Machining process of ball pin for automobile

A processing technology and ball pin technology, which is applied in the field of automotive ball pin processing technology, can solve problems such as poor bonding, shortening the shot blasting process, and reducing production efficiency, so as to improve production efficiency, save shot blasting time, and achieve a good surface The effect of roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

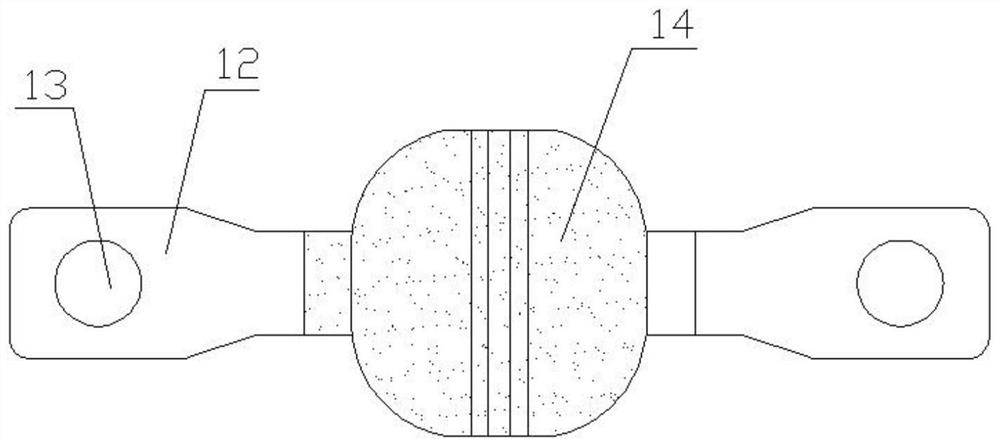

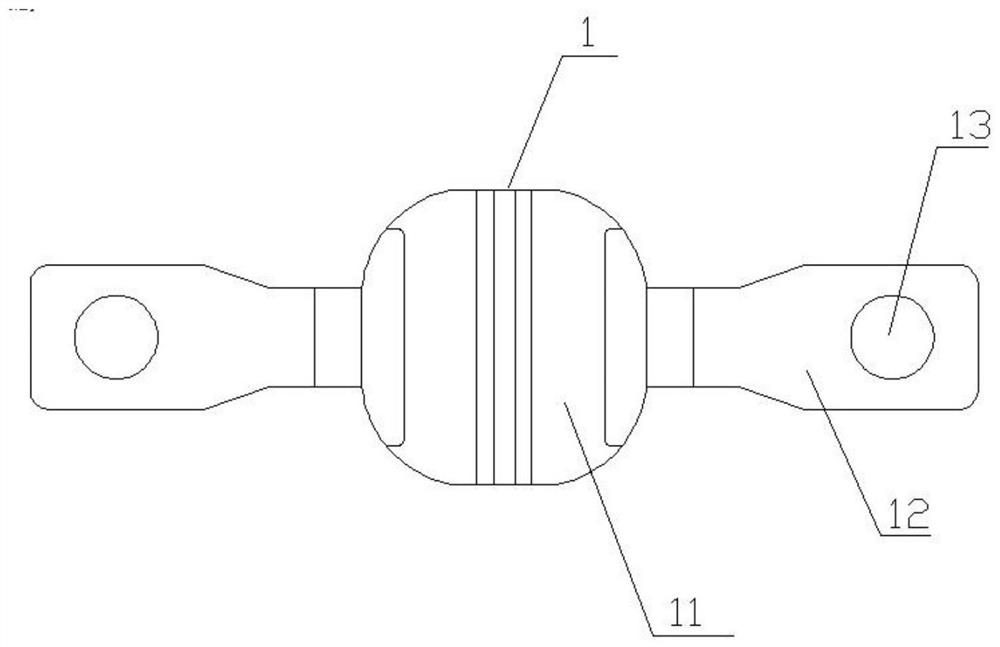

[0022] Such as Figure 1-2 As shown, the present embodiment provides a processing technology of a ball pin for automobiles, comprising the following steps:

[0023] a. Forging heat treatment: use 40Cr steel material, adopt forging and heat treatment to obtain the ball pin skeleton 1, so that its surface hardness reaches HRC25-30; the ball pin skeleton 1 includes the center ball pin body 11 and the ball pin body 11 on both sides end cap 12;

[0024] b. Finishing: the ball pin body 11 is turned into an arc surface, and the end cover 12 is turned into a cylindrical surface; wherein, the ball pin body 11 is cylindrical, and the arc surface is located at the central axial periphery of the ball pin body 11;

[0025] c. Milling hole: Mill out the mounting hole 13 on the end cover 12;

[0026] d. Shot blasting: Use a shot blasting machine to perform shot blasting treatment on the ball pin frame 1, and the shot blasting time is 6-10 minutes;

[0027] e. Adhesive coating, vulcanizati...

experiment example

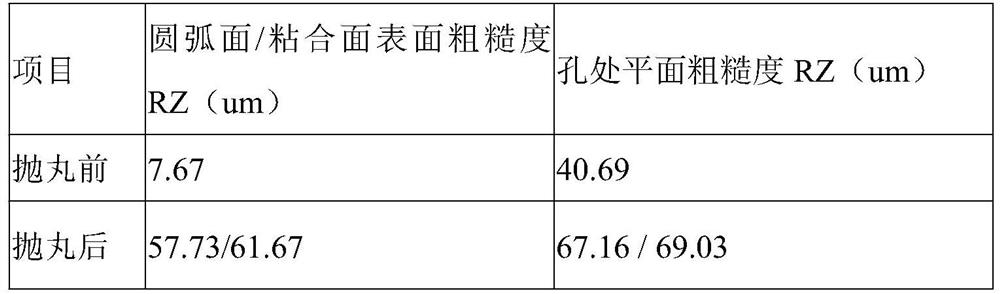

[0029] In the prior art, the shot blasting time is 40 minutes, and the roughness of the arc surface / adhesive surface and the plane roughness at the mounting hole are tested before and after shot blasting. The specific test results are shown in Table 1:

[0030] Table 1

[0031]

[0032] Using the scheme of the embodiment of the present invention, the roughness of the arc surface / adhesive surface and the plane roughness at the mounting hole were detected before and after shot blasting in multiple batches. The specific test results are shown in Table 2:

[0033] Table 2

[0034]

[0035] It can be seen from the above table that the roughness RZ of the arc surface / adhesive surface and the plane roughness RZ of the hole after 8 minutes of shot blasting in the three batches are close to or even better than those after 40 minutes of shot blasting. Moreover, the original shot blasting time is 40 minutes, and it takes 5 minutes to assist loading and unloading. A shot blasting m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com