improve reliabilitySmall sizeElectric power distributionTransformersElectric machineElectrical connection

An electrical power supply including an asynchronous machine, an arrangement for driving a rotor of the asynchronous machine in rotation by a rotor of an engine, and an electrical connection for powering electrical equipment by the rotor of the asynchronous machine. The asynchronous machine is configured to receive AC electrical power via a stator of the asynchronous machine, and it presents, over a predetermined range of drive speeds of the rotor of the asynchronous machine under drive by the rotor of the engine, efficiency in transferring electrical power from the stator to the rotor that is privileged relative to the efficiency with which rotary mechanical power is converted into electrical power.

Owner:SAFRAN TRANSMISSION SYST

Method, Computer Program Product And System For Operating An Asynchronous Machine And Asynchronous Machine

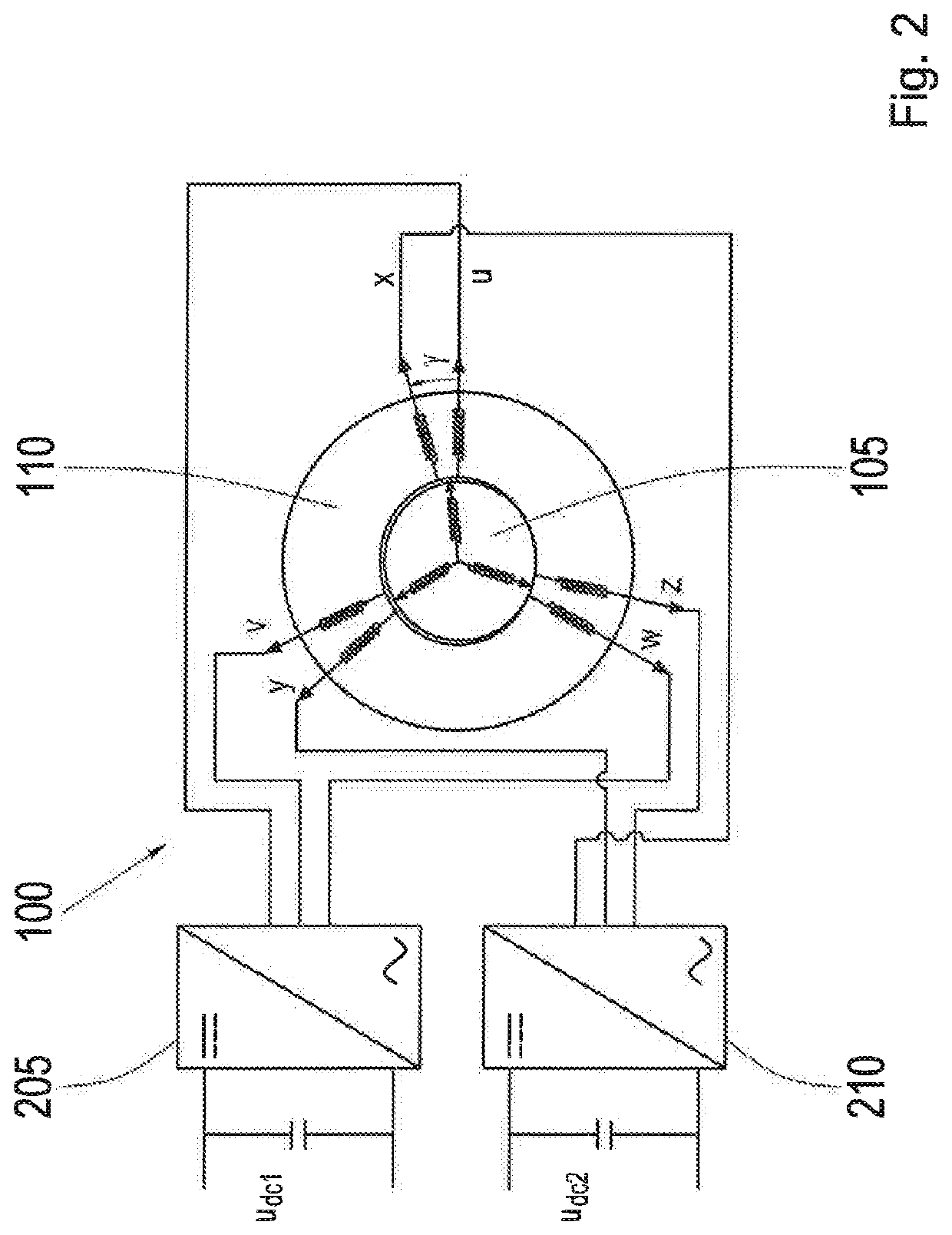

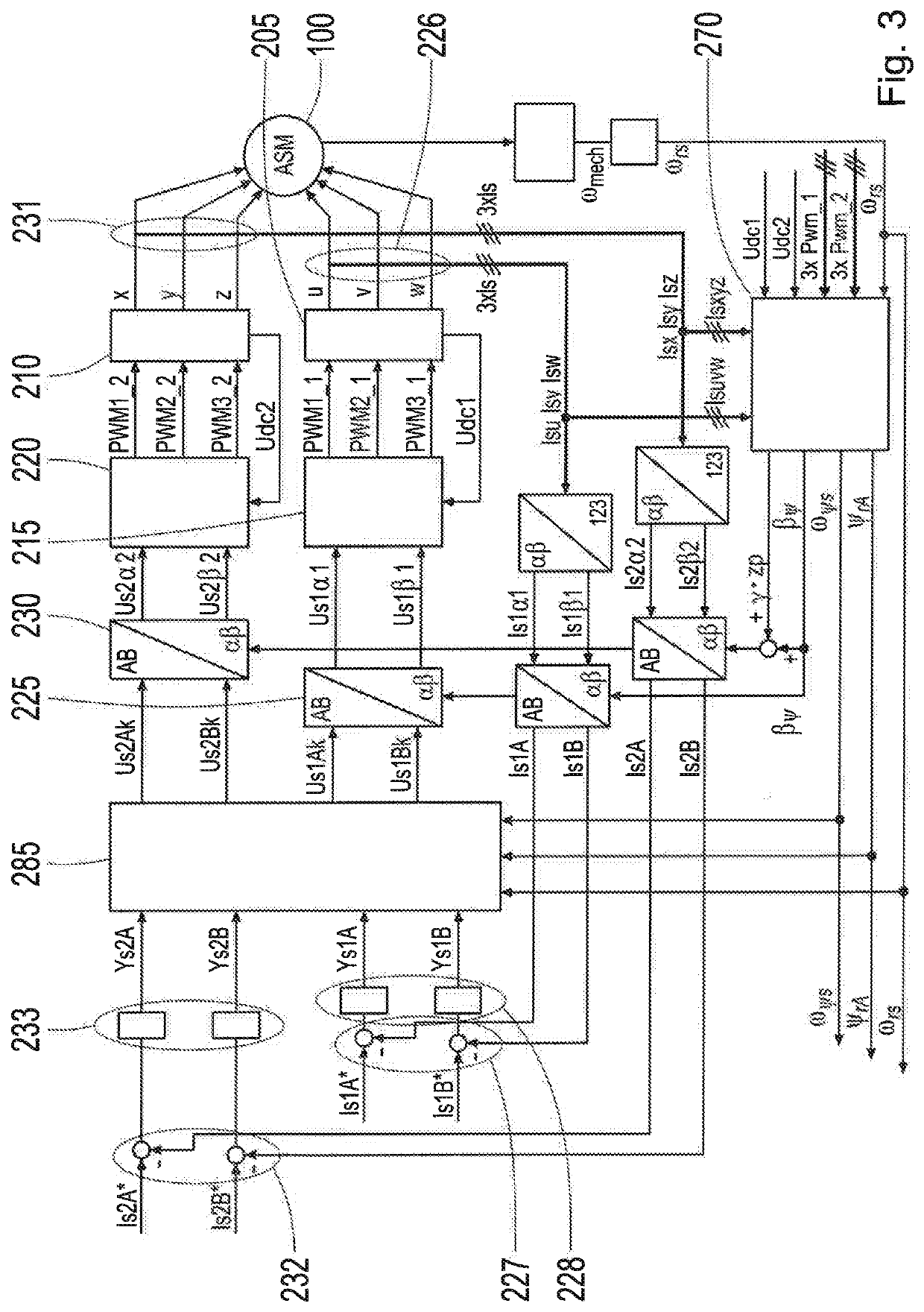

ActiveUS20190356256A1Full powerQuality improvementElectronic commutation motor controlAC motor controlDeviation vectorLoop control

Operating an asynchronous machine includes: closed loop control of a first and a second three-phase winding by a first and a second closed loop control method, respectively. The second closed loop control method supplies a voltage vector to a second inverter device, and changes from the first closed loop control method to a first open loop control method. The first open loop control method includes supplying a first reference current vector to a first filter device, supplying a filtered first reference current vector to a calculation device for calculating an electrical angle, supplying the electrical angle to a first transformation device for transforming a first open loop control deviation vector, transforming a first open loop control deviation vector into a third voltage vector, and supplying the third voltage vector to the first inverter device for the operation of the first three-phase winding.

Owner:ZF FRIEDRICHSHAFEN AG

Direct current (ZLDL) asynchronous motor

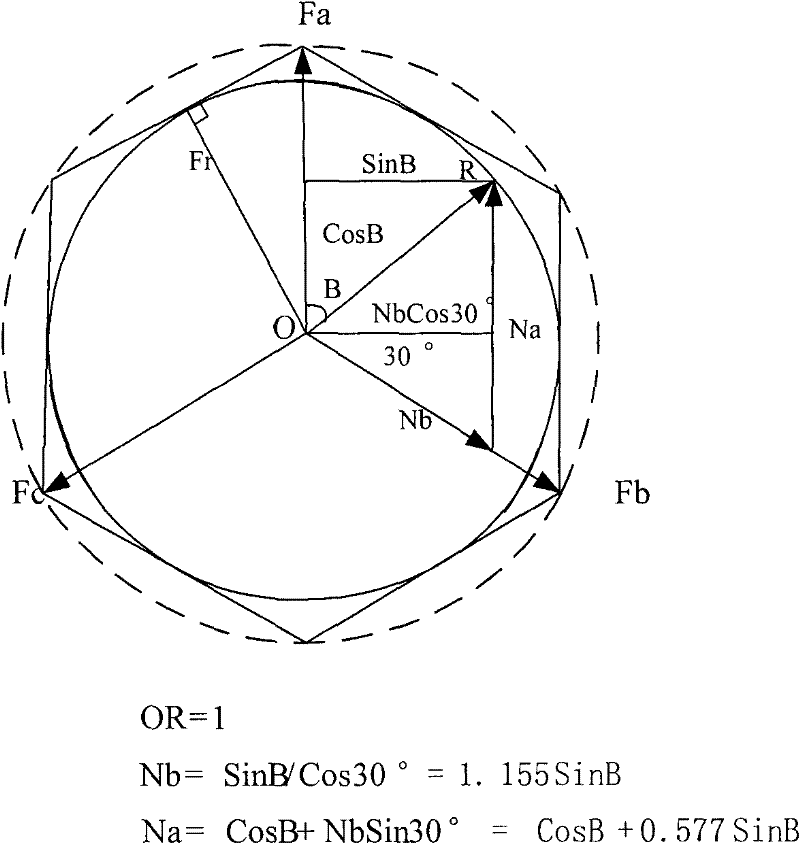

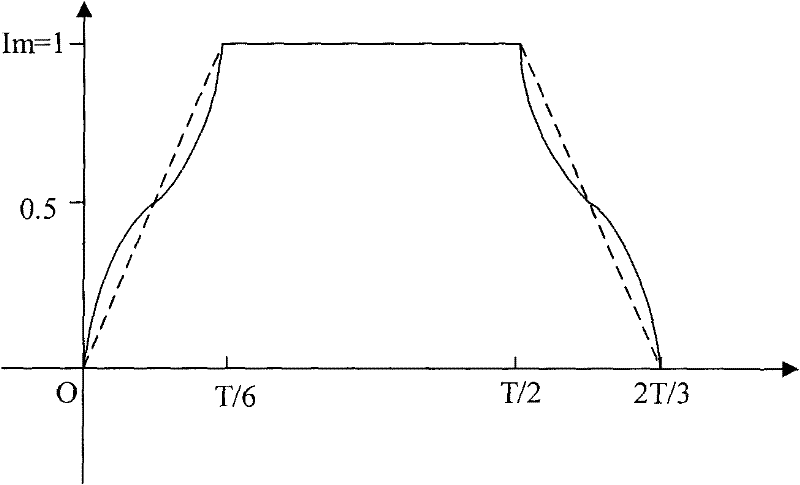

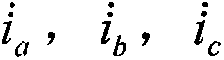

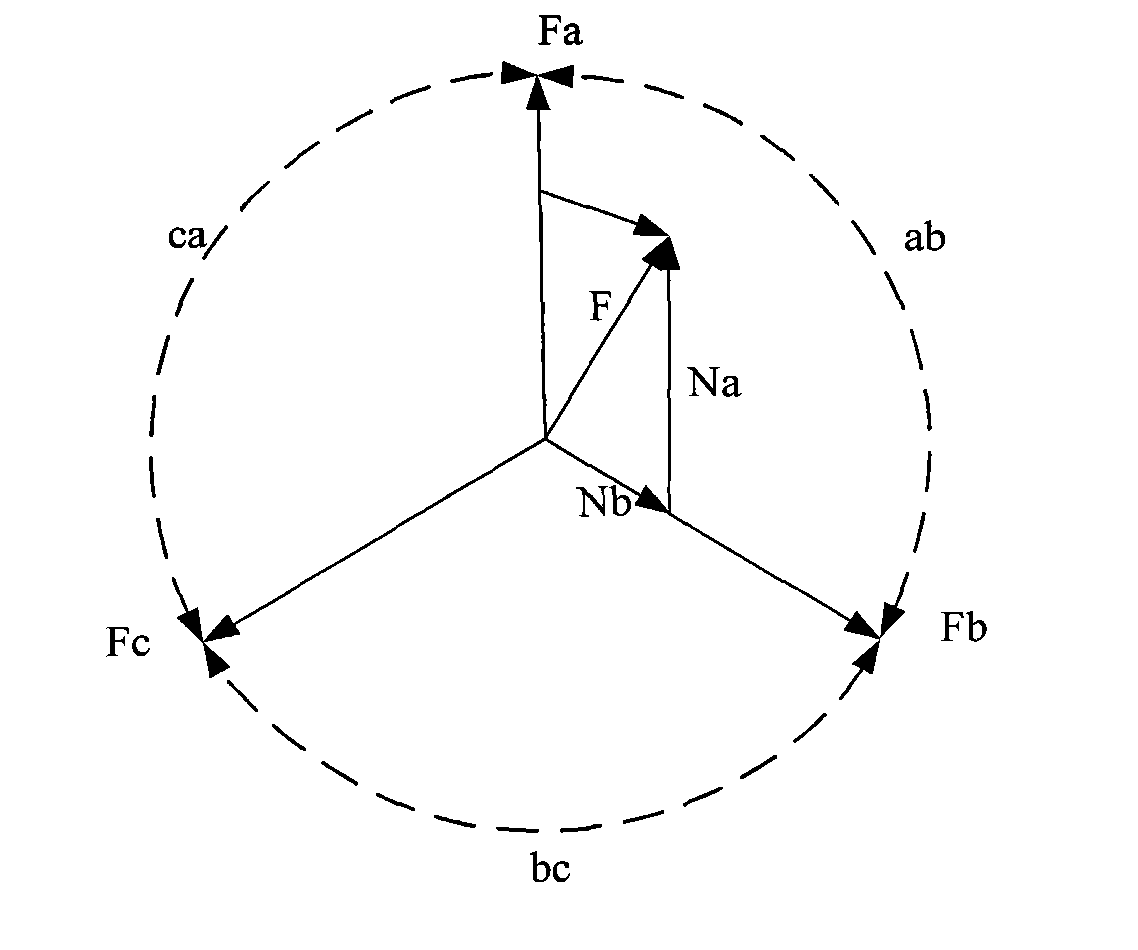

The invention relates to a direct current (ZLDL) asynchronous motor which describes a method for modifying an alternating current (AC) asynchronous motor driven by an AC voltage source into a direct current (DC) asynchronous motor driven by a direct current source. The direct current (ZLDL) asynchronous motor provides a theoretical basis for developing high-quality low-price asynchronous motor speed regulators and vehicle motors. The direct current (ZLDL) asynchronous motor gives the waveform of normal work direct current of the DC asynchronous motor and the block diagram of a drive for generating the current waveform.

Owner:HANGZHOU BAIYA MARINE MECHANICAL & ELECTRICAL TECH

Direct-current asynchronous motor and driving control method

Provided are a direct-current asynchronous motor and a driving control method. The direct-current asynchronous motor comprises a direct-current power supply, a motor, a detector, a driving converter and a controller. The driving control method leads the driving control method to be converted from an alternating-current motor driven by an alternating-current voltage source to the direct-current asynchronous motor driven by a direct-current current source; and a specific achievement scheme of a direct-current current source driving conversion circuit of the direct-current asynchronous motor is disclosed. According to the direct-current asynchronous motor and the driving control method, the performance advantages of the motor and current source driving can be brought into full play, the problems of power factor and efficiency reduction, noise increasing and the like when the alternating-current voltage source drives the asynchronous motor at low speed can be effectively solved, and theoretical basis is supplied to researching of a speed adjustment device of the asynchronous motor and the motor for the electric car which both have super quality and competitive price. The waveform of the direct current capable of leading the direct-current asynchronous motor to work normally and a block diagram of a driving device capable of generating the direct current waveform are further provided.

Owner:张加胜

Asynchronous electromechanical mixing spring-free antitheft alarming lock

InactiveCN104405198AReasonable structureEasy to manufactureNon-mechanical controlsKeysRemote controlControl theory

The invention discloses an asynchronous electromechanical mixing spring-free antitheft alarming lock. A connection body of the asynchronous electromechanical mixing spring-free antitheft alarming lock is hidden in a hidden hole and is separated from a rear lock cylinder; an expansion sheet locks a front lock cylinder; the front lock cylinder and the rear lock cylinder are completely separated and asynchronously rotate to realize alarming; an electronic remote control device is mounted in a power supply circuit of an electromagnet in a hiding manner; electromechanical interlocking hiding, mechanical interlocking, connection hiding of the front lock cylinder and the rear lock cylinder and asynchronous alarming are integrated, so that a thieve cannot open an interlocking device and rotate the rear lock cylinder; even if an external expanded lock and the connection body part are damaged by a savage way, the thieve can only rotate the front lock cylinder, and the rear lock cylinder cannot be rotated; even if the thieve drills off the front cylinder lock and the rear cylinder lock with an electric hand drill and rotates a connection tongue with a tool such as a clamp, a rotating contact is not in contact with a fixed contact, so that the power supply circuit of the electromagnet cannot be conducted; furthermore, the electronic remote control device interrupts the power supply circuit of the electromagnet, so that the thieve cannot open an insurance lock lever, and a complete and thorough burglary prevention effect is achieved.

Owner:徐毓艺

Asynchronous machine stator flux estimation system based on current model and method

ActiveCN102983806BSolve inaccurateGood flux estimation effectElectronic commutation motor controlAC motor controlStator voltageMotor speed

Owner:SUZHOU INOVANCE TECH CO LTD

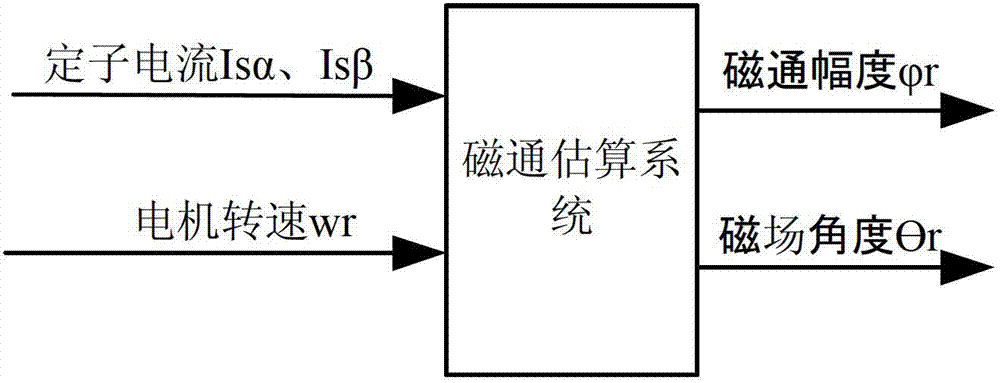

System and method for estimating magnetic flow of asynchronous machine based on current model

ActiveCN102820845ASolve inaccurateGood flux estimation effectElectronic commutation motor controlVector control systemsStator voltageEngineering

The invention provides a system for estimating the magnetic flow of an asynchronous machine based on a current model. The system comprises a stator current sampling unit, a stator voltage sampling unit, a motor rotation speed sampling unit, a coordinate converting unit, a magnetic flow calculating unit and a motor control unit, wherein the stator current sampling unit, the stator voltage sampling unit and the motor rotation speed sampling unit are respectively used for sampling stator three-phase current and stator three-phase voltage of a three-phase motor, and motor rotor rotation speed; the coordinate converting unit is used for converting the obtained stator three-phase current and the stator three-phase voltage to obtain stator current and stator voltage of alpha axis and beta axis; and the magnetic flow calculating unit is used for calculating magnetic flow amplitude and magnetic filed synchronizing angle of the motor according to the stator current and the stator voltage of the alpha axis and the beta axis, and the motor rotor rotation speed. The invention also provides a corresponding method. A good magnetic flow estimating effect is achieved by de-coupling the cross coupling item of magnetic flow estimation of the alpha axis and the beta axis in a static coordinate system.

Owner:SUZHOU INOVANCE TECH CO LTD

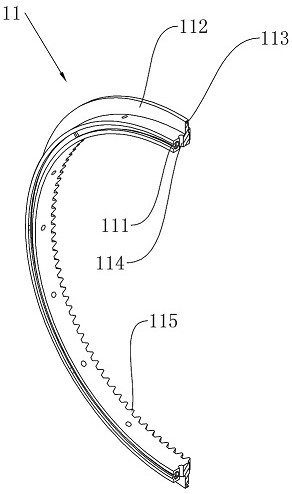

Pipeline flange connecting device and fluid equipment using same

ActiveCN114754208AClamp tightlyNot easy to separatePressurized chemical processPipe supportsRatchetControl theory

The invention relates to the technical field of pipeline connection, in particular to a pipeline flange connecting device and fluid equipment using the same. A pipeline flange connecting device comprises a first supporting part, a second supporting part, a clamping part, a ratchet mechanism, a transmission mechanism and an adjusting mechanism. The first supporting part comprises a first supporting ring frame and a first threaded ring, and the second supporting part and the first supporting part are the same in structure, are oppositely arranged and comprise a second supporting ring frame and a second threaded ring. The clamping part comprises a plurality of clamping plates arranged on the two sides of the flanges of the two pipelines. The adjusting mechanism comprises a plurality of bevel gears, a plurality of handles, an asynchronous mechanism and a switching part. According to the pipeline flange connecting device, the first threaded ring and the second threaded ring are firstly driven to rotate synchronously, so that the two flanges are close to each other, and the first pipeline and the second pipeline are connected. And then one threaded ring is fixed, and the other threaded ring is rotated, so that the flange is clamped more tightly. The fluid equipment using the connecting device is not prone to liquid leakage.

Owner:NANTONG CILDON BOSSH FLUID EQUIP

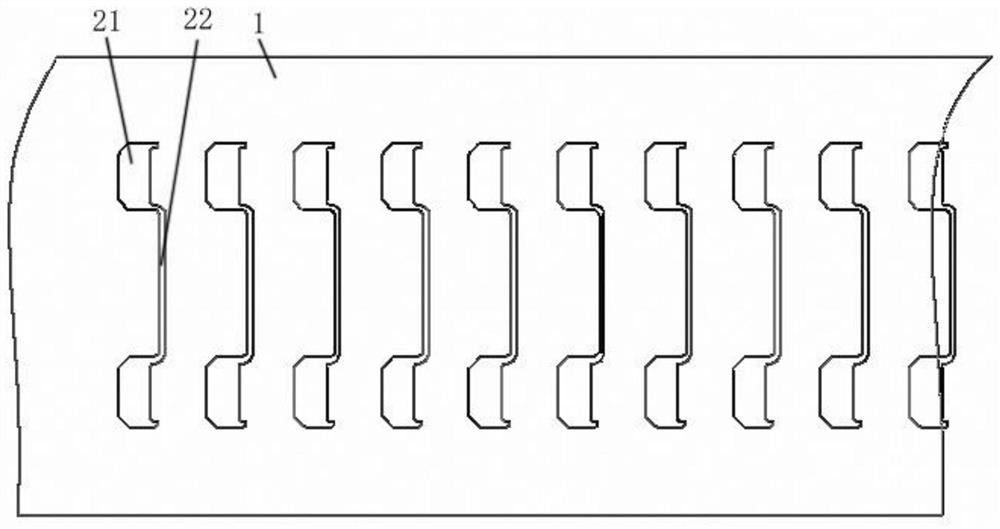

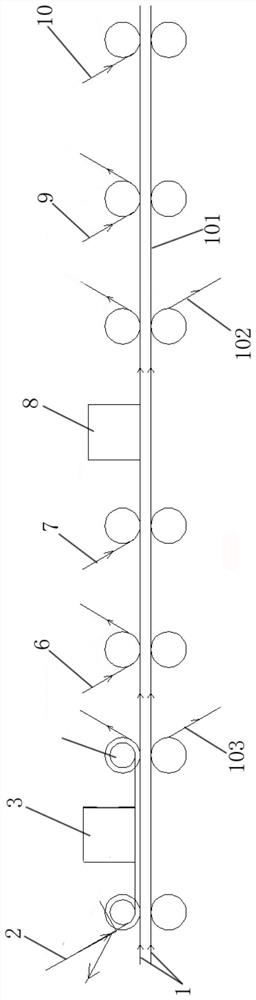

Machining process for solving waste discharging and material saving

InactiveCN113233226ALow costReduce processing costsFilm/foil adhesivesMetal working apparatusProduction lineEngineering

The invention provides a machining process for solving waste discharging and material saving. Punching and compounding are conducted through a single production line, finished products are output, the machining cost is reduced, and the machining precision is high. A roll material advances along a roller way by a jumping distance A, double-faced adhesive tape advances by a jumping distance B through an asynchronous machine after a lower release film of the double-faced adhesive tape is peeled off, the portions, with the first area shapes, of the double-faced adhesive tape are punched by knives A to be compounded on the upper surface layer of the roll material, A is larger than B, and then the roll material carries the double-faced adhesive tape with the first area shapes arranged at intervals to advance step by step. Upper release films on the portions, corresponding to the first area shapes, of the double-faced adhesive tape are rolled up through box sealing adhesive tape, then a complete PET film is compounded on the upper surface formed by the double-faced adhesive tape and the roll material, the portions, with the first area shapes, of the double-faced adhesive tape are punched again through knives B, then waste is discharged through the PET film, and the residual PET film connected to the upper surface of the double-faced adhesive tape is rolled up through the box sealing adhesive tape again. Then, injection-molded parts are attached to the double-faced adhesive tape in the set shape one by one, and finally a finished product is obtained through roll material rolling.

Owner:SUZHOU ANJIE TECH

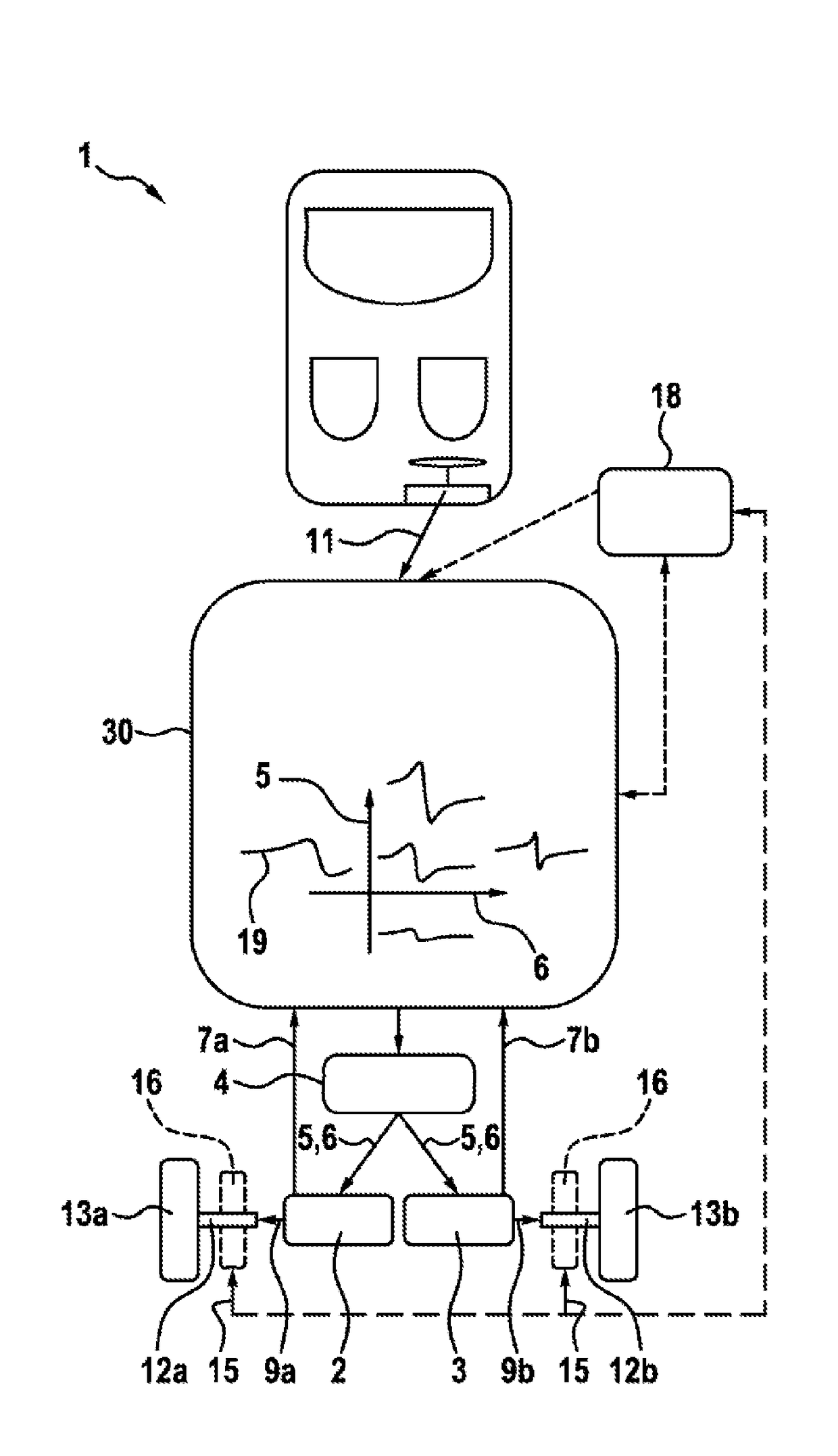

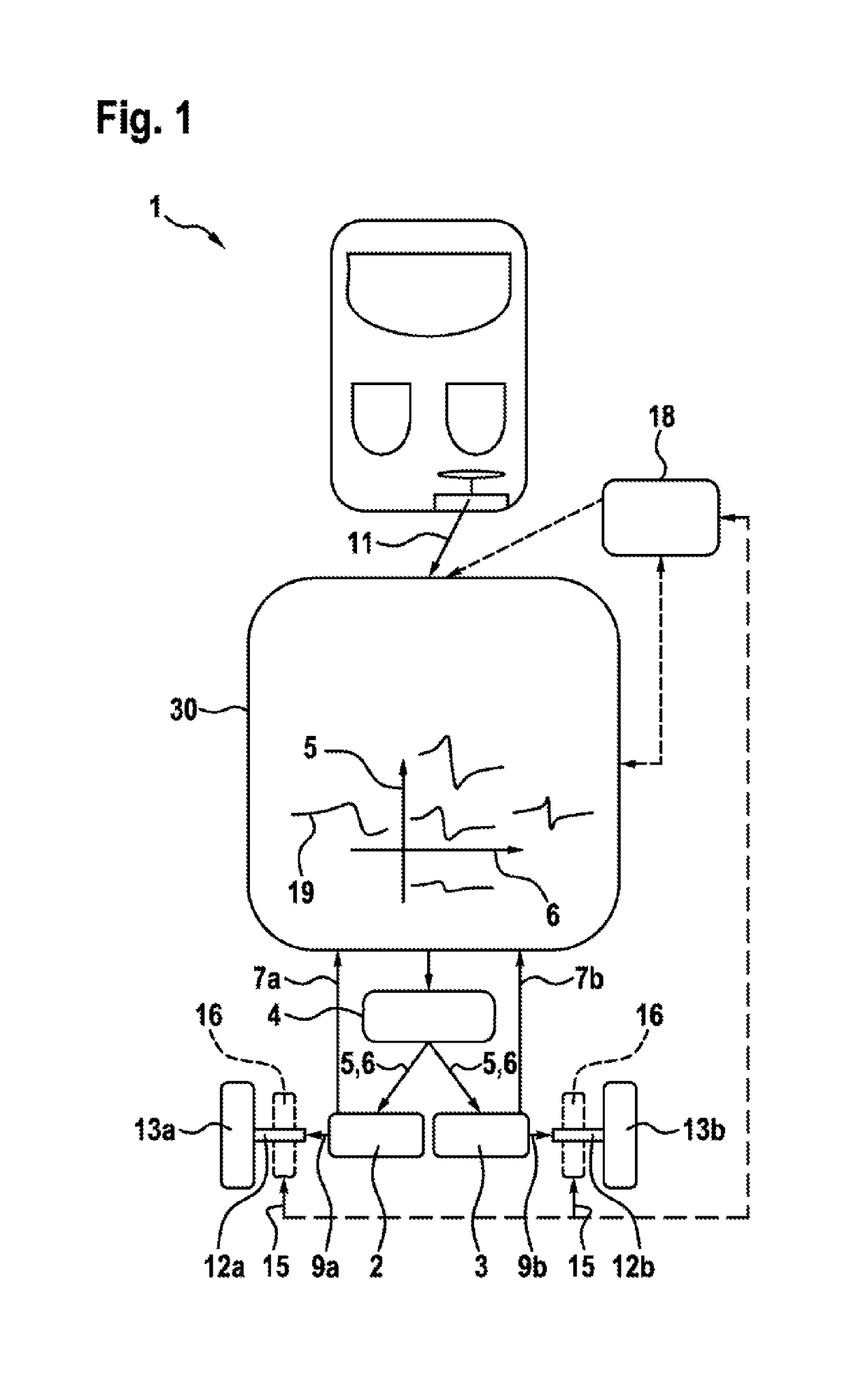

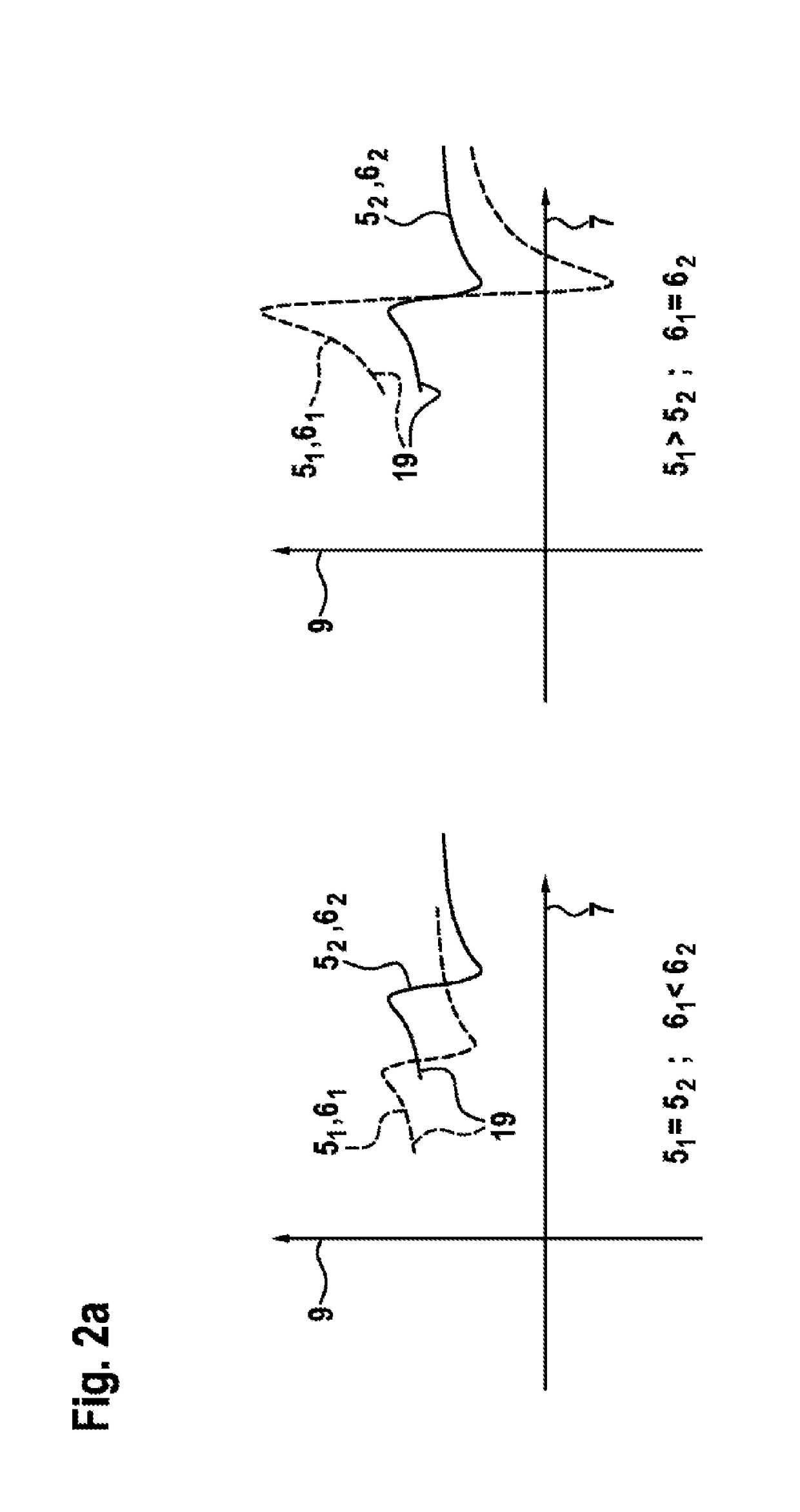

Control device and method for jointly controlling asynchronous machines of a motor vehicle

ActiveUS20180013361A1Reduce spacingReduce weightHybrid vehiclesSpeed controllerStator voltageControl engineering

The invention relates to a method for jointly controlling asynchronous machines (2; 3) of a motor vehicle (1) having a first asynchronous machine (2) and a second asynchronous machine (3) for driving the motor vehicle (1); an inverter (4), which is designed to supply the first asynchronous machine (2) and the second asynchronous machine (3) with a common stator voltage (5) at a common stator frequency (6). The method comprises the steps of determining a specified setpoint drive torque (11) of the motor vehicle (1) for a current driving situation of the motor vehicle (1); sensing a first rotational speed (7a) of the first asynchronous machine (2) and a second rotational speed (7b) of the second asynchronous machine (3); determining a common operating strategy of the first asynchronous machine (2) and of the second asynchronous machine (3) according to the specified setpoint torque (11) while taking into account the sensed rotational speeds (7a; 7b); and controlling the stator voltage (5) and the stator frequency (6) in order to set the drive torques (9a; 9b) of the asynchronous machines (2; 3) according to the operating strategy.

Owner:ROBERT BOSCH GMBH

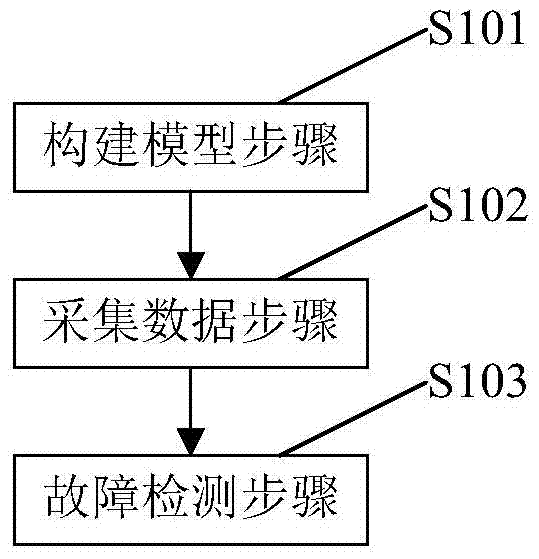

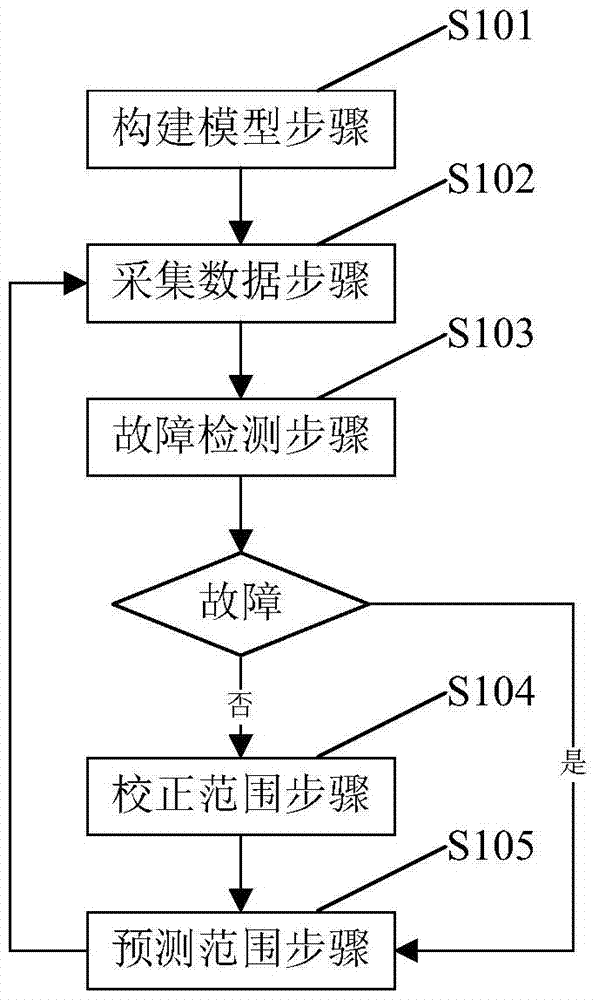

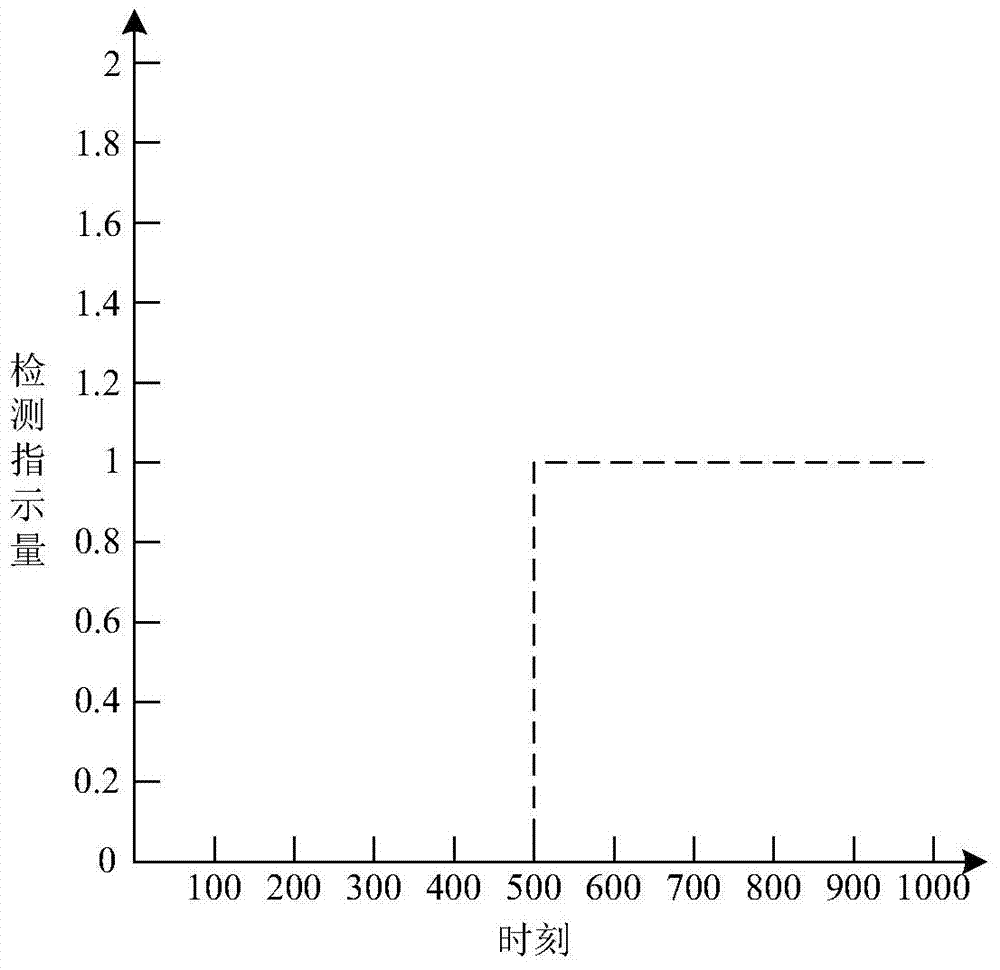

A Fault Detection Method for Asynchronous Traction Motor

ActiveCN104569819BNo failureGuarantee application requirementsDynamo-electric machine testingElectric machineState space

The invention discloses a fault detection method of an asynchronous traction motor, which belongs to the technical field of fault diagnosis, so that the fault detection method of the asynchronous traction motor of a high-speed railway train can still be accurately detected when the constructed model has uncertainty break down. The detection method of the asynchronous traction motor includes: building a model step: constructing a discrete state space model of the asynchronous traction motor; collecting data step: collecting output current data and input voltage data of the asynchronous traction motor at the current moment; fault detection step : Obtain the pre-stored state range of the asynchronous traction motor at the current moment, combine the output current data and the input voltage data, and use the discrete state space model to detect whether there is a fault in the asynchronous traction motor. This method is suitable for asynchronous traction motors of high-speed railway trains.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com