Water-cooled asynchronous motor for hybrid vehicle

A hybrid electric vehicle and asynchronous motor technology, which is applied to asynchronous induction motors, electric components, electrical components, etc., can solve the problems of harsh use environment and front-end bearing burning, and achieve easy hot extrusion, smooth water flow, and uniform heat dissipation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

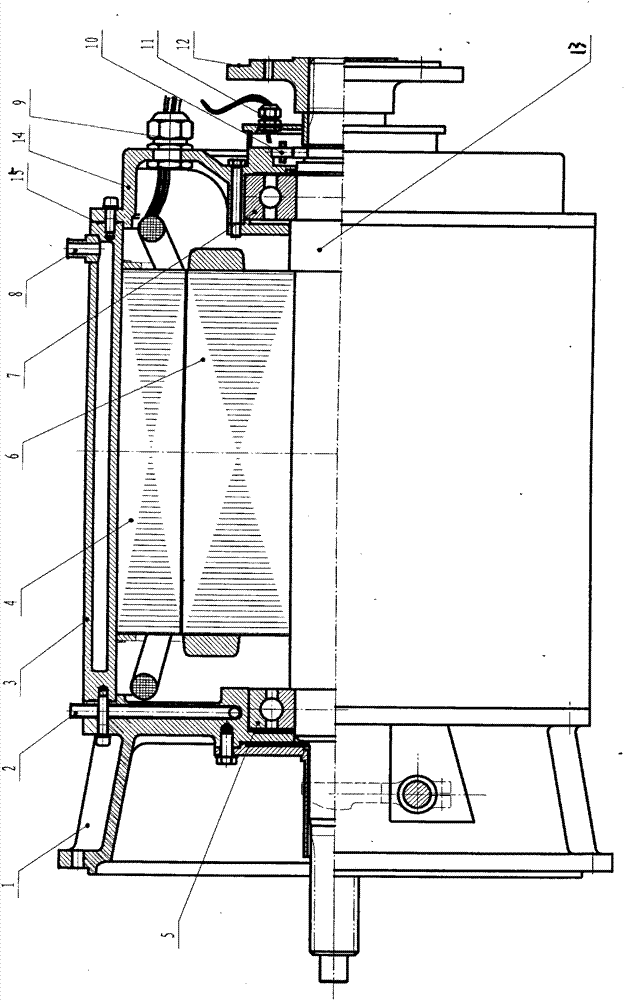

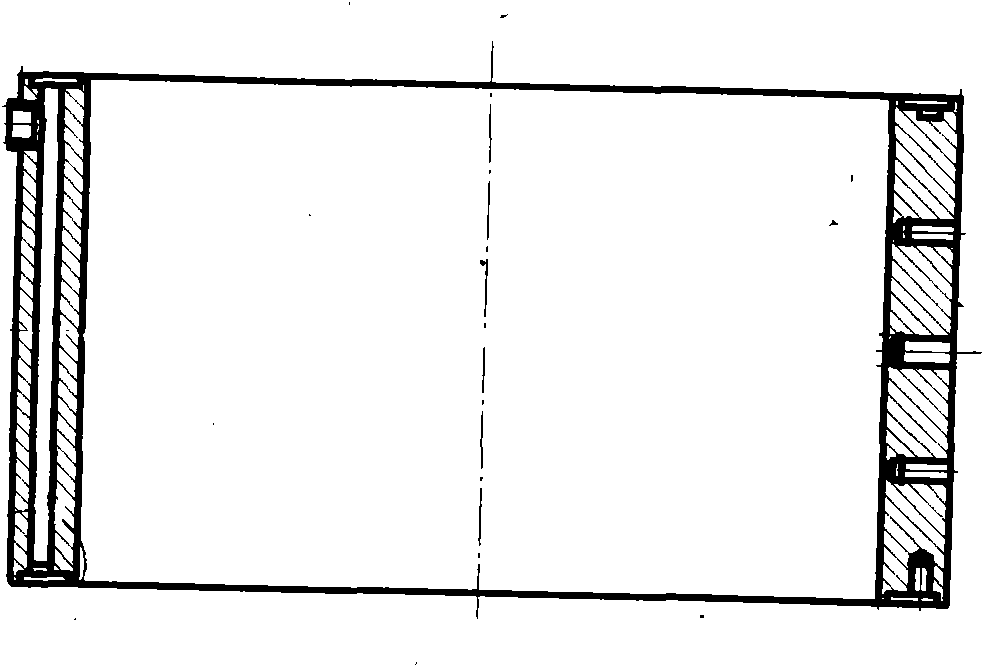

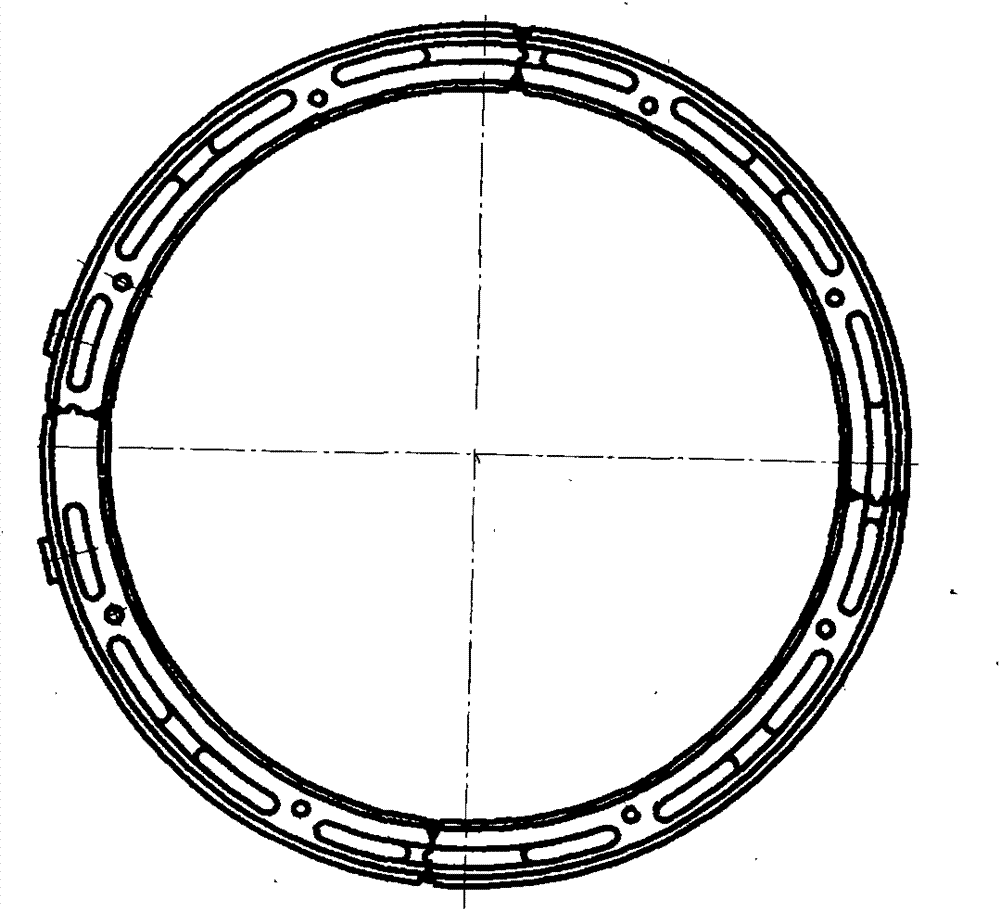

[0030] There is an asynchronous motor main shaft 13, the front end of the main shaft is provided with a front end cover 1 which is connected with a cooling water pipe through the front bearing 5, the front end cover is provided with a front cover water inlet and outlet 2, and the rear end of the front cover is connected with an internal set. The water-cooled casing 3 of the cooling water pipe, the motor stator 4 is installed at the inner end of the water-cooled casing, the rotor 6 that is matched with it and fixed on the main shaft is installed in the stator, the water-cooled casing is provided with a water-cooled casing inlet and outlet 8, and the water-cooled casing A sealing ring (pad) 15 is provided at the upper and lower end faces in the axial direction, and the other end of the water-cooled casing is provided with a rear end cover 14 fixedly connected to the rear bearing 7; The rear end of the end cover is also connected with a resolver 10 , a resolver outlet sheath 11 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com