Permanent magnet synchronous motor

A permanent magnet synchronous, motor technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, manufacturing stator/rotor body, etc. The problem of low multiples can improve the axial ventilation effect, reduce the vibration phenomenon, and reduce the demagnetization intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

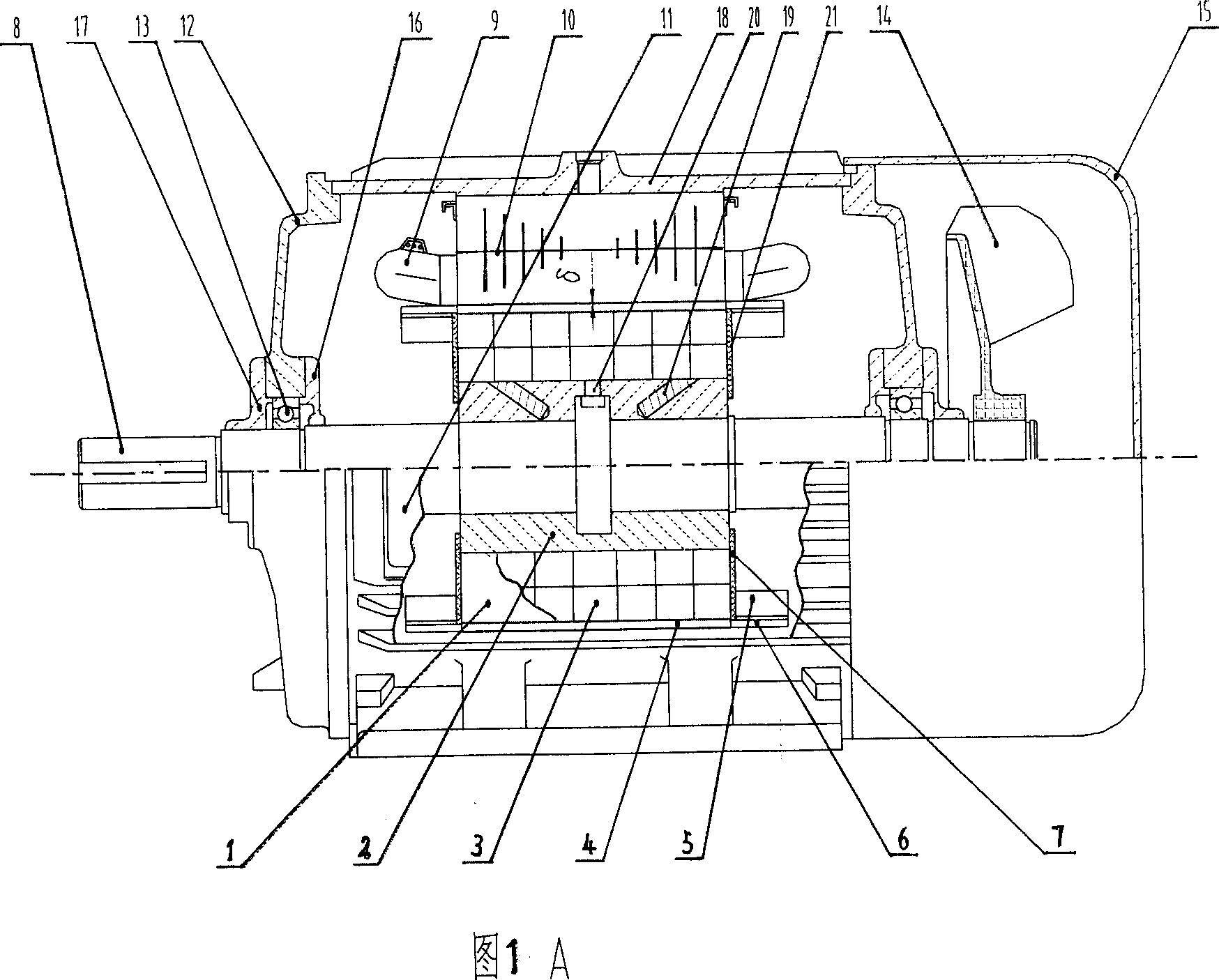

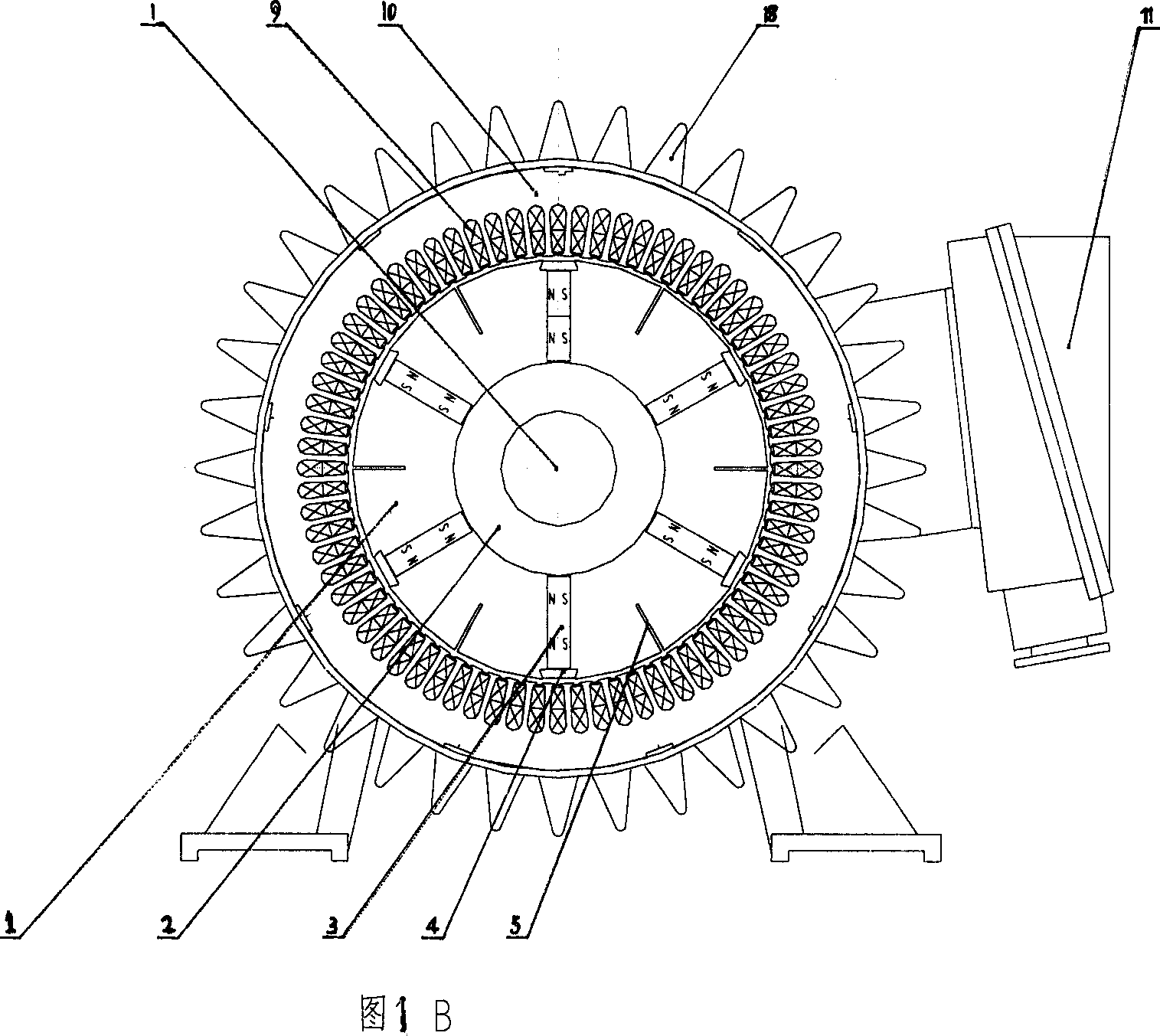

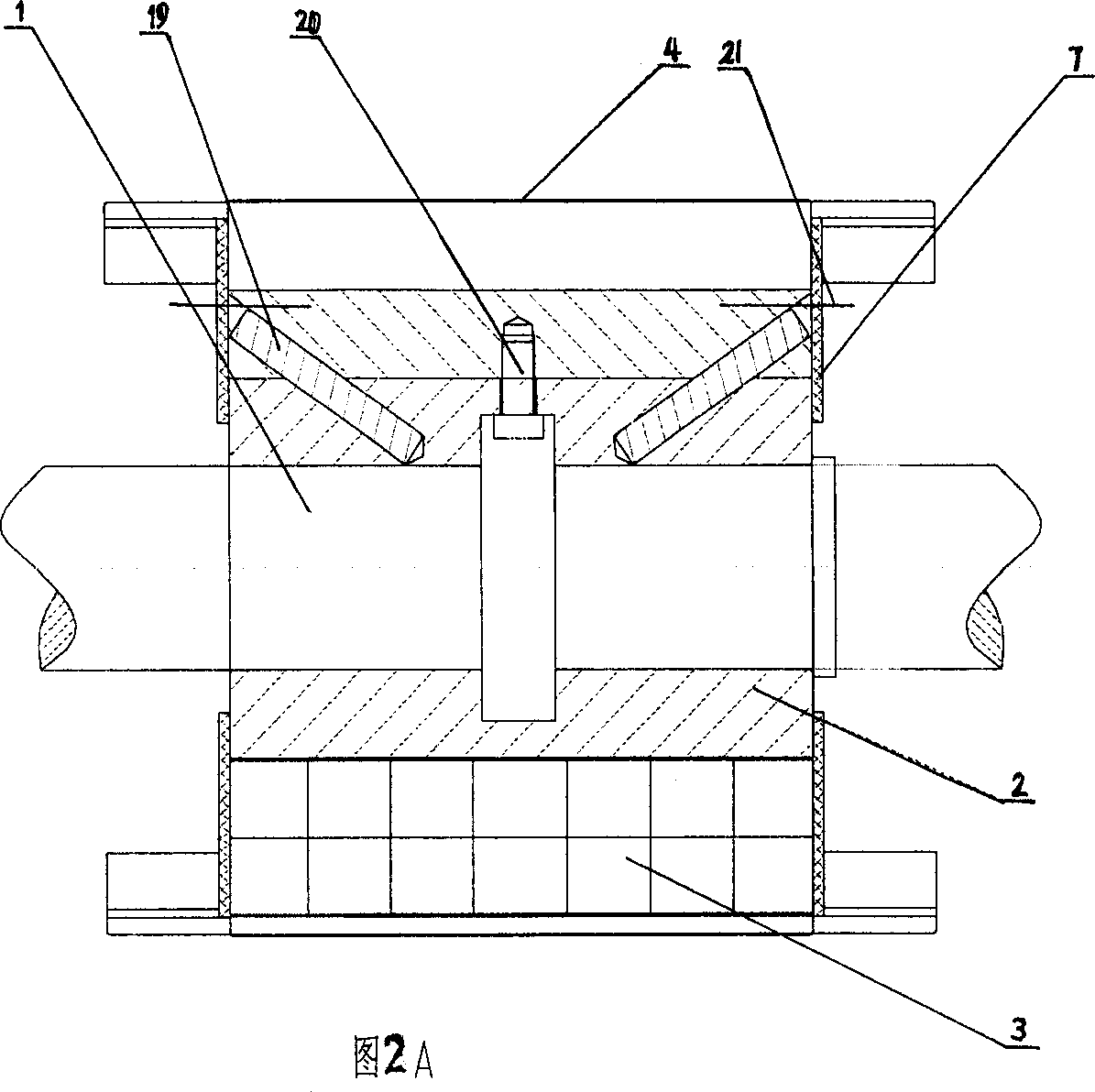

[0071] The permanent magnet synchronous motor with rare earth NdFeB excitation of the present invention has a capacity of 15KW, and its large air gap δ m Ratio to the minimum air gap δ: δ m / δ=1.7 / 1.7 (as shown in Figure 1); polar arc coefficient α=0.84; copper end ring thickness × width is 3 × 40 (mm); central small groove width / height is 1.5mm / 26mm (Figure 3A); each A permanent magnet a × b × h is 19mm × 20mm × 12mm. The ratio of the side length a of the rectangular block to the thickness h in the direction of magnetization is a / h≤2.5 (Figure 6).

Embodiment 2

[0073] The permanent magnet synchronous motor with rare earth NdFeB excitation of the present invention has a capacity of 45KW, and its large air gap δ m Ratio to the minimum air gap δ: δ m / δ=2.9 / 2.9 (as shown in Figure 1); polar arc coefficient α=0.845; copper end ring thickness × width is 3 × 45 (mm); central small groove width / height is 2mm / 32mm (Figure 3B); each The permanent magnet a×b×h is 28mm×30.8mm×20mm. The ratio of the side length a of the rectangular block to the thickness h in the direction of magnetization is a / h≤2.5 (Figure 6).

Embodiment 3

[0075] The permanent magnet synchronous motor with rare earth NdFeB excitation of the present invention has a capacity of 315KW, and its large air gap δ m Ratio to the minimum air gap δ: δ m / δ=4.2 / 6.1 (as shown in Figure 1); polar arc coefficient α=0.82; copper end ring thickness × width is 4 × 55 (mm); central small groove width / height is 4mm / 40mm (Figure 3C); each The permanent magnet a×b×h is 39.4mm×39.4mm×32.8mm. The ratio of the side length a of the rectangular block to the thickness h in the direction of magnetization is a / h≤2.5 (Figure 6).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com