Surface treatment process of HDI plate based on chemical nickel-gold plating coating

An electroless nickel-plating gold and surface treatment technology, which is applied in the processing of insulating substrates/layers, metal processing equipment, printed circuit liquid treatment, etc., can solve the problems of low production efficiency of electroless nickel-plating gold coatings, and achieve improved production Efficiency, guaranteed stability, and convenient production management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

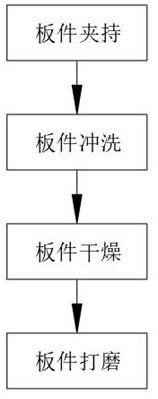

[0037] see Figure 1-7 As shown, a surface treatment process of an HDI board based on electroless nickel-gold coating includes the following steps:

[0038]The first step, plate clamping: to carry out surface treatment on the HDI board in the surface treatment equipment, firstly, the HDI board is fed into the interior of the processing box 10 through the feeding mechanism of the board, wherein the feeding mechanism can be a mechanical arm or other intelligent mechanism, one side of the HDI board is placed between the two discharge plates 207, and then the electromagnet 209 is powered off. Under the action of the elastic potential energy of the spring 212, the two discharge plates 207 are close to each other, so that the HDI board is firmly The ground is limited between the two discharge plates 207 to complete the clamping of the HDI board;

[0039] The second step, plate flushing: drive the movable frame 205 to slide down the lower part of the fixed frame 203 through the driv...

Embodiment 2

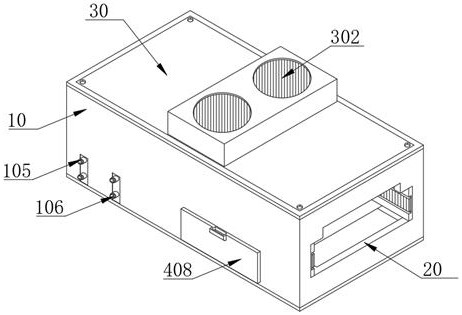

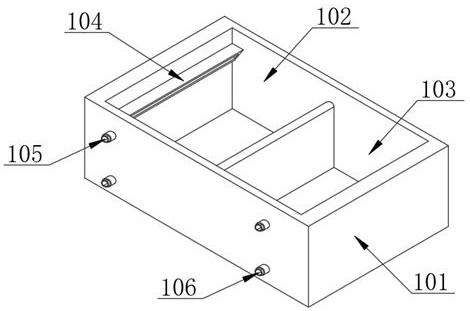

[0043] see Figure 2-3 As shown, the surface treatment equipment in the present invention includes a treatment box 10, both sides of the treatment box 10 are provided with material openings 20, and the top of the treatment box 10 is provided with a top plate 30, and the left inside of the treatment box 10 is provided with a material washing mechanism, The washing mechanism includes a washing tank 101, and the washing tank 101 is provided with a water washing tank 102 and a pickling tank 103. The water washing tank 102 and the pickling tank 103 are provided with a nozzle 104 on one side, and the washing tank 102 and the pickling tank 103 are provided with a nozzle 104. The front of the pickling tank 103 is connected with a water inlet pipe 105 and a water outlet pipe 106. One ends of the water inlet pipe 105 and the water outlet pipe 106 both penetrate the treatment box 10 and extend to the outside of the treatment box 10, and one end of the two water inlet pipes 105 are respect...

Embodiment 3

[0045] see Figure 4-6 As shown, in the present invention, the inside of the processing box 10 is provided with a material guide mechanism, and the material guide mechanism includes a horizontal frame 201, and two horizontal frames 201 are symmetrically arranged inside the processing box 10, and the two horizontal frames 201 are on opposite sides. A linear motor 202 is provided, and a fixing frame 203 is provided on the opposite side of the two linear motors 202, and a servo electric cylinder 204 is arranged on both sides of the top of the fixing frame 203, and the two servo electric cylinders 204 drive shafts One end of each frame penetrates through the fixing frame 203 and extends to the bottom of the fixing frame 203 , a movable frame 205 is slidably arranged below the fixing frame 203 , and the two sides of the top of the movable frame 205 extend to the fixing frame respectively with the drive shafts of the two servo electric cylinders 204 The bottom end of the 203 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com