Machine tool control method and control device

A technology of operating machinery and control methods, which is applied in the direction of automatic control devices, feeding devices, program control, etc., can solve the problems of cutting edge loss of processing tools, poor roughness of processing surfaces, etc., to increase processing time and improve roughness of processing surfaces degree, the effect of preventing chattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, embodiments to which the control method and control device for a working machine according to the present invention are applied will be described in detail with reference to the drawings. In addition, this invention is not limited to this embodiment.

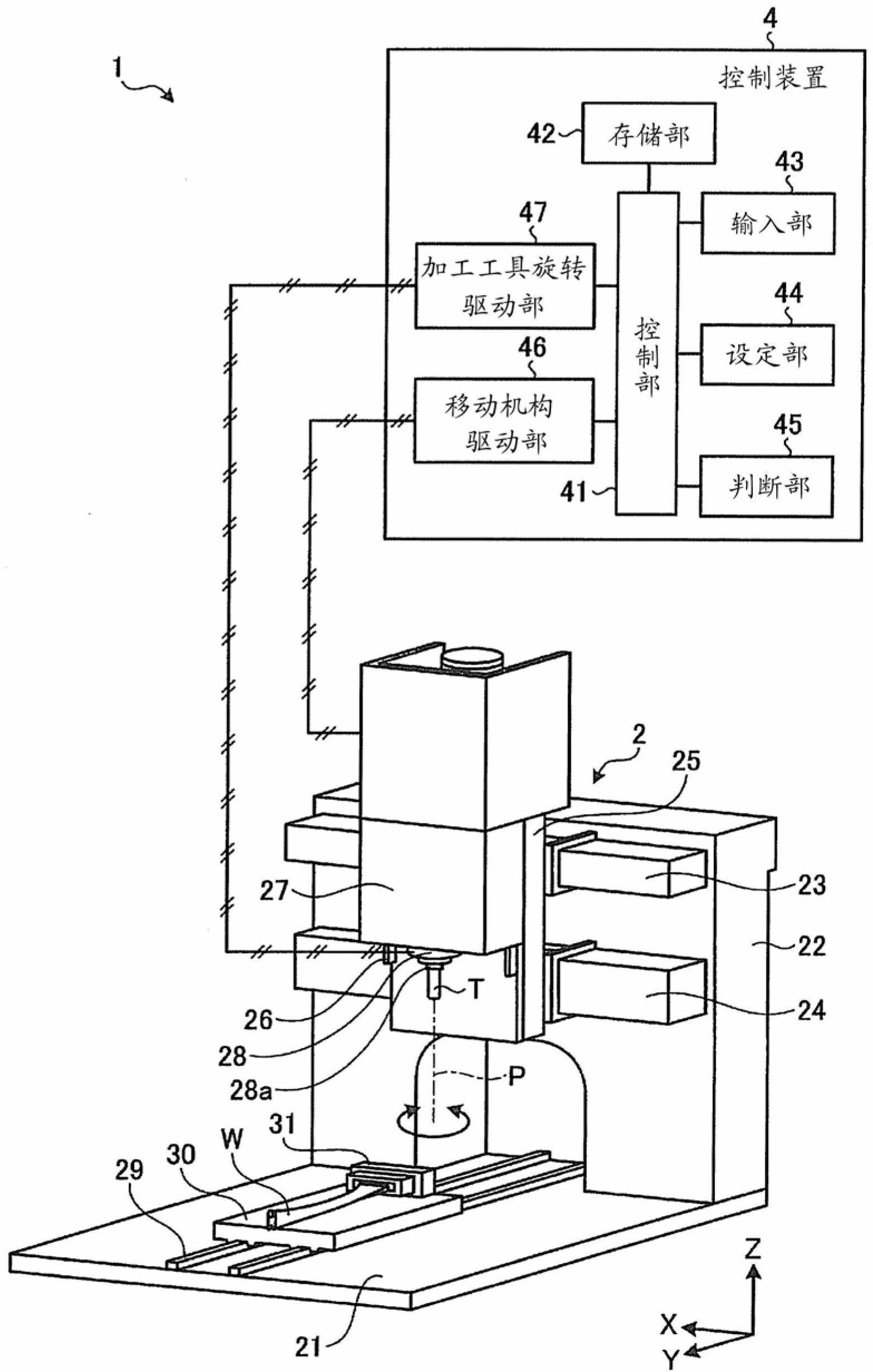

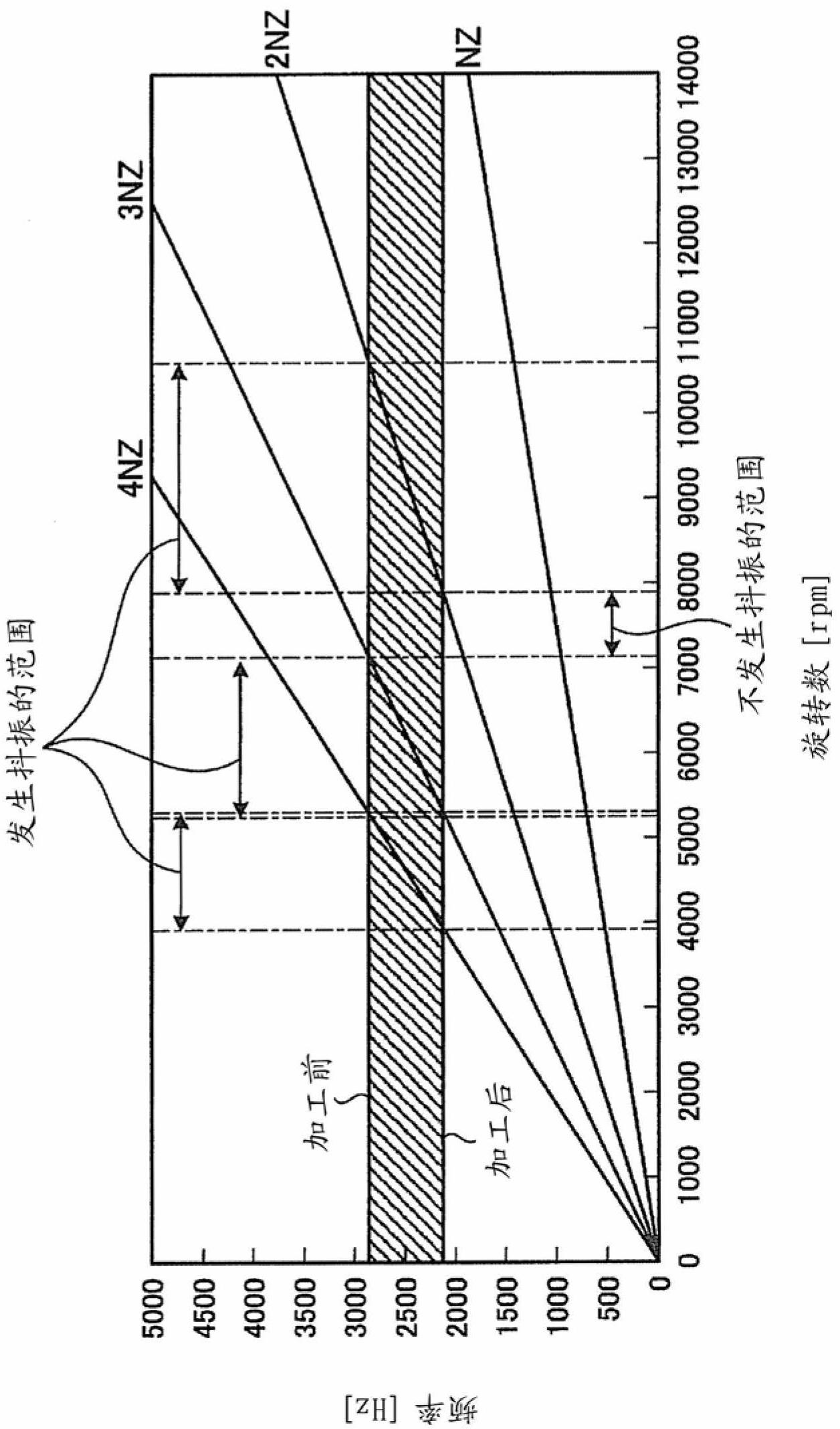

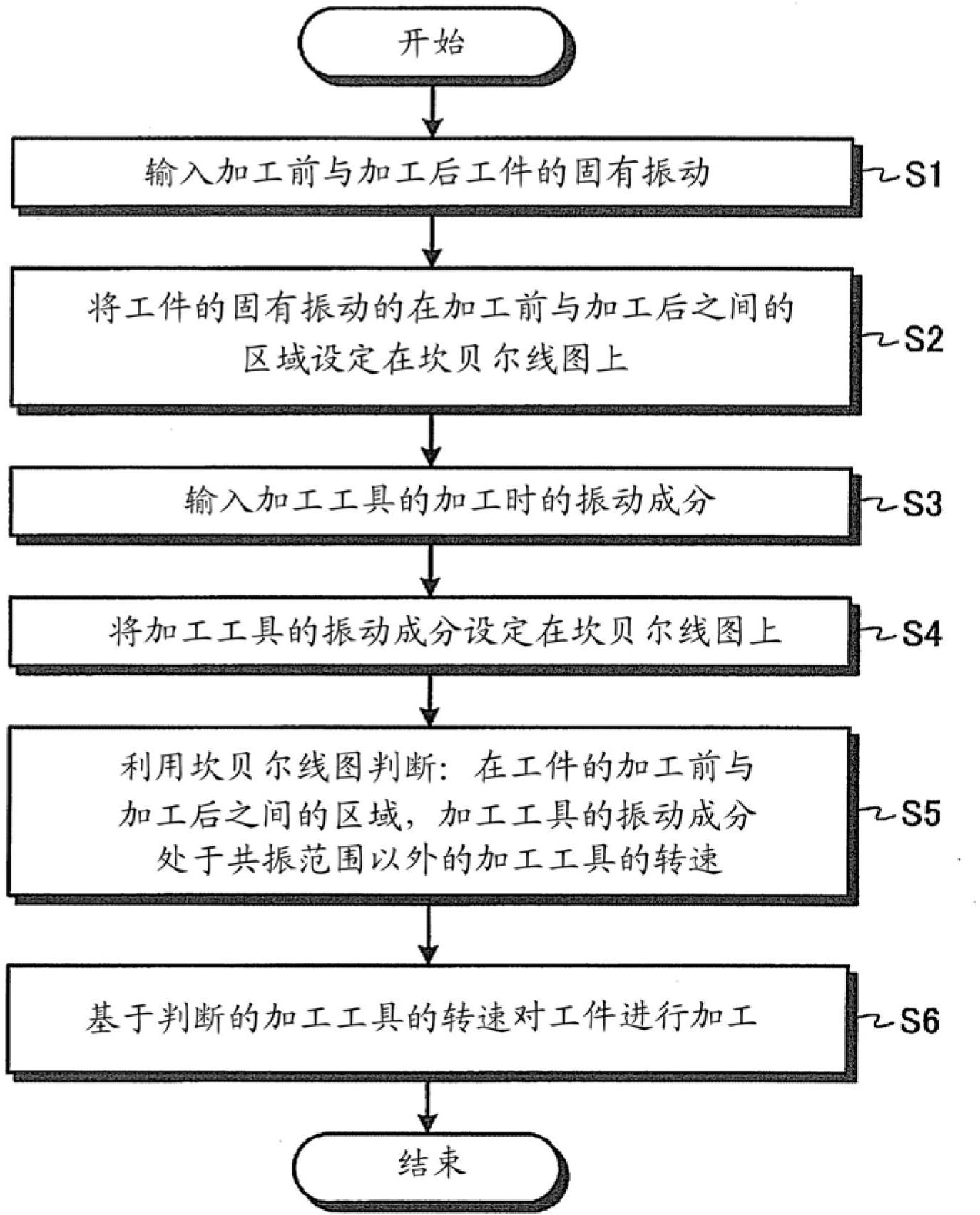

[0024] figure 1 is a schematic configuration diagram showing a working machine control device according to an embodiment of the present invention, figure 2 is a Campbell diagram for judging the working conditions of the machining tool, image 3 yes figure 1 A flow chart of the operation (control method) of the control device of the working machine is shown.

[0025] Such as figure 1 As shown, a workpiece processing device 1 as a working machine has a processing unit 2 and a control device 4 .

[0026] A base 21 is provided at the lower part of the processing part 2 . A door-shaped pillar 22 is arranged on the base 21 . A mount 25 is reciprocally supported on the front surface of the pillar 22 via guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com