Oil field winch direct drive motor

A direct-drive motor and winch technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of the general heat dissipation effect of the motor and the inability to completely and effectively suppress the temperature rise of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

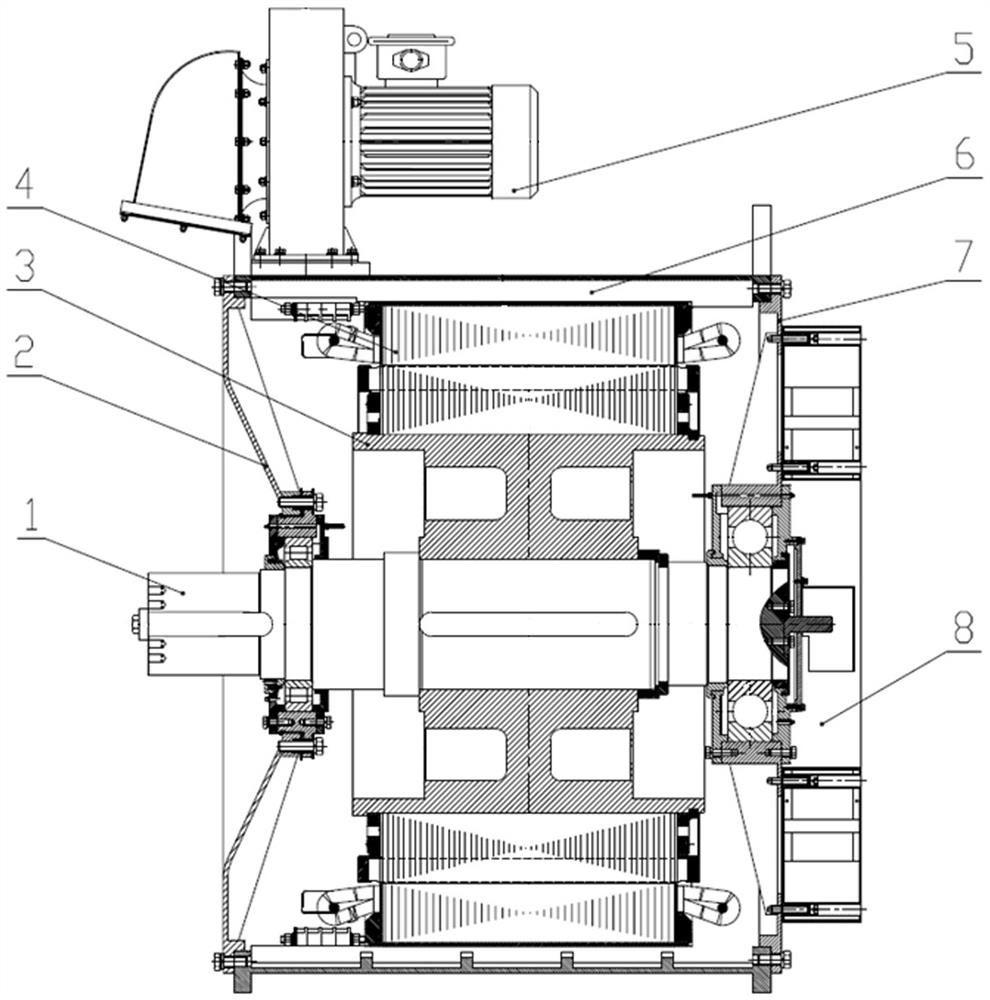

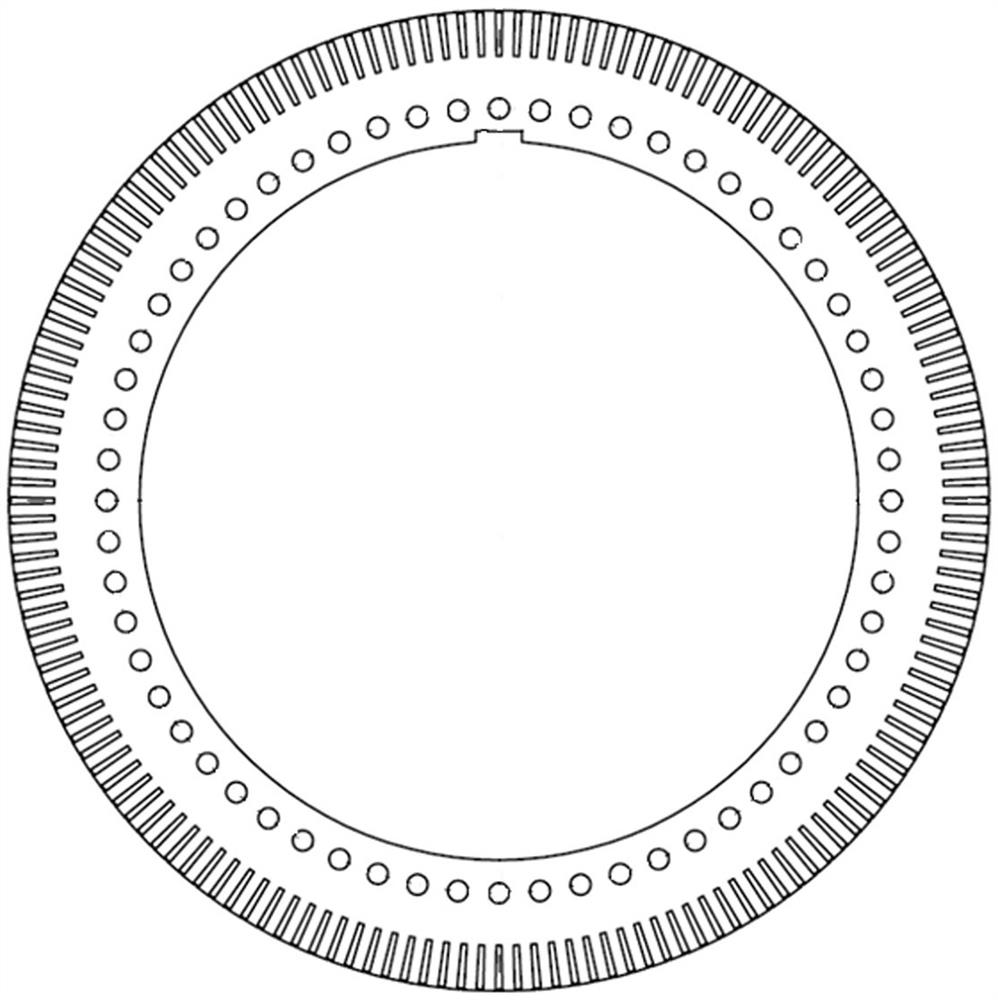

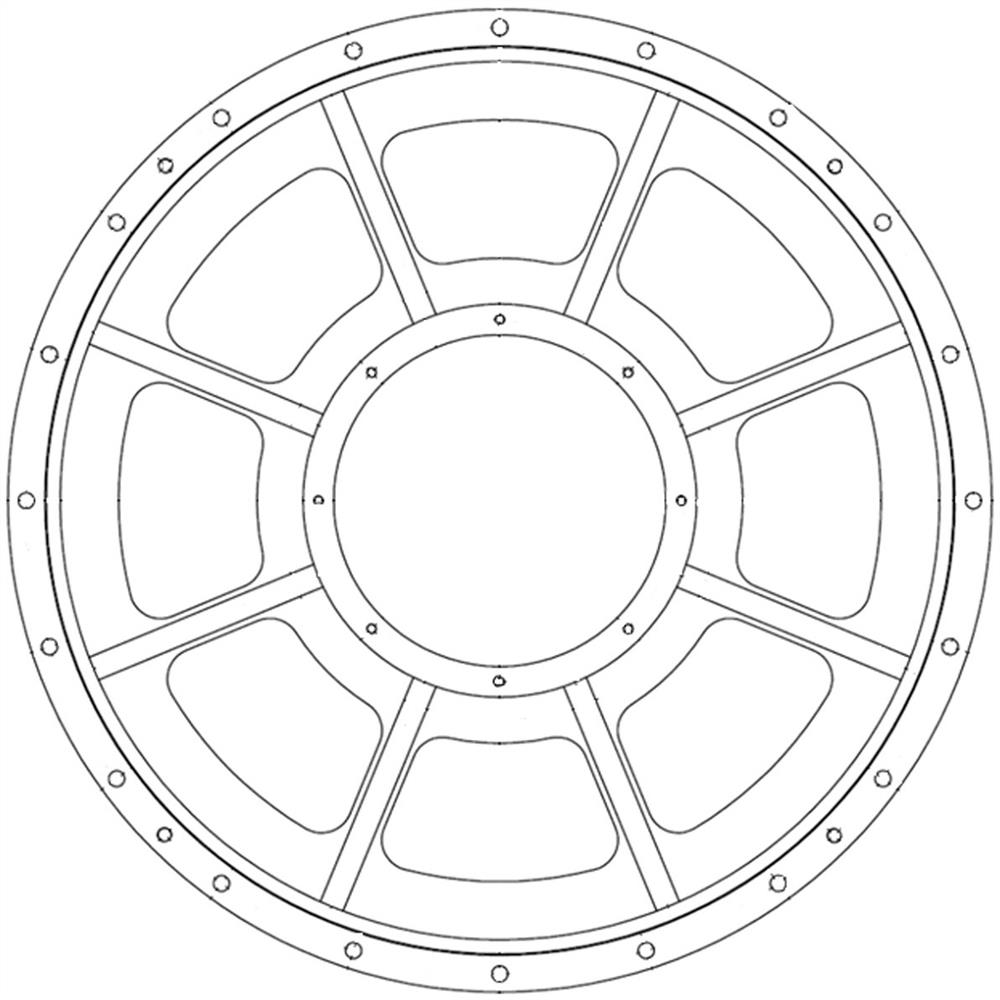

[0025] The patent of the present invention provides a direct drive motor for an oilfield winch, which mainly includes a rotating shaft 1, a rear end cover 2, a rotor 3, a stator 4, a fan 5, a frame 6, a front cover 7 and an air outlet cover 8. Such as figure 2 As shown, the rotor 3 adopts the spoke shaft support structure, and the rotor punching adopts a circular sheet structure, which can save the raw material of the rotor punching and meet the requirement of the large diameter of the rotor; The raw material of the stator punching sheet, and the stator and rotor slots match 144 / 160, and the number of poles is 12. This structure increases the outer diameter of the stator while keeping the volume basically unchanged, shortens the length of the iron core, and the overall electromagnetic load is low, which can effectively improve the rotation speed of the motor. Moment density; the front end cover 7 is equipped with an air outlet cover 8 parts, which are fastened with hexagon so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com