Cutting method of aramid fiber composite material

A kind of aramid fiber and composite material technology, applied in metal processing and other directions, can solve the problems of poor surface roughness, large cutting heat, large cutting resistance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

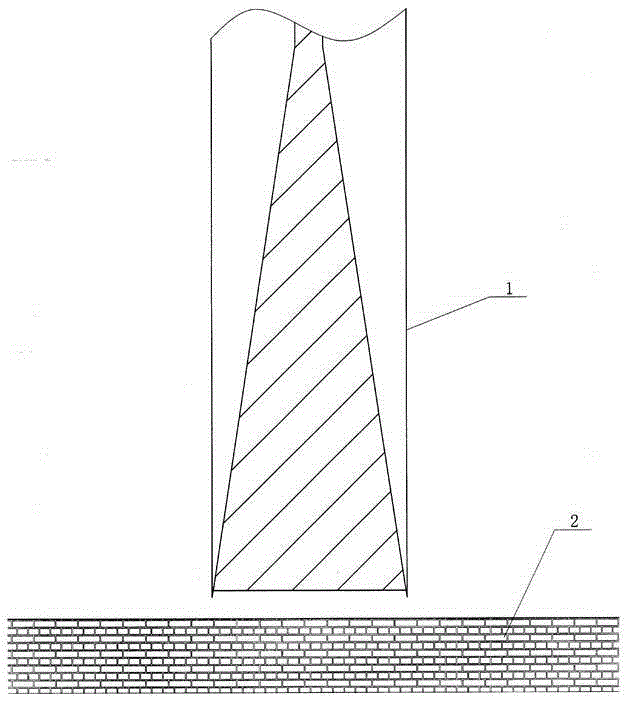

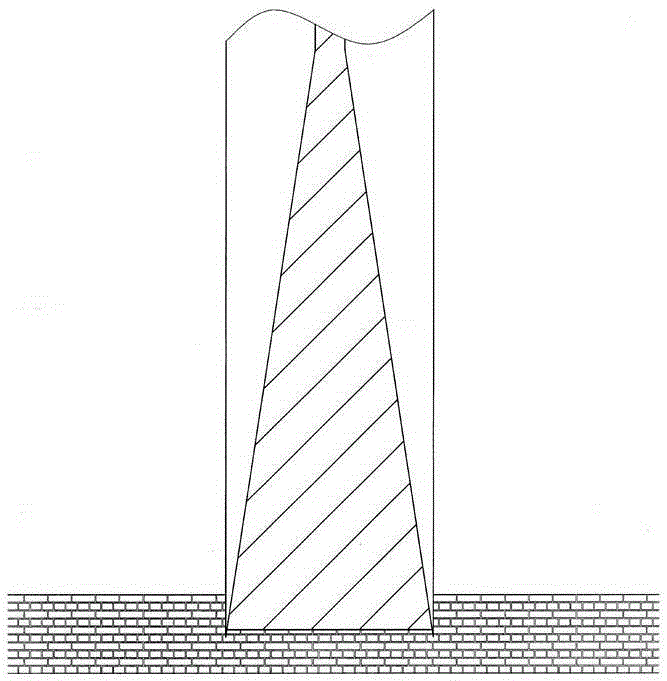

[0018] A cutting processing method of an aramid fiber composite material, using a cutter 1 to first cut off the aramid fiber, and then cutting off the aramid fiber composite material 2 to be removed.

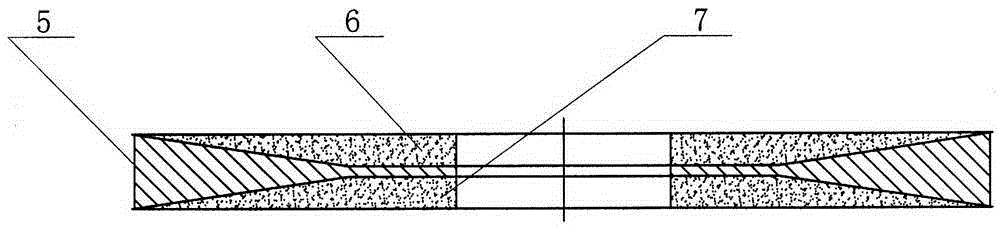

[0019] like Figure 1 to Figure 4 As shown, the cutter 1 is composed of two identical circular solid carbide cutting blades 6, 7 and a high-speed steel disc milling cutter 5, wherein the two identical circular solid carbide cutting blades 6 , 7 are symmetrically installed on both sides of the high-speed steel disc milling cutter 5. The circular solid carbide cutting blades 6 and 7 have a diameter of 80 mm, a thickness of 3 mm, and a wedge angle of 8° to 10°. The diameter of described high-speed steel disc milling cutter 5 is made into 79mm, the installation thickness is made into 2mm, and the rake angle of cutting edge is 0°~3°. 5 has a diameter difference of 1 mm.

[0020] The cutting parameters of the tool 1: the rotation speed is 800rpm, and the feed rate is 80mm / min.

Embodiment 2

[0022] A cutting processing method for an aramid fiber composite material, using a cutter 3 to first cut off the aramid fiber, and then cutting off the aramid fiber composite material 2 to be removed.

[0023] like Figure 5 to Figure 8 As shown, the cutter 3 includes a blade 8, a shank 9 and a connecting hole 10 for connecting with a tool chuck. The blade 8 is in the shape of a strip in the feeding direction of the cutter, and several serrated cuts The units are arranged in two rows along a straight line on the blade portion 8, the cutting units in each row have the same structure, and the cutting units in the two rows are arranged symmetrically and staggered in the direction of tool feed. The centripetal angle of the blade portion 8 is 5°. The normal rake angle of the cutting edge on the one row of cutting units is 60°, and the normal rake angle of the cutting edge on the other row of cutting units is 45°.

[0024] The cutting parameters of the tool 3: the cutting speed is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com