A rotor structure with split pressing plate

A rotor structure, split technology, applied in the magnetic circuit shape/style/structure, magnetic circuit rotating parts and other directions, can solve the problems of poor axial ventilation of the magnetic pole module, potential safety hazards, rework, etc., to reduce the frequency of rework, improve Work efficiency and the effect of eliminating safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

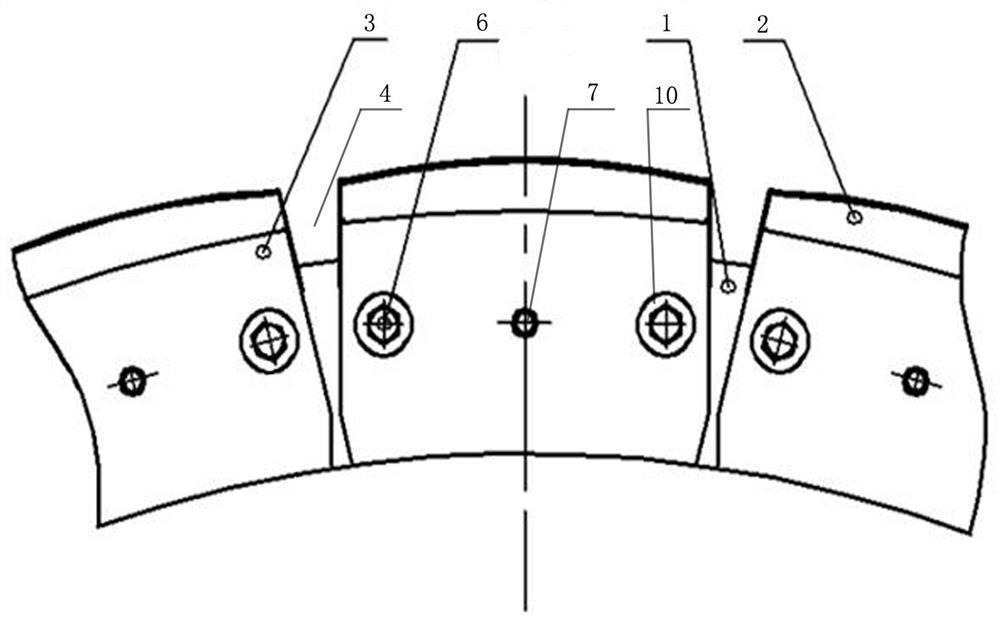

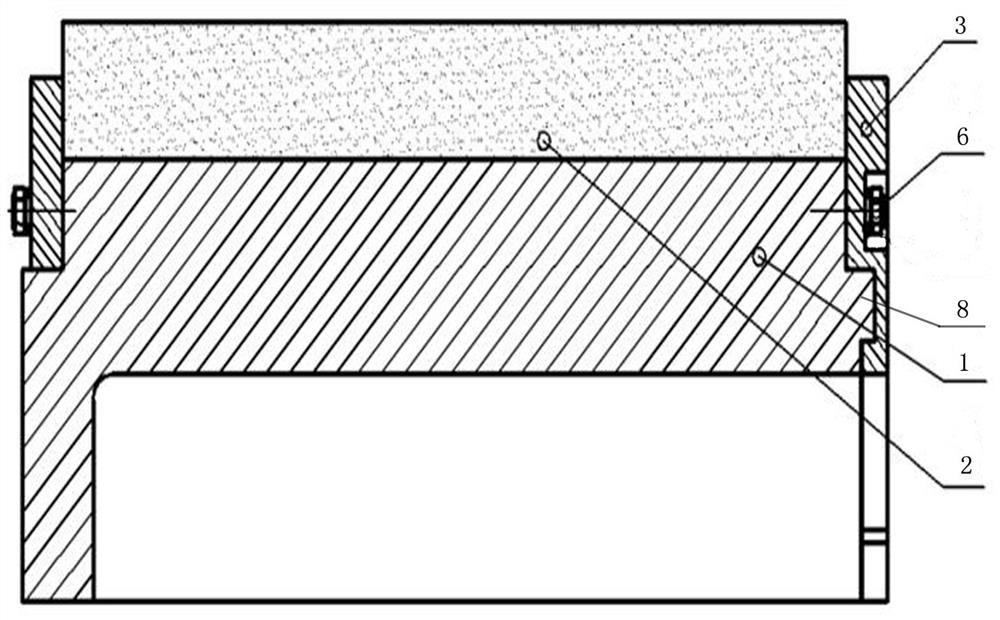

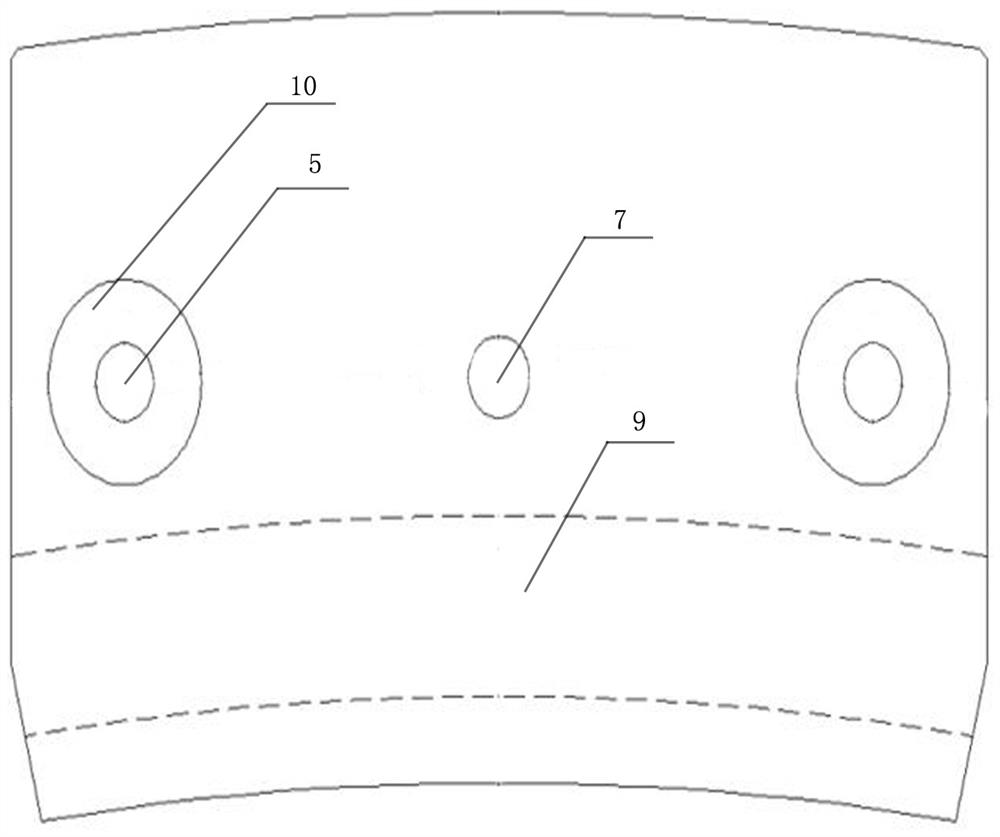

[0012] refer to Figure 1 to Figure 4 , a rotor structure with a split pressure plate in the present invention, including a rotor yoke 1, a plurality of split magnetic pole modules 2 are evenly distributed on the outer circumference of the rotor yoke 1, and the axial ends of the rotor yoke 1 are provided with Press the pressure plate of the magnetic pole module 2, and the pressure plate at least one end of the rotor yoke 1 is set as a split type pressure plate (the "at least" here includes two technical solutions: one is that both ends of the rotor yoke 1 are set as split. One-piece pressure plate, the other is that one end of the rotor yoke 1 is set as a split type pressure plate, and the other end adopts an existing integrated pressure plate), the split type pressure plate is composed of several concentric and equal-diameter fan rings or deformed fan ring baffles 3 components ("concentric" means the center of the circle is the same, "equal diameter" means that the inner diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com