Machining process for solving waste discharging and material saving

A processing technology and material-saving technology, which is applied in the field of material punching and compounding, and can solve the problems of high cost, small product size, and difficulty in forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

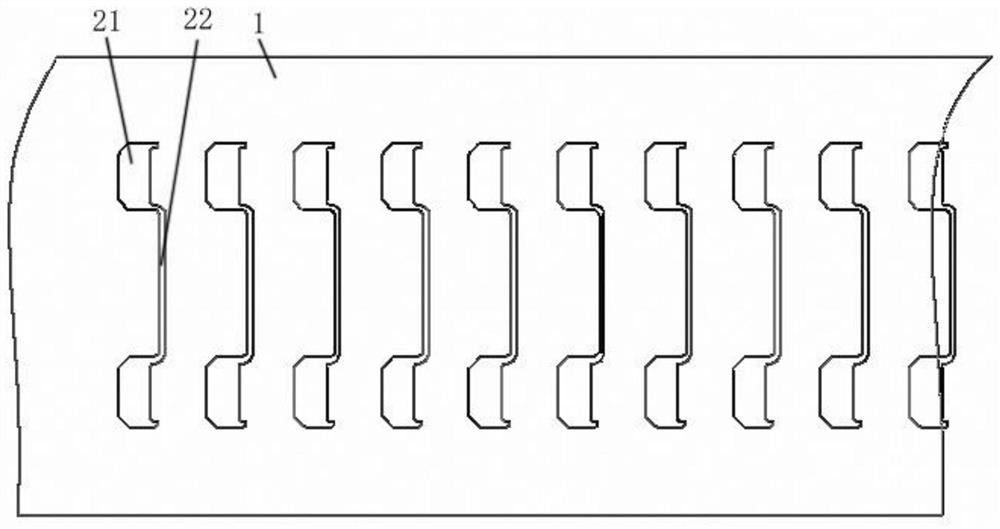

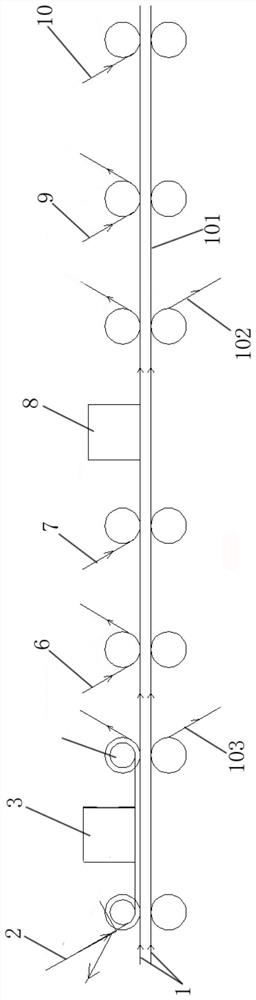

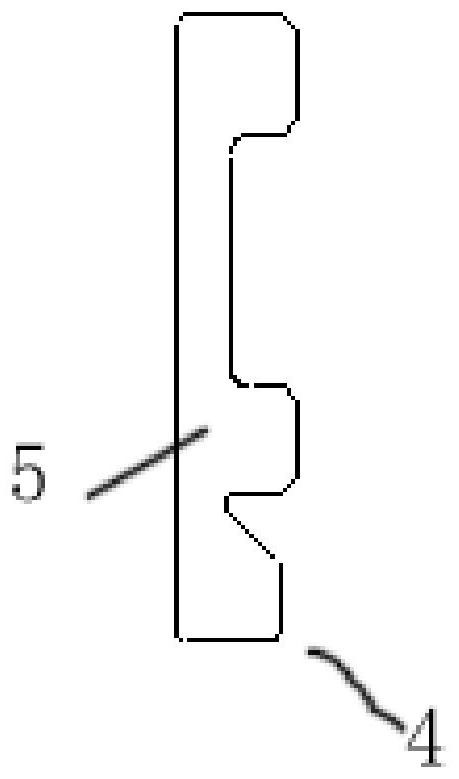

[0024] A processing technology that solves waste discharge and saves materials, see Figure 1-Figure 5 : Coil material 1 advances along the roller table with skipping distance A, double-sided adhesive tape 2 peels off the lower release film, passes through asynchronous machine 3 skipping distance B, and punches double-sided tape with shape 5 in the first area through A knife 4 2 Composite on the upper surface layer of the roll material 1, wherein A is greater than B, and then the roll material 1 carries the double-sided adhesive tape with the first area shape 5 arranged at intervals in 2 steps, and the first side is rewound by the first sealing tape 6 The upper release film of the double-sided adhesive 2 corresponding to the domain shape 5, and then the complete PET film 7 is compounded on the upper surface formed by the double-sided adhesive 2 and the roll material 1, and the first area is punched again by the B knife 8 The double-sided adhesive 2 of shape 5 is then discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com