External spline shaft hub motor

A technology of external splines and shaft wheels, applied in the field of vehicle motors, can solve the problems of staying in the development stage, immature technology, complex applicability, etc., and achieve reliable performance, easy pole-changing speed regulation, complex control, and heat dissipation performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

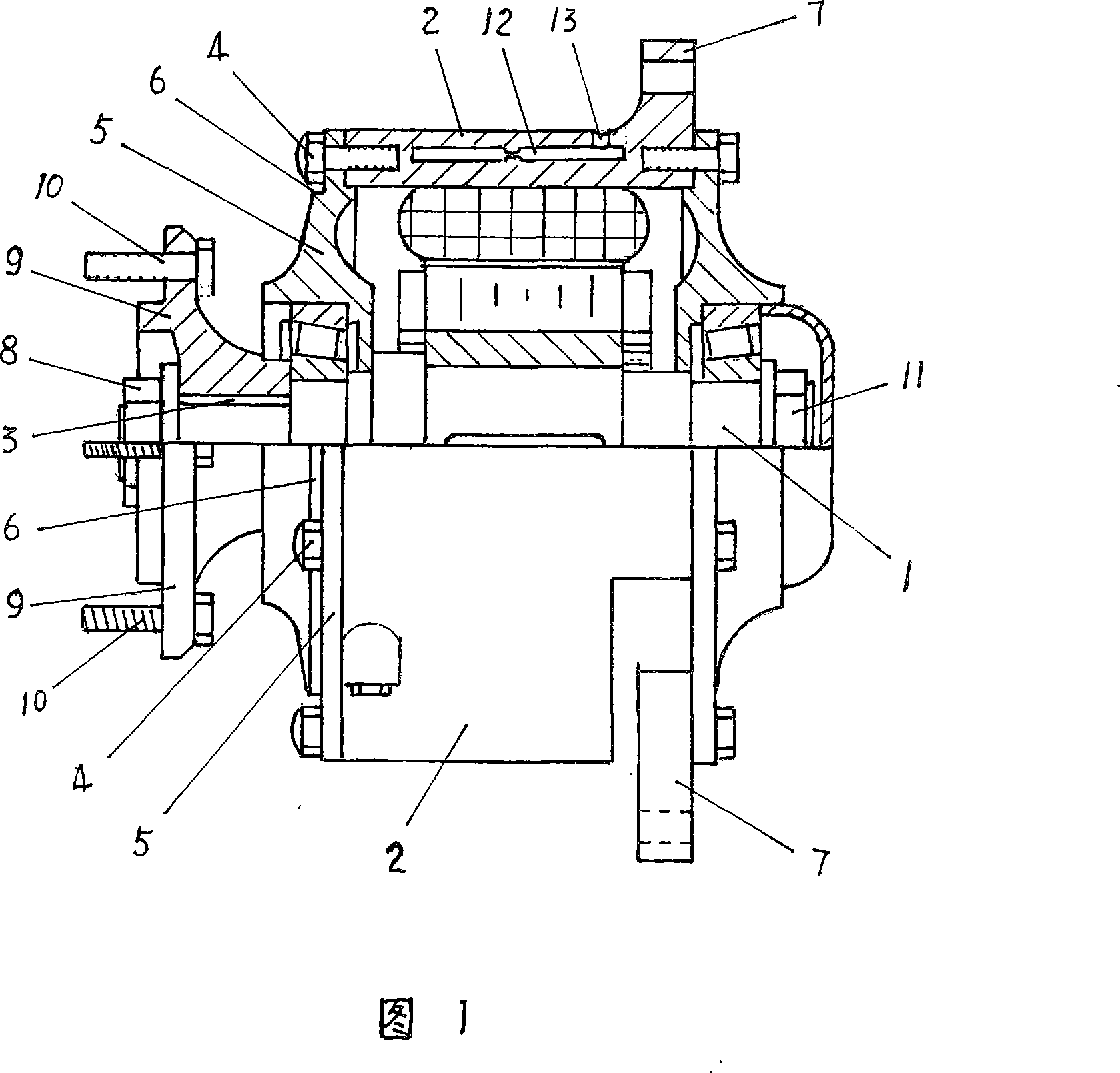

[0015] In accompanying drawing 1: the outer end of motor shaft 1 is provided with external spline 3, is installed with wheel connector 9 through fixing nut 8, and is installed with wheel bolt 10, and the inner end of motor shaft 1 is equipped with clearance adjustment nut 11 , used to adjust the bearing clearance, that is, to adjust the wheel clearance in practical applications; the outer shell 2 is equipped with multi-purpose bolts 4, and an outer end cover 5 is installed, and the outer end cover 5 is provided with positioning steps 6, and multi-purpose bolts 4 Together, it is used for the installation and fixing of the brake base plate 15 or the brake caliper bracket 17; the two sides of the casing 2 are provided with the motor base 7 perpendicular to the motor shaft 1; the casing 2 is provided with a cooling water chamber 12, and is equipped with a cooling Water circulation port 13.

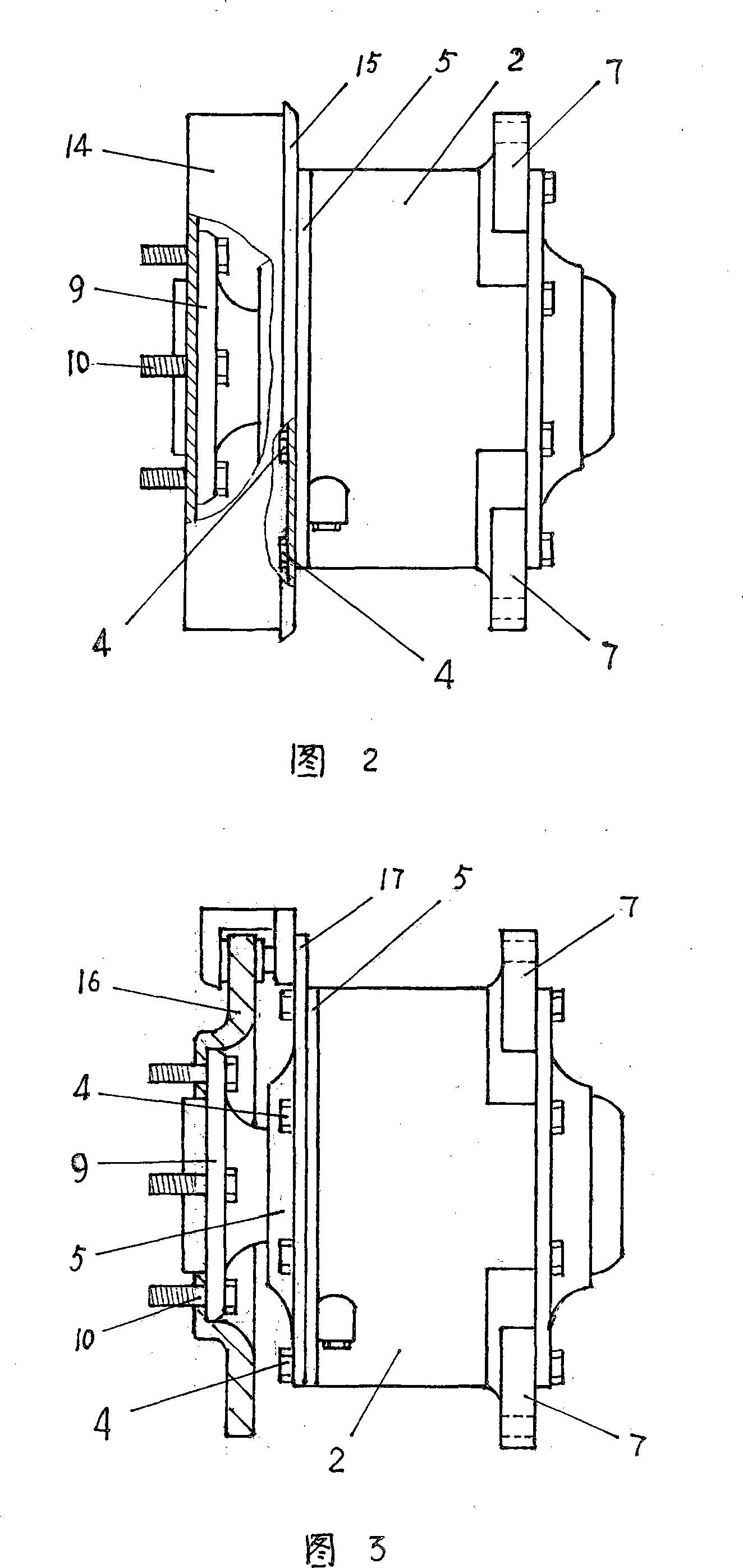

[0016] In accompanying drawings 2 and 3: the brake drum 14 or the brake disc 16 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com