Manufacturing technology of air spring rubber stack

A manufacturing process, air spring technology, applied in springs, spring/shock absorbers, gas shock absorbers, etc., can solve problems such as poor bonding of rubber piles, achieve good cleaning effect, improve adhesion, and improve surface roughness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

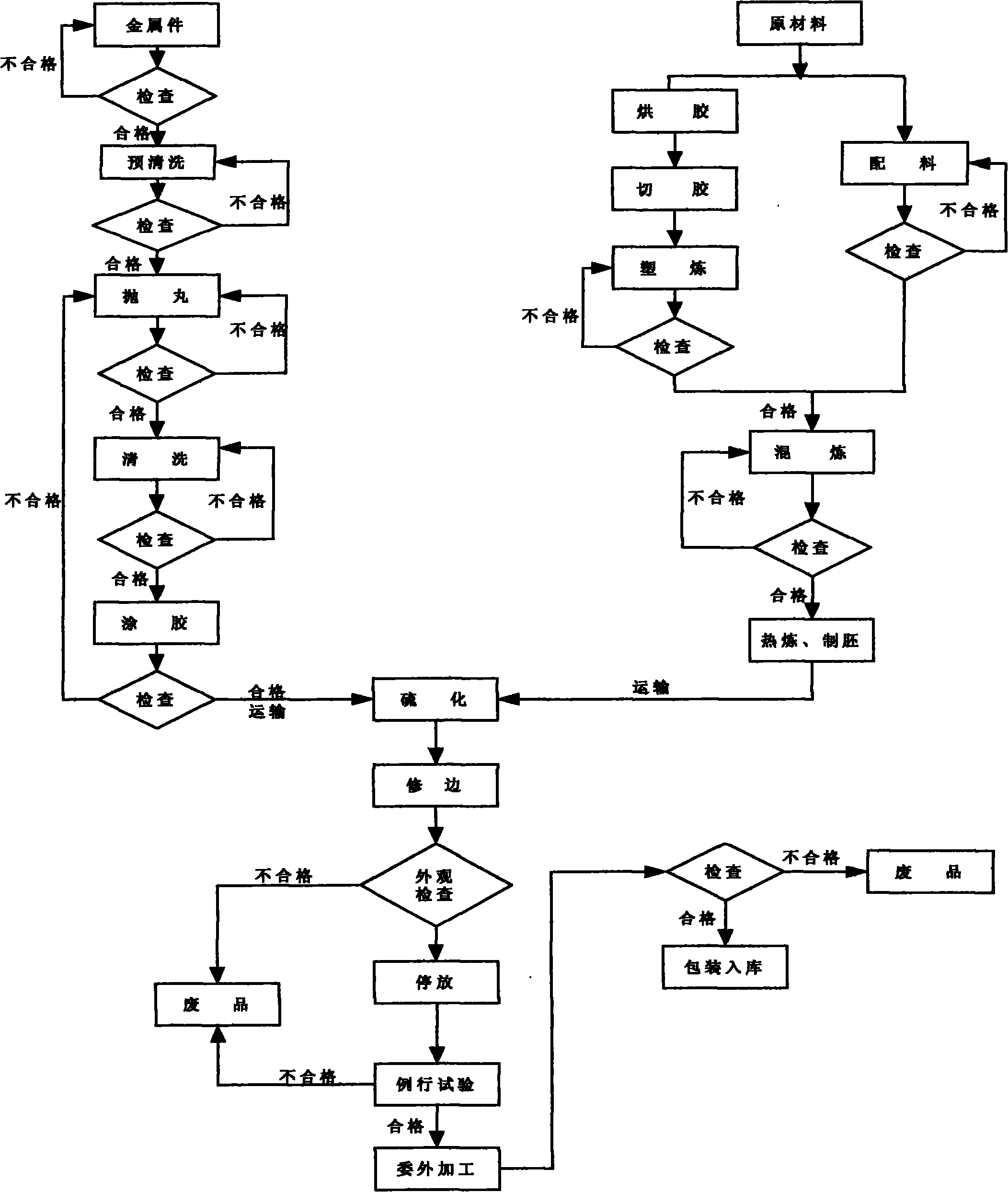

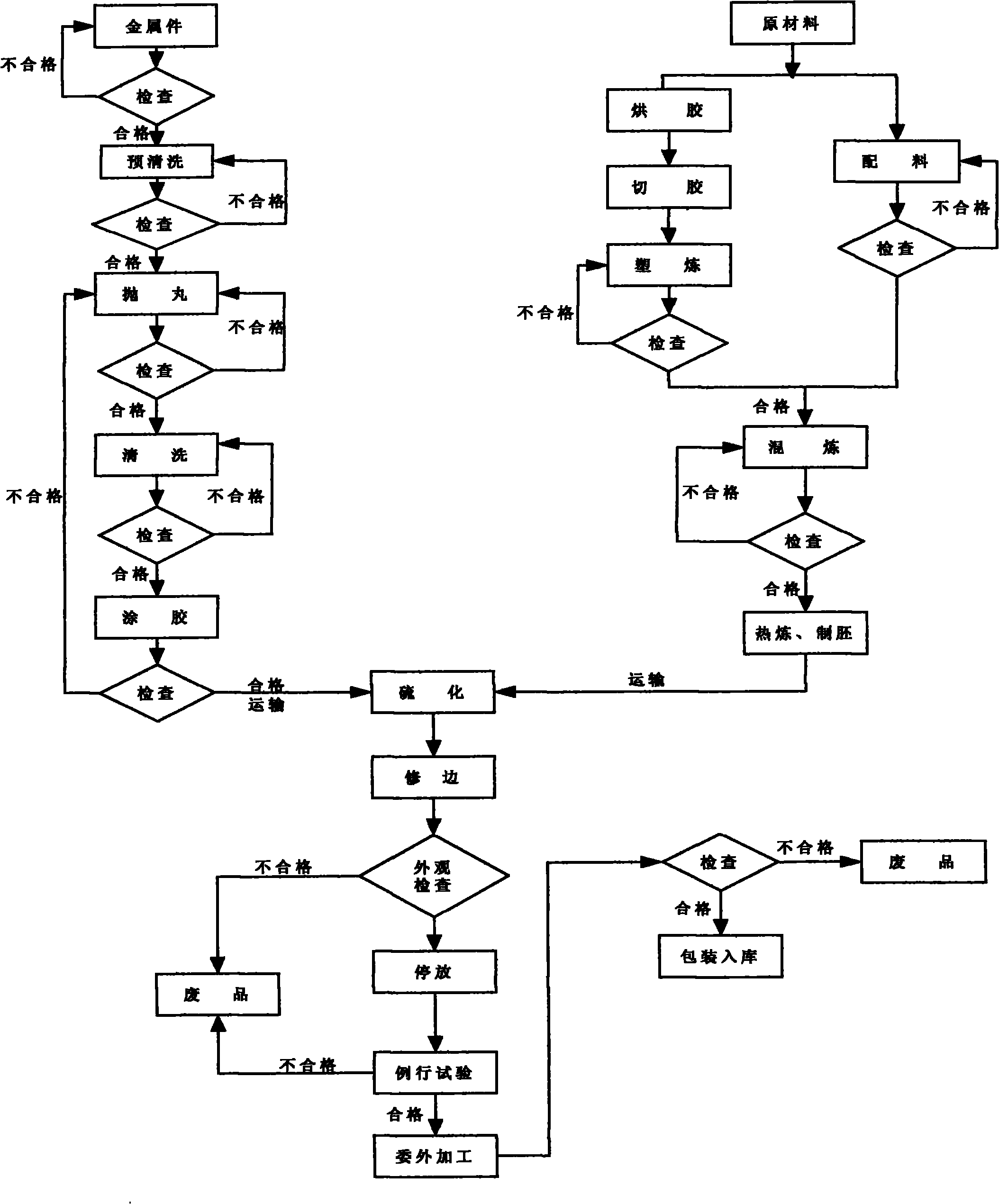

[0023] The specific embodiment of the present invention is as follows: a kind of manufacturing process of air spring rubber pile, comprises the treatment process of metal parts, the preparation process of rubber material and vulcanization process,

[0024] 1. The processing steps of metal parts are as follows:

[0025] (1) Pre-cleaning process: The pre-cleaning process uses MJ line equipment, which is composed of three parts: alkali washing one, alkali washing two, and water washing. The first stage of alkali washing is 7-12 minutes at 30-40 °C; The stage is 5-7 minutes at 30-40°C; the washing stage is 3-5 minutes;

[0026] (2) Shot blasting process: the shot blasting frequency of the partition part is set to 38-42Hz, the time is 22-30 minutes, and the current is 6-10A; the shot blasting frequency of the mandrel part is set to 38-42Hz, and the time is 20 -25 minutes, the current is 6-10A; the shot blasting frequency of the coat part is set to 38-42Hz, the time is 6-10 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com