Patents

Literature

47 results about "Electroless coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processes for texturing a surface prior to electroless plating

InactiveUS20090302005A1Improve surface roughnessEasy to understandDecorative surface effectsBlade accessoriesOXALIC ACID DIHYDRATEAqueous solution

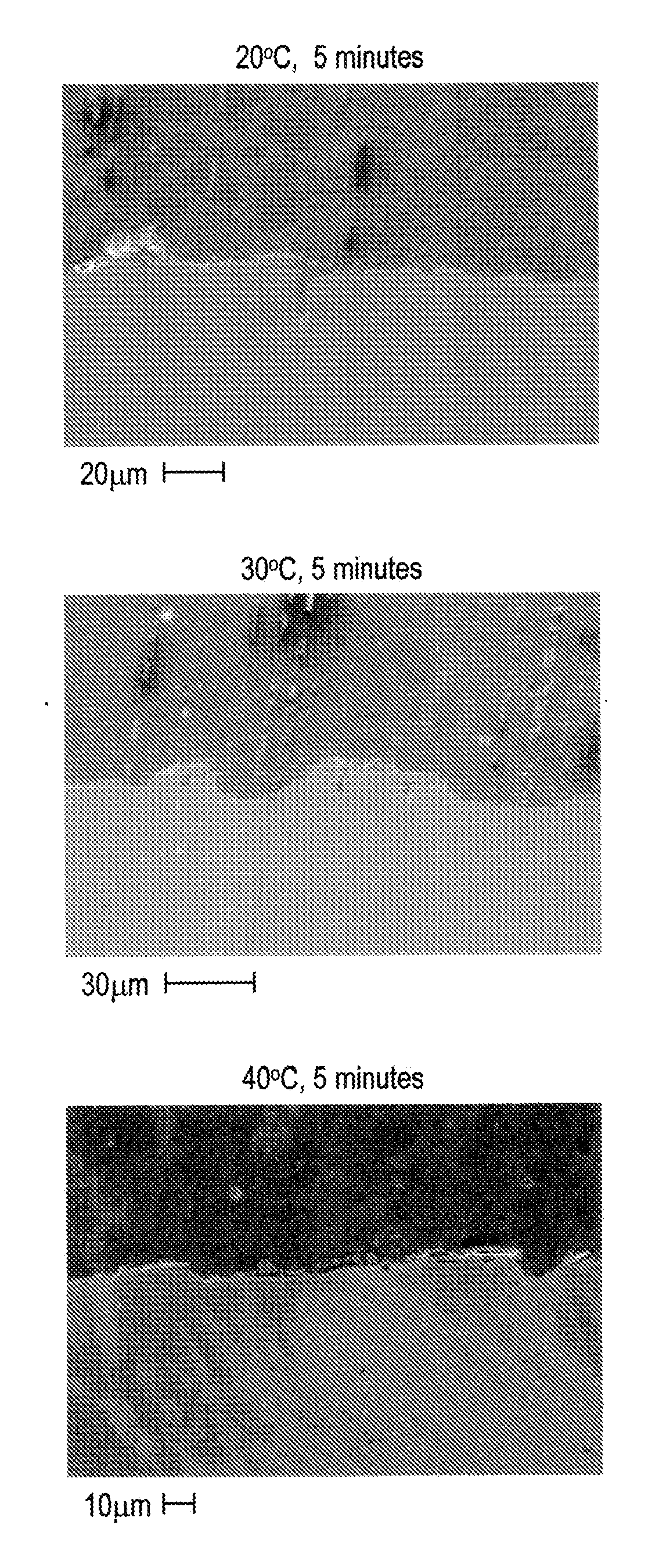

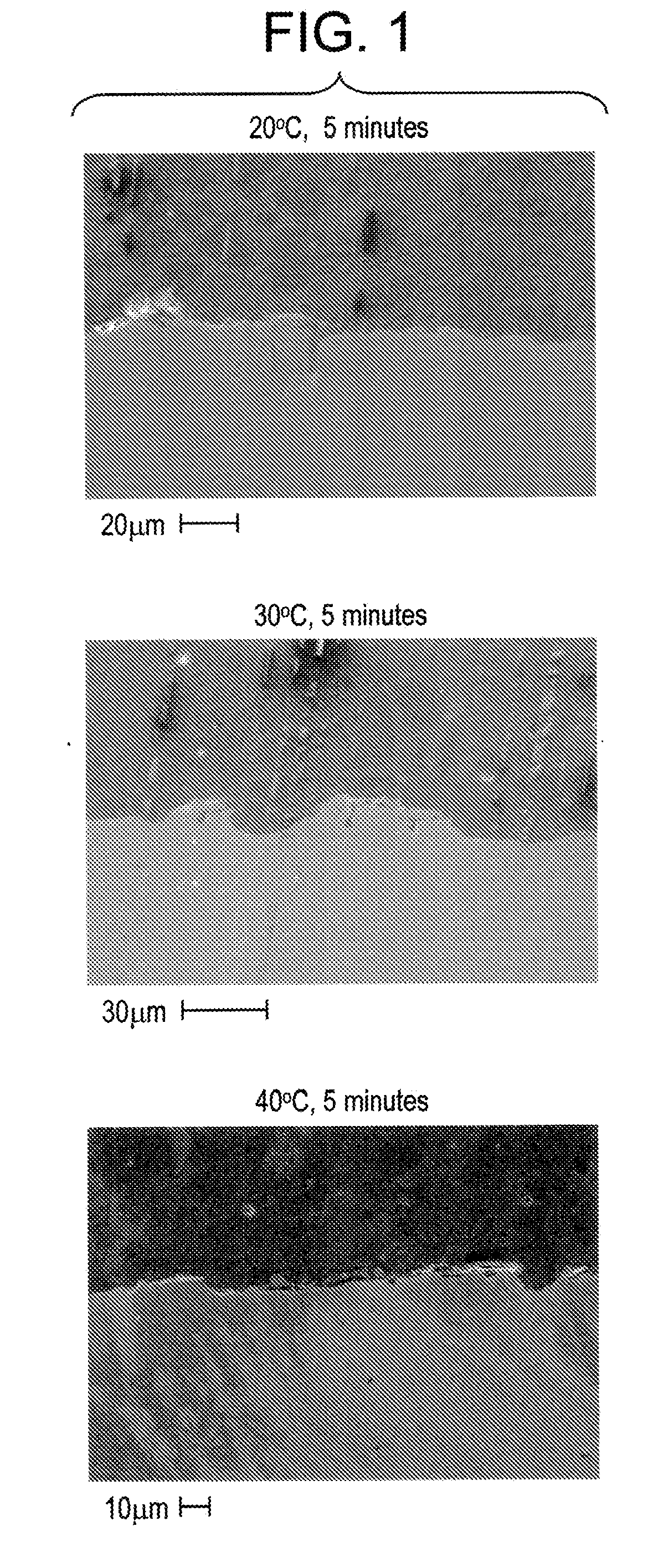

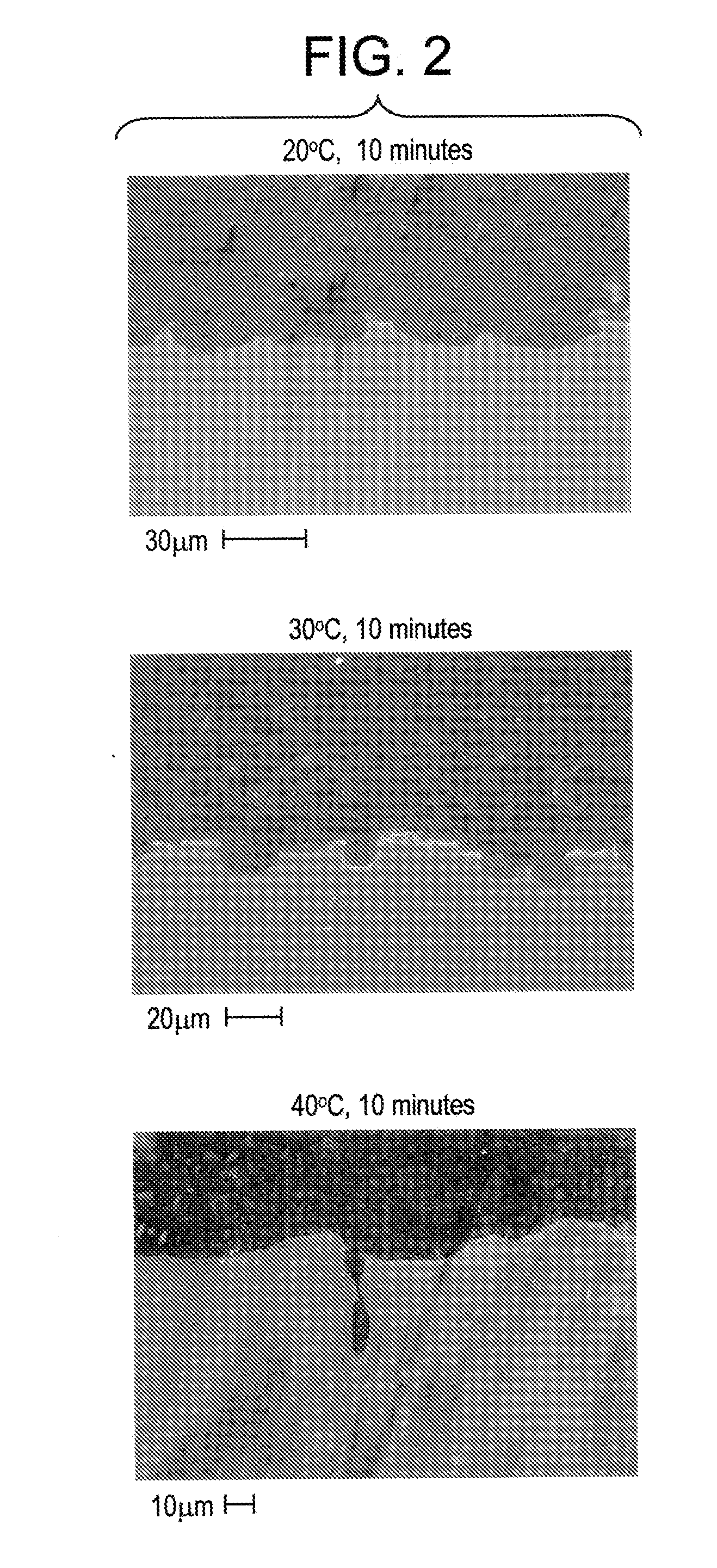

Process for roughening a surface of a base metal substrate includes contacting the surface with an aqueous solution comprising oxalic acid, sulfuric acid, and hydrogen peroxide at a temperature and for a period of time effective to roughen the surface to an average roughness greater than 60 Ra, removing a modest amount of base material, and generating no narrow and deep crevices at all. The surface is roughened prior to application of an electroless coating onto the substrate.

Owner:GENERAL ELECTRIC CO

Method for coating surfaces and use of the articles coated using said method

A method for electroless coating of substrates by applying an activating coat of polyelectrolyte or salt with a first aqueous composition; rinsing the activating coat such that the activating coat not being entirely removed; contacting and coating of the activated surfaces that have remained after rinsing with an aqueous composition in the form of a solution, emulsion or suspension, to form an organic secondary coat; and drying. The activating coat is a solution, emulsion or suspension containing a anionic polyelectrolyte or at least one anionic salt in solution in water. The aqueous composition forming the secondary coat has constituents which can be precipitated, deposited or salted out and which are anionically, zwitterionically, sterically or cationically stabilized. The dry film formed in the process, comprising the activating coat and the secondary coat, has a thickness of at least 1 μm.

Owner:CHEMETALLGMBH

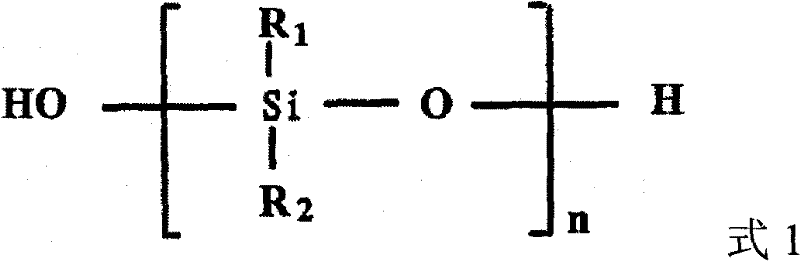

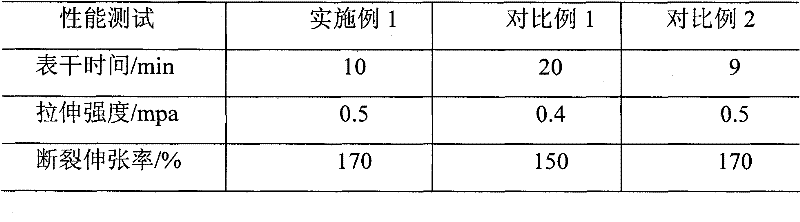

Organosilicon coating for electroplating and preparation method thereof, and protective coating for electroplating

A silicone coating for electroplating, comprising: a hydroxyl-terminated polyorganosiloxane, a reinforcing filler, a crosslinking agent, and a catalyst, wherein a diluent is added to the silicone coating, and the diluent is a volatile organic Solvent; based on 100 parts by weight of hydroxyl-terminated polyorganosiloxane, the content of the above components is: reinforcing filler: 0-100 parts by weight; crosslinking agent: 0.5-20 parts by weight; catalyst: 0.05-10 parts by weight parts by weight; diluent: 100-300 parts by weight. The present invention also relates to a preparation method of the above-mentioned organosilicon paint, and using the organosilicon paint as a protective coating for electroplating. The organosilicon coating provided by the invention has excellent storage and operability. By adding a diluent to the system, it can be operated for more than 4 hours before coating, and the curing time of the coating after coating is 10 to 15 minutes. It is suitable for use in electroplating. The non-plated areas are coated.

Owner:BYD CO LTD

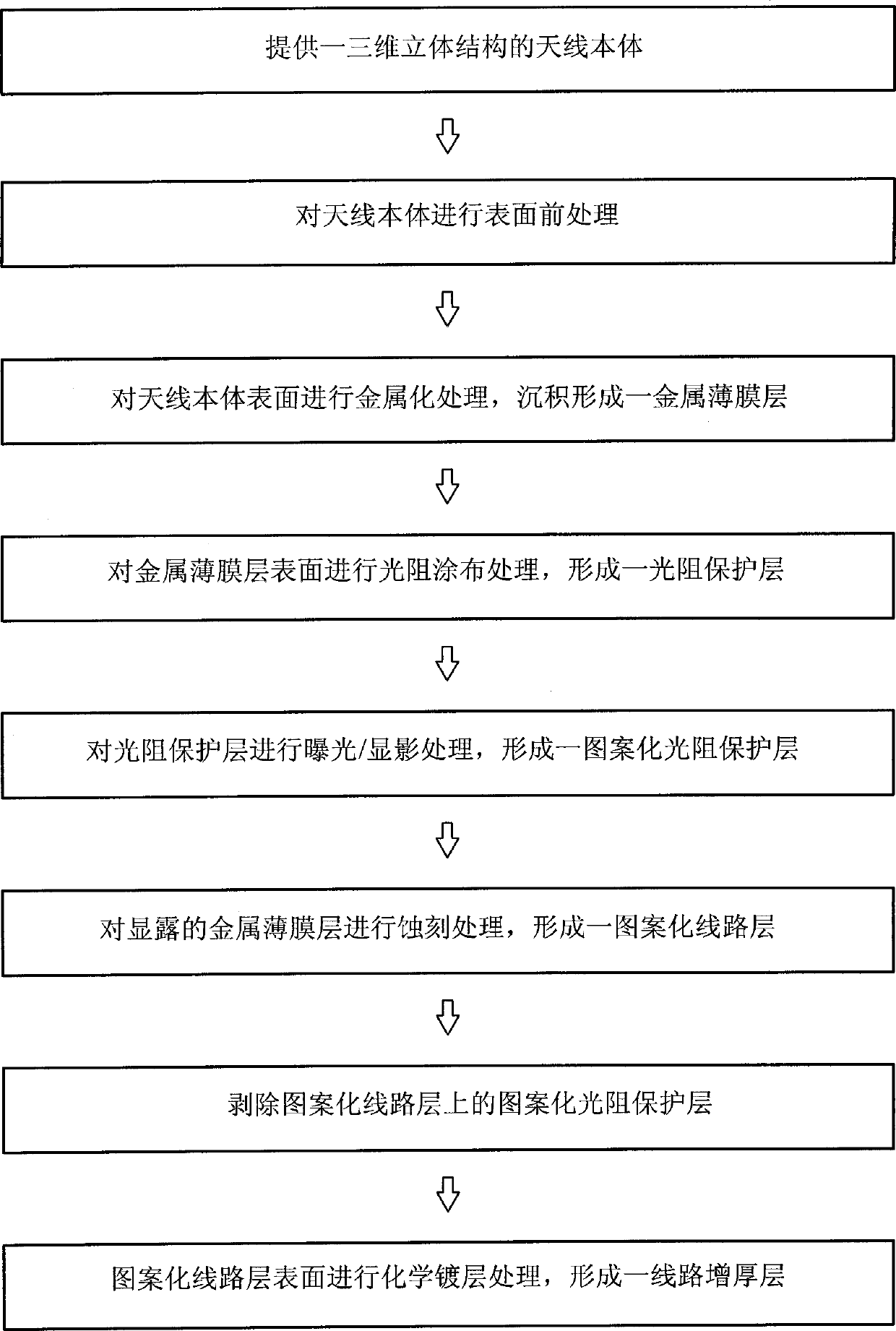

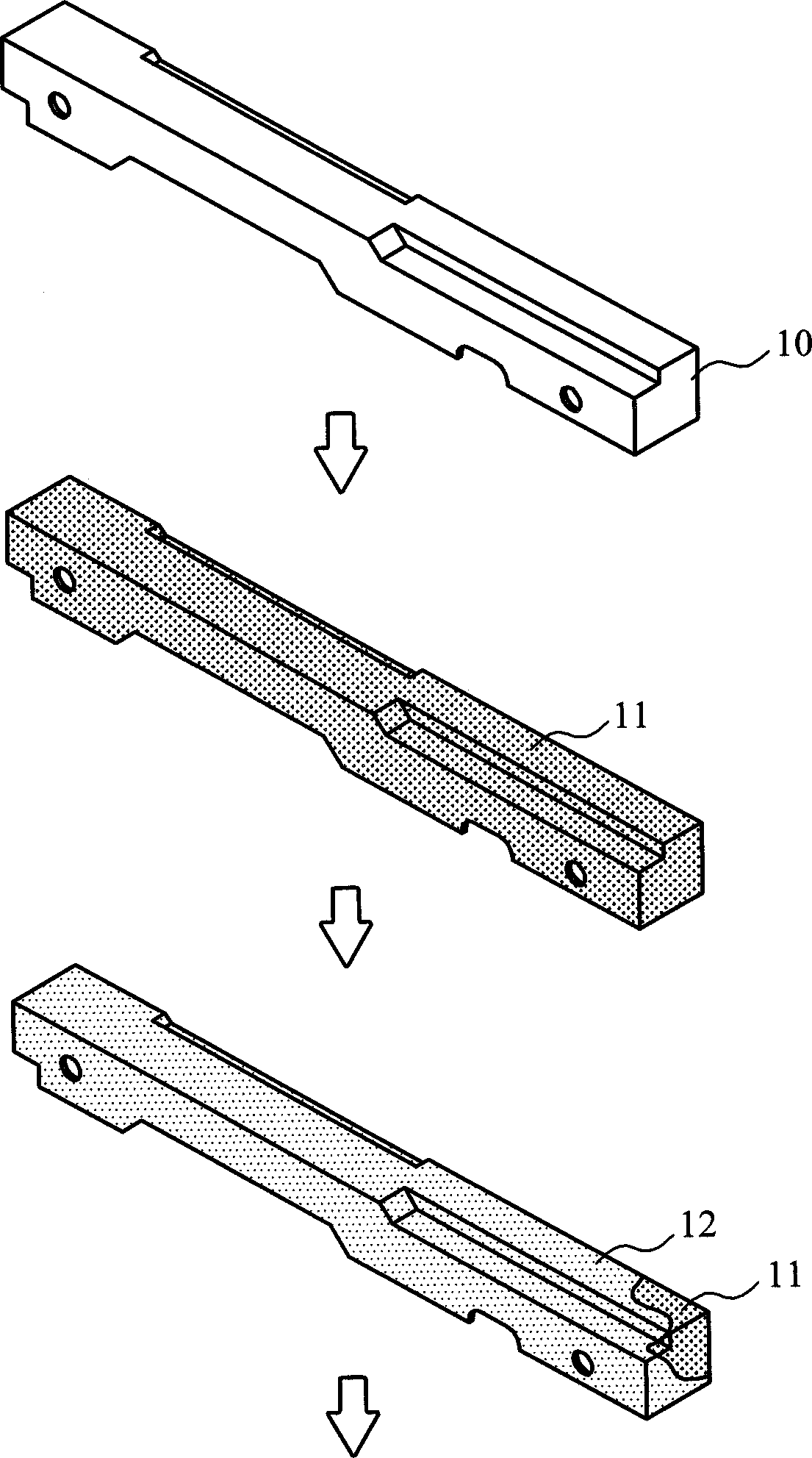

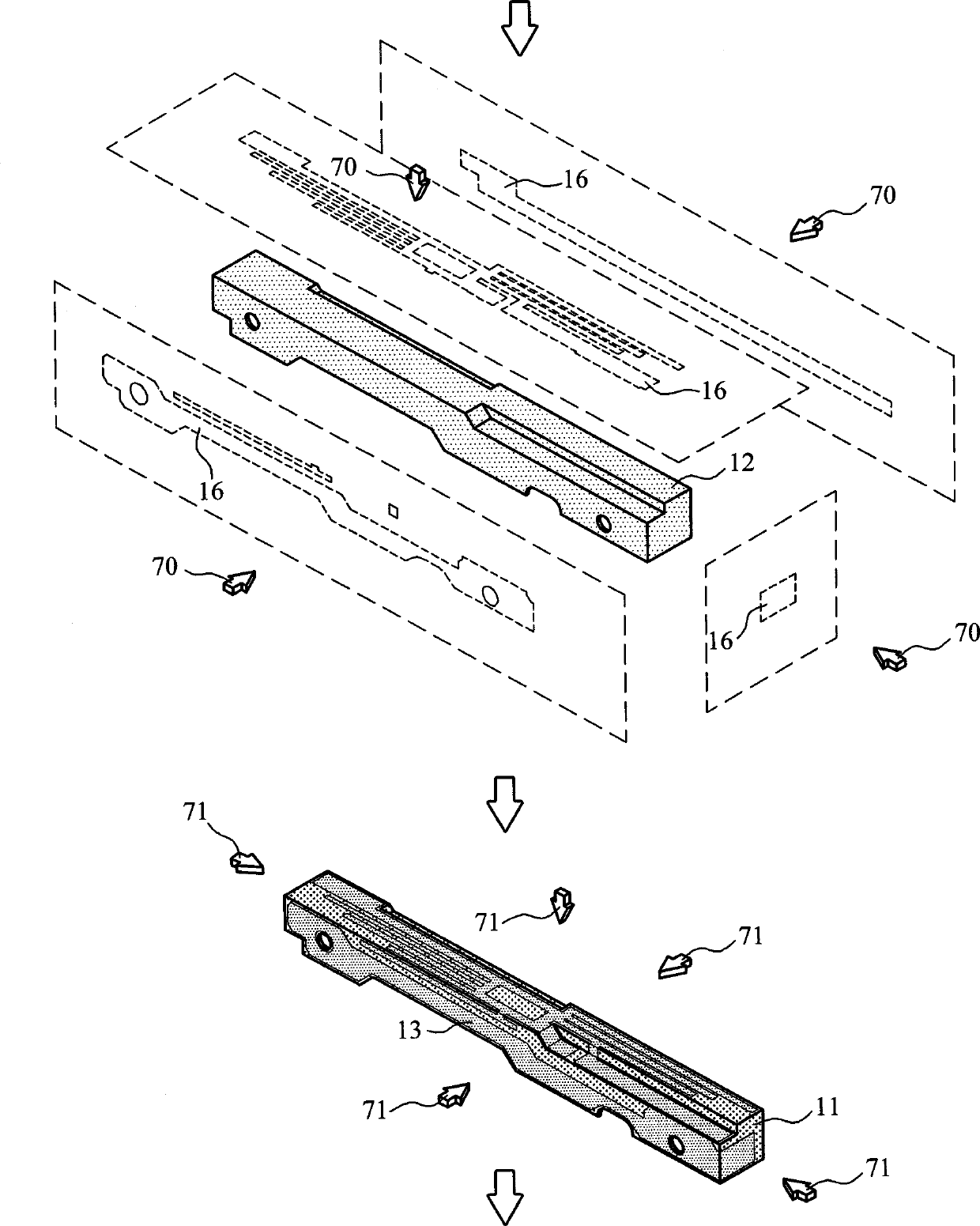

Method for manufacturing three-dimensional circuit

InactiveCN102892252AHigh selectivityLower acquisition costsInsulating substrate metal adhesion improvementRadiating elements structural formsChemical platingHemt circuits

The invention relates to a method for manufacturing a three-dimensional circuit. The method comprises the following steps of: providing a body with a three-dimensional structure; carrying out surface degreasing and roughening treatments on the body; carrying out metallization treatment on the body surface, and forming a metal film layer through precipitation; carrying out photoresist coating treatment on the surface of the metal film layer so as to form a photoresist protective layer; carrying out exposure / developing treatment on the photoresist protective layer so as to form a patterned photoresist protective layer; etching the exposed metal film layer so as to form a patterned line layer; removing the photoresist protective layer from the patterned line layer; and carrying out chemical plating treatment on the surface of the patterned line layer so as to form a line thickening layer. According to the method disclosed by the invention, a three-dimensionally wired circuit pattern can be directly formed on the body with the three-dimensional structure, and a circuit carrier is unnecessary to arrange on the body additionally, therefore the requirements of lightness, thinness, shortness and smallness are met.

Owner:KUNSHAN LIANTAO ELECTRONICS CO LTD +1

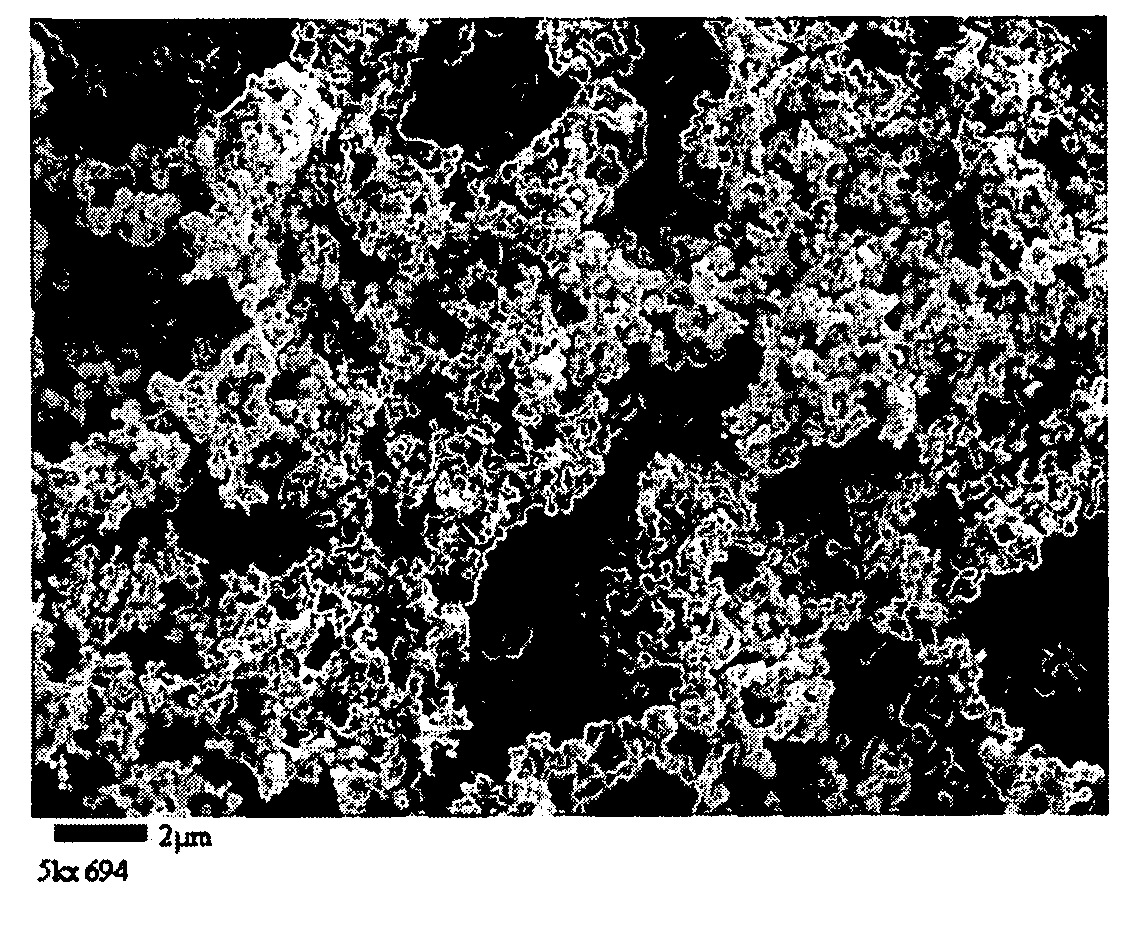

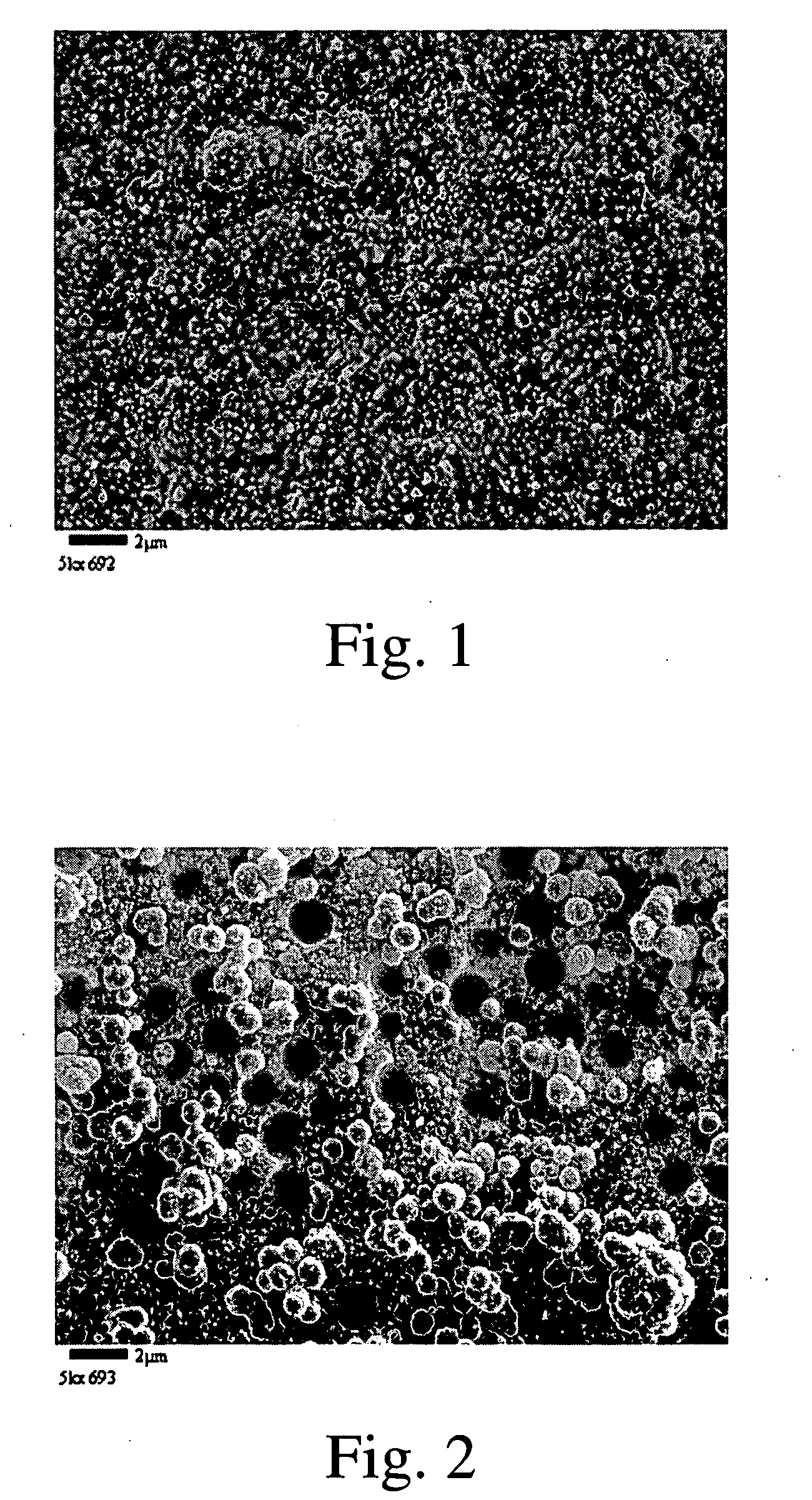

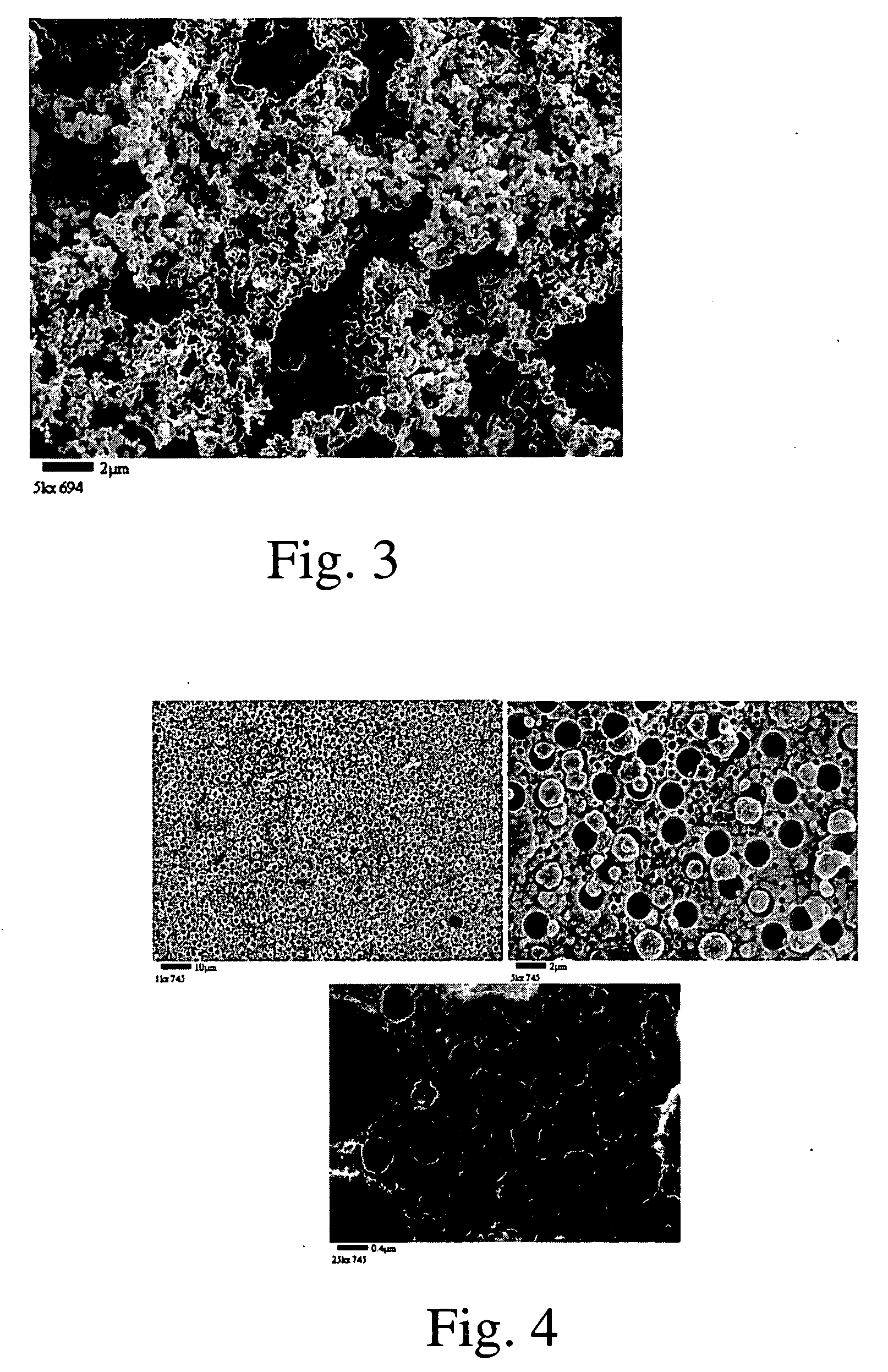

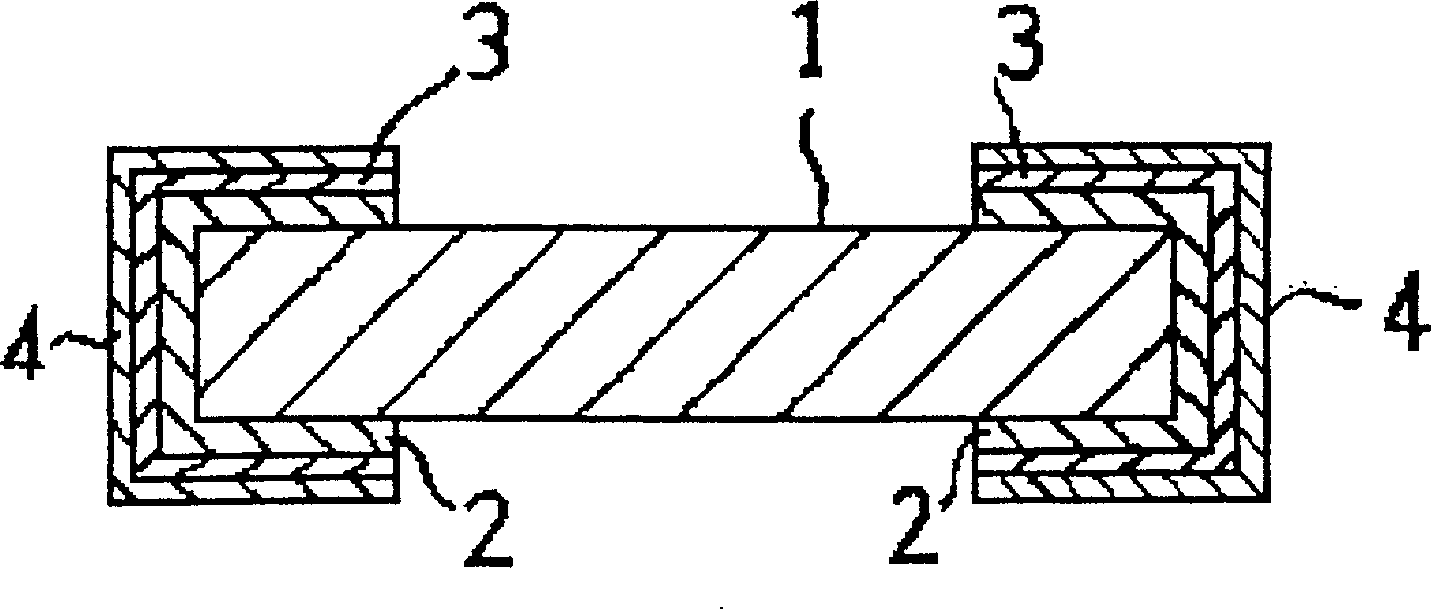

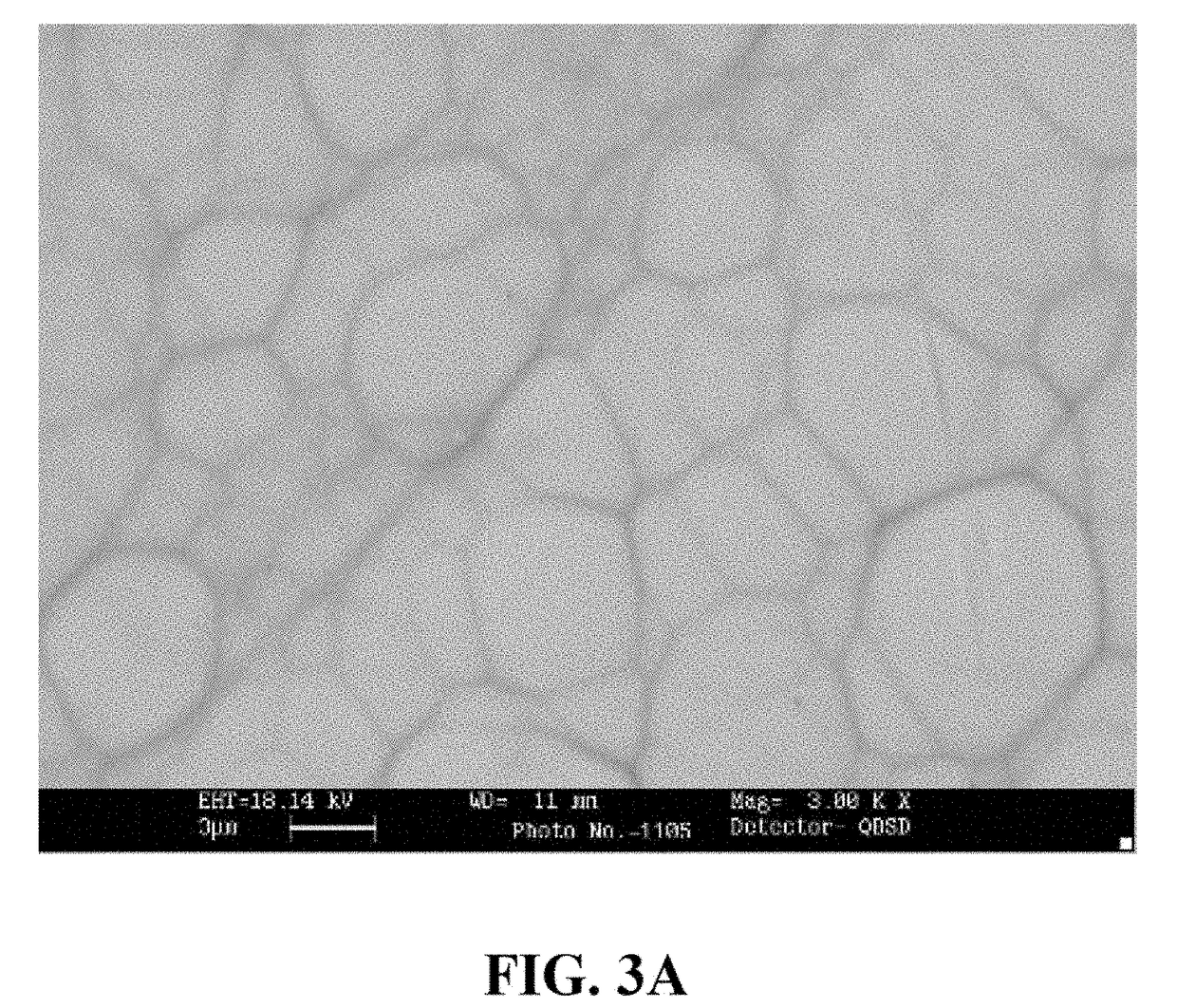

Porous Electrolessly Deposited Coatings

InactiveUS20090075156A1Improve thermal conductivityLong processPhysical/chemical process catalystsCell electrodesMetal coatingMetallurgy

A new electroless plating approach to generate a porous metallic coating is described in which a metal is electrolessly deposited on a surface. Microparticles in the metal are removed to leave pores in the metal coating. Another method of forming electroless coatings is described in which a blocking ligand is attached to the surface, followed by a second coating step. The invention includes coatings and coated apparatus formed by methods of the invention. The invention also includes catalyst structures comprising a dense substrate and a porous metal adhered to the dense substrate, which is further characterized by one or more of the specified features.

Owner:VELOCYS CORPORATION

Nano hole sealing polyurethane coating and preparation process thereof

InactiveCN1450134AStable storageSimple preparation processPolyurea/polyurethane coatingsPolymer sciencePolyurethane coating

The present invention relates to a polyurethane paint with hole-sealing function, it is formed from two components of modified synthetic resin and solidifying agent which are matched each with other and used together. The described synthetic resin is formed from 0.1-20% of nano slurry, 30-70% of synthetic resin, 0-30% of pigment and the resit is solvent. Its preparation method includes the following steps: firstly, adding the nano slurry into synthetic resin solution, then adding the solvent, mixing then with pigment, dispersing and grinding, filtering to obtain modified synthetic resin, thenmatching it with solidifying agent to form the invented nano hole-sealing polyurethane paint.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Printed circuit board and method of fabricating same

InactiveUS20060070769A1Printed circuit aspectsPrinted circuit manufactureElectroless platingPrinted circuit board

Disclosed is a PCB which includes an insulating layer. At least one via hole is formed through the insulating layer. A first electroless plating layer is formed on a wall of the via hole and on at least one side of the insulating layer so as to have a predetermined pattern, and is etched at its edge portion corresponding to an edge portion of the pattern in a dimension that is in proportion to a thickness thereof. A second electroless plating layer is formed on the first electroless plating layer. An electrolytic plating layer is formed on the second electroless plating layer, and is etched at its edge portion in a dimension that is in proportion to the thickness of the first electroless plating layer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Mfg. method of electronic parts and siad electronic parts, electroless coating method

InactiveCN1428458AImprove film thickness uniformityLow costStacked capacitorsSoldering apparatusElectronMaterials science

A work piece is mixed with Ni pieces having an average diameter of 1 mm and exhibiting catalytic activity to oxidation reaction of sodium phosphinate (NaH2PO2) added as a reducing agent in a plating bath containing the reducing agent and a Ni salt to form a Ni-P film on an electrode made of Cu, Ag or Ag-Pd by auto-catalytic electroless plating. Then, the work piece is dipped in a plating bath containing an Au salt to form an Au film on the surface of the Ni-P film by substitutional electroless plating. This method is capable of forming a desired plating film only on a desired portion at a low cost.

Owner:MURATA MFG CO LTD

Lead-free electroless tin plating solution

InactiveCN102994994AEnables continuous autocatalytic depositionReduce typesLiquid/solution decomposition chemical coatingSolubilityPorosity

The invention relates to a lead-free electroless tin plating solution. The lead-free electroless tin plating solution is characterized by comprising the following components: 20 to 30g / L of stannous mono-sulphate, 60 to 120g / L of thiourea, 15 to 25g / L of citric acid, 20 to 50g / L of sulfur dioxide, 3 to 5g / L of ethylene diamine tetraacetic acid, 0.01 to 0.05g / L of polyethylene glycol, 20 to 55m / L of 98% of concentrated sulfuric acid, 0.5 to 1.0g / L of gelatin, and the balance of regulator. The lead-free electroless tin plating solution has the advantages that few categories of chemical materials are used and cost is low; the tin can be continuously deposited at a high speed on copper and a copper alloy substrate, thus semi-bright chemical coatings with different thicknesses can be produced, and the flatness of the chemical coatings can be improved; and the lead-free electroless tin plating solution is remarkable in grain refinement, low in porosity, simple in formula of plating solution, easy to control, stable in plating solution, long in service life and high in stability in batch production; and polyethylene glycol is a nontoxic and nonirritating substance with high water solubility, and can be combined with other materials without producing harmful substances.

Owner:NANTONG HUIFENG ELECTRONICS TECH

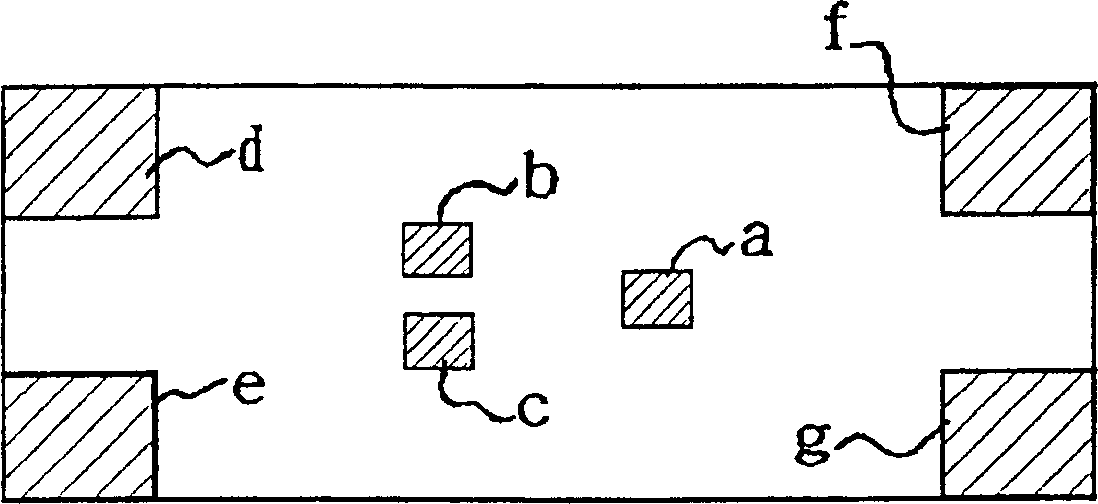

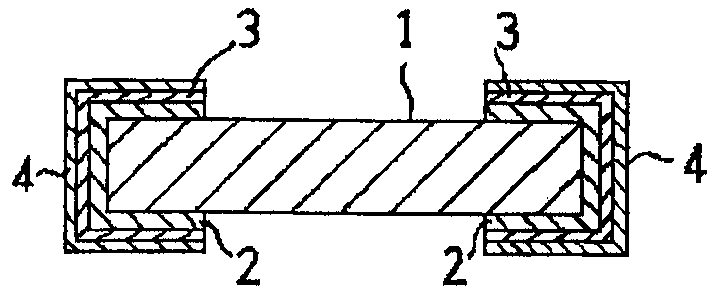

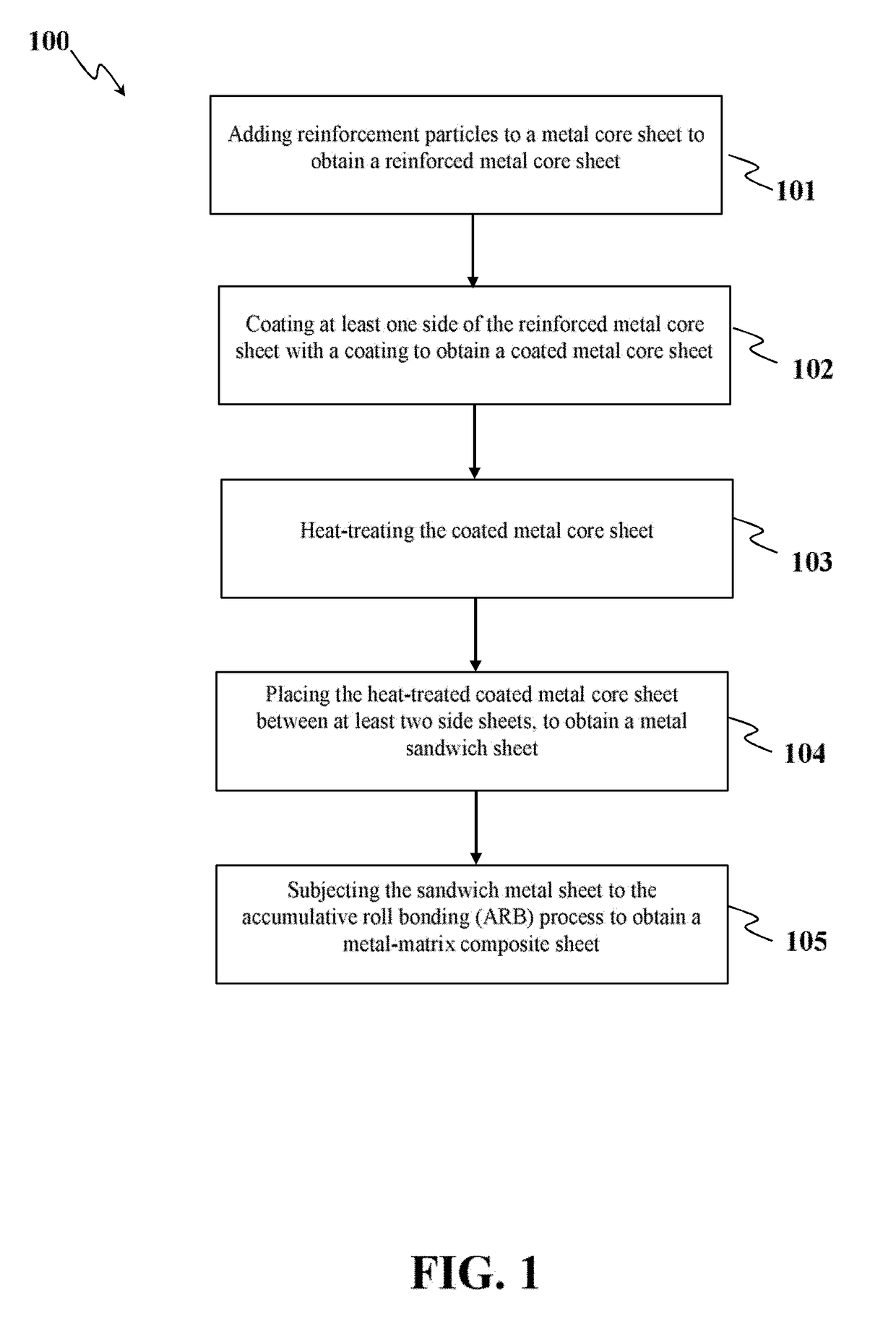

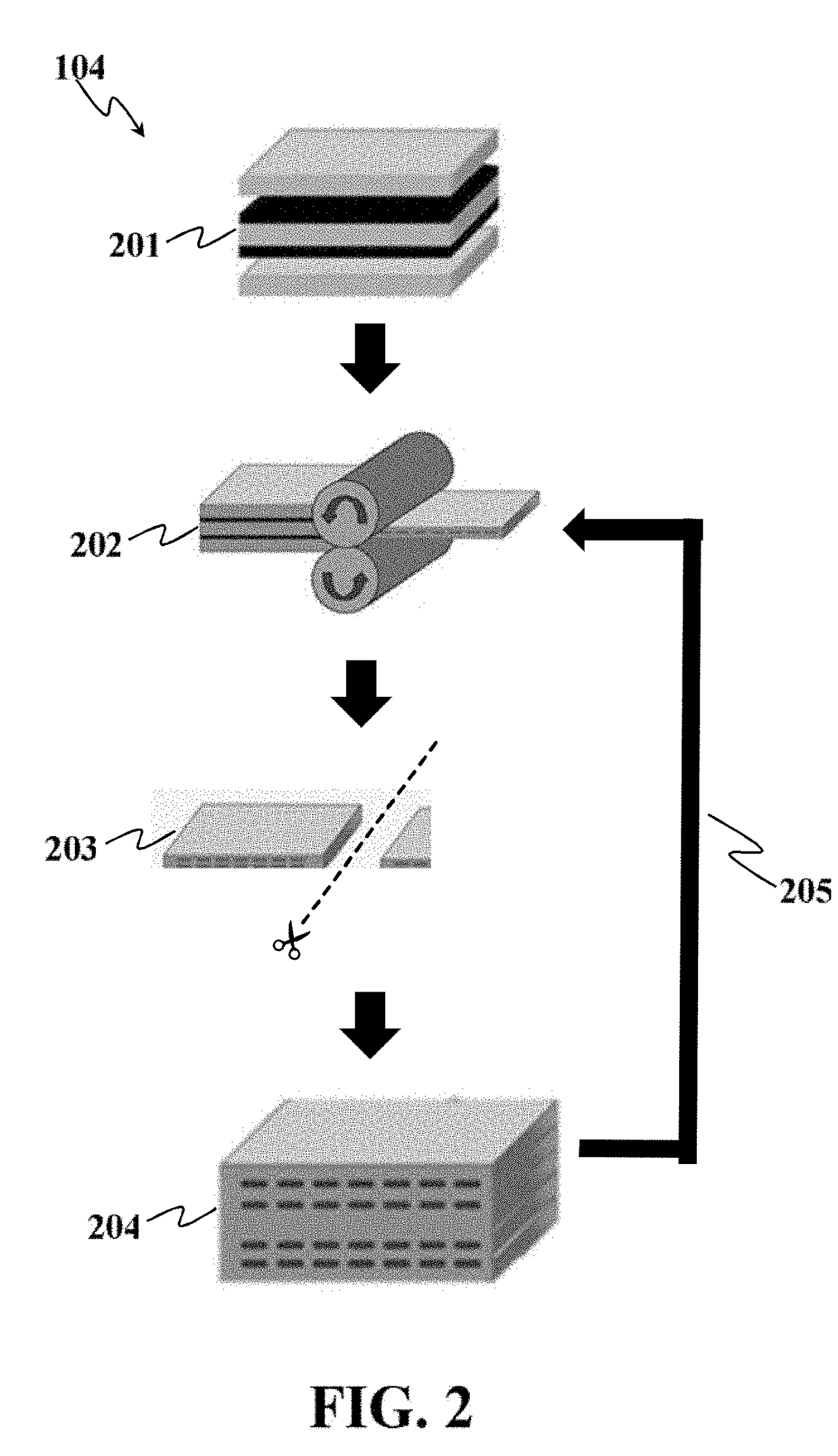

Multilayer metal matrix composite and fabrication thereof

InactiveUS20180057944A1Improve fracture toughnessMolten spray coatingVacuum evaporation coatingMetal matrix compositeAccumulative roll bonding

A multilayer metal-matrix composite that includes a metal core sheet and a plurality of side sheets is disclosed in which the metal core sheet is reinforced with a reinforcement material selected from the group consisting of ceramic reinforcements. The reinforced metal core sheet is coated with an electroless coating. A method of fabricating a multilayer metal-matrix composite with reinforced particles and a coating using a combination of electroless coating method and accumulative roll bonding method is further described in this disclosure with the aim of reducing the number of required accumulative roll bonding cycles to obtain improved or desired properties.

Owner:MOHAMMADIAN NADER +2

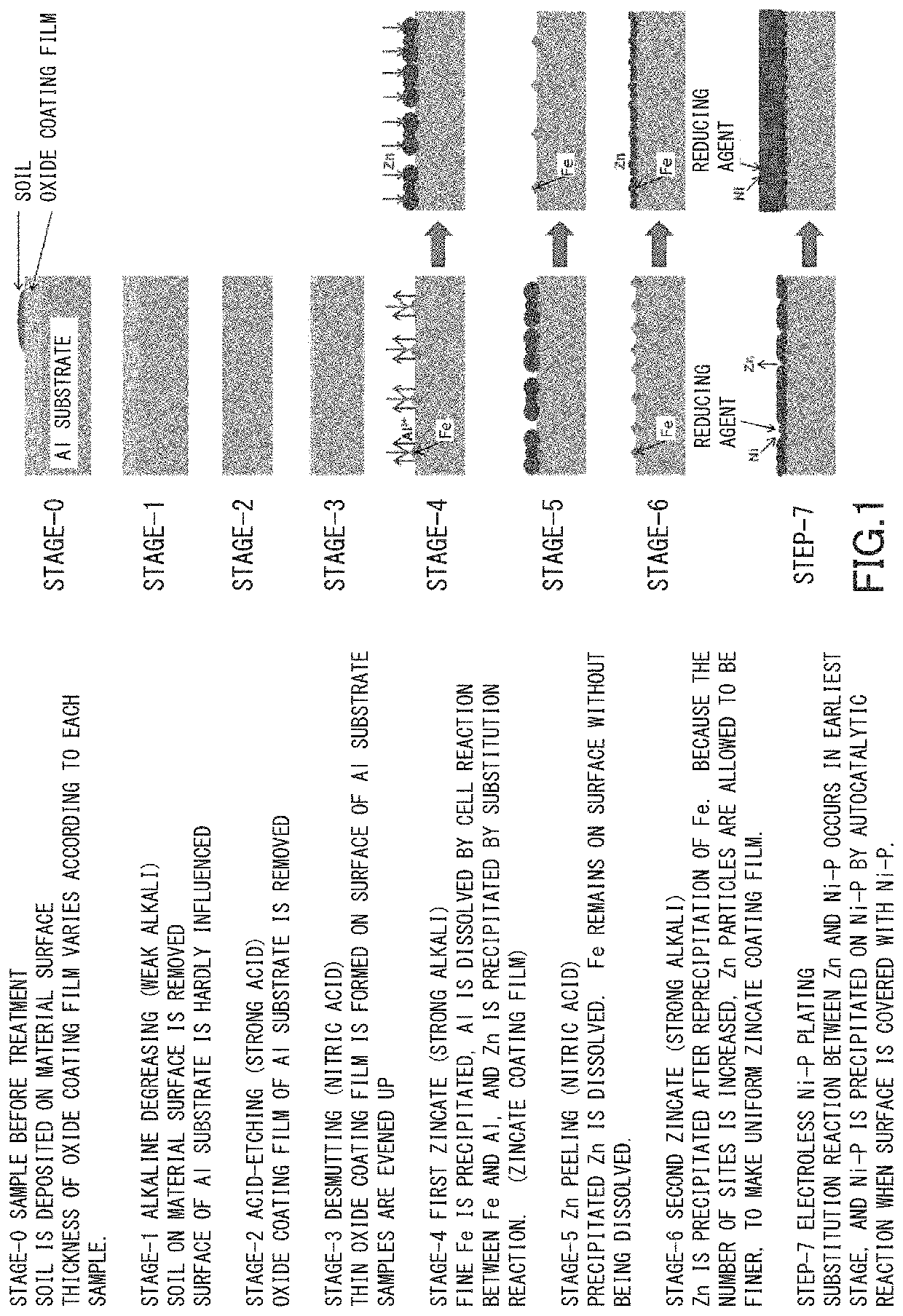

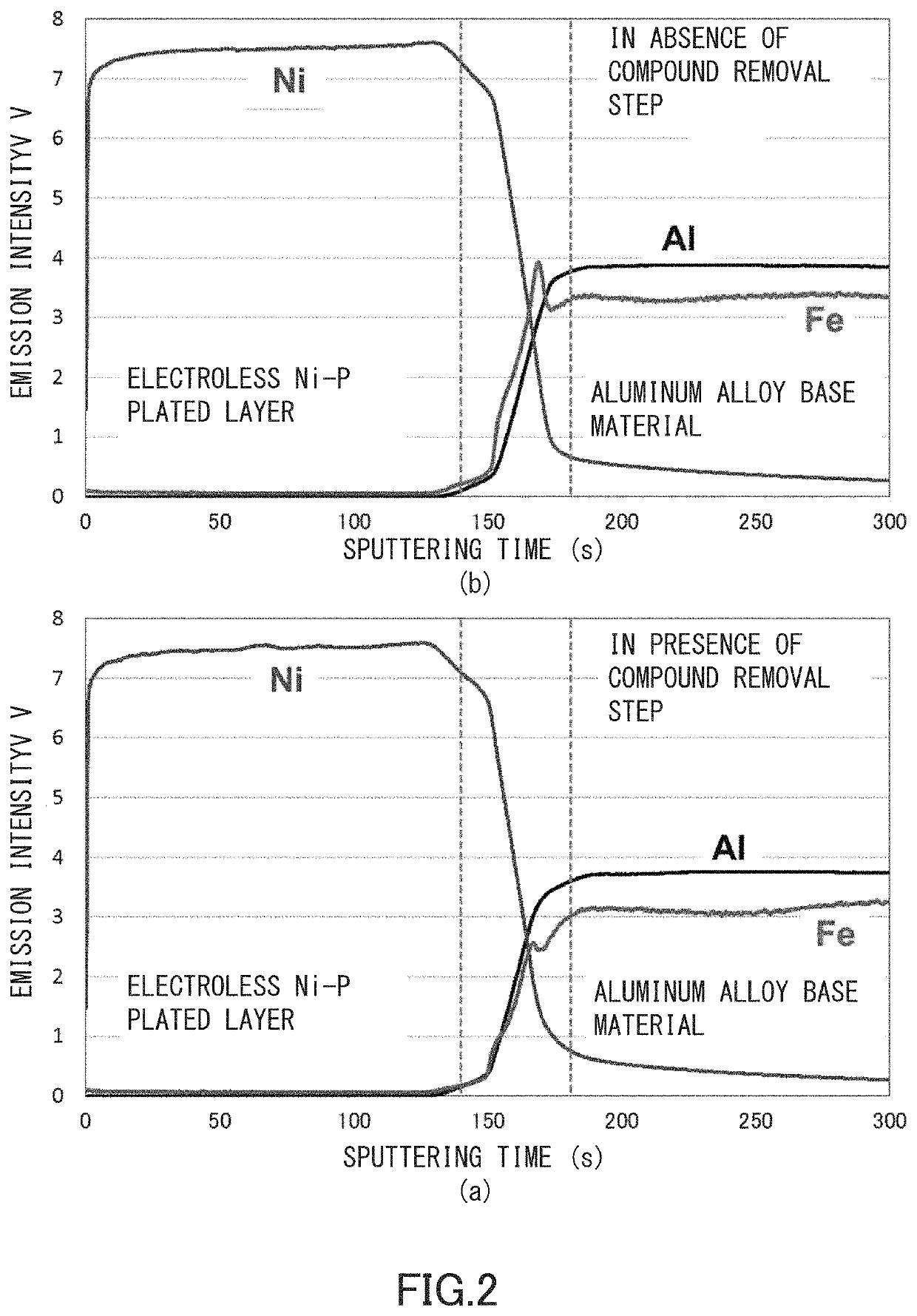

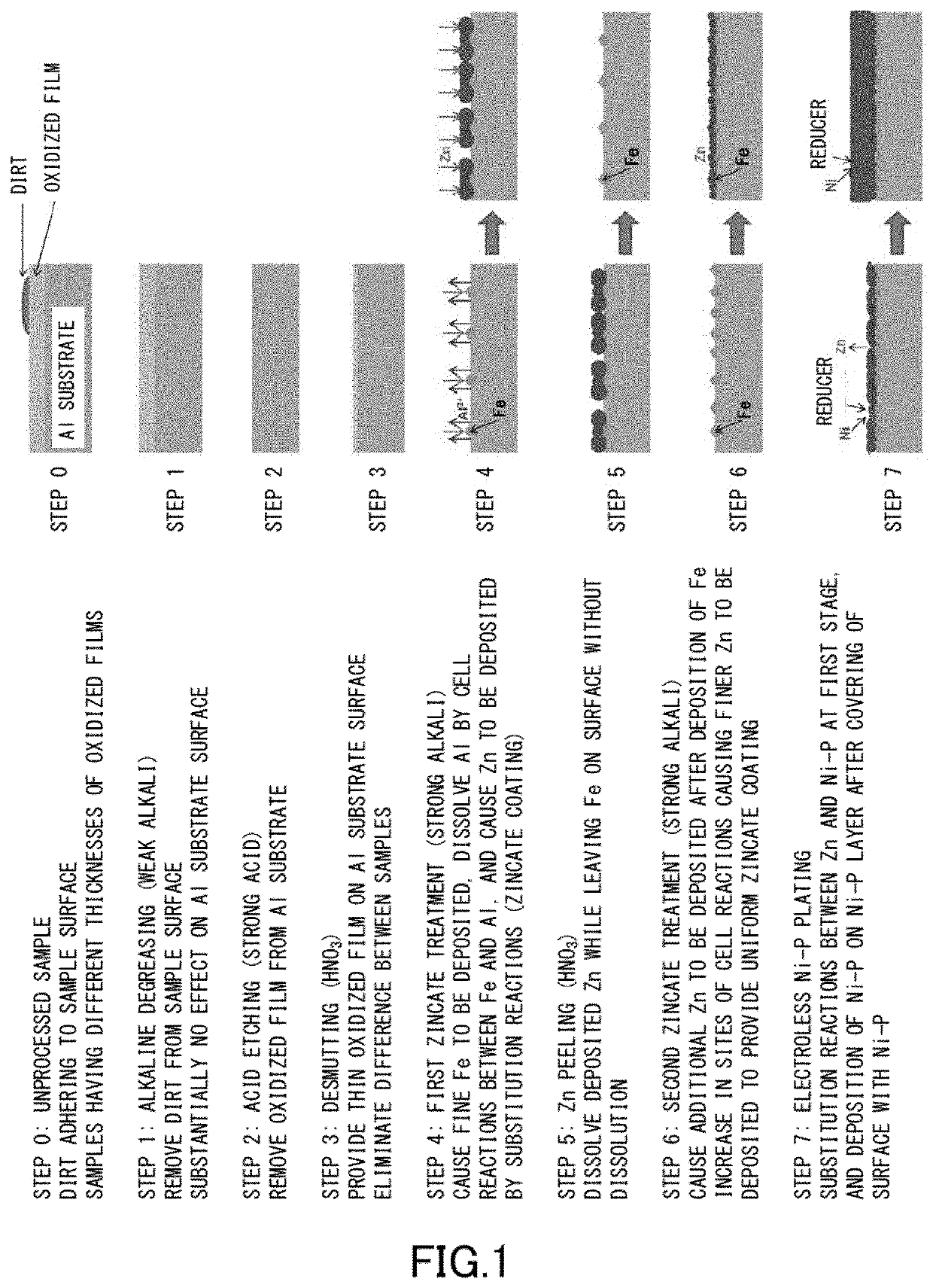

Aluminum alloy magnetic disk substrate and method for producing same

ActiveUS10767247B2Reduce defectsLarge capacityBase layers for recording layersRecord information storageOptical spectrometerOptical emission spectrometry

There are provided: an aluminum alloy magnetic disk substrate including: an aluminum alloy base material including an aluminum alloy containing 0.4 to 3.0 mass % (hereinafter, simply referred to as “%”) of Fe, 0.1 to 3.0% of Mn, 0.005 to 1.000% of Cu, and 0.005 to 1.000% of Zn, with the balance of Al and unavoidable impurities; and an electroless Ni—P plated layer formed on a surface of the aluminum alloy base material, in which the peak value (BLEI) of Fe emission intensity at an interface between the electroless Ni—P plated layer and the aluminum alloy base material, as determined by a glow discharge optical emission spectrometry device, is lower than Fe emission intensity (AlEI) in the interior of the aluminum alloy base material, as determined by the glow discharge optical emission spectrometry device; and a method for producing the aluminum alloy magnetic disk substrate.

Owner:FURUKAWA SKY ALUMINUM CORP +1

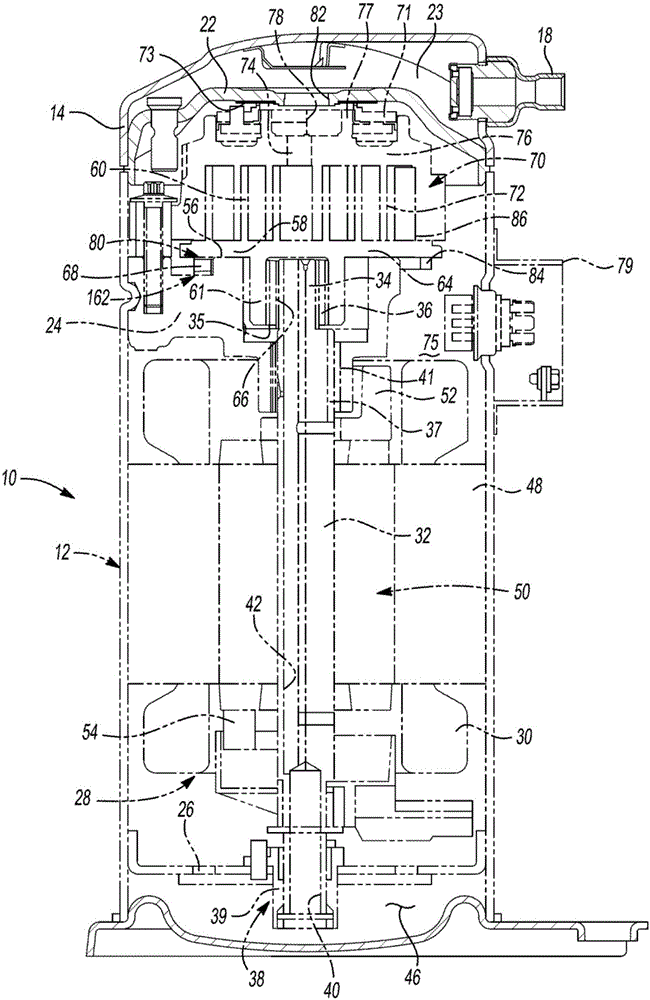

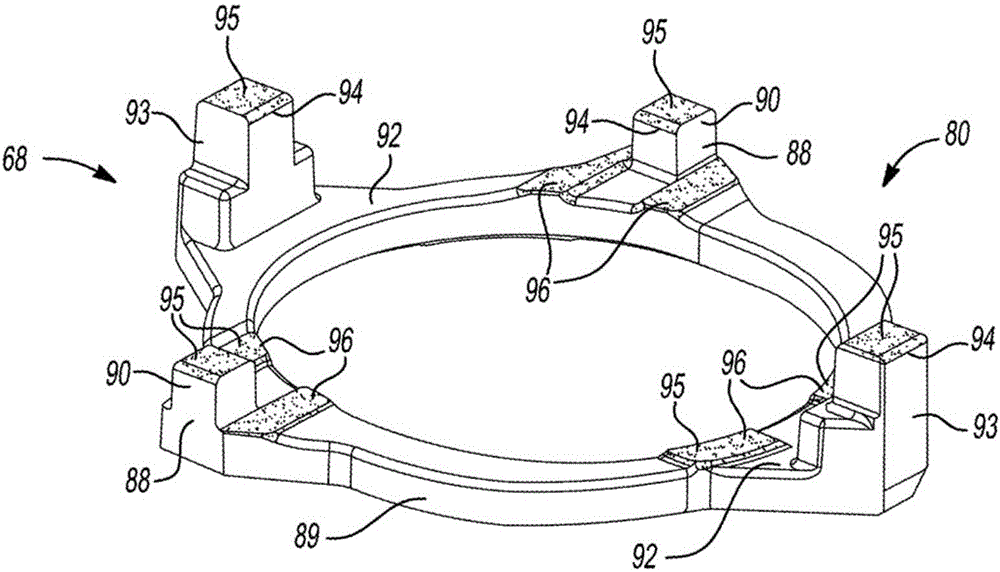

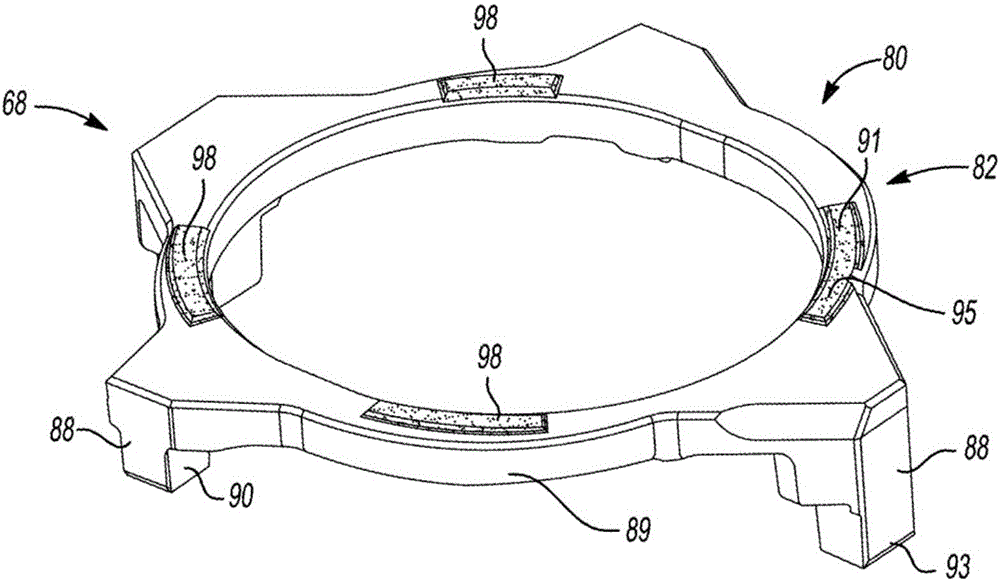

Components for compressors having electroless coatings on wear surfaces

ActiveCN105705793ARotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsWear resistantBoron nitride

The invention provides components for compressors having electroless coatings on wear surfaces. Carbon dioxide compressors having one or more coatings with wear surfaces having electroless surface coatings are provided. Alternatively, propane compressors are contemplated having wear surface coatings. The coating is electrolessly applied and may comprise nickel and wear resistant particles, such as boron nitride. The electroless surface coatings for use with compressor machines improve corrosion and wear resistance, as well as anti-friction properties for compressors processing CO2 or C3H8 containing refrigerants. In certain aspects, a scroll machine has an Oldham coupling and / or lower bearing comprising aluminum and has an electroless surface coating comprising nickel boron nitride particles disposed on one or more wear surfaces. In other aspects, a reciprocating compressor has a wear surface, such as on a connecting rod and / or piston coated with an electrolessly applied nickel and boron nitride particle layer. Methods for making the electroless surface coatings are also provided.

Owner:EMERSON CLIMATE TECH INC

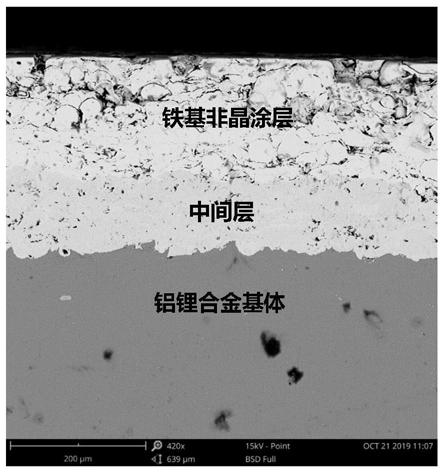

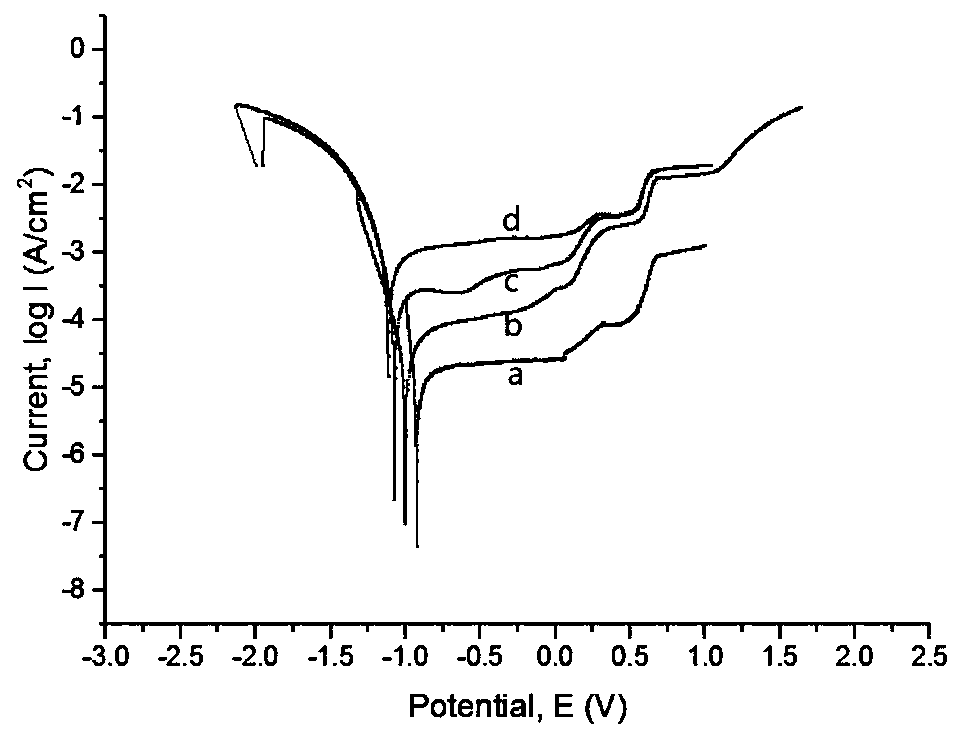

Aluminum alloy surface high-corrosion-resistant wear-resistant iron-based amorphous coating and preparation method thereof

InactiveCN111088471AHigh hardnessImprove corrosion resistanceMolten spray coatingSand blastingMaterials science

The invention discloses an aluminum alloy surface high-corrosion-resistant wear-resistant iron-based amorphous coating and a preparation method thereof. Aluminum alloy serves as a matrix, and the high-corrosion-resistant wear-resistant iron-based amorphous coating is prepared on the surface of the matrix, so that the material has good corrosion resistance and wear resistance under certain conditions, and the coating and the matrix have good bonding strength. The preparation process comprises the following steps that (1) the aluminum alloy matrix is pretreated; (2) sand blasting treatment is carried out on the surface of the pretreated aluminum alloy matrix; and (3) supersonic flame spraying is carried out on the surface of the aluminum alloy matrix obtained after sand blasting treatment toprepare the iron-based amorphous coating. Compared with existing surface treatment technologies such as electrostatic spraying, electroless plating, anodic oxidation and vapor deposition, the prepared hot-spraying iron-based amorphous coating has high corrosion resistance and wear resistance under certain conditions. The coating and the aluminum alloy matrix can form good interface bonding, the bonding strength of the coating and the matrix is enhanced, and the coating is prevented from falling off, so that the coating has excellent durability, and the surface of aluminum alloy can be effectively protected.

Owner:UNIV OF SCI & TECH BEIJING

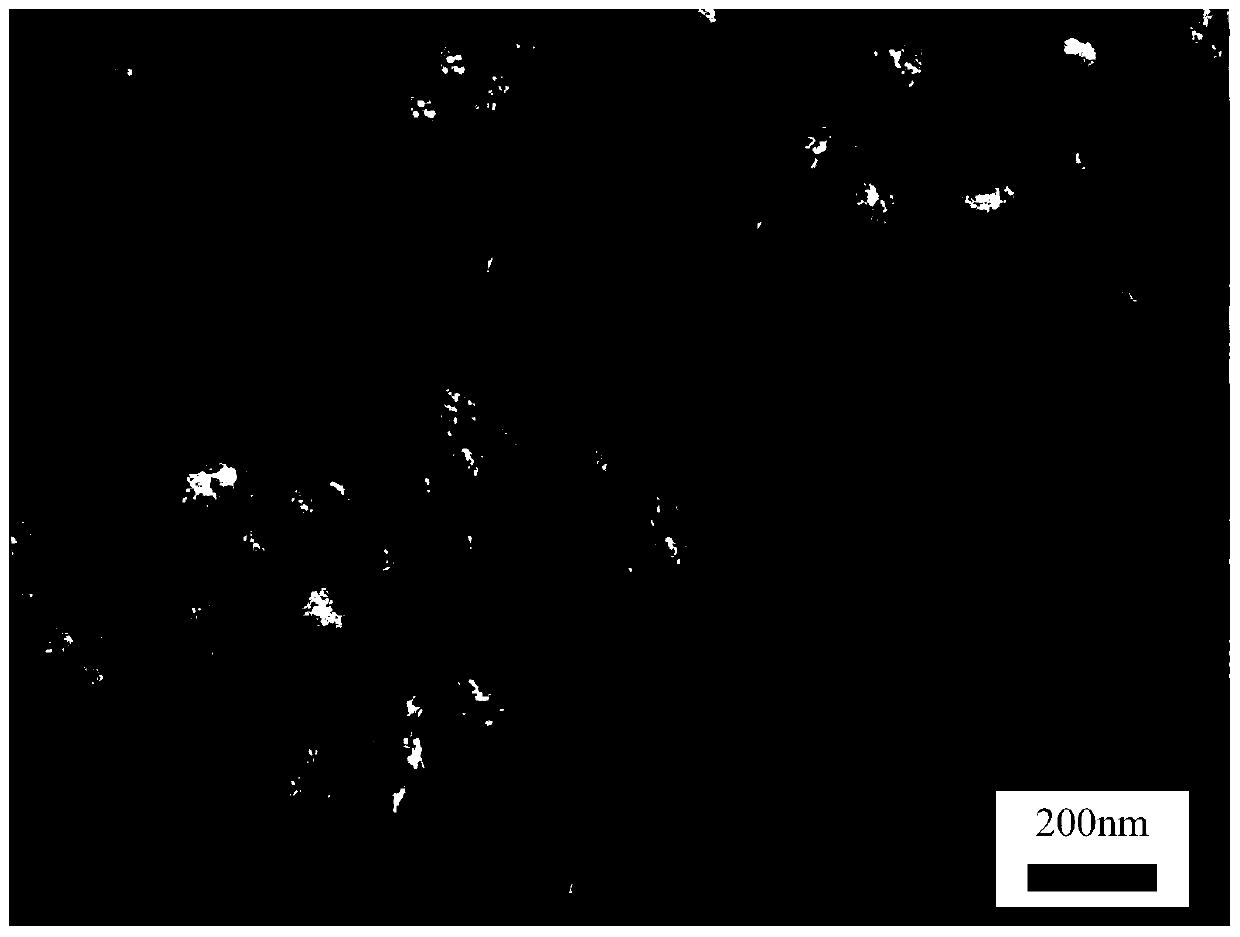

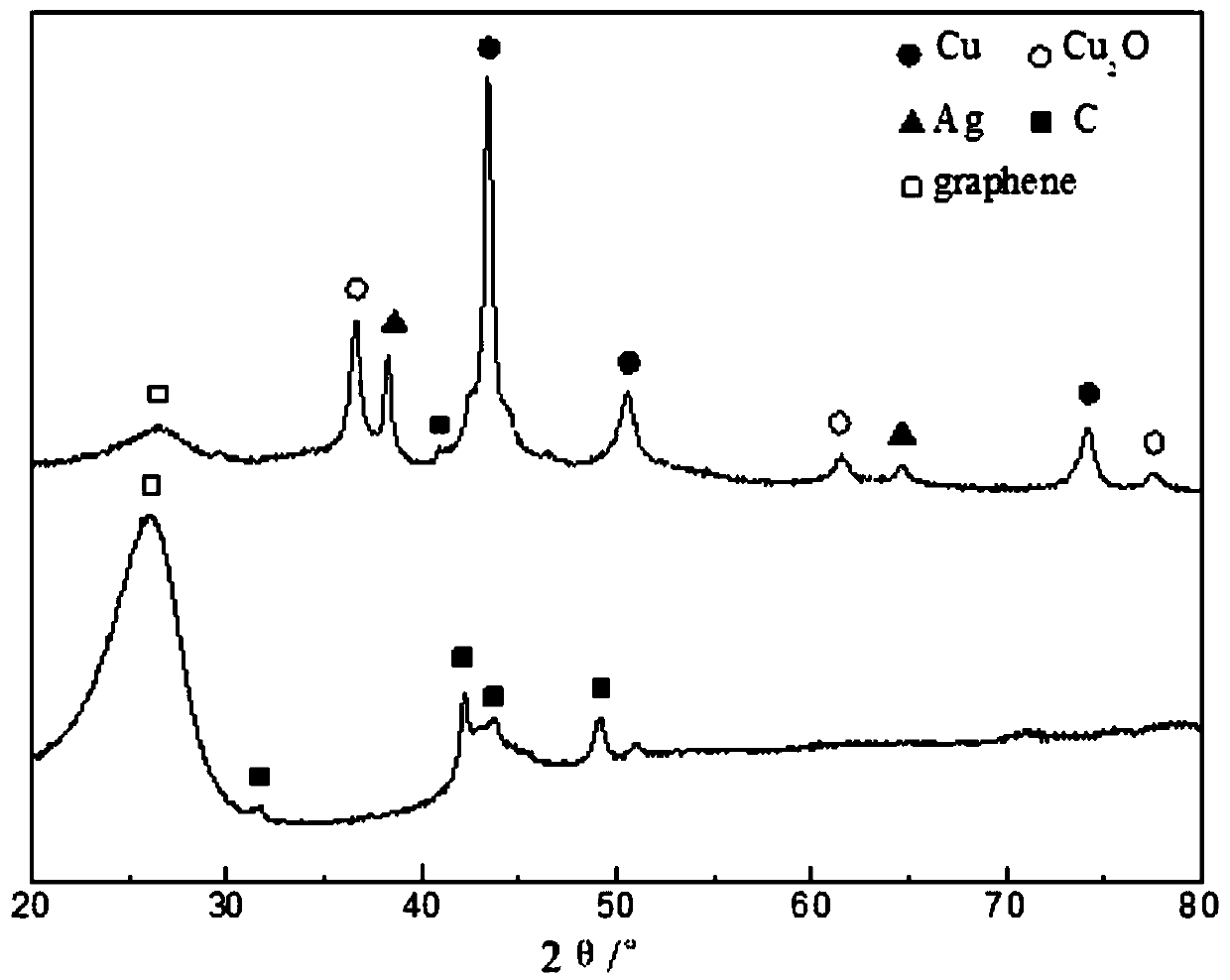

Graphene-loaded nano copper particle composite material and preparation method thereof

InactiveCN110923679AImprove bindingComplete structureTransportation and packagingMetal-working apparatusGraphene flakeNano copper

The invention discloses a graphene-loaded nano copper particle composite material and a preparation method thereof. The composite material is composed of a graphene sheet layer and a chemical coatingon the surface of the graphene sheet layer, and the chemical coating is nano copper with a face-centered cubic structure. The preparation method comprises the following steps: (1) immersing graphene into water for ultrasonic dispersion, then putting the graphene into sensitization liquid, and carrying out sensitization treatment on 90-100 DEG C; (2) taking out and washing the sensitized graphene,putting the sensitized graphene in an activating solution, and stirring and activating to obtain activated graphene; (3) taking out and washing the activated graphene, and then placing the activated graphene in a plating solution containing main salt and reducing agent components; (4) heating the plating solution, adjusting the pH value, and preserving heat; and (5) washing and drying the copper plating graphene. According to the method disclosed by the invention, the stable combination between the graphene and the nano copper particles can be realized, the surface defects of the graphene arerepaired, and the comprehensive performance of the graphene is improved.

Owner:NORTHEASTERN UNIV

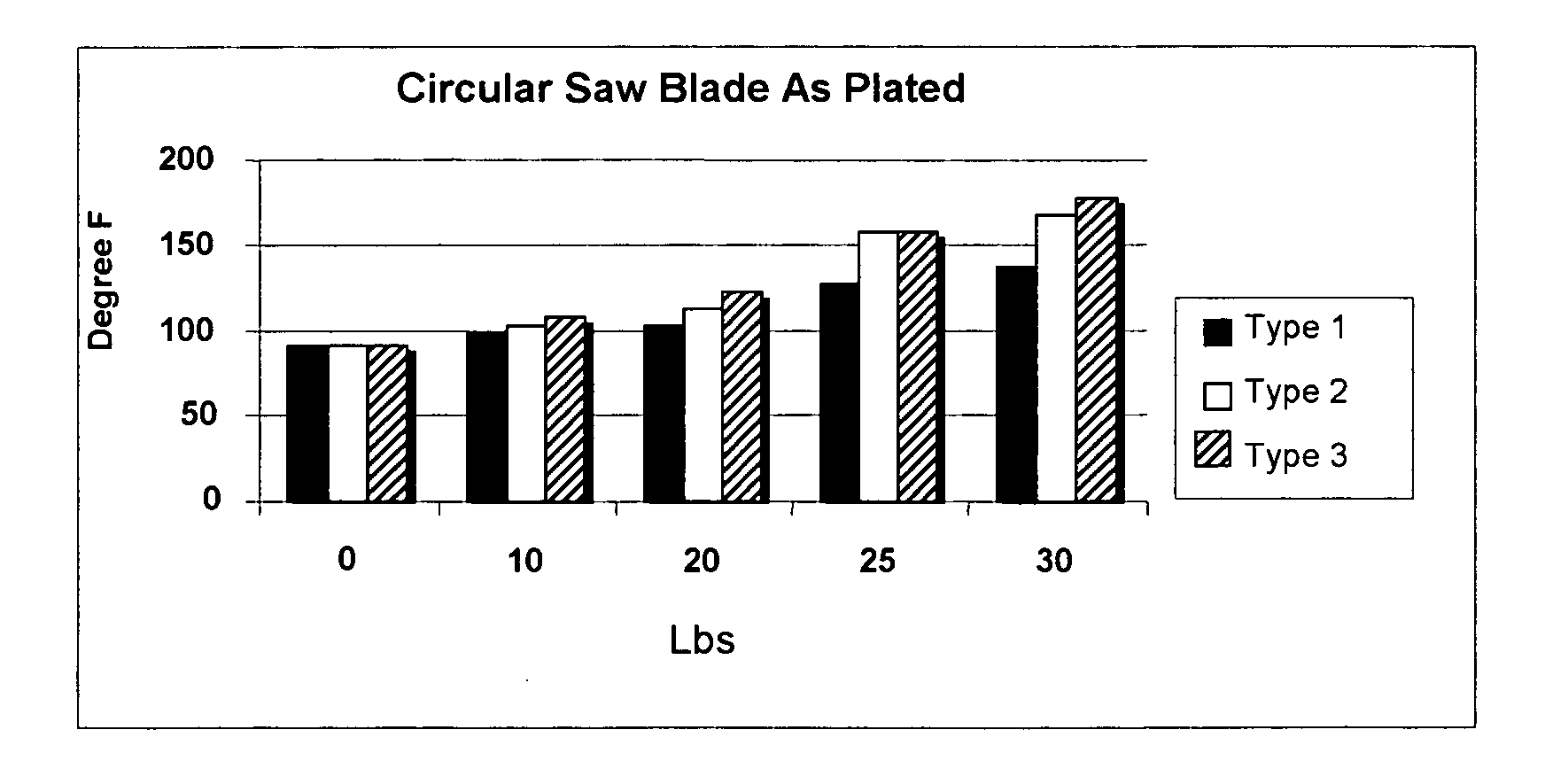

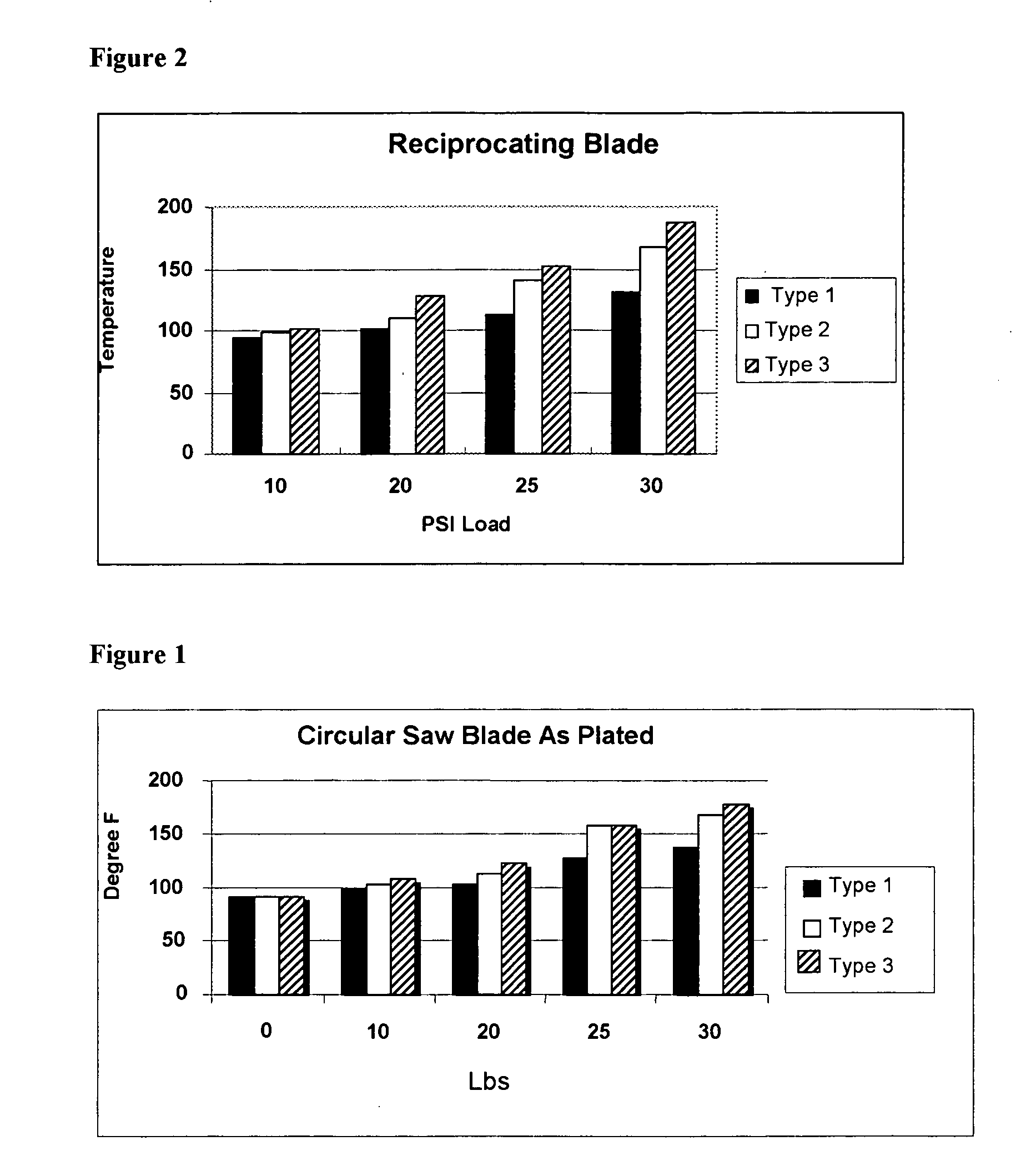

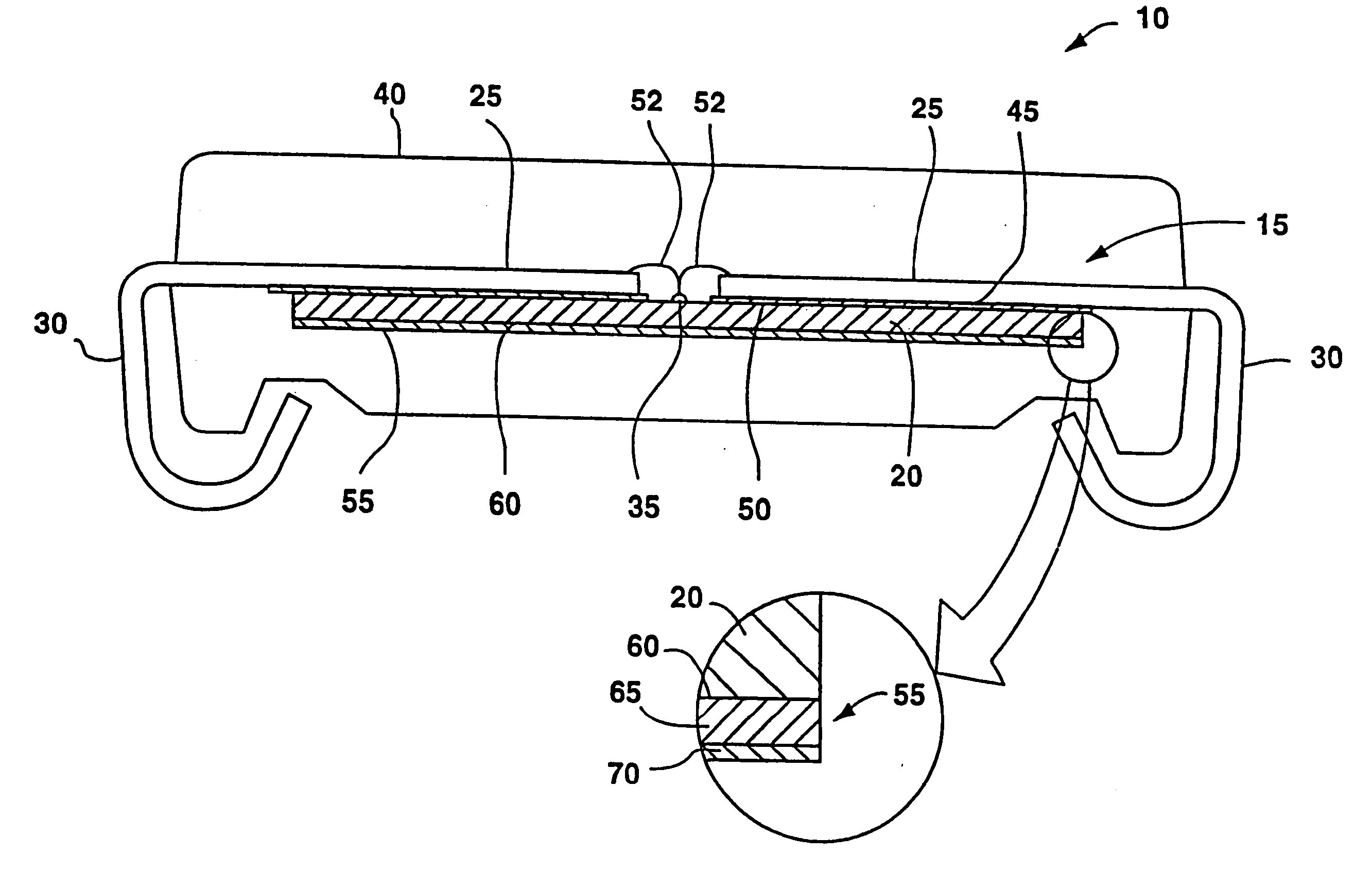

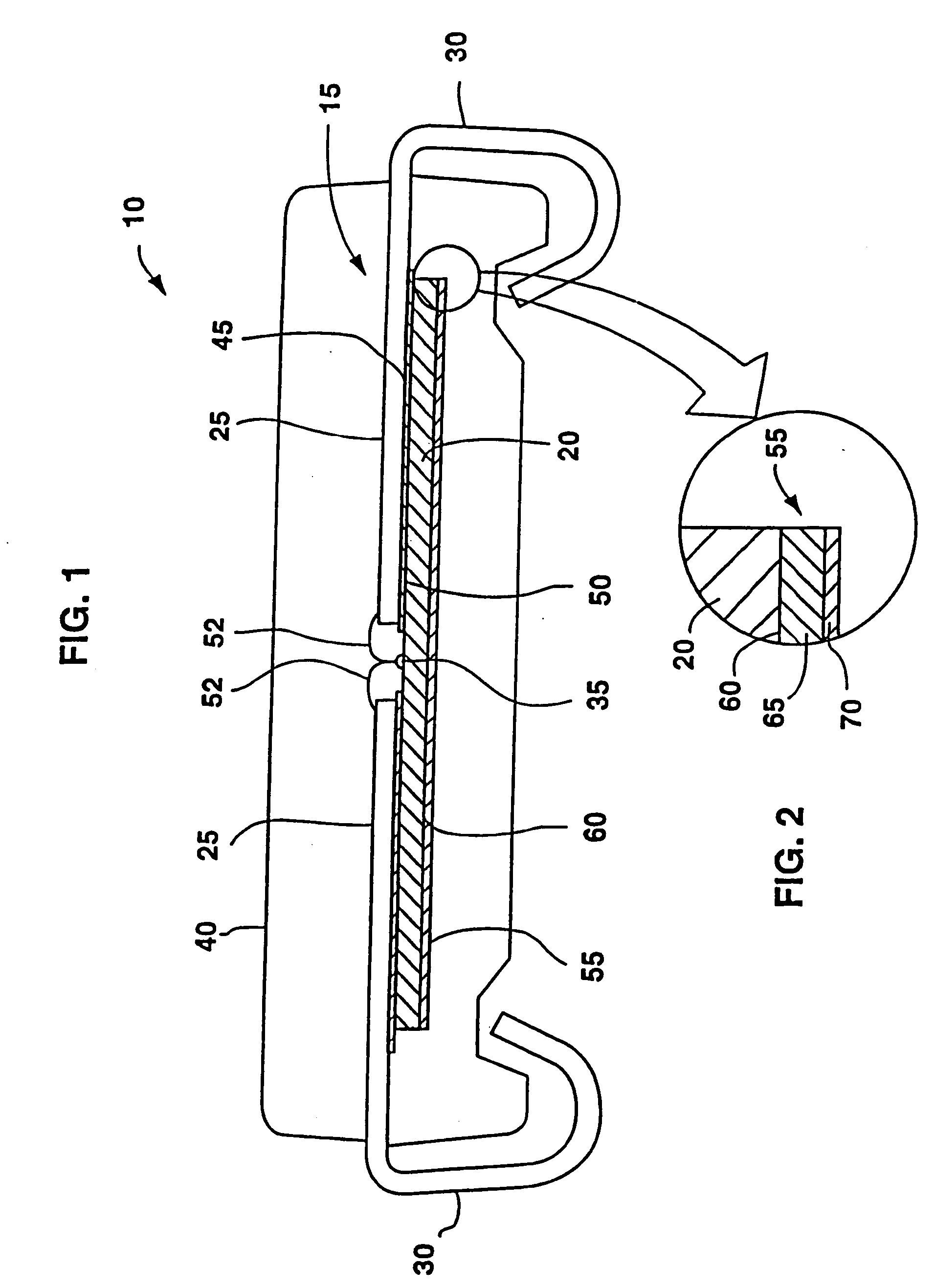

Blades coated with a nickel boron metal coating

InactiveUS20090151525A1Metal sawing toolsLiquid/solution decomposition chemical coatingMetal coatingElectroless nickel

The saw and cutting blades of this invention have an electroless nickel boron coating applied from a bath containing metal stabilizers. The metal stabilizer is usually introduced into the coating from an electroless coating bath and is co-deposited into the coating. The source of the metal stabilizer is usually a metal compound or salt that is used to stabilize the nickel boron bath.

Owner:ED MCCOMAS

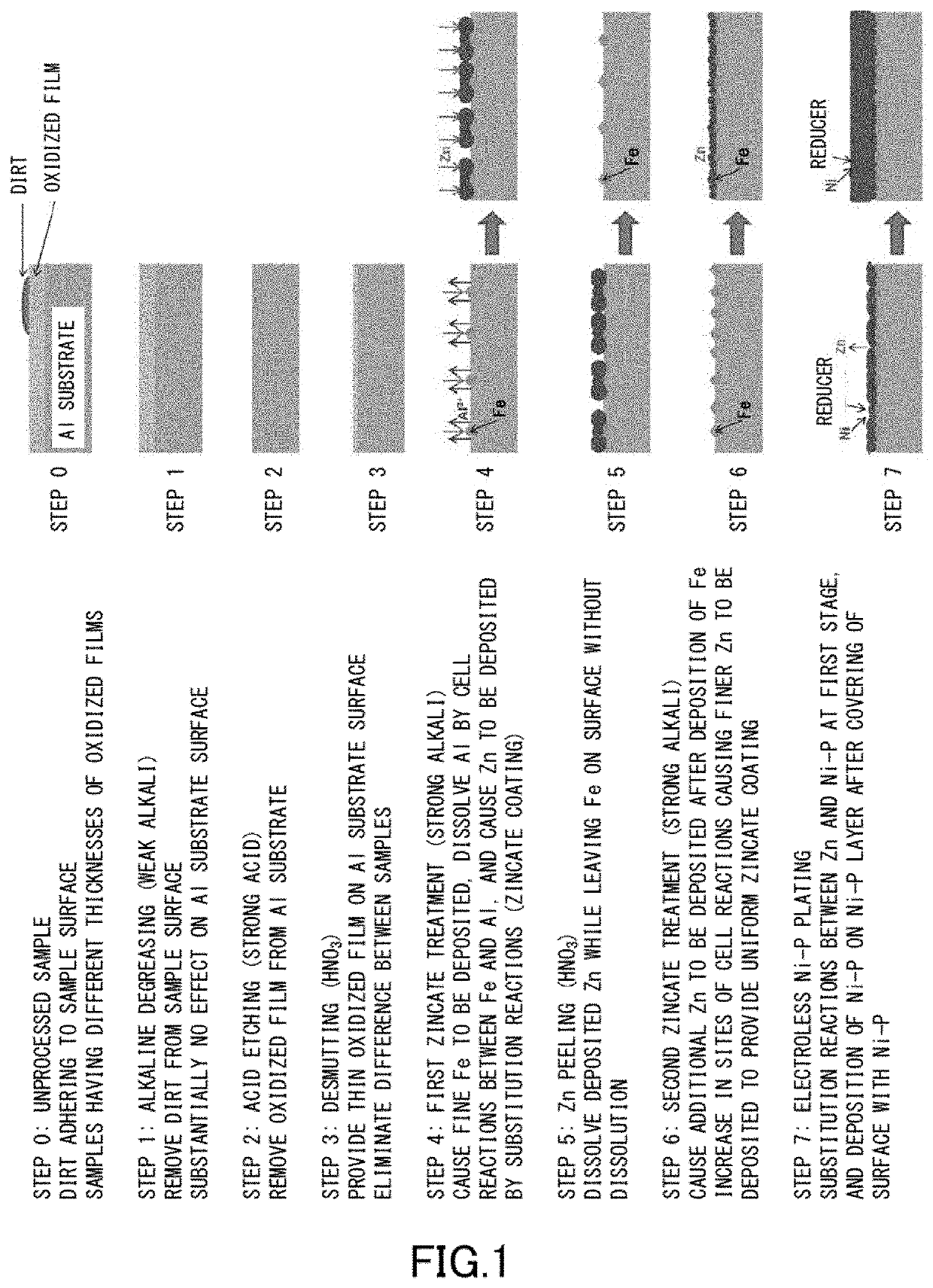

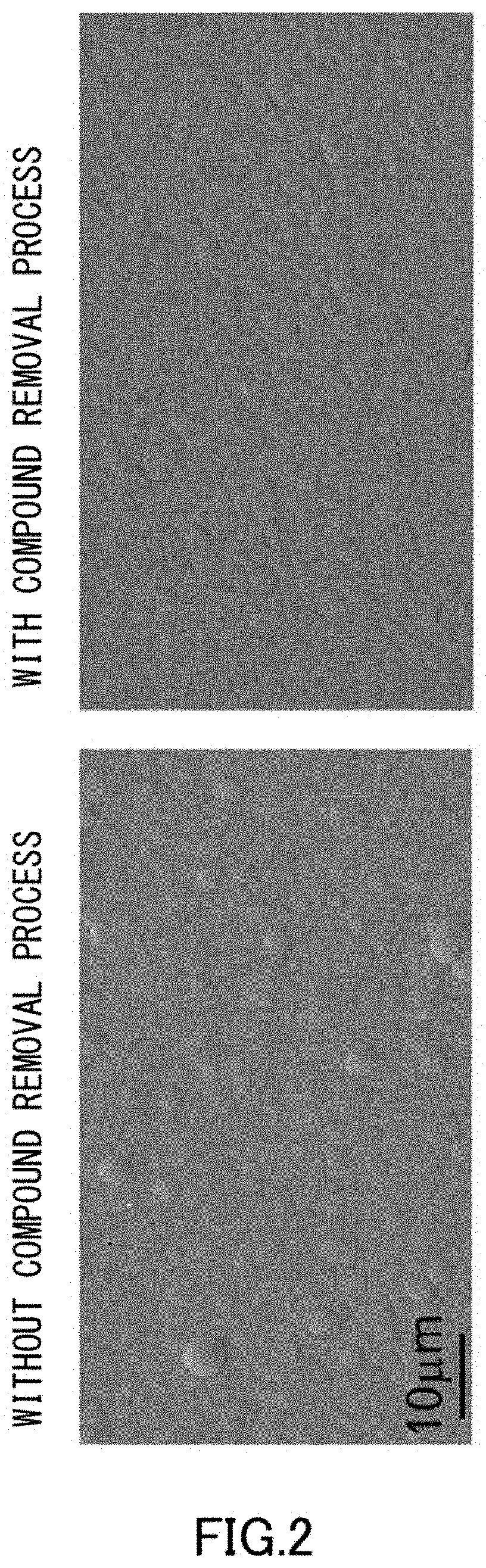

Magnetic disc, aluminum alloy substrate for magnetic disc, and production method for aluminum alloy substrate

ActiveUS20210012801A1High strengthLow levelBase layers for recording layersMagnetic layer production by platingAlloy substrateWavelength range

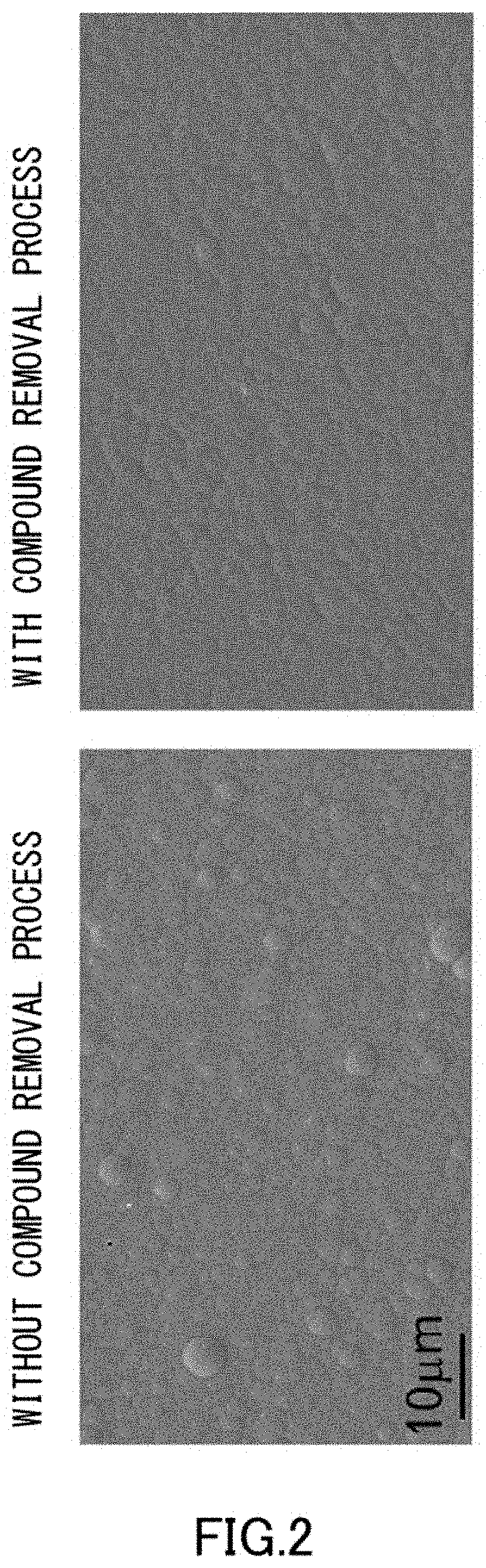

Provided are a magnetic disk and a method of fabricating the magnetic disk. The magnetic disk includes an aluminum alloy plate fabricated by a process involving a CC method and a compound removal process, and an electroless Ni—P plating layer disposed on the surface of the plate. The aluminum alloy plate is composed of an aluminum alloy containing 0.4 to 3.0 mass % (hereinafter abbreviated simply as “%”) of Fe, 0.1% to 3.0% of Mn, 0.005% to 1.000% of Cu, 0.005% to 1.000% of Zn, with a balance of Al and unavoidable impurities. In the magnetic disk, the maximum amplitude of waviness in a wavelength range of 0.4 to 5.0 mm is 5 nm or less, and the maximum amplitude of waviness in a wavelength range of 0.08 to 0.45 mm is 1.5 nm or less.

Owner:FURUKAWA SKY ALUMINUM CORP +1

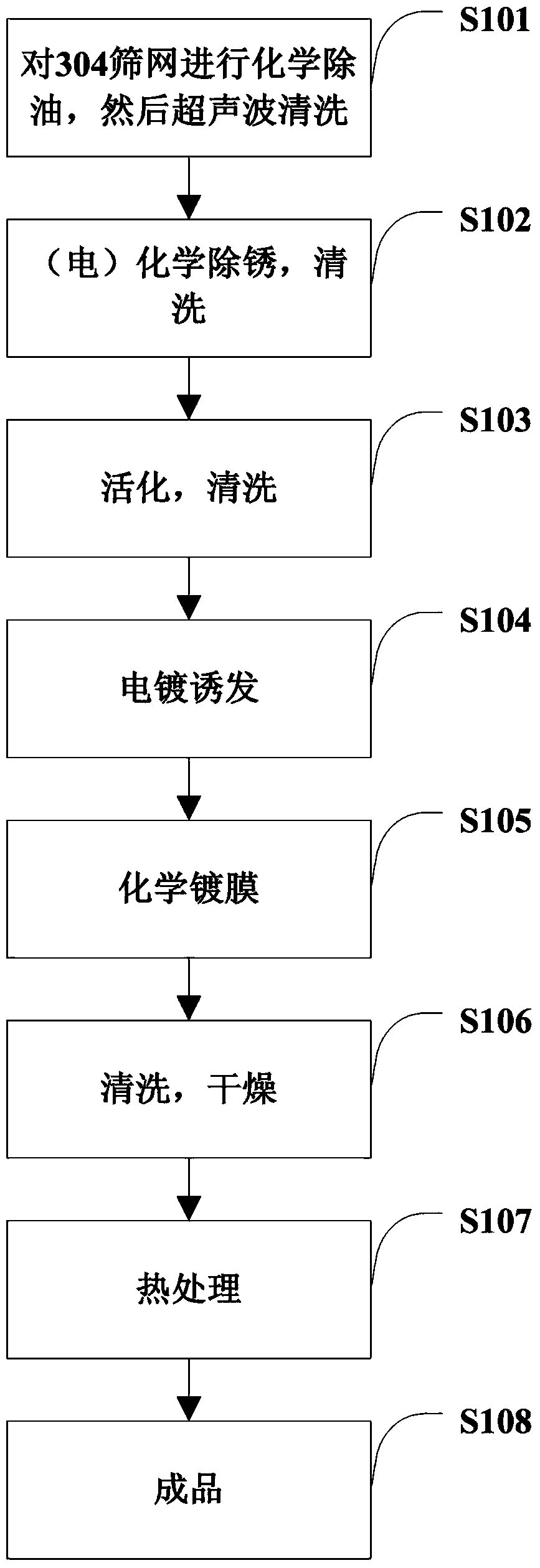

Manufacturing method of chemically-plated metal wire screen

InactiveCN104178753AImprove wear resistanceImprove corrosion resistanceLiquid/solution decomposition chemical coatingChemical platingMetal filament

The invention discloses a manufacturing method of a chemically-plated metal wire screen, which comprises the following steps: carrying out chemical deoiling on the metal wire screen (such as 304 stainless steel wire screen), and carrying out ultrasonic cleaning; carrying out (electro)chemical rust removal, and cleaning; activating and cleaning; carrying out electroplating induction; carrying out chemical plating, and cleaning; drying; and carrying out heat treatment to obtain the finished product. A Ni-P (or Ni-W-P, Ni-Mo-P or the like) chemical coating is plated on the existing carbon steel metal wire screen, or 304, 316L or any other stainless steel metal wire screen, so that the abrasion resistance of the metal wire screen is obviously enhanced, the corrosion resistance of the metal wire screen is improved, and the service life of the metal wire screen is greatly prolonged by 22-57 times under identical conditions, thereby obviously lowering the use cost of the screen.

Owner:HENAN INST OF SCI & TECH

Adhesion enhanced semiconductor die for mold compound packaging

InactiveUS20050001295A1Improve adhesionReduce layeringSemiconductor/solid-state device detailsSolid-state devicesShell moldingCopper

A semiconductor die includes a metal layer deposited thereon for enhancing adhesion between the die and a mold compound package. The metal layer is substantially oxide free. The die is coated with a layer or layers of copper (Cu) and / or palladium (Pd) by electroplating or electroless coating techniques. The metal layer provides a uniform wetting surface for better adhesion of the die with the mold compound package during encapsulation. The increased adhesion reduces the delamination potential of the die from the package.

Owner:KING JERROLD L +2

Material for forming electroless plate, coating solution for adhering catalyst, method for forming electroless plate, and plating method

InactiveUS8389123B2No discolorationImprove performanceSynthetic resin layered productsPretreated surfacesHydrophilic monomerPolymer science

Owner:KIMOTO CO LTD +1

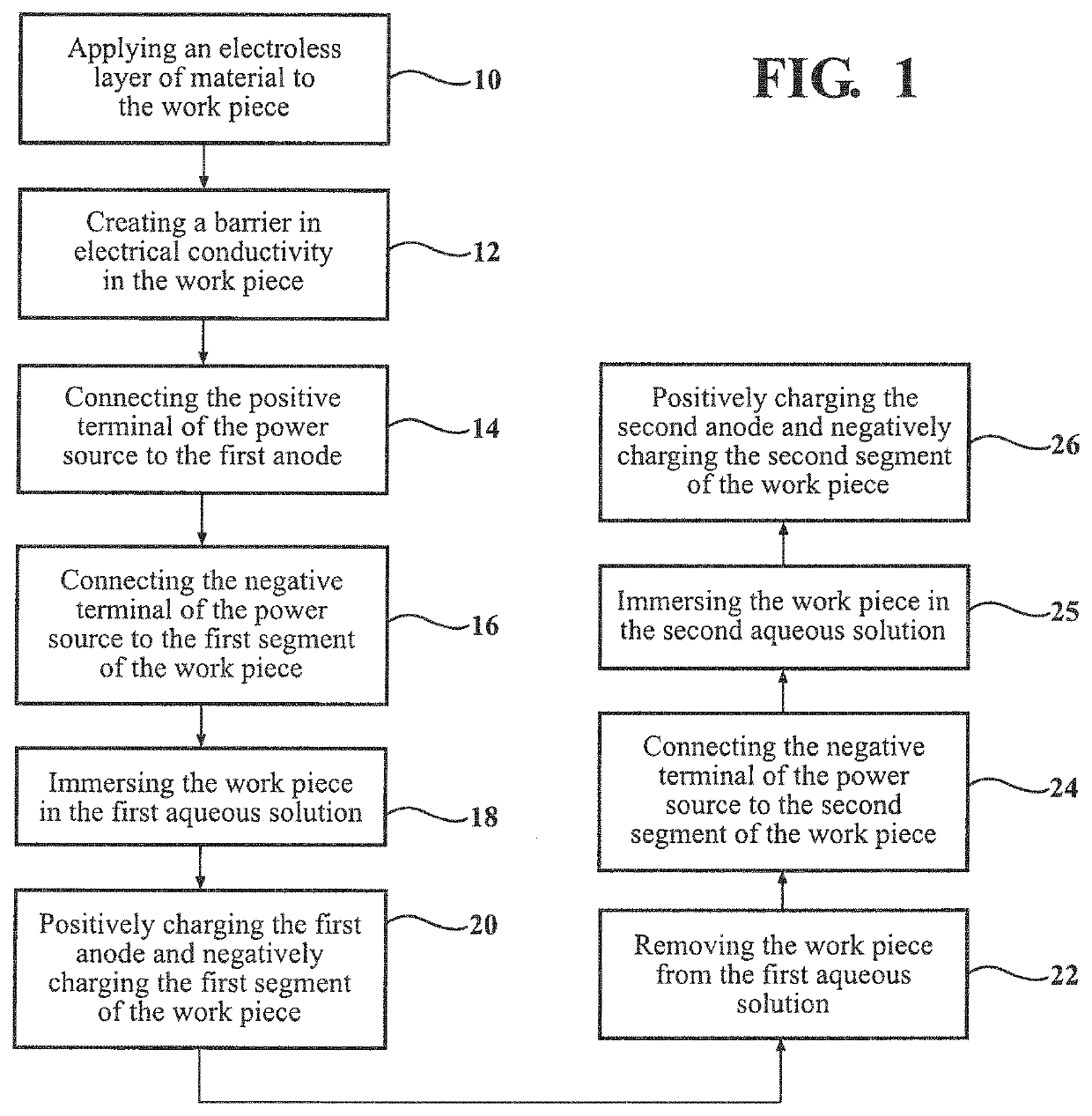

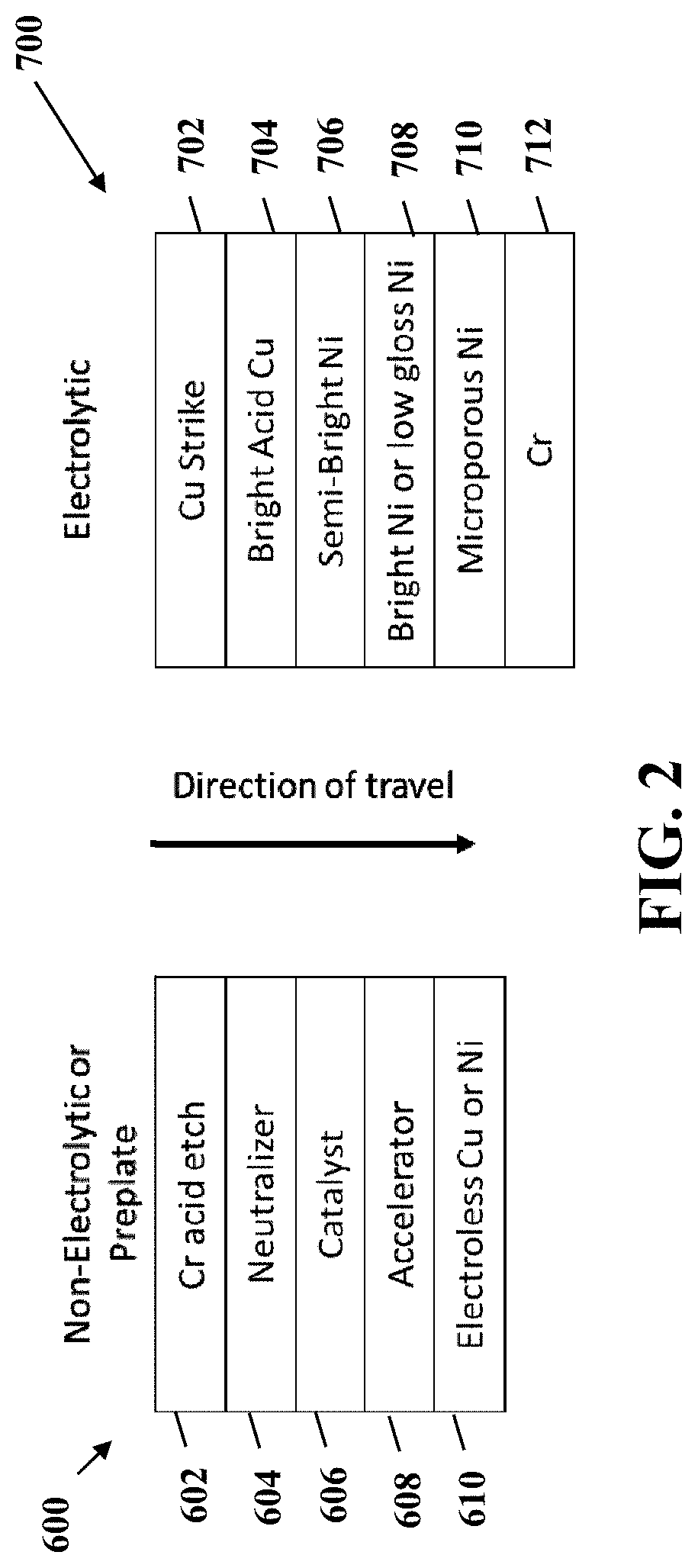

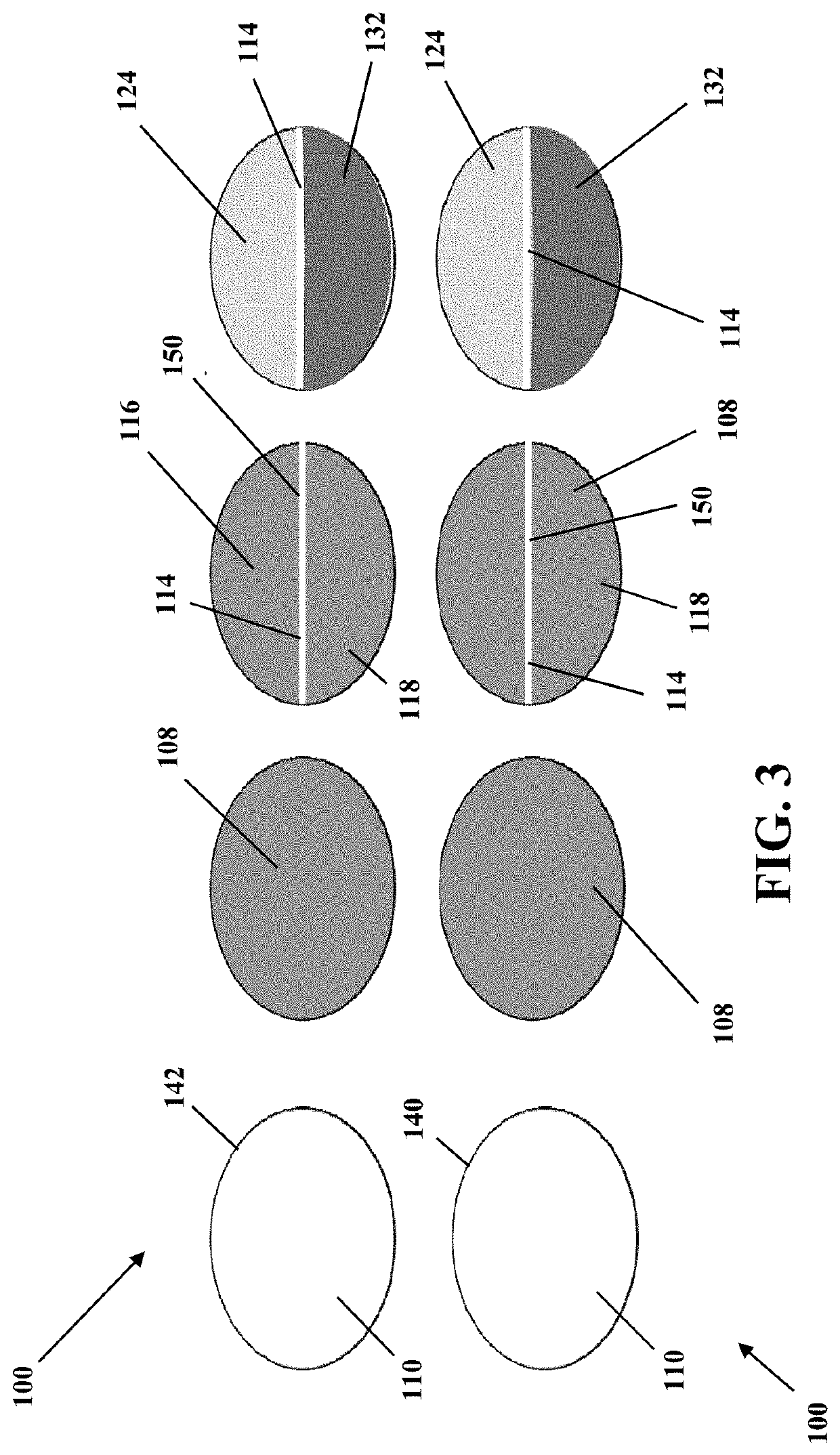

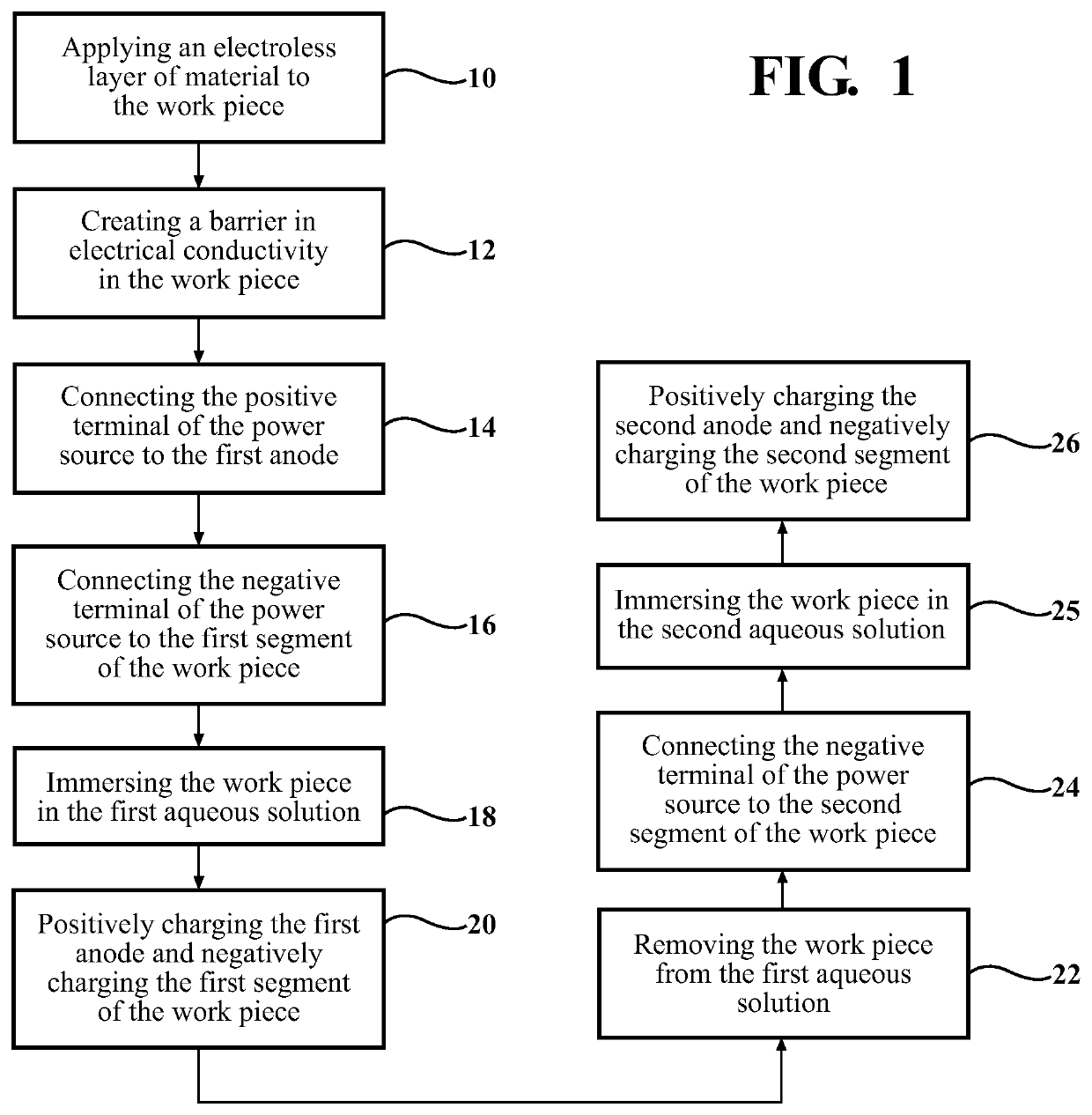

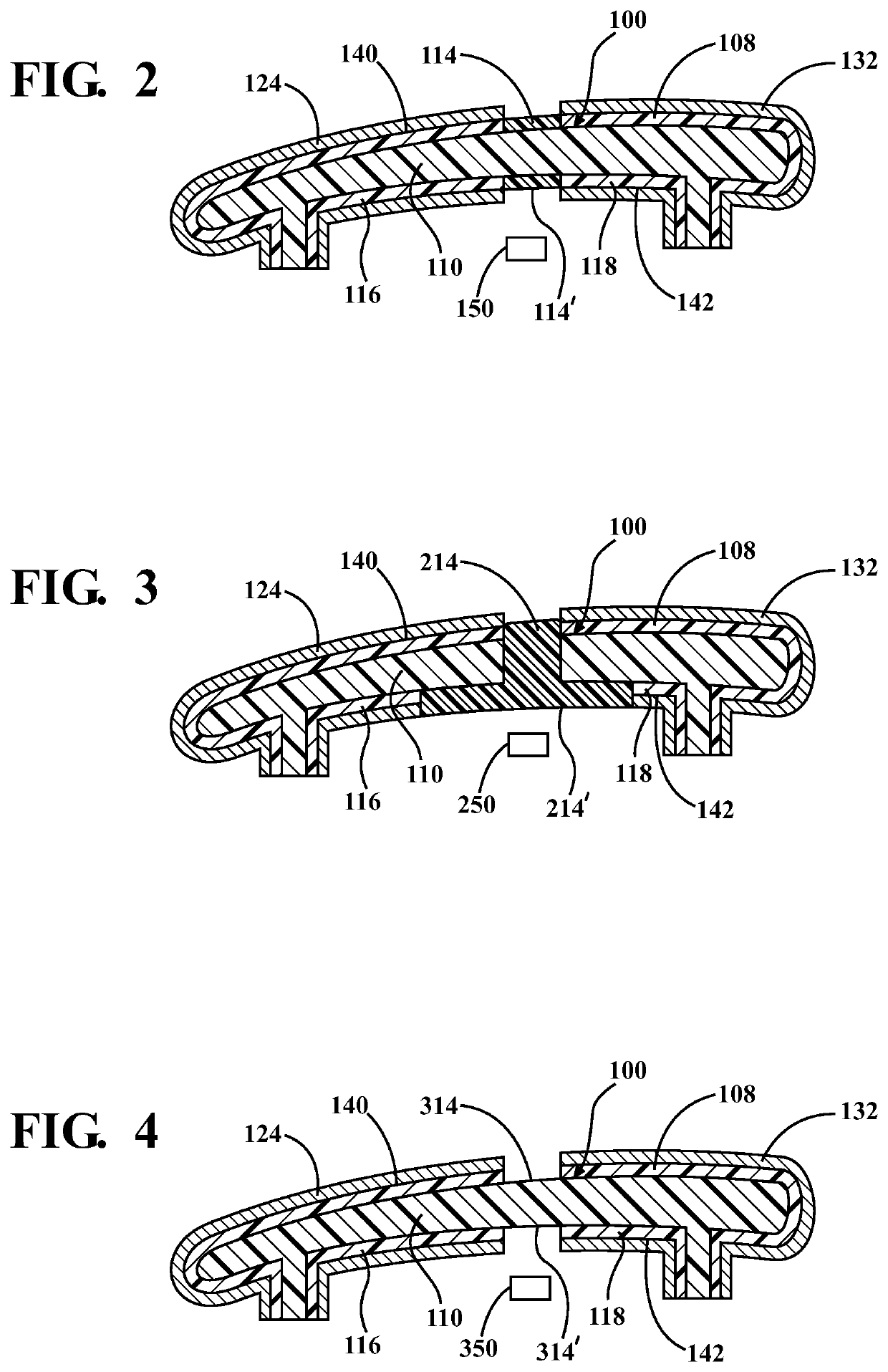

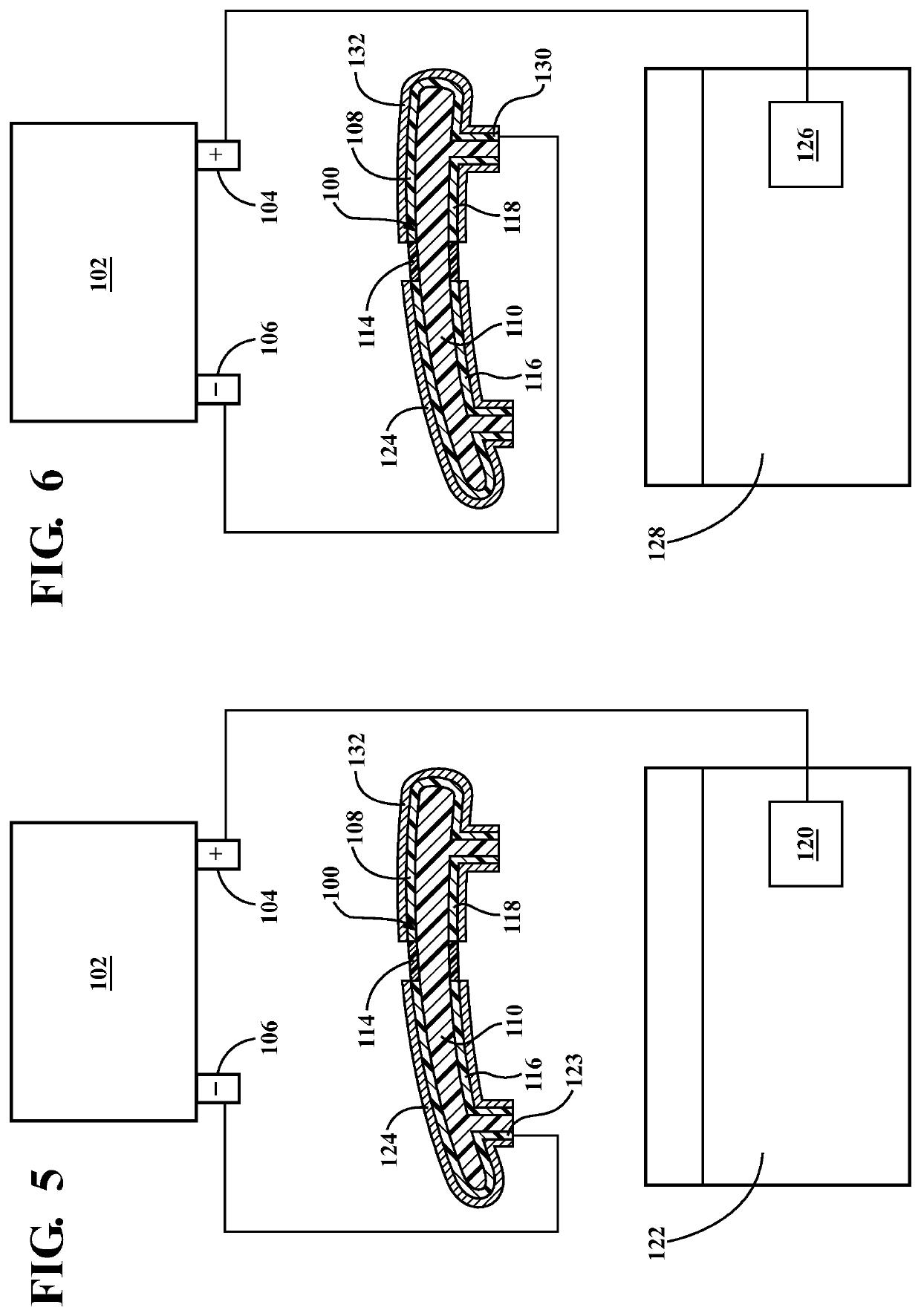

Method for creating multiple electrical current pathways on a work piece using laser ablation

PendingUS20210207280A1Eliminate needSimple and inexpensive processCellsDecorative surface effectsEngineeringPhoto ablation

A method for creating multiple current pathways for plating a work piece is provided. An electroless layer of material is applied to the work piece using an electroless plating process. The method includes creating a barrier in electrical conductivity in the work piece to divide the work piece into a first segment and a second segment which are substantially electrically insulated from one another, prior to electroplating the work piece. After depositing the electroless layer of material, laser ablation is performed on at least a portion of the work piece to remove a portion of the electroless layer of material to define at least a portion of the barrier. Prior to electroless plating, a resist material may be applied to at least a portion of the work piece, with the resist material combining with the removed material to define the barrier.

Owner:LACKS ENTERPRISES

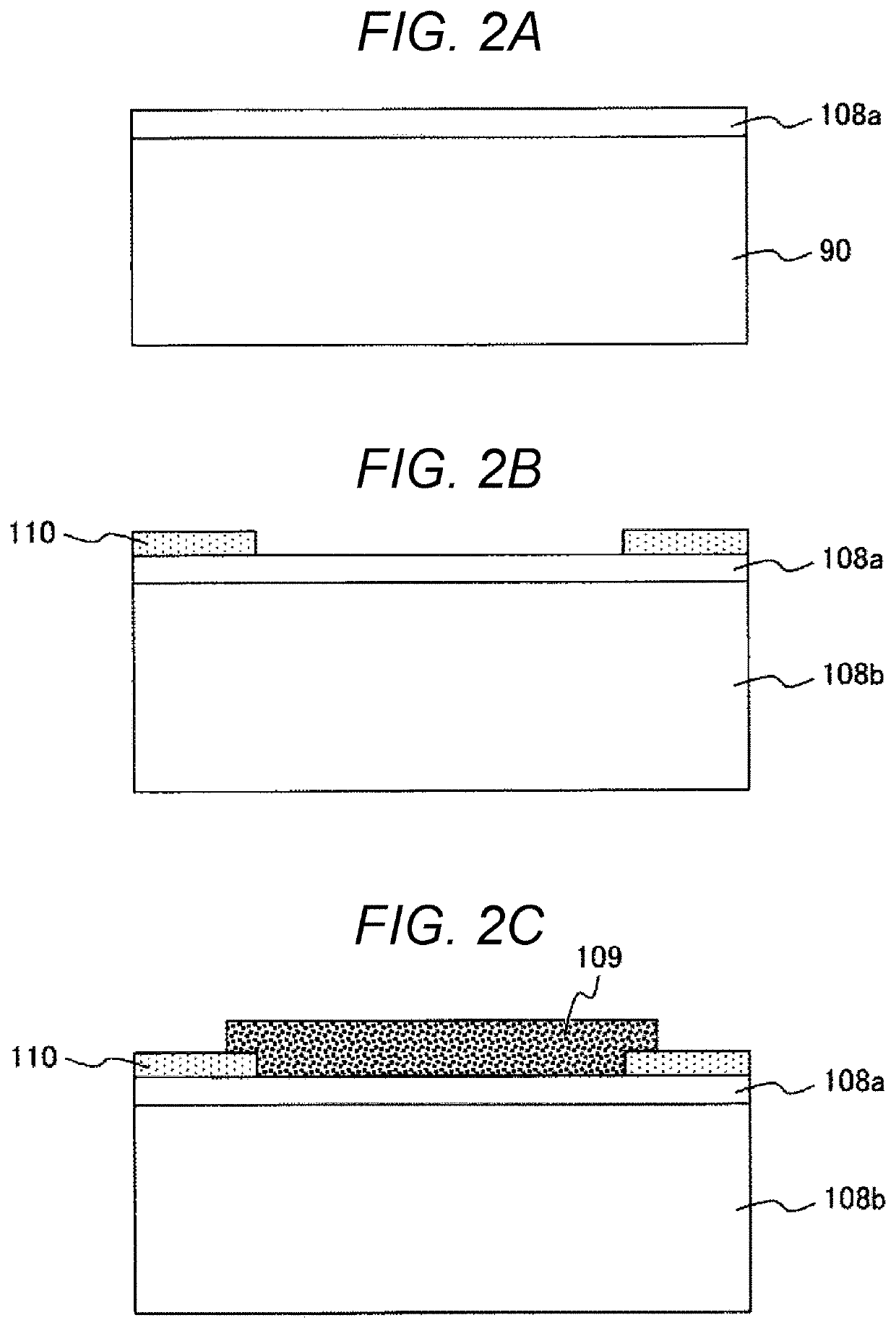

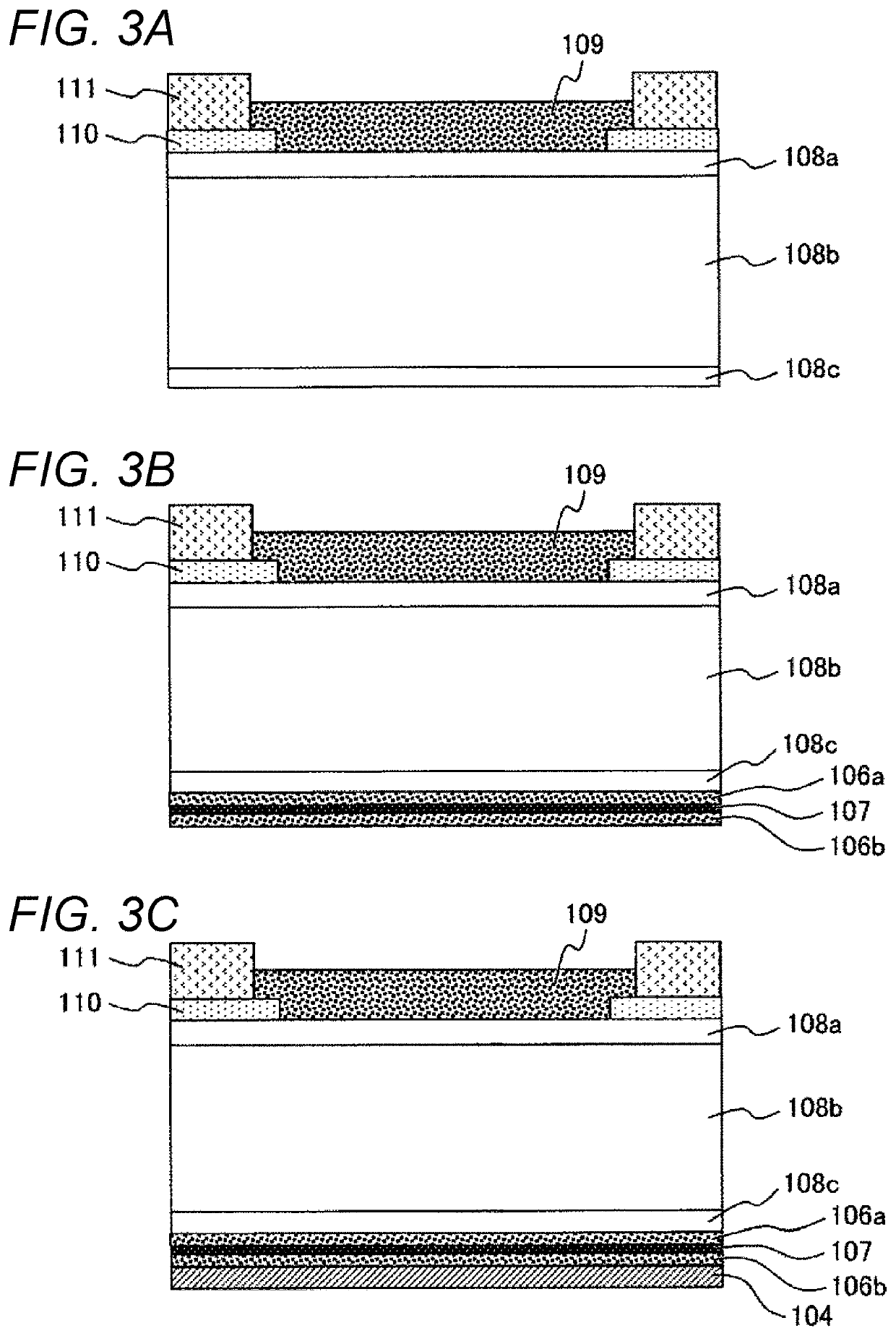

Method of manufacturing a semiconductor element front side electrode

ActiveUS11335595B2Suppress generationSemiconductor/solid-state device detailsSolid-state devicesElectroless nickelElectroless coating

Provided is a semiconductor element including: a front-back conduction-type substrate including a front-side electrode and a back-side electrode; and an electroless plating layer formed on at least one of the electrodes of the front-back conduction-type substrate. The electroless plating layer includes: an electroless nickel-phosphorus plating layer; and an electroless gold plating layer formed on the electroless nickel-phosphorus plating layer, and has a plurality of recesses formed on a surface thereof to be joined with solder.

Owner:MITSUBISHI ELECTRIC CORP

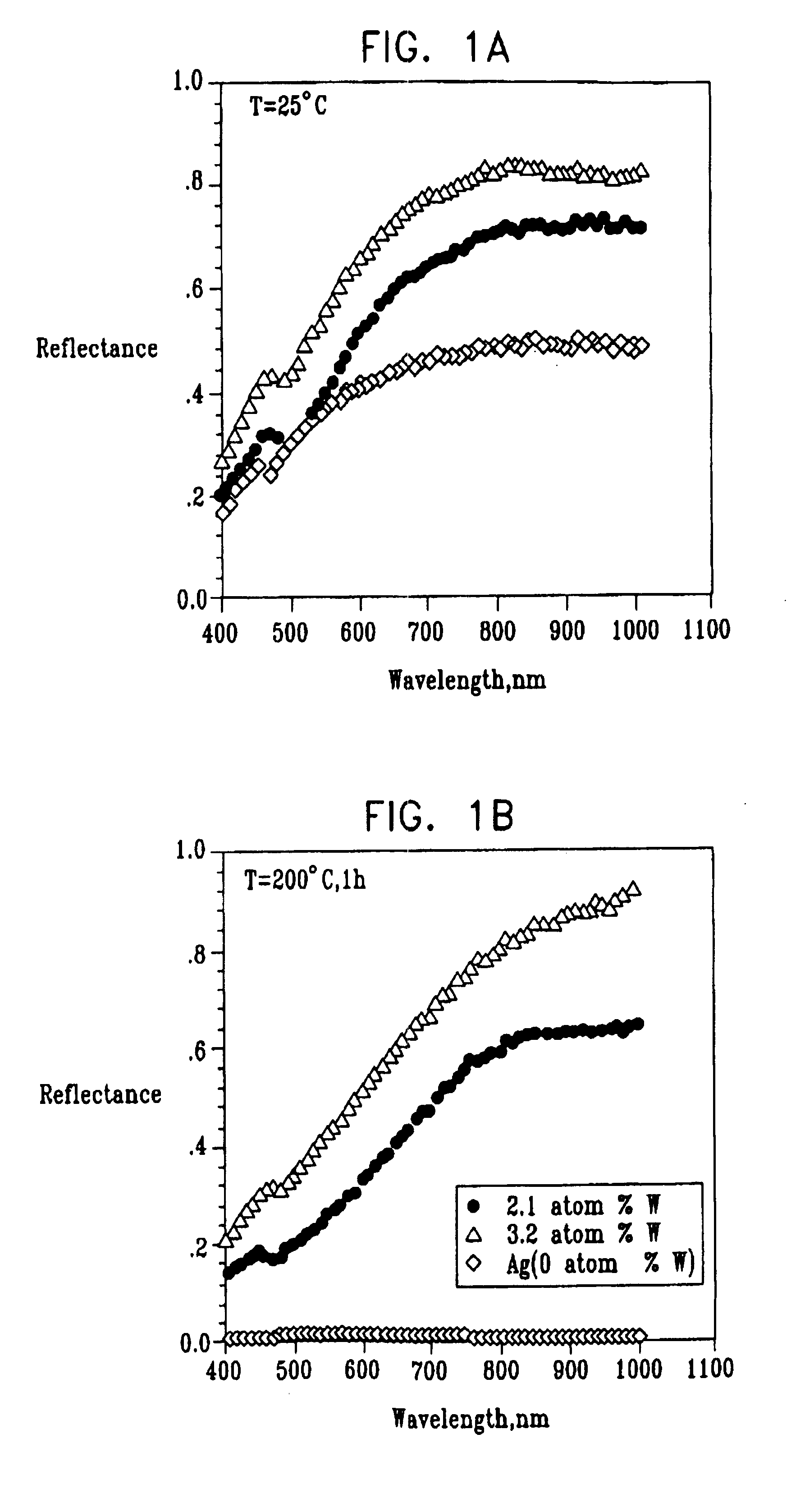

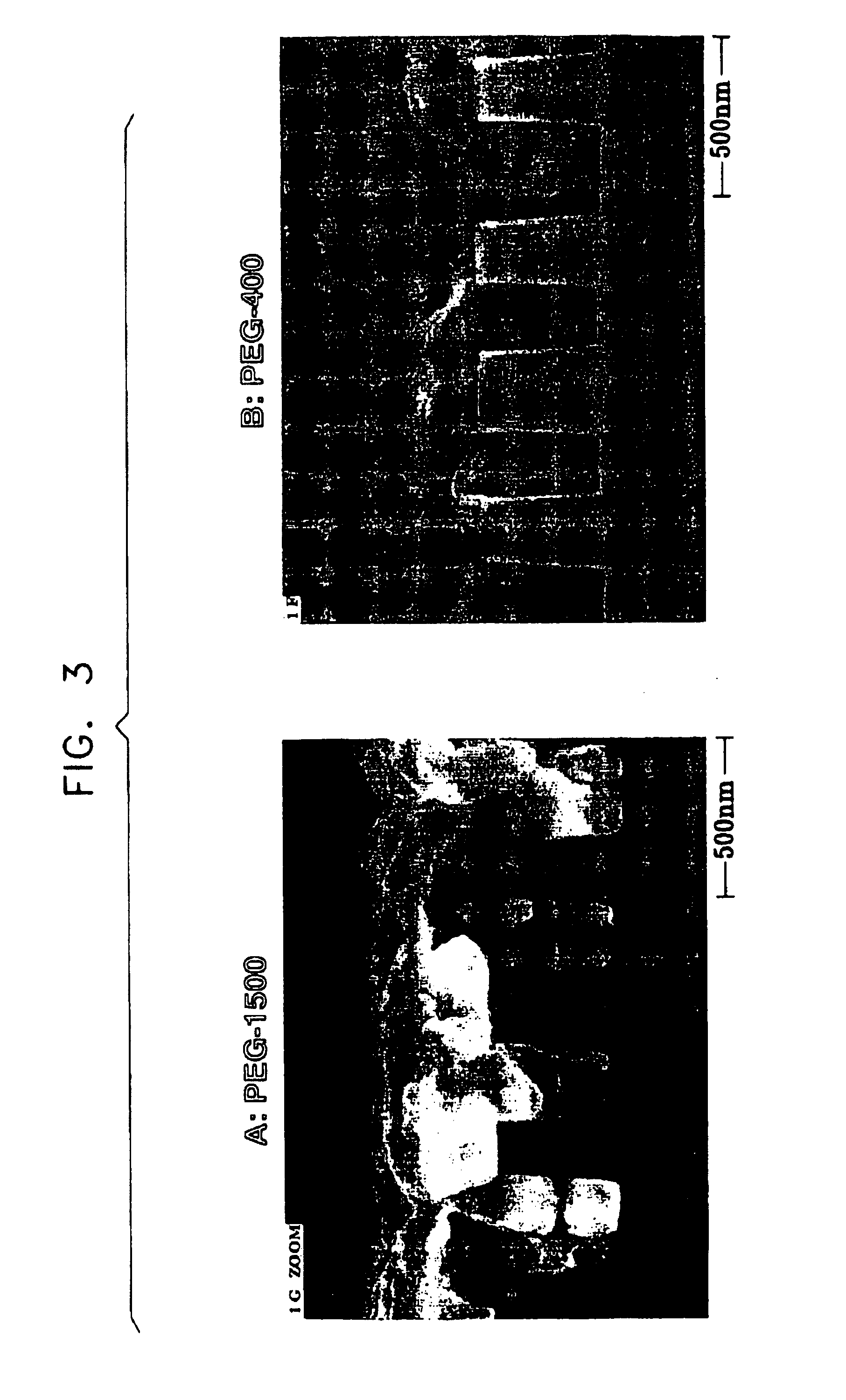

Electroless coating methods for depositing silver-tungsten coatings, kits and products

InactiveUS20070172691A1Improved surface reliabilityImproves tarnish resistanceLiquid surface applicatorsLiquid/solution decomposition chemical coatingMedicineAmbient air

Materials, methods and kits are disclosed for providing an electrolessly-deposited tarnish-resistant silver-tungsten coated object, the electrolessly-deposited tarnish-resistant silver-tungsten coated object comprising: an object; a silver-tungsten coating on the object, wherein the silver-tungsten coating has a substantially constant reflectivity of more than 90% at 500 nm after exposure of the coated object to ambient air for a time period of at least one week.

Owner:RAMOT AT TEL AVIV UNIV LTD

Method for creating multiple electrical current pathways on a work piece

ActiveUS11408086B2Eliminate needSimple and inexpensive processElectrophoretic coatingsLiquid/solution decomposition chemical coatingEngineeringElectric current flow

Owner:LACKS ENTERPRISES

Magnetic disc, aluminum alloy substrate for magnetic disc, and production method for aluminum alloy substrate

ActiveUS11211088B2High strengthLow levelBase layers for recording layersMagnetic layer production by platingAlloy substrateWavelength range

Provided are a magnetic disk and a method of fabricating the magnetic disk. The magnetic disk includes an aluminum alloy plate fabricated by a process involving a CC method and a compound removal process, and an electroless Ni—P plating layer disposed on the surface of the plate. The aluminum alloy plate is composed of an aluminum alloy containing 0.4 to 3.0 mass % (hereinafter abbreviated simply as “%”) of Fe, 0.1% to 3.0% of Mn, 0.005% to 1.000% of Cu, 0.005% to 1.000% of Zn, with a balance of Al and unavoidable impurities. In the magnetic disk, the maximum amplitude of waviness in a wavelength range of 0.4 to 5.0 mm is 5 nm or less, and the maximum amplitude of waviness in a wavelength range of 0.08 to 0.45 mm is 1.5 nm or less.

Owner:FURUKAWA SKY ALUMINUM CORP +1

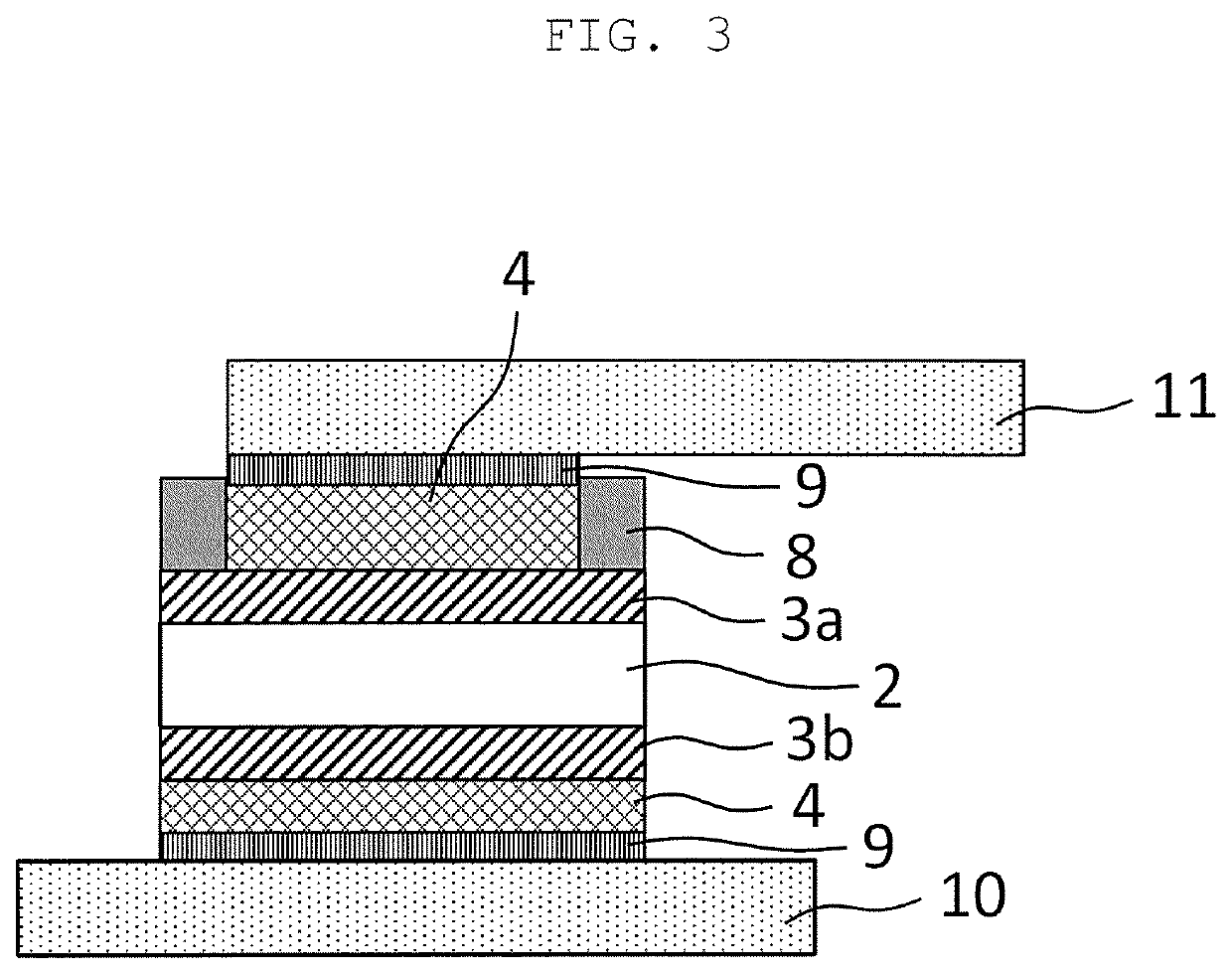

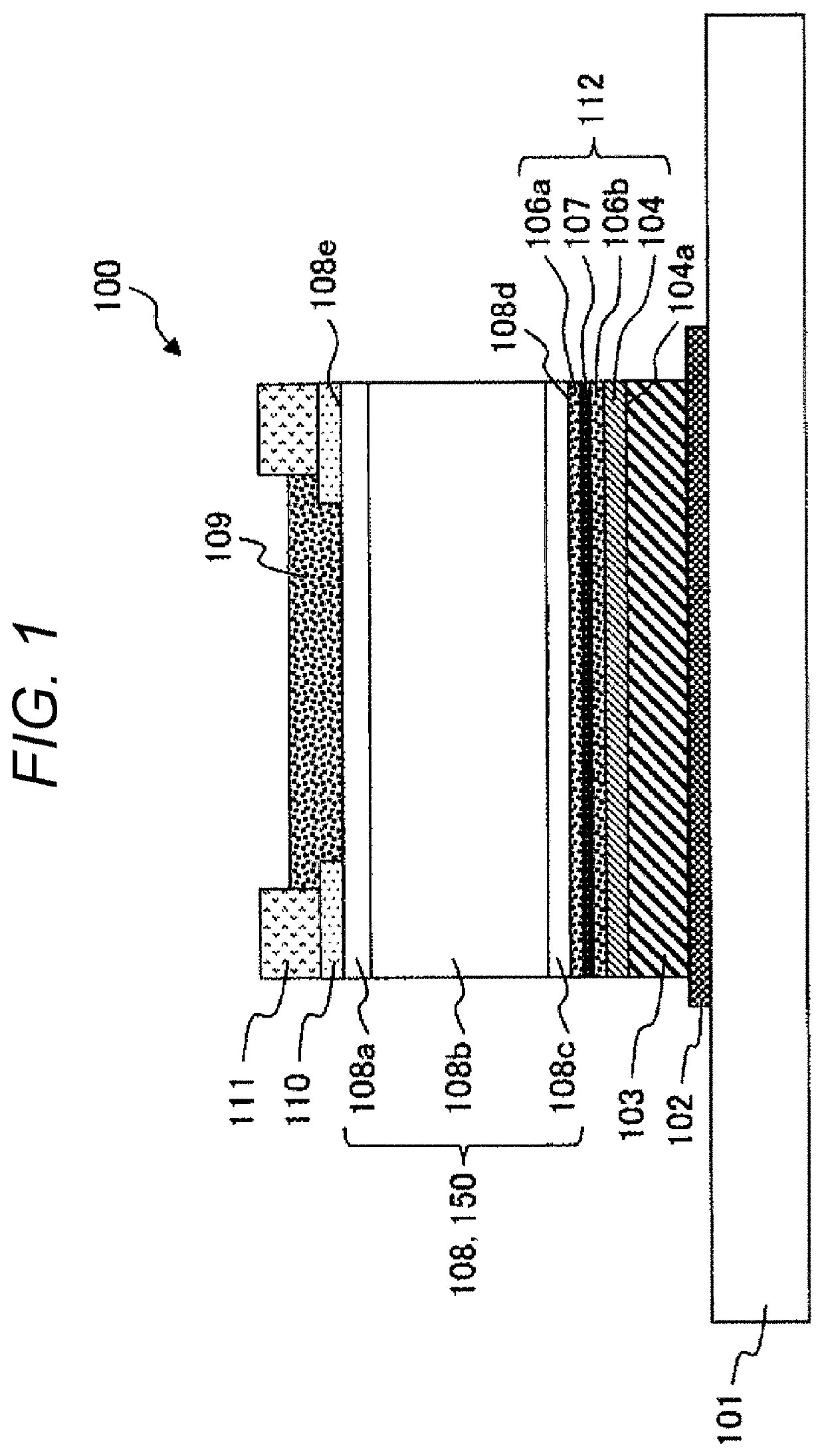

Semiconductor device having a stacked electrode with an electroless nickel plating layer

ActiveUS10847614B2Improve reliabilitySmall sizeTransistorSemiconductor/solid-state device detailsMetallurgyDevice material

Owner:HITACHI POWER SEMICON DEVICE

A kind of tin salt sensitization activation method for electroless plating on titanium alloy surface

ActiveCN113186522BHigh bonding strengthHigh surface hardnessLiquid/solution decomposition chemical coatingAcid etchingElectroless nickel

The invention discloses a tin salt sensitization activation method for electroless plating on the surface of titanium alloy, comprising: mechanically grinding and polishing titanium alloy, organic degreasing, chemical alkali washing degreasing, acid etching, zinc immersion once, and zinc stripping , secondary zinc dipping, sensitization: put the titanium alloy sample after secondary zinc dipping into the sensitizing solution, soak at room temperature for 2-5 minutes; then rinse it with deionized water; electroless plating: at 90-100°C, Put the sensitized titanium alloy sample into the electroless plating solution for 2-3 hours, rinse it with deionized water at 60°C-70°C, and dry it to complete the preparation of nickel-boron coating on the surface of the titanium alloy. The electroless nickel-boron coating prepared by the method can improve the bonding strength between the electroless coating and the titanium alloy substrate; significantly improve the wear resistance of the titanium alloy; at the same time, the coating can improve the surface hardness of the titanium alloy and significantly improve the wear resistance of the titanium alloy. Surface hardness.

Owner:SOUTHWEAT UNIV OF SCI & TECH

A silver-based circuit board with electroless nickel-palladium-gold plating and preparation method thereof

ActiveCN110468394BReduce thicknessReduced contentLiquid/solution decomposition chemical coatingElectroless nickelGold layer

The invention discloses a silver-based circuit board with electroless nickel-palladium-gold plating and a preparation method thereof. The silver-based circuit board includes a silver-based substrate, and the surface of the silver-based substrate is sequentially plated with a nickel layer, Palladium layer, gold layer. The preparation method includes the following steps: performing micro-etching, pickling, pre-dipping, palladium activation, and post-dipping pre-treatment on the cleaned silver-based substrate in sequence, and then performing pre-treatment on the pre-treated silver-based substrate in sequence. Electroless nickel plating, electroless palladium plating, and electroless gold plating are silver-based circuit boards containing nickel-palladium-gold coating. Compared with traditional copper-based electroless nickel-palladium-gold plating, the thickness of nickel-palladium-gold electroless plating can be greatly reduced, thereby saving The use content of metals, while avoiding the problem of pollution to the environment. Furthermore, with the silver base as the base, the entire product has stronger electrical and thermal conductivity, higher sensitivity, longer life, and better overall performance.

Owner:珠海联鼎化工设备有限公司

Surface treatment process of HDI plate based on chemical nickel-gold plating coating

ActiveCN114599156AGood surface roughnessHigh speedPrinted circuit liquid treatmentInsulating layers/substrates workingChemical platingPrinted circuit board

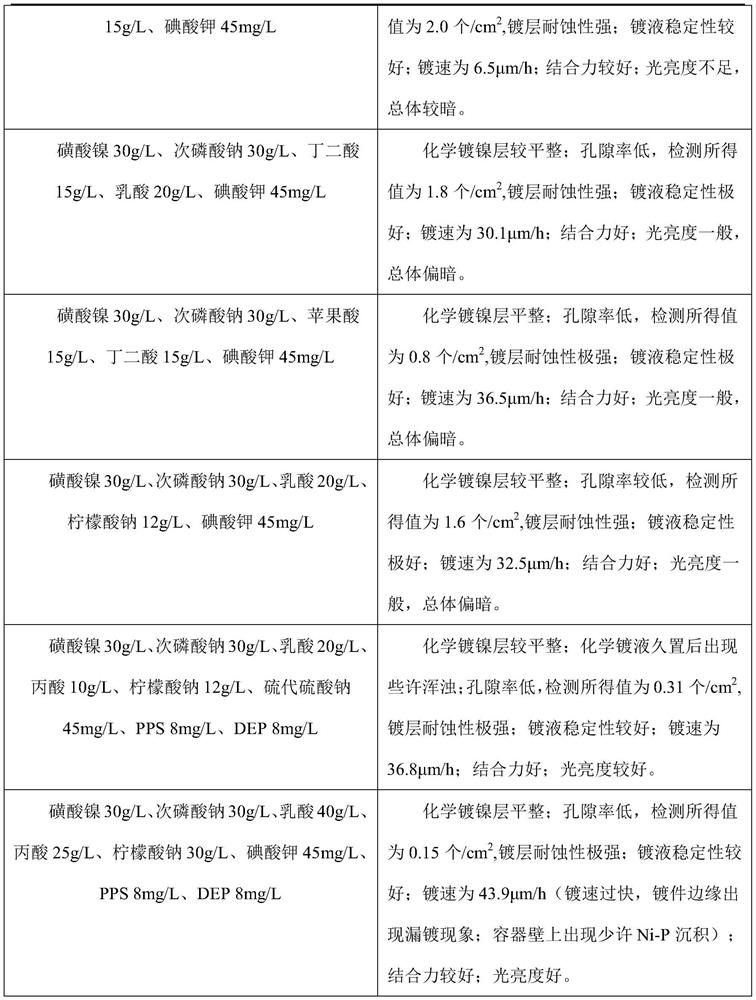

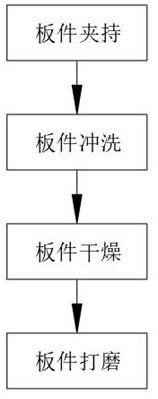

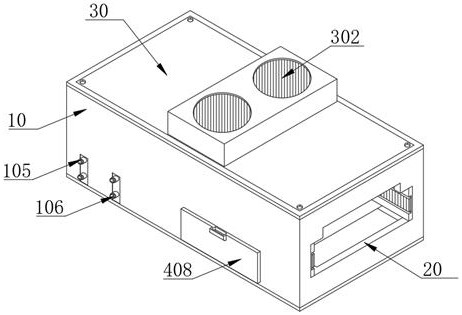

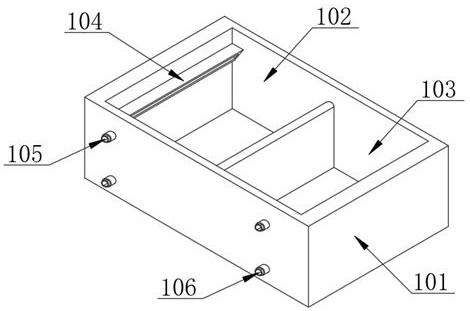

The invention relates to the technical field of surface treatment, in particular to a surface treatment process of an HDI plate based on a chemical nickel-gold plating coating, and the surface treatment process comprises the steps of clamping, washing, drying and polishing a plate, a washing tank is arranged in a treatment box, and the surface of the HDI plate is washed by using a pickling solution, so that the surface of the HDI plate is subjected to micro-etching; the method comprises the following steps: removing rust scale, an oxidation film and other rust on the metal surface of a pre-plated printed circuit board, activating the metal surface of an HDI plate, adding chemical plating accelerators with different functions into a pickling solution, sufficiently adsorbing the accelerators on the inner walls of blind holes and through holes of the HDI plate before chemical plating, feeding the HDI plate into a chemical plating tank, and carrying out chemical plating on the inner walls of the blind holes and the through holes of the HDI plate after the HDI plate is fed into the chemical plating tank. As the concentration of the accelerator adsorbed in the blind hole is higher than that of the accelerator adsorbed on the plate surface, the growth speed of the chemical plating layer is obviously higher than that of the plate surface, so that a good metal plating layer is obtained, and the generation efficiency of the surface coating of the HDI plate can be effectively improved.

Owner:CHANGZHOU AOHONG ELECTRONICS

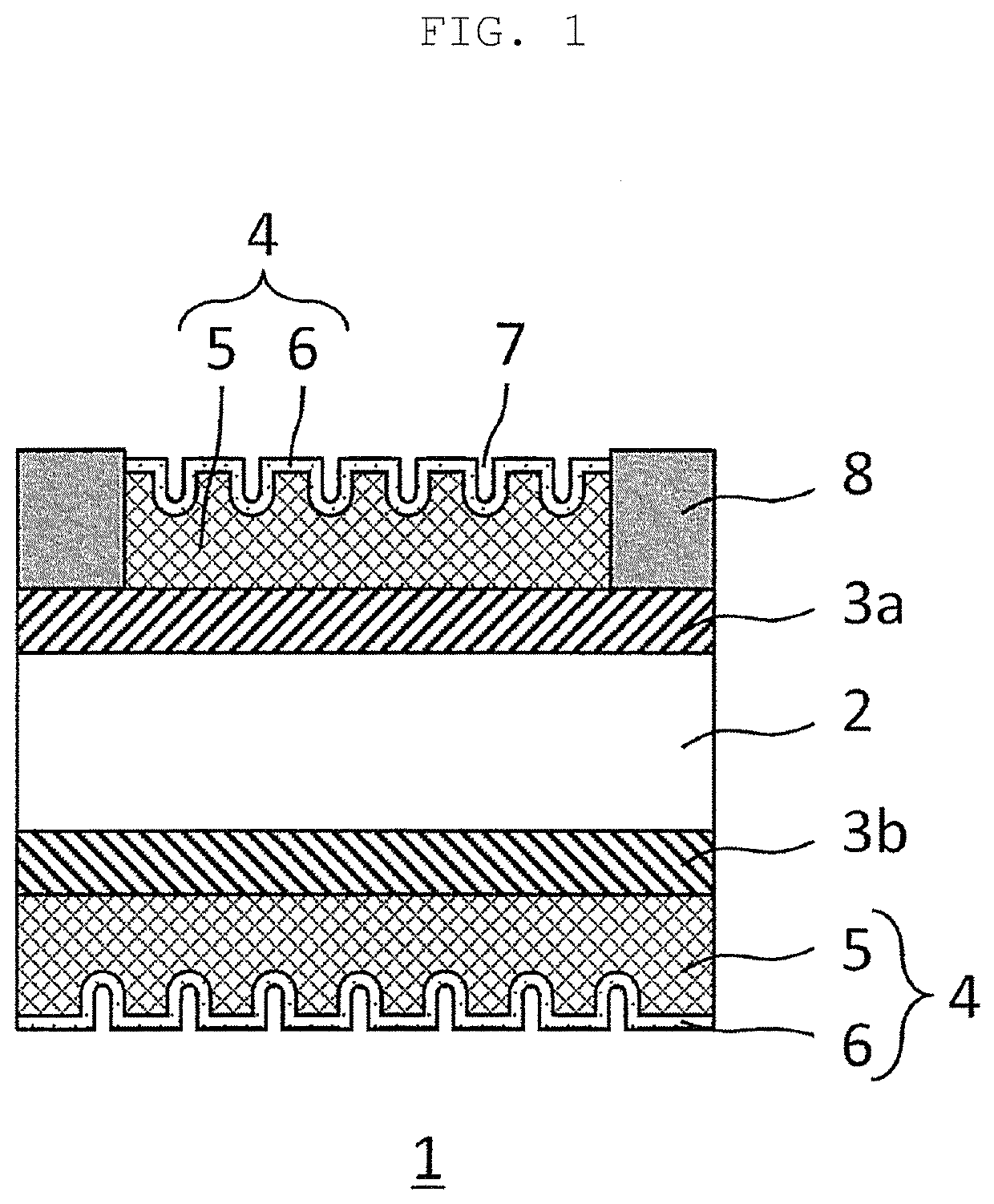

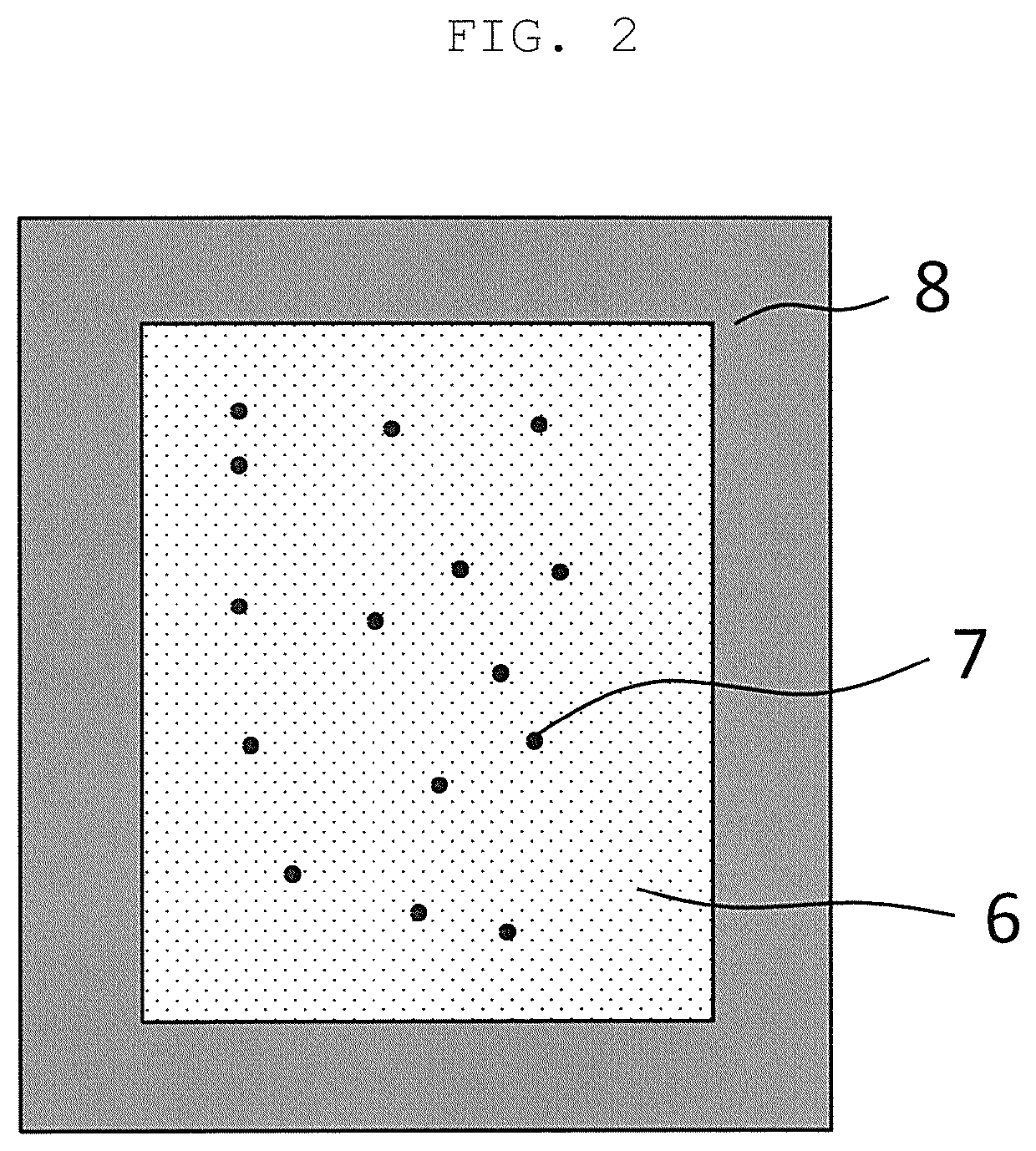

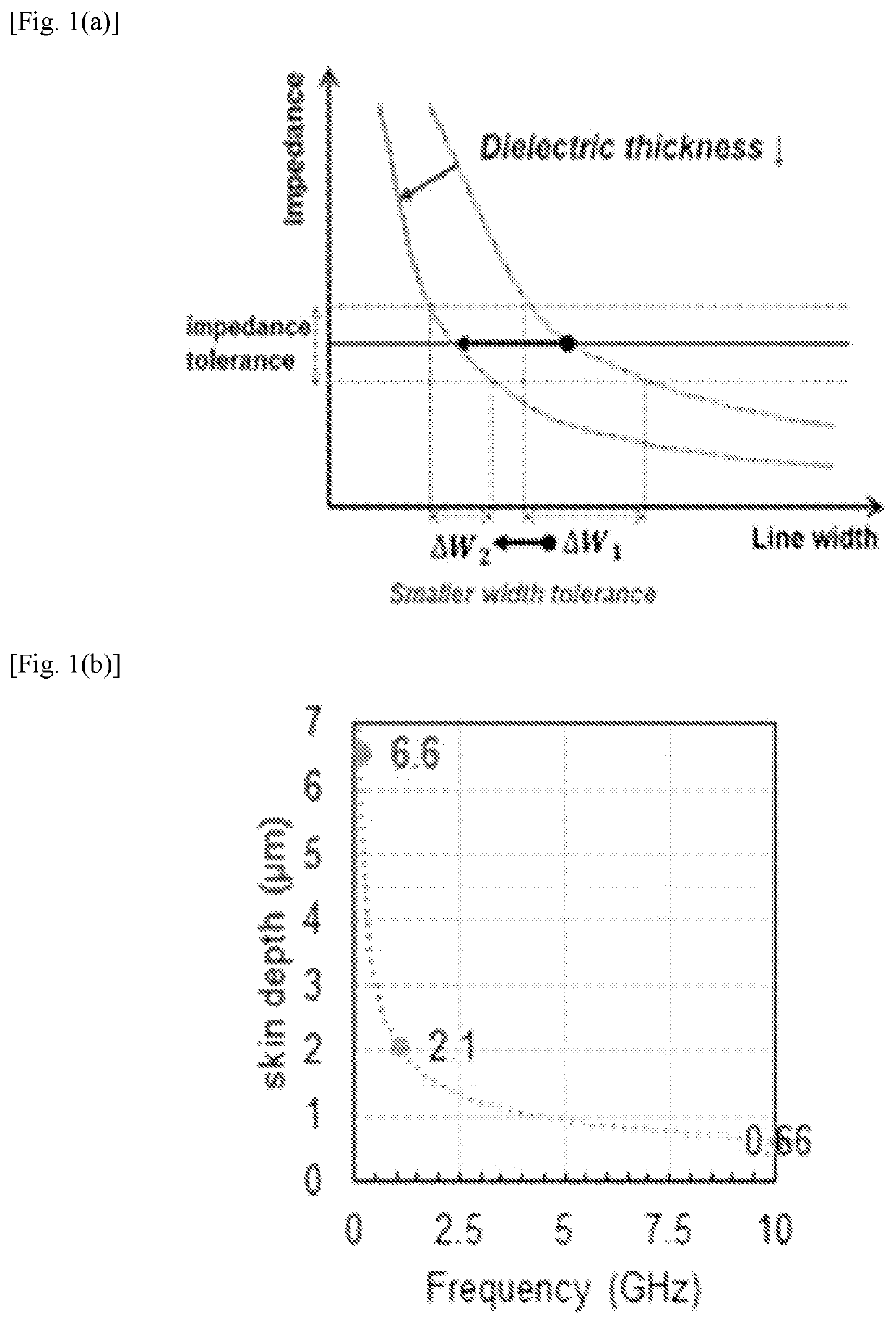

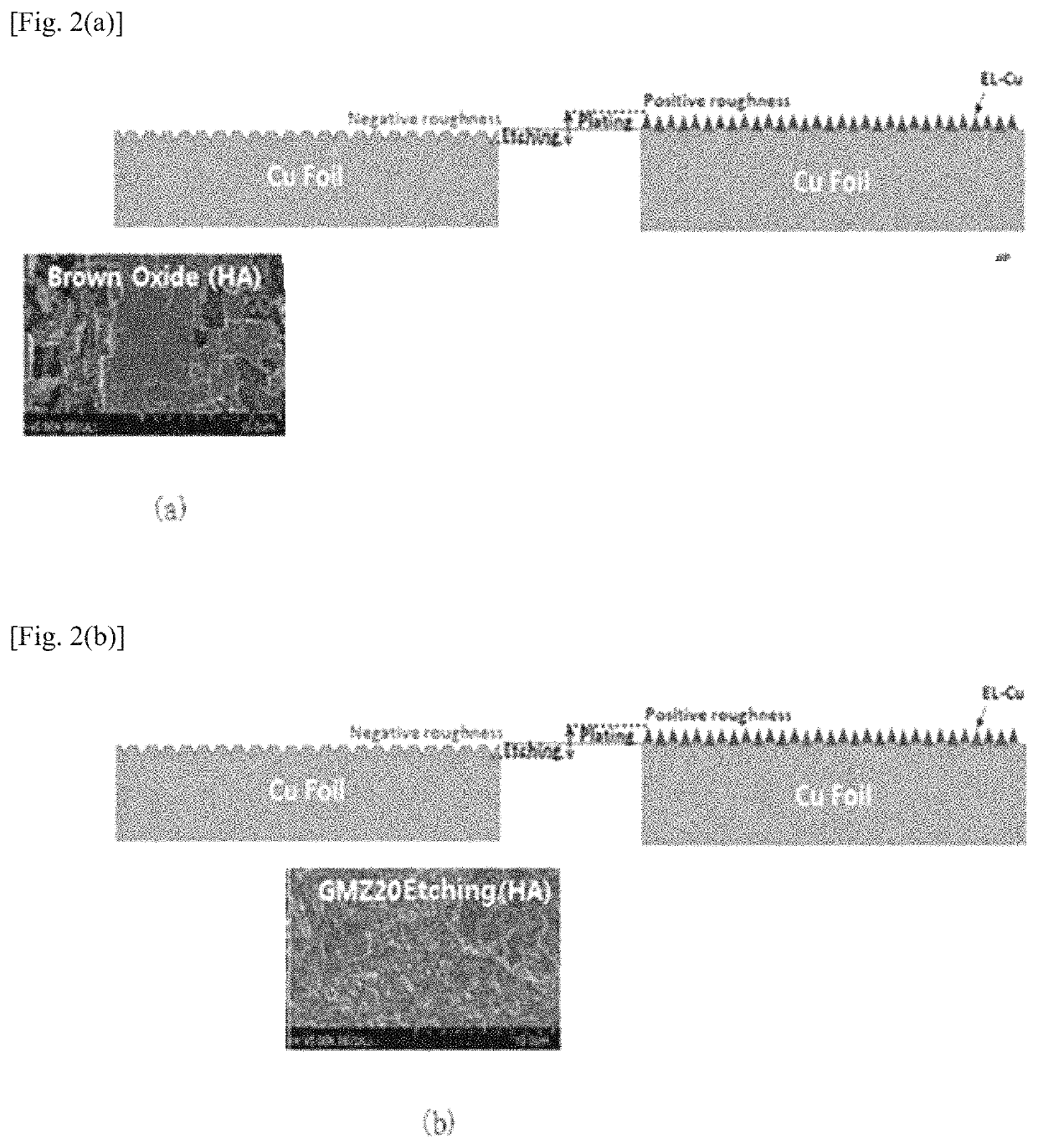

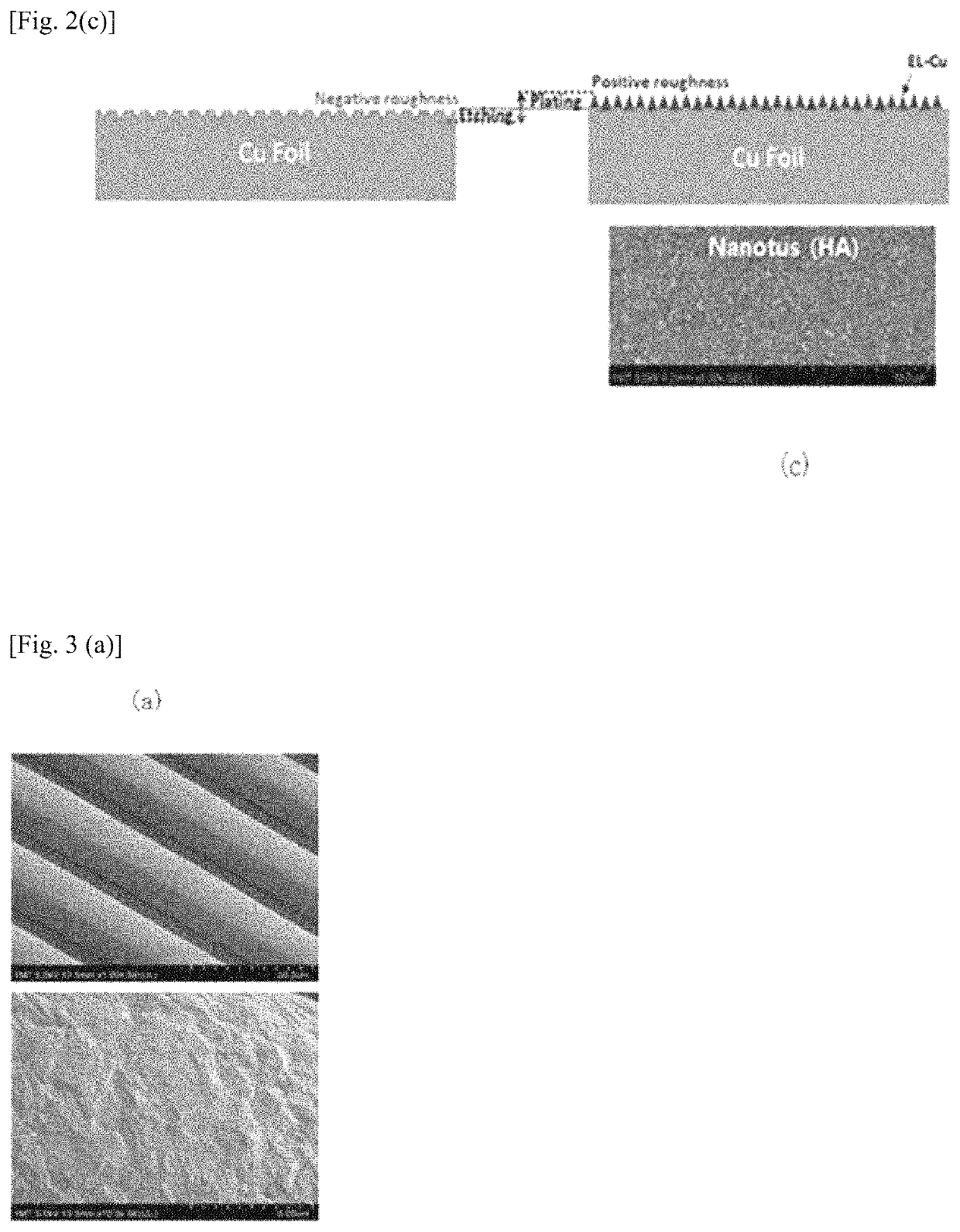

Plated laminate and printed circuit board

ActiveUS11499233B2Economic efficiencyEconomic workabilityPrinted circuit aspectsLiquid/solution decomposition chemical coatingCopper foilMechanical engineering

Provided is a plating lamination technology for providing a highly adhesive inner layer of a printed circuit board. The plating lamination technology is effective in providing an electroless plated laminate, including a non-etched / low-roughness pretreated laminate or a low-roughness copper foil, and a printed circuit board including the plated laminate.

Owner:YMT CO LTD

Porous electrolessly deposited coatings

InactiveUS9893364B2Increase resistanceImprove electrical performanceCell electrodesLiquid/solution decomposition chemical coatingMetal coatingMicroparticle

A new electroless plating approach to generate a porous metallic coating is described in which a metal is electrolessly deposited on a surface. Microparticles in the metal are removed to leave pores in the metal coating. Another method of forming electroless coatings is described in which a blocking ligand is attached to the surface, followed by a second coating step. The invention includes coatings and coated apparatus formed by methods of the invention. The invention also includes catalyst structures comprising a dense substrate and a porous metal adhered to the dense substrate, which is further characterized by one or more of the specified features.

Owner:VELOCYS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com