Molybdenum wire guide for electric spark wire cutting machine

A technology of cutting machine tools and electric discharge wires, applied in the field of guides, can solve the problems of reducing the running speed of molybdenum wire and failing to reach

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

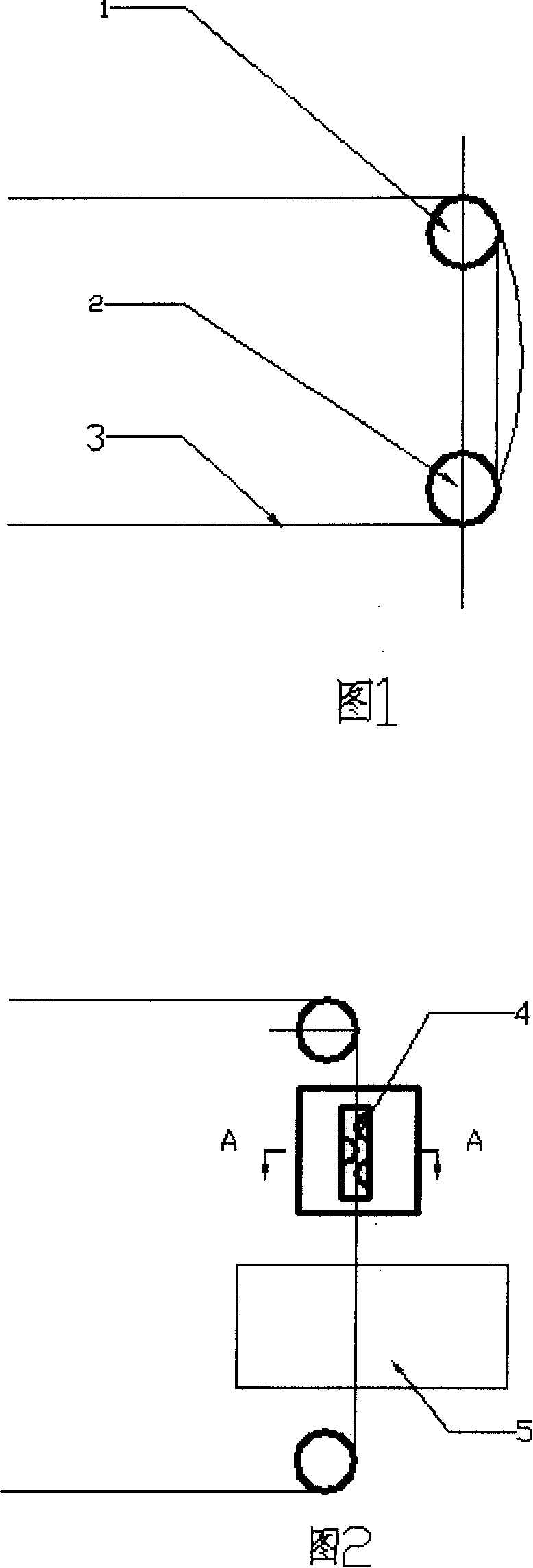

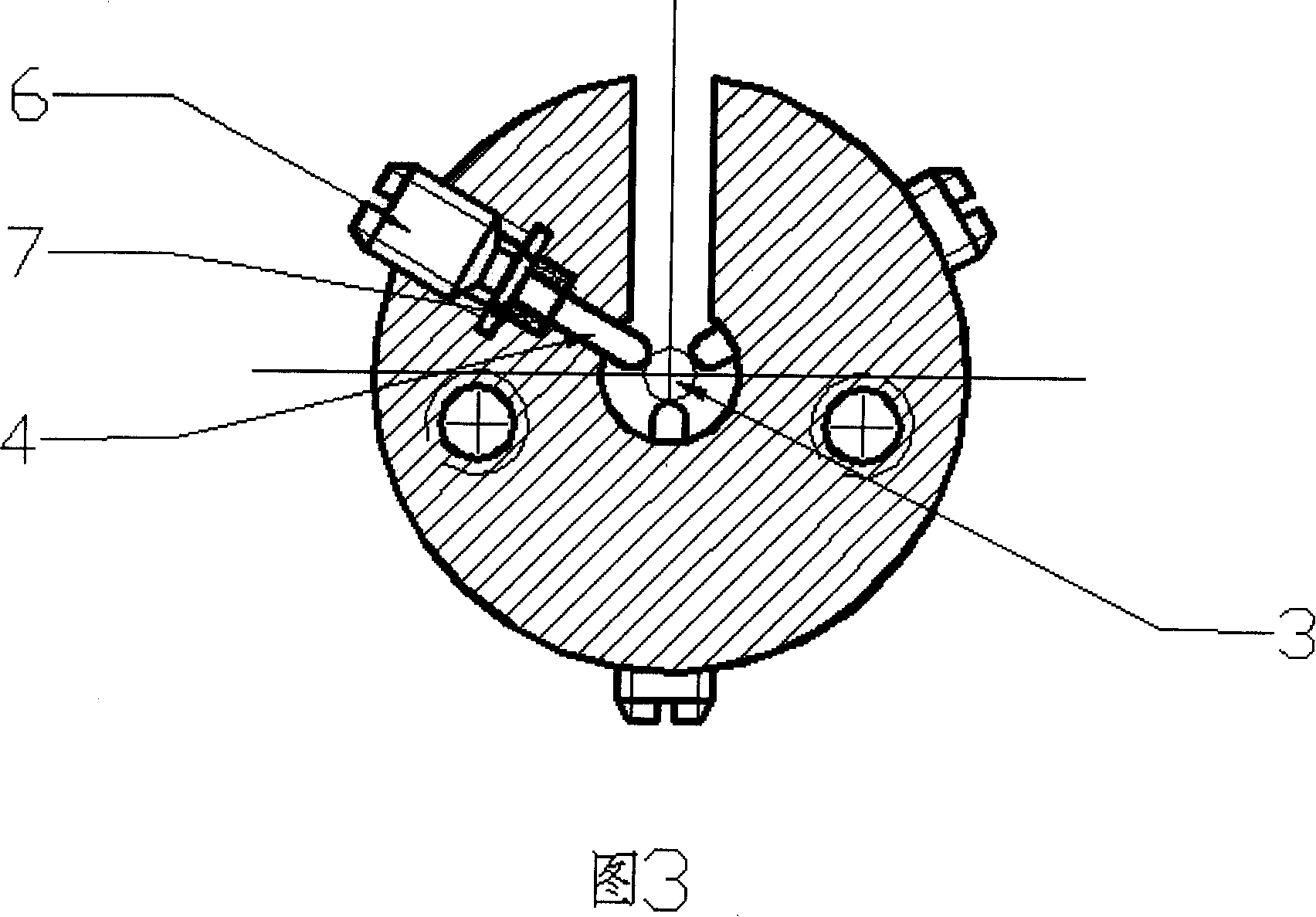

[0010] The structure of the present invention is described in detail below. A molybdenum wire guide for a wire EDM machine tool, which is characterized by a hollow cylindrical support seat 8 with a gap on one side. The support seat 8 is surrounded by a fret-shaped installation of three groups consisting of diamond 4, spring 7, and fine adjustment. Molybdenum wire limit mechanism connected by screws 6 in sequence.

[0011] The specific structure of the diamond 4, the spring 7, the fine adjustment screw 6 and the support base 8 is as follows: the fine adjustment screw 6 and the support base 8 are connected by threads. Turning the fine adjustment screw can make the diamond advance and retreat along the molybdenum wire radial direction in the support base.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com