Preparation method of modified diamond abrasive particles

A technology of diamond and abrasive grains, which is applied in the field of preparation of modified diamond abrasive grains, which can solve the problems of simple preparation process, low cost, high preparation cost, and poor strength of diamond abrasive grains, and achieve good surface roughness and low production cost , the effect that the strength will not decrease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023]为了使本发明的目的、技术方案及优点更加清楚明白,以下结合附图及实施例,对本发明进行进一步详细说明。

[0024]本发明公开了一种改性金刚石磨粒的制备方法,其包括以下步骤:

[0025]首先,准备好规定尺寸的金刚石微粒,通常尺寸为0.1-1000μm之间,具体尺寸根据实际使用场合来定。

[0026]然后,对金刚石微粒进行清洗,清除金刚石磨粒表面的杂质。清洗干净的金刚石微粒烘干备用。可以先用酸或碱或无机盐进行清洗,然后再用清水冲洗干净。使用酸洗或碱洗或无机盐清洗是本领域人员所熟知的技术,本案中不再赘述。

[0027]之后,通过CVD法在金刚石磨粒表面生成金刚石凸起。将金刚石磨粒置于加热设备中,在高温条件下,加入碳化物气体和催化气体。在催化气体的作用下,碳化物气体裂解出碳单元体(C)、碳复合体(C1 / C2 / C3 / C6等)以及CHn-(CH- / CH2-等),其中,碳单元体以金刚石磨粒为衬底并在其表面生长出规则形状的金刚石凸起。

[0028]碳化物气体为烯烃类气体或含烯烃类气体的混合气体,烯烃类气体的化学式为CxHy,其中,x=1-4,y=2-10。作为优选,碳化物气体为丙烯、丙烷、乙烯、乙烷、甲烷和煤气中的一种或多种。催化气体则为氢气和氮气。

[0029]金刚石凸起的生长过程因不同晶面间距不同而呈现出不一样的生长速率。大体上来说,反应过程中,加热设备的内腔温度控制在700-1500℃,反应时间控制在1-8h。碳化物气体和催化气体的流速均控制在5-100L / min。此外,碳化物气体和催化物气体的体积含量,即氮气、氢气和碳化物气体的体积含量为:氮气40-89%,氢气1-10%,碳化物气体10-50%。

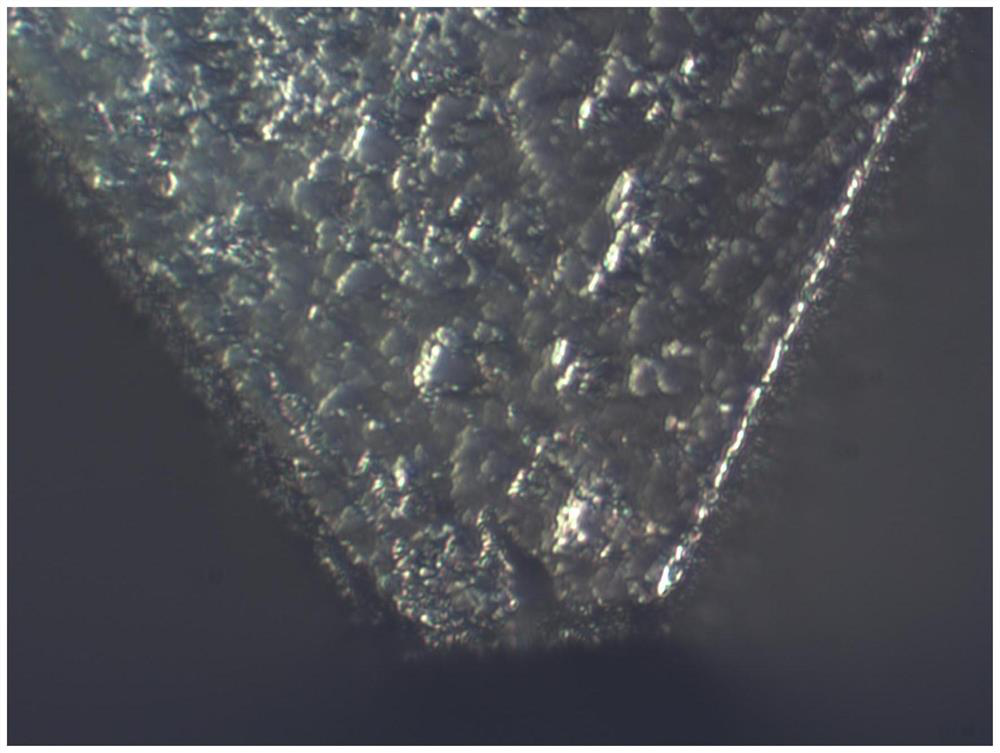

[0030]在反应时间结束后,等待加热设备自然冷却后即得改性金刚石磨粒,经本发明制备出的改性金刚石磨粒其表面示意图如图3-4所示。

[0031]为了验证本发明的可行性,选用10μm(误差控制在±1μm内)、100μm(误差控制在±3μm内)和1000μm(误差控制在±5μm内)三种规格的金刚石磨粒为原型,并等量称取,通过选用不同的碳化物气体,同时选择不同的反应过程参数进行试验验证,具体参数设置如表1所示,对于各实施例制备出的改性金刚书磨粒,各实施例中选取5粒进行检测,各实施例对应的检测结果的平均数如表2所示。

[0032]表1

[0033]

[0034]表2

[0035]

[0036]

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com